Antirust oil composition, and preparation method and application thereof

A composition and technology of anti-rust oil, applied in the directions of lubricating composition, petroleum industry, etc., can solve the problem of conflict between anti-rust performance and filtration cleanliness of anti-rust oil, and achieve good anti-oxidation performance, good application effect, and degree of refinement high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

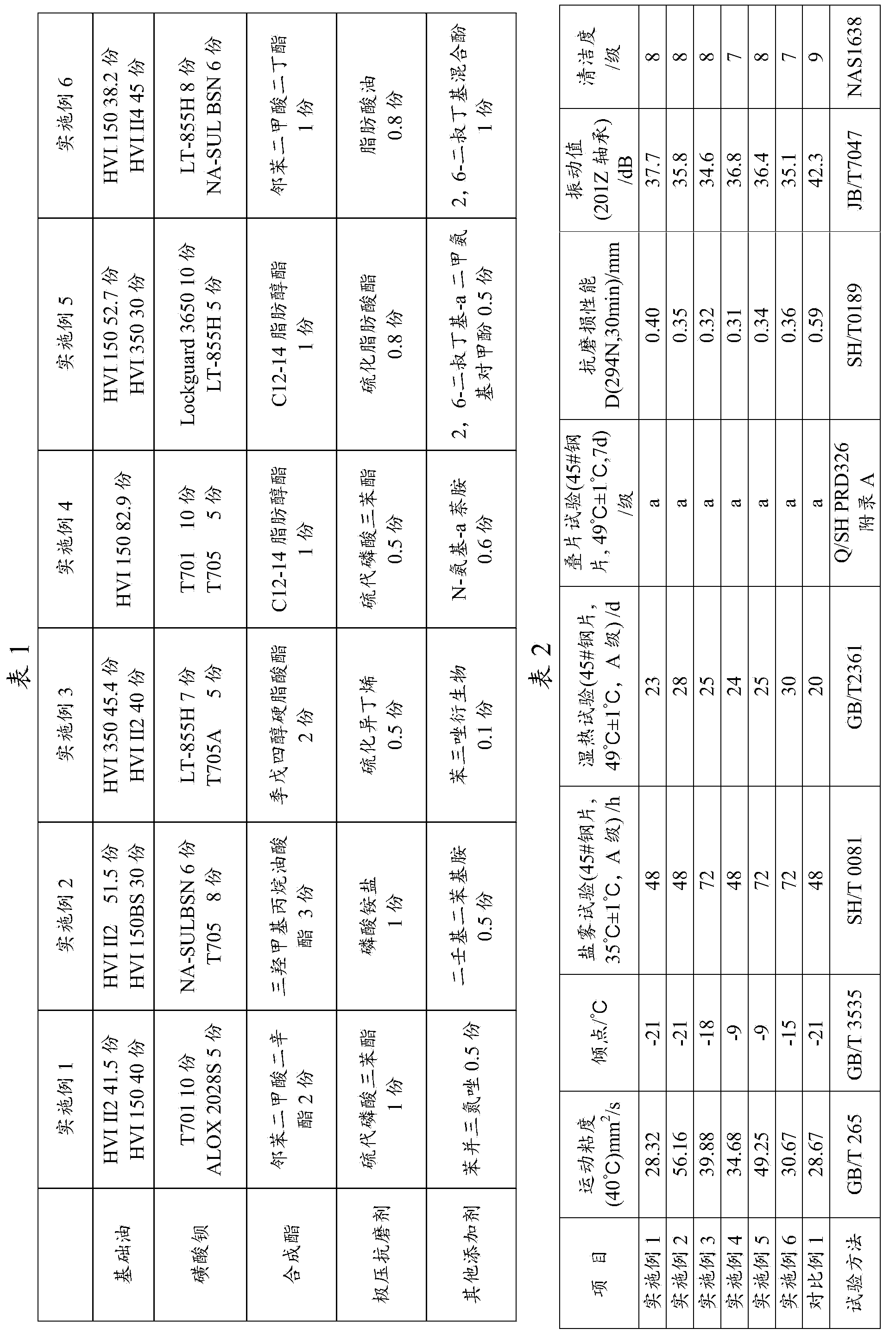

Embodiment 1~6

[0027] According to the parts by weight in Table 1, add the base oil into the blending kettle, heat and stir at 60-90°C, then add oil-soluble sulfonate rust inhibitor, synthetic ester, extreme pressure anti-wear agent and other additives, 45-55 Stirring at constant temperature at ℃ for 1-2 hours, vacuum circulating filtration for 0.5-2 hours, and then successively passing through 3 stages of filtration at 10um, 5um and 2um to obtain the anti-rust oil composition of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com