Quadraphonic ultrasonic heat meter

An ultrasonic and heat meter technology, applied in the field of four-channel ultrasonic heat meters, can solve problems such as unsuitable fluid flow, flow velocity distribution distortion, poor adaptability, etc., to reduce the difficulty of correction, reduce installation requirements, and improve adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] Four-channel ultrasonic heat meter of the present invention, its preferred embodiment is:

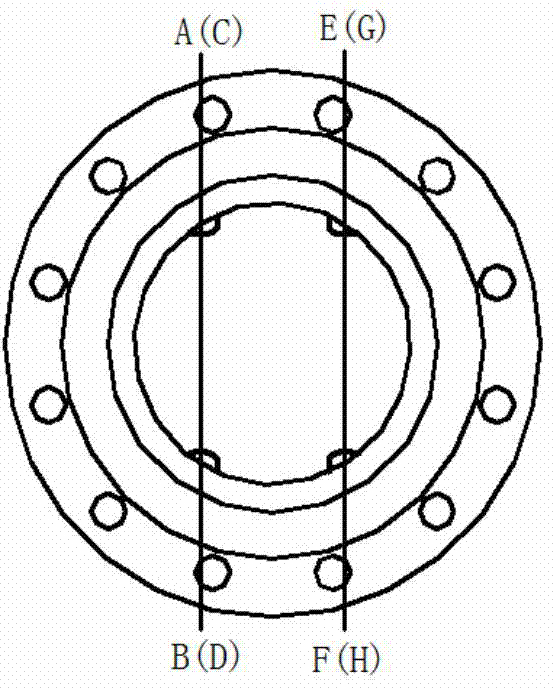

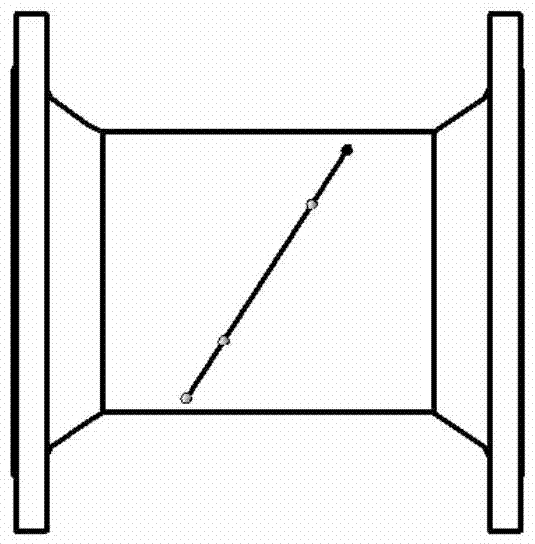

[0015] Including the pipe body, the wall of the pipe body is provided with eight installation ports, and each installation port is respectively equipped with an ultrasonic transducer, and the eight ultrasonic transducers are opposite to each other to form a sound channel, and among the four sound channels The axes of every two sound channels are parallel to each other, have the same length and are symmetrically distributed on both sides of the axis of the tube body, and the distances between the axes of the two sound channels and the axis of the tube body are equal.

[0016] Viewed from the end face of the tube body, each transducer protrudes 1 / 3-1 / 4 of the inner cavity of the pipeline.

[0017] A transducer mounting seat is welded on the pipe body at the installation port, and the ultrasonic transducer is coaxially installed with the transducer mounting seat.

[0018] Both ends...

specific Embodiment

[0030] Such as Figure 1a to Figure 3b As shown, eight oblique holes are precisely machined on the pipe body, two of which are coaxial; based on the oblique holes, eight transducer mounting seats are welded on the steel pipe; then the flanges are welded on both ends of the pipe body; The ultrasonic transducer assembly is put into it, and the transducer gland is covered.

[0031] Viewed from the end face of the tube, A transducer is coaxial and opposite to B transducer, C transducer is coaxial and opposite to D transducer; E transducer is coaxial and opposite to F transducer , the G transducer and the H transducer are coaxial and opposite; the signals of the four channels are independent of each other and are in the required position.

[0032] Working process: A transducer, C transducer, E transducer, G transducer can transmit ultrasonic signals at the same time, or send and transmit ultrasonic signals in time-sharing; B transducer, D transducer, F transducer , The G transduc...

Embodiment 1

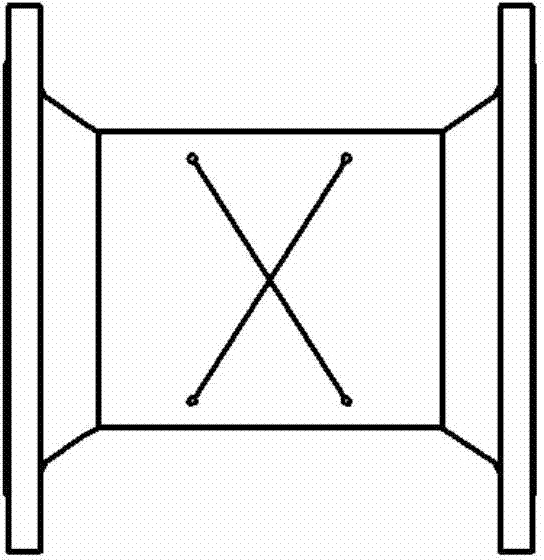

[0036] Such as Figure 1a , 1b As shown, the distance between the channel and the axis of the pipe body is equal to the value of the two channels, the AB channel and the CD channel are on the same plane and cross, the EF channel and the GH channel are on the same plane and cross, the structure is the most Simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com