Flow compensation method and flow compensation device for proportional control pump

A technology of proportional control and flow compensation, applied in fluid pressure actuators, servo motors, servo meter circuits, etc., can solve problems such as unstable output flow, loss of volumetric efficiency, abnormal movement, etc., to reduce the difficulty of correction and improve output Effect of Scale Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

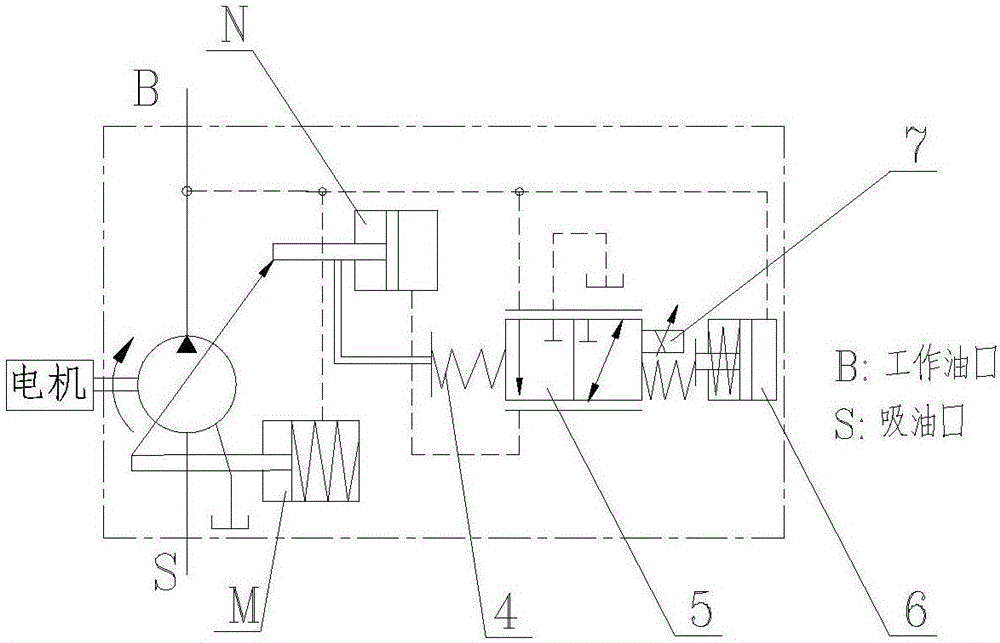

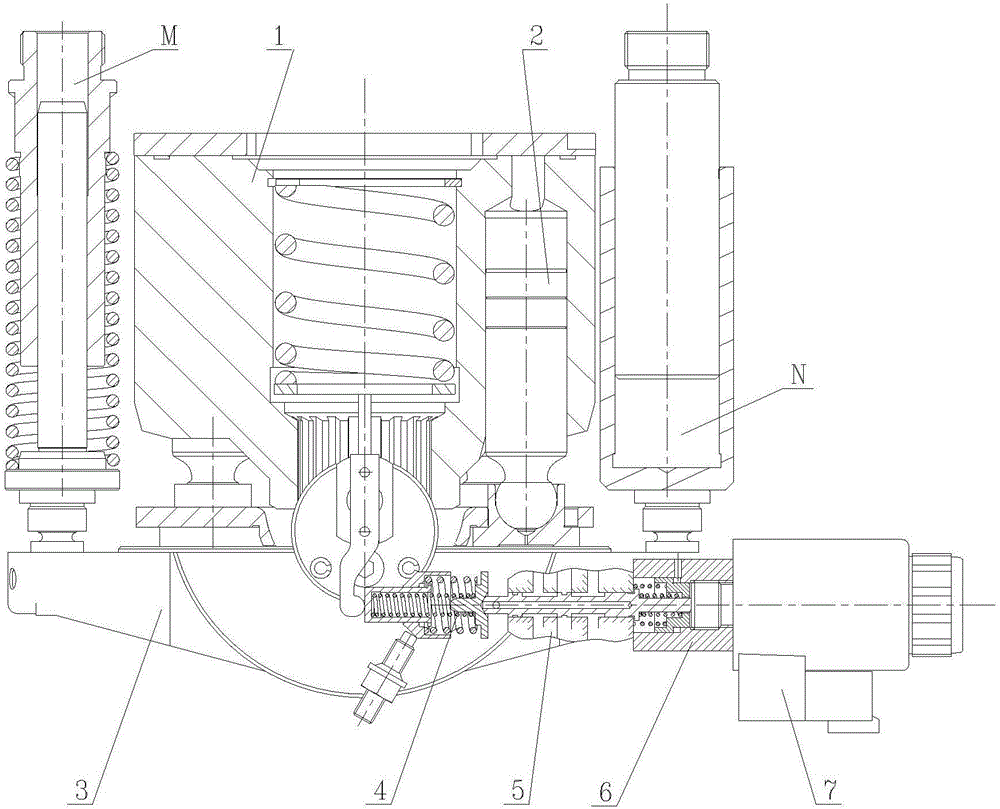

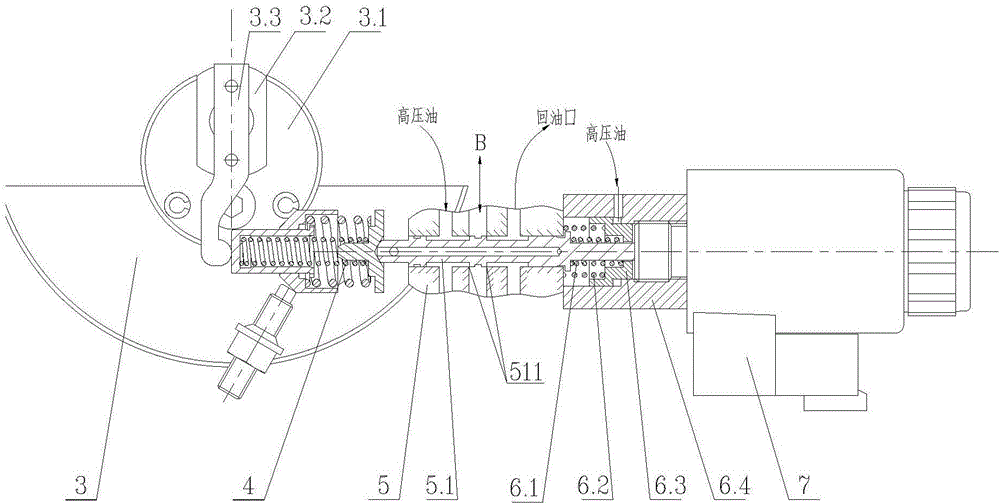

[0017] Example. The flow compensation method of the proportional control pump is characterized in that: when the outlet pressure of the proportional control pump changes, the pressure compensation is performed at the tail end of the spool of the proportional control valve, and the compensated force generates an incremental value of the swash plate angle, and the swash plate The proportional control pump output flow incremental value generated by the angle incremental value compensates the flow value due to the outlet pressure loss. Specifically, pressure compensation is performed by setting a pressure compensation valve at the end of the spool of the proportional control valve; the pressure change of the proportional control pump causes a change in the preload of the compensation spring of the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com