Double-sound-track ultrasonic heat meter

An ultrasonic and heat meter technology, which is applied in the field of dual-channel ultrasonic heat meters, can solve problems such as poor adaptability, decreased measurement accuracy, and failure to use normally, and achieve accurate measurement results, reduced correction difficulty, and accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] Two-channel ultrasonic heat meter of the present invention, its preferred embodiment is:

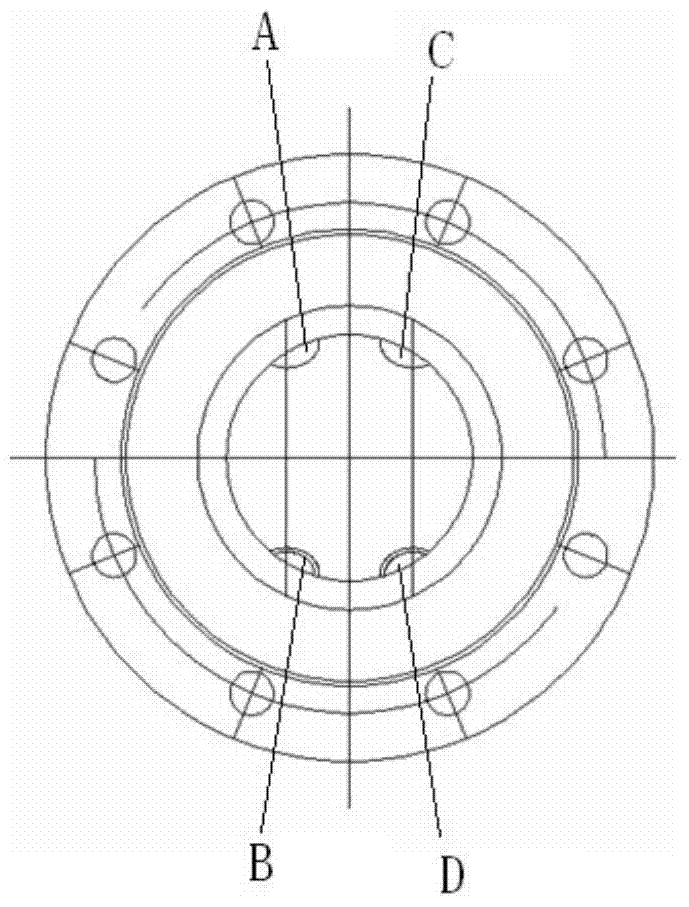

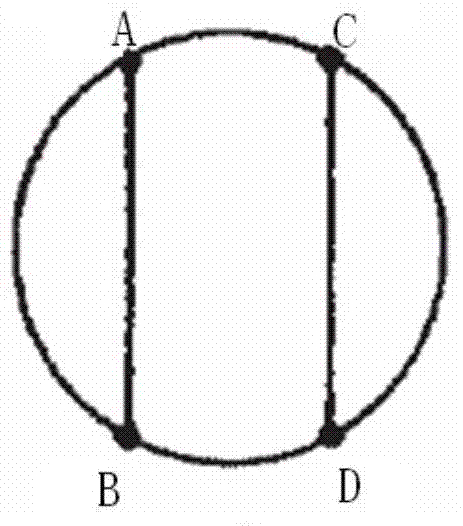

[0019] Including the pipe body, the wall of the pipe body is provided with four installation ports, and each installation port is respectively equipped with an ultrasonic transducer, and the four ultrasonic transducers are opposite to each other to form a sound channel, and two sound channels The axes of the channels are parallel to each other, have the same length and are symmetrically distributed on both sides of the axis of the tube body, and the axes of the two channels are at the same distance from the axis of the tube body.

[0020] The included angle between the axes of the two sound channels and the axis of the pipe body is less than 90 degrees.

[0021] Viewed from the end face of the pipe body, each ultrasonic transducer protrudes 1 / 4 to 1 / 3 of the inner cavity of the pipe.

[0022] A transducer mounting seat is welded on the pipe body at the installation port, and the ...

specific Embodiment

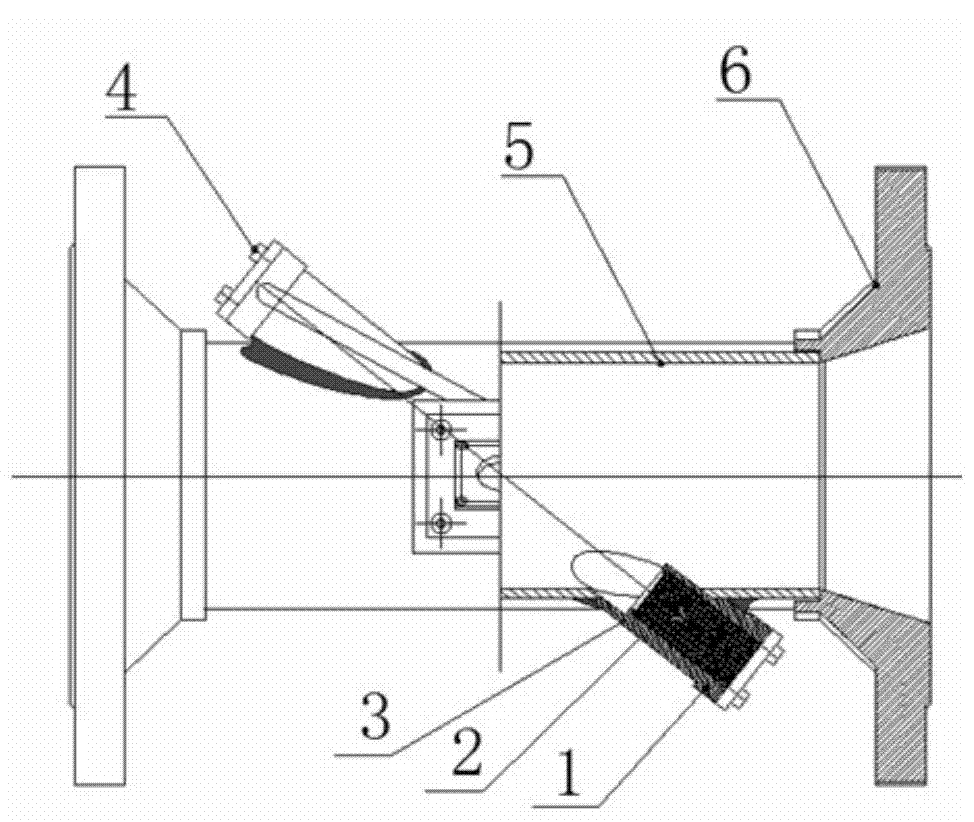

[0029] Such as Figure 1a , Figure 1b , 2a , 2b, four inclined holes are precisely machined on the pipe body, two of which are coaxial; based on the inclined holes, four transducer mounting seats are welded on the steel pipe; and then the flanges are welded on both ends of the pipe body ; Put the ultrasonic transducer assembly into it, and cover the transducer gland.

[0030] Viewed from the end face of the tube body, the first transducer is coaxial and opposite to the second transducer, and the third transducer is coaxial and opposite to the fourth transducer; the signals of the two channels are independent of each other, in the required position.

[0031] The transducer assembly is coaxially fixed in the transducer mounting seat, and is pressed with a gland so that there will be no relative displacement after the two are assembled. In addition, the transducer assembly contains an O-ring, which makes the flowmeter flow during the measurement process. , there will be no le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com