Device and method for correcting cutterhead jacking direction in real time during manual pipe jacking construction

A real-time correction and cutter head technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as low correction efficiency, inability to correct deviation in motion, and difficulty in correcting deviation, so as to reduce overall cost, Effects of improving safety and shortening correction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

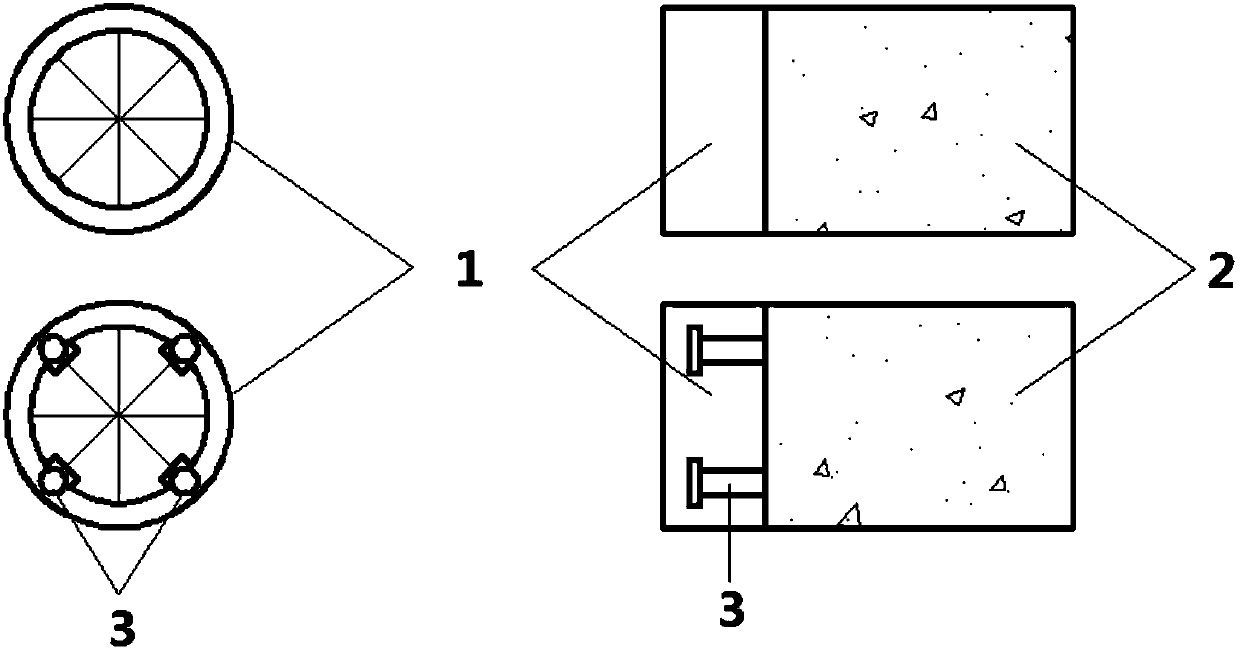

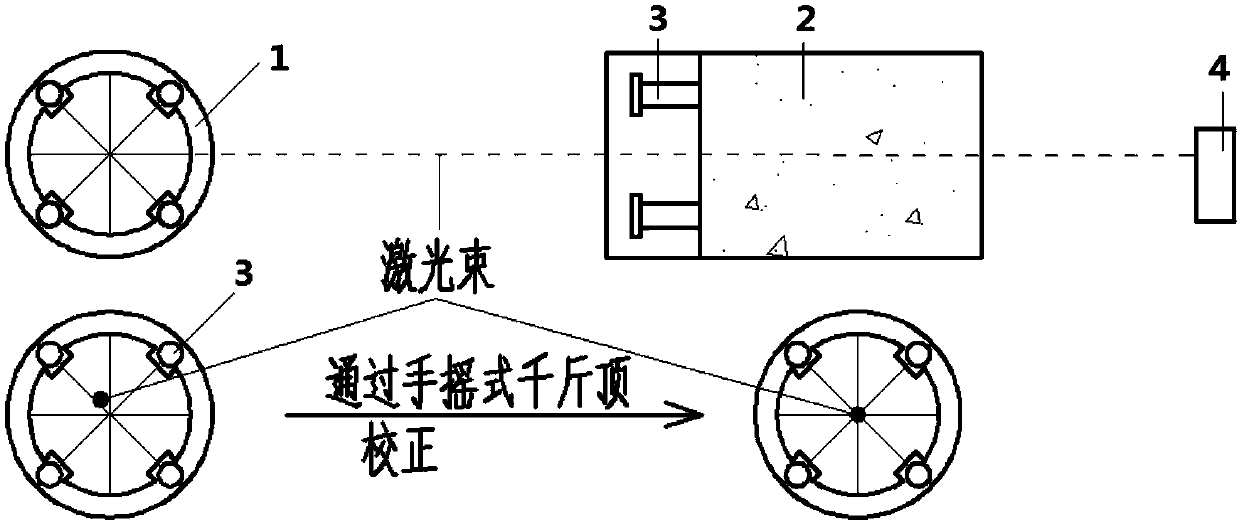

[0023] see figure 1 As shown, the embodiment of the present invention provides a device for correcting the jacking direction of the cutter head in real time during manual pipe jacking construction. The device is used in conjunction with the manual pipe jacking equipment. Four hand-operated jacks 3 are evenly distributed on the inner side of the cutterhead 1 circumference, and the four hand-operated jacks 3 are welded and fixed to the inner side of the cutterhead 1 circumference, and the casing of the cutterhead 1 is extended to the cover Four hand-operated jacks 3 are housed, and the cutter head 1 is fixedly connected to the pipeline 2 through the four hand-operated jacks 3 .

[0024] The embodiment of the present invention also provides a method for real-time correction of the jacking direction of the cutter head during manual pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com