Patents

Literature

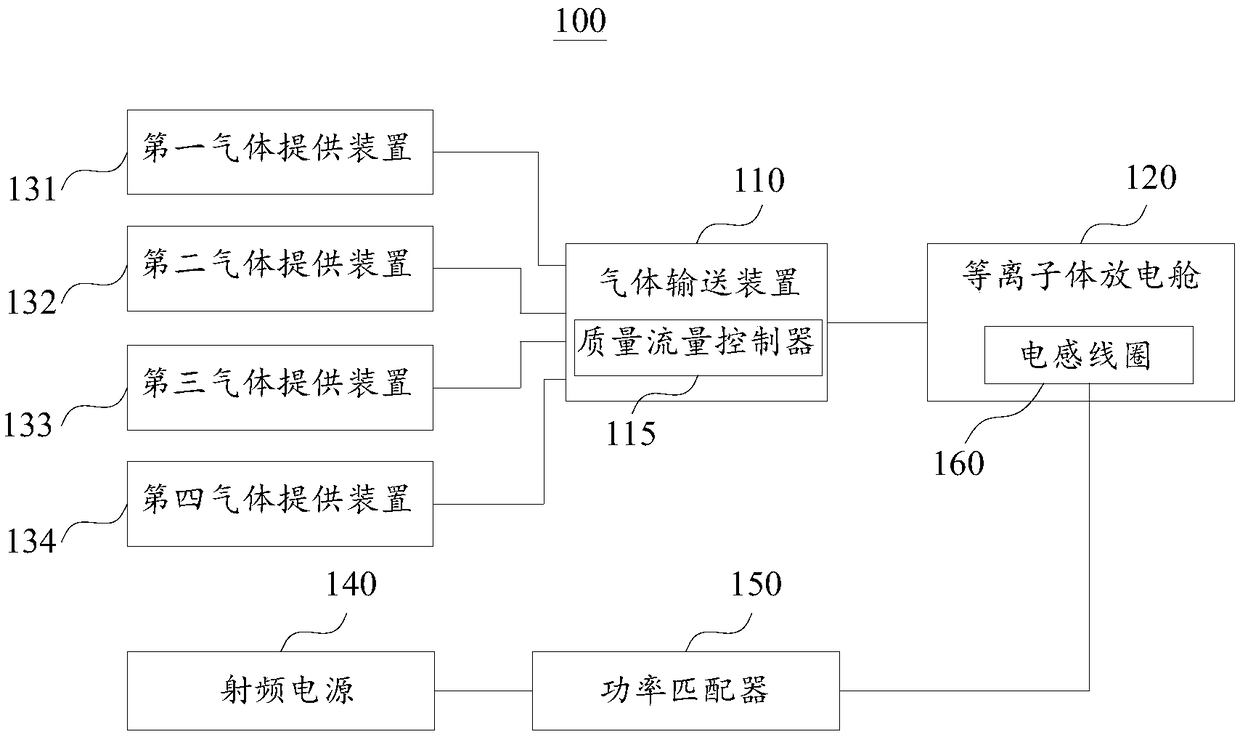

65results about How to "Reduce time to correct" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

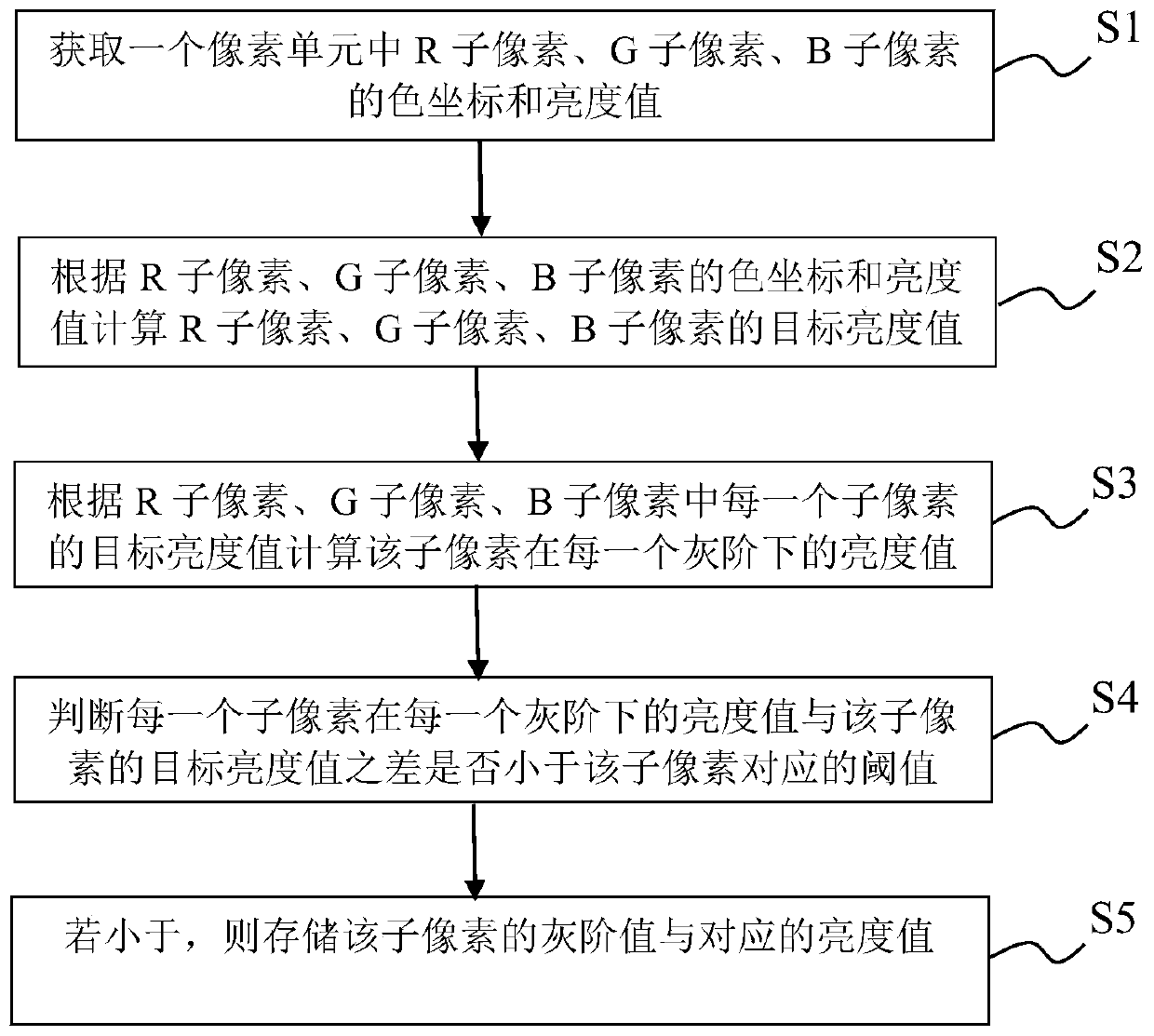

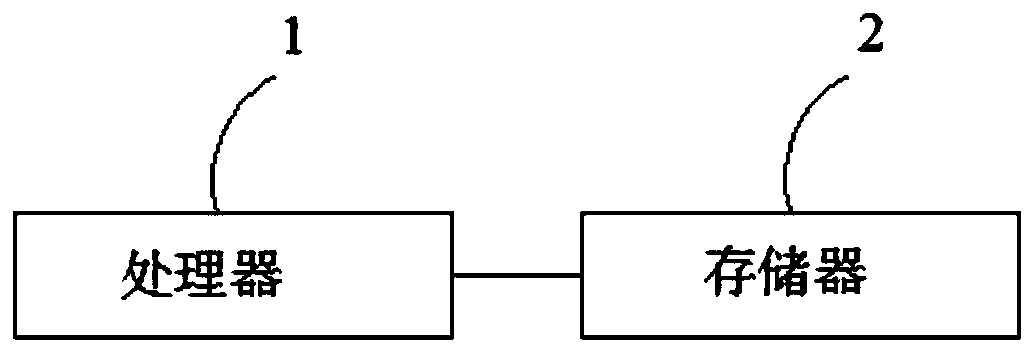

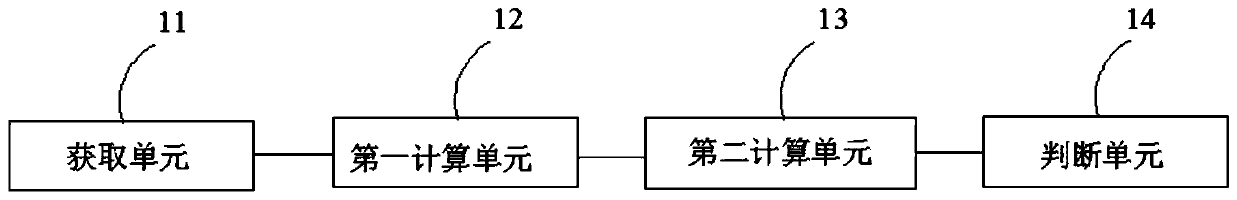

Gamma correction system and gamma correction method

ActiveCN108182914ASimple methodReduce calibration timeStatic indicating devicesGray levelBrightness perception

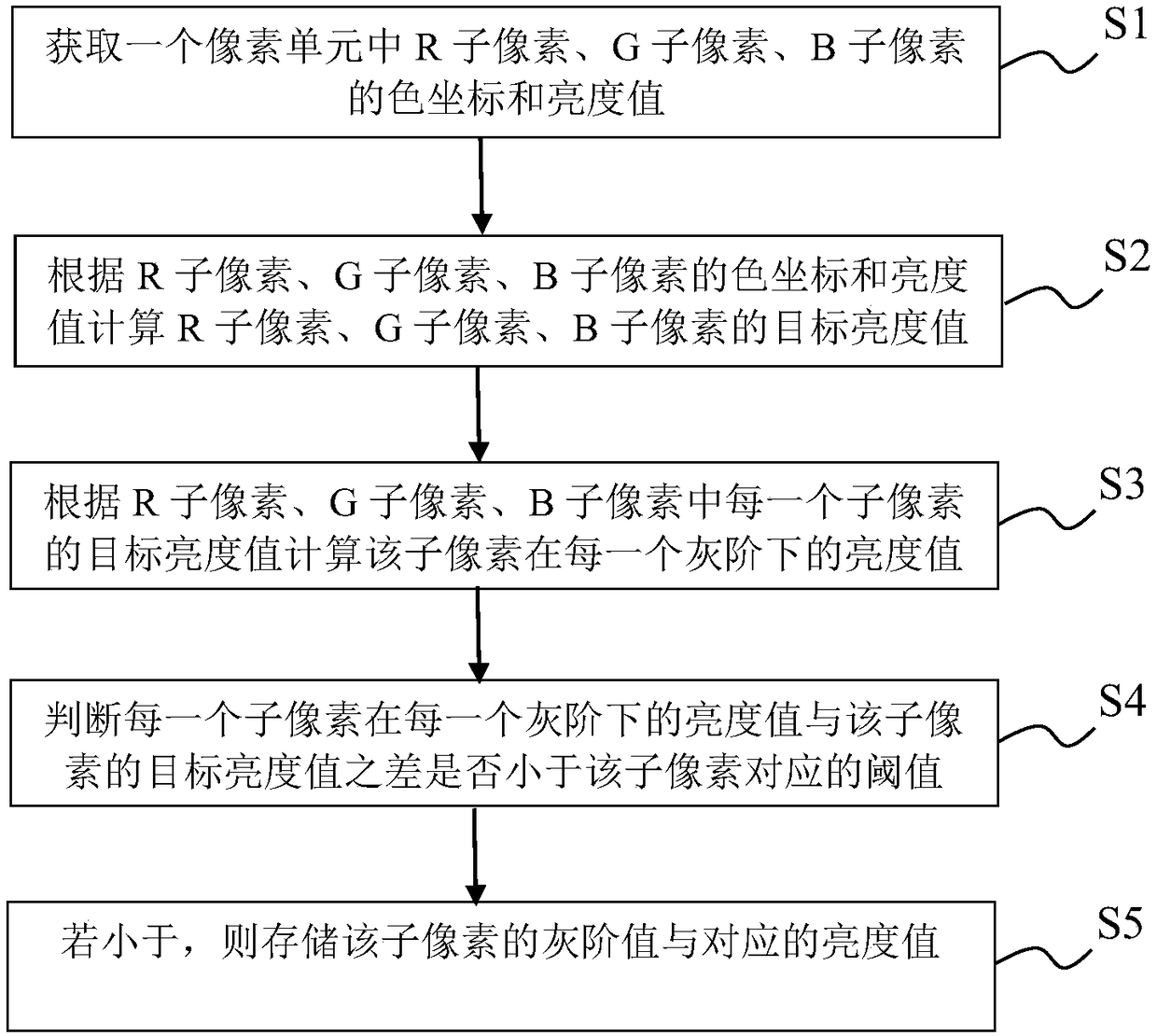

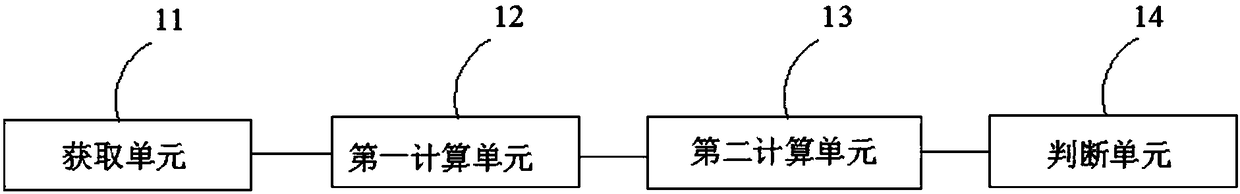

The invention provides a gamma correction system and a gamma correction method. The gamma correction method includes: acquiring the color coordinates and the brightness values of a R sub-pixel, a G sub-pixel, and a B sub-pixel; calculating the target brightness values of the R sub-pixel, the G sub-pixel, and the B sub-pixel according to the color coordinates and the brightness values of the R sub-pixel, the G sub-pixel, and the B sub-pixel, and calculating the brightness value of each sub-pixel at each grayscale according to the brightness value of each of the R sub-pixel, the G sub-pixel, andthe B sub-pixel; determining whether a difference between the brightness value of each sub-pixel of the R sub-pixel, the G sub-pixel, and the B sub-pixel at each grayscale and the target brightness value of each sub-pixel is smaller than a threshold corresponding to the sub-pixel; if so, storing the grayscale value and corresponding brightness value of the sub-pixel. The gamma correction method saves storage resources, greatly shortens correction time and improves correction efficiency.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Image distortion correction method based on look-up table

ActiveCN105095896AReduce time to correctRelaxed lengthCharacter and pattern recognitionDistortion correctionImage resolution

The invention discloses an image distortion correction method based on a look-up table, and the method comprises the steps: generating the look-up table according to selected reference points in plane grids; enabling a plurality of pixels to be mapped at the same position according to the look-up table; and calculating a mapping proportion of each row according to the look-up table. Moreover, the method can carry out image collection while carrying out image correction. Through the above mode, the method can meet the requirements of target images with different resolution, saves the time in image collection and correction, and relaxes the restriction on the length and width of an image.

Owner:JIANGSU BRMICO ELECTRONICS

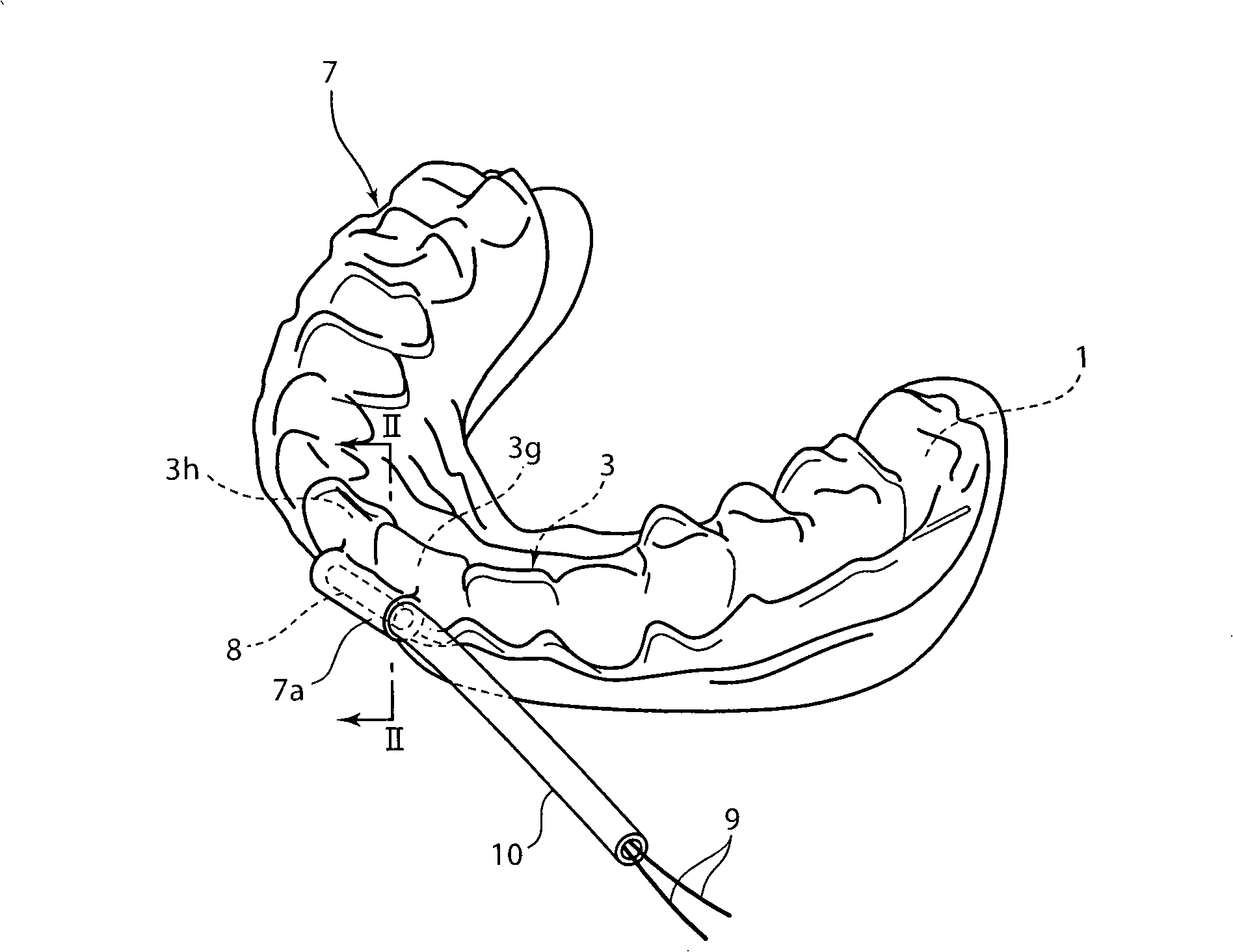

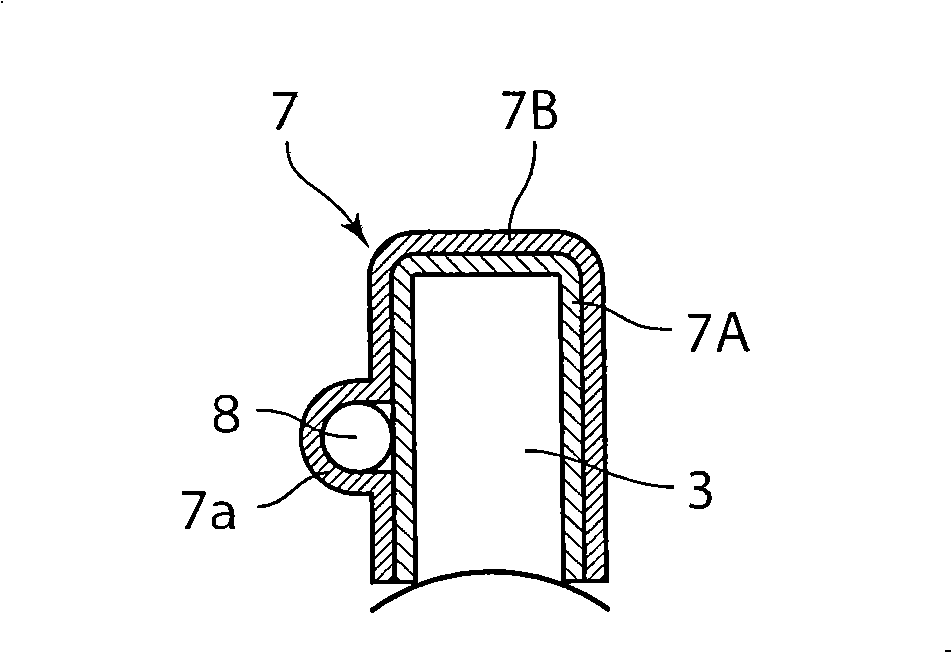

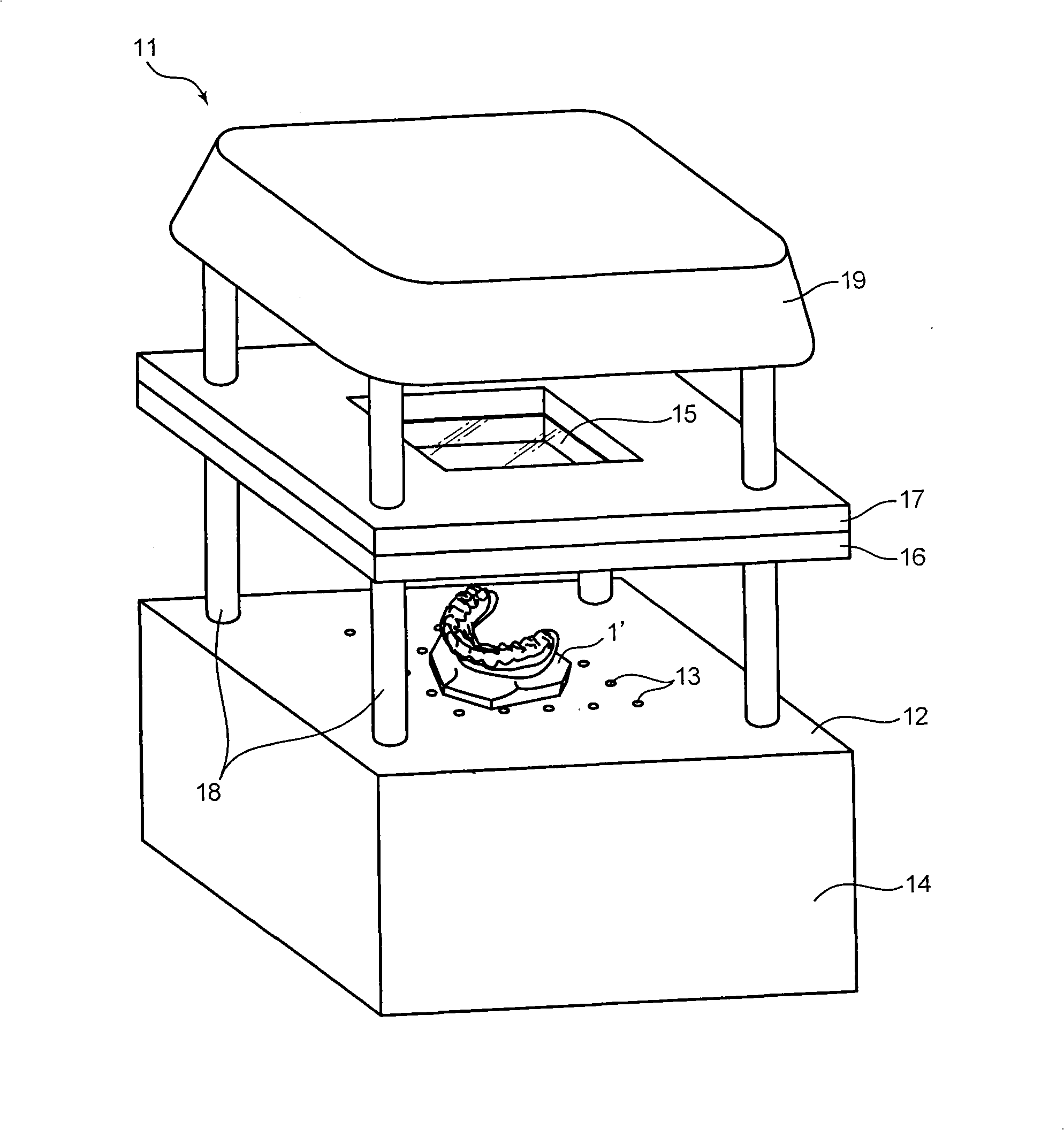

Dentition correcting device

InactiveCN101404952AImprove the correction effectReduce time to correctOthrodonticsDental prostheticsEngineeringBiological activation

Owner:PANASONIC HEALTHCARE HLDG CO LTD

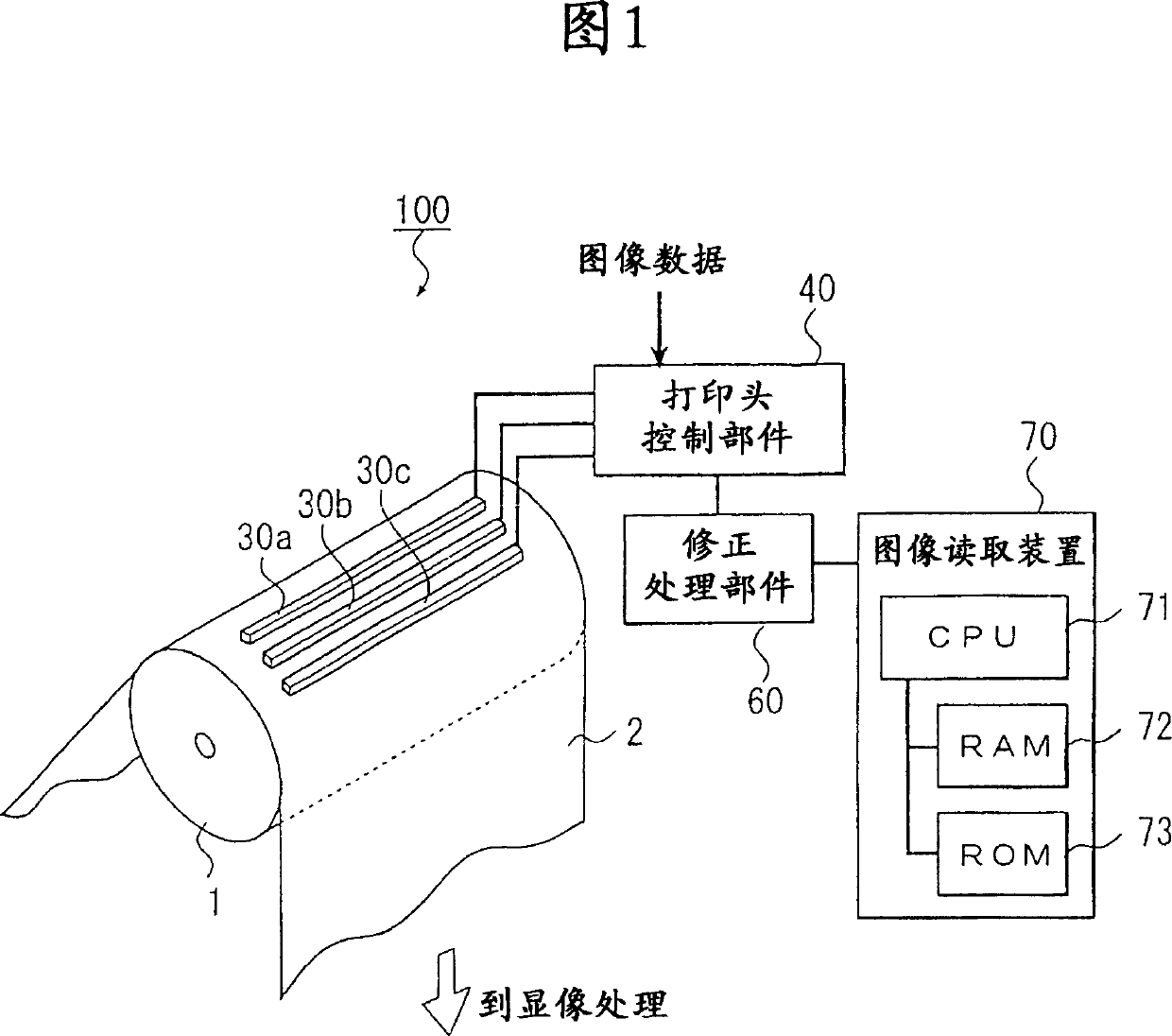

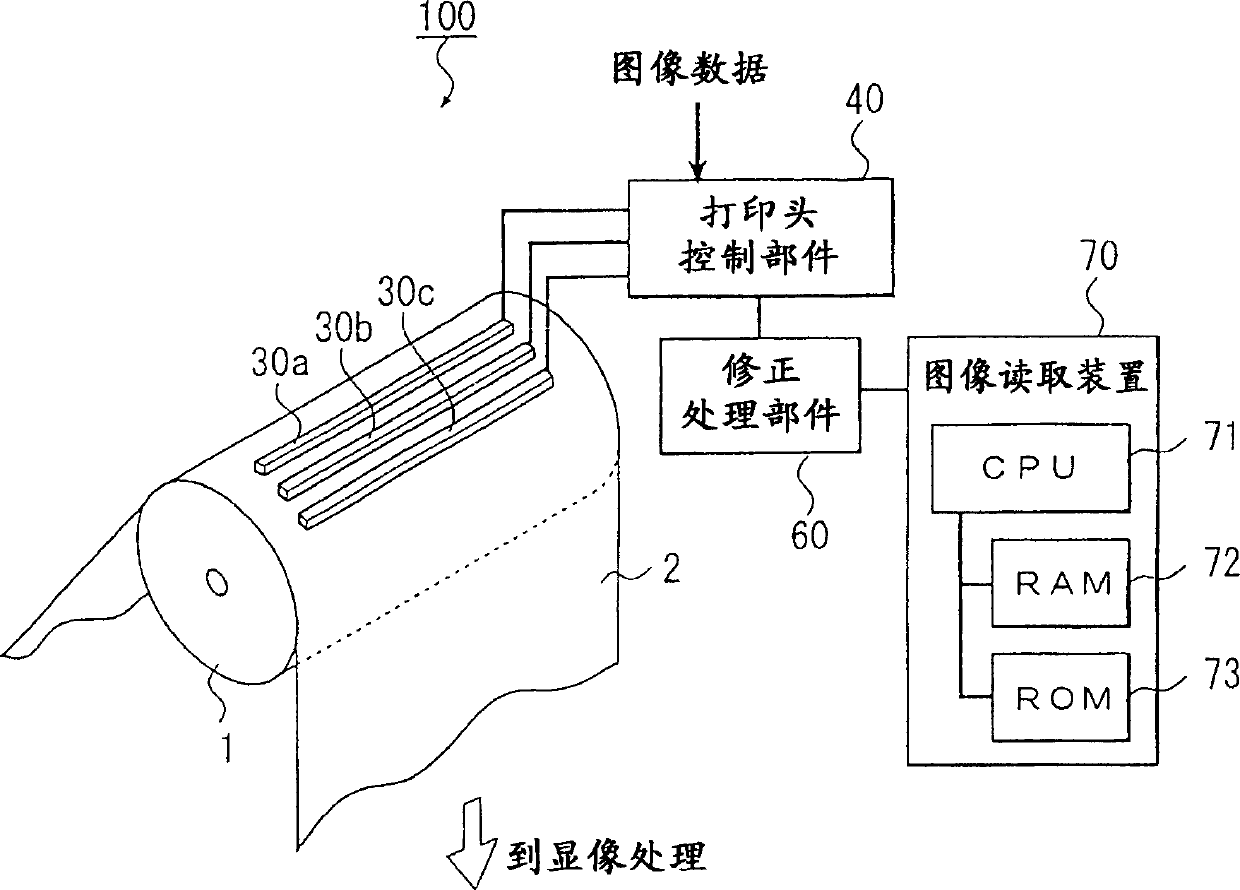

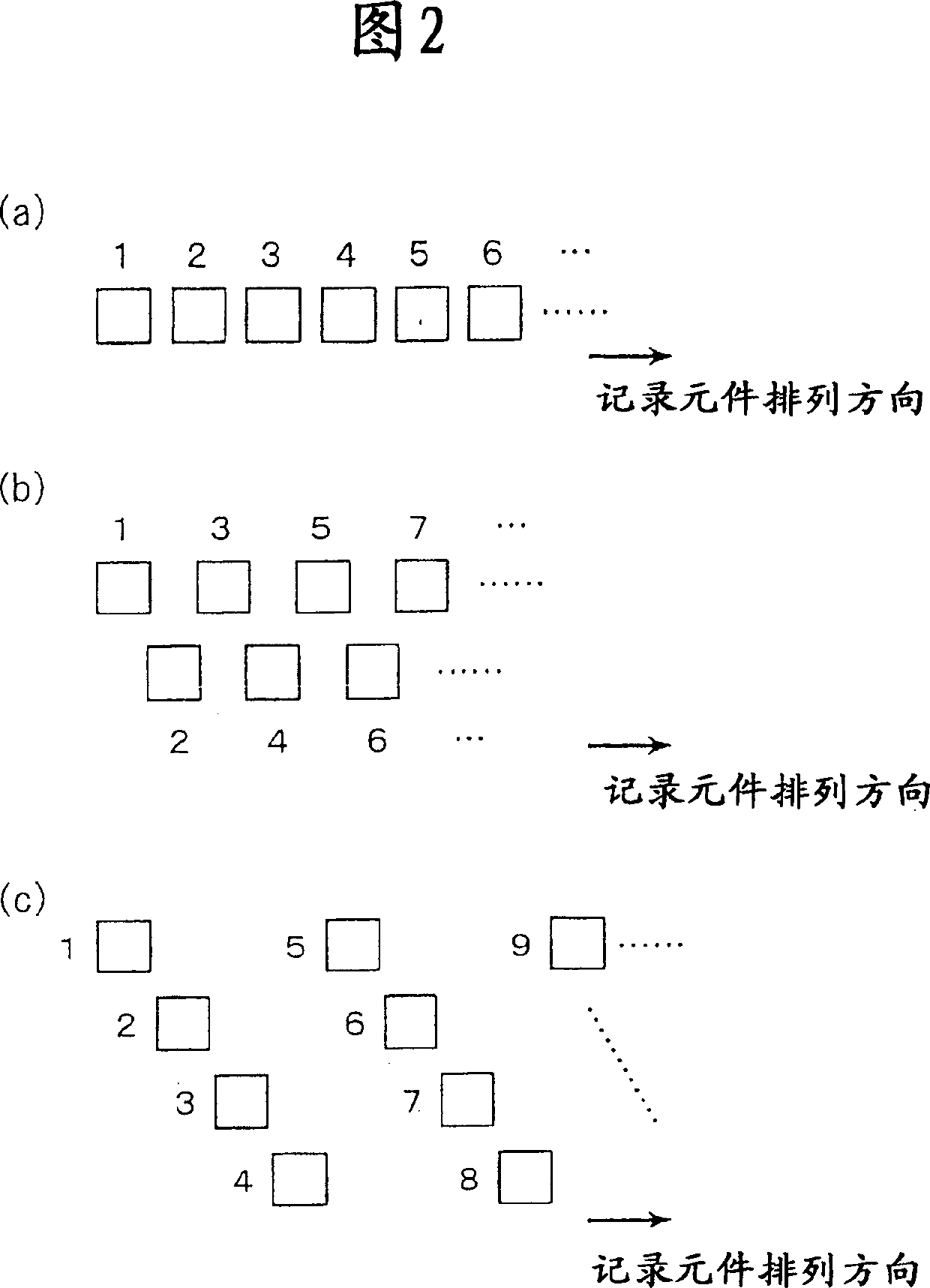

Output correction method of image forming device and image forming appts.

InactiveCN1539646AImprove image qualityHigh precisionOther printing apparatusPictoral communicationCorrection methodInformation data

Provided is a means of precisely reducing irregular concentrations in an array-like printhead for a long picture. An information of concentrations from each image N to be corrected (step S2) is obtained in the first place before a concentration information data DNi that corresponds to each recording pixel i is specified(step S4), and a deviation -DNi=DNi-DNave, iscalculated treating an average of the concentration data DNi as DNave (step S5). Then, a difference of the quantity of light, -ENi, corresponding to the deviation -ENi is obtained using a straight line of conversion (step S6), followed by (step S7) that calculates a correction quantity CNi=10(--ENi) that meets each recording pixel and (step S9) that composes the quantity of correction CNi calculated from each correction image N.

Owner:KONICA MINOLTA OPTO

Method for correcting C-shaped steel casting

ActiveCN107716624AEasy to operateShorten the correction timeShaping toolsSteel platesProduction cycle

The invention discloses a method for correcting a C-shaped steel casting. The method comprises the following steps: preparing a steel plate according to the dimensions of a C-shaped steel casting to be corrected, fixedly welding a fixing block on the steel plate, enabling a mounting hole to be formed in the fixing block in the length direction, mounting a rotating shaft in the two ends of the mounting hole through first bearings, enabling two threaded sections with equal lengths and opposite spiral directions to be formed on the rotating shaft, mounting a threaded sleeve on each of the two threaded sections, and further arranging an arc-shaped preheating pipe used for heating the steel casting at the arc top on the inner side of the C-shaped steel casting. The method for correcting the C-shaped steel casting has the benefits as follows: large-sized correcting auxiliary equipment does not need to be used, the operation is simple, easy to carry out, safe and reliable, the C-shaped steelcasting is corrected from the two ends simultaneously, the correcting time is shortened, the correcting efficiency is higher, and the two ends are corrected simultaneously so as to ensure the consistency of the correcting forces borne by the steel casting at the two ends; besides, the dimensional welding repair quantity of the casting due to deformation is greatly reduced, the welding cost is saved, and the production cycle of the casting is shortened.

Owner:QINGDAO YINGLONG MACHINERY

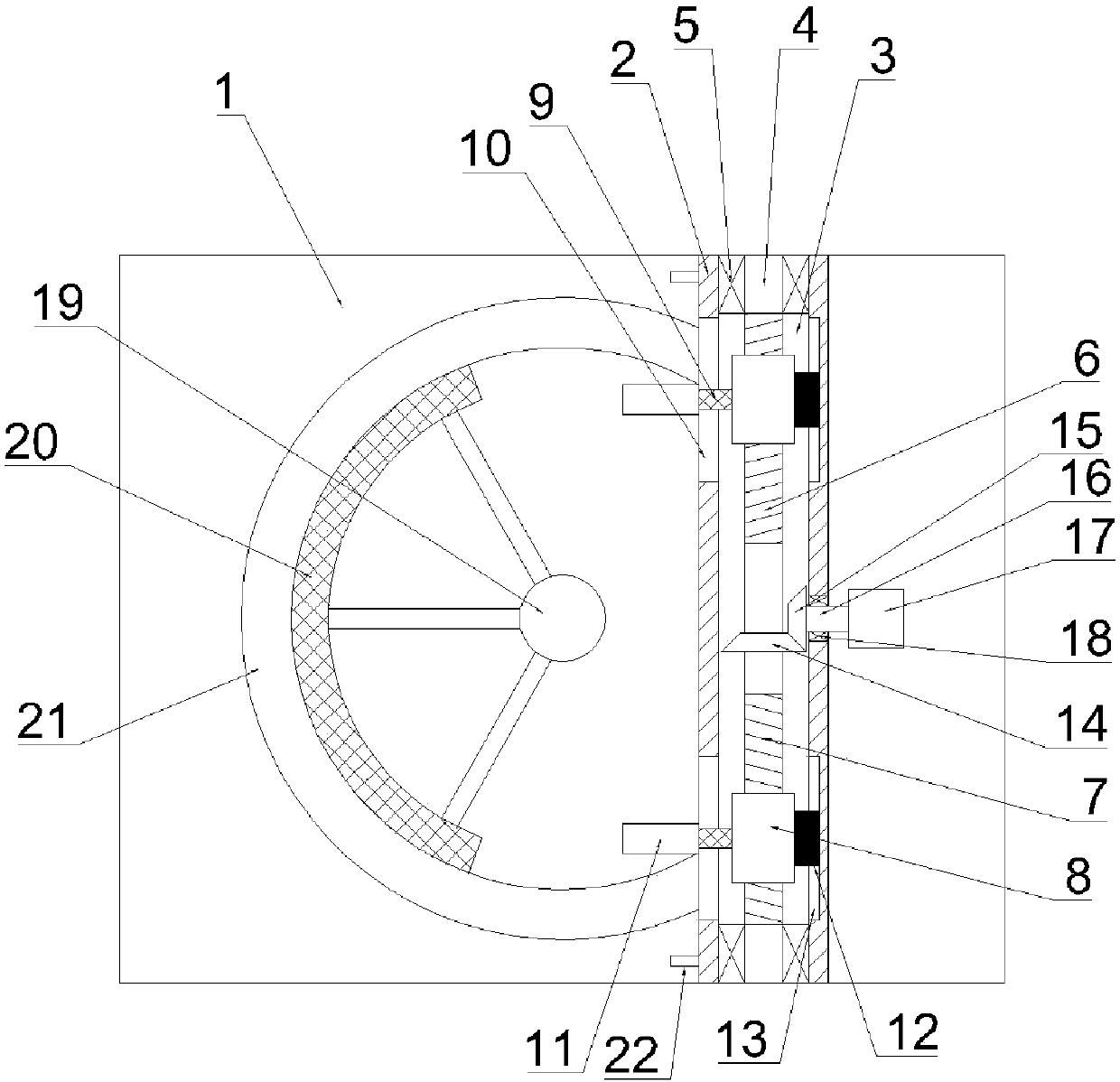

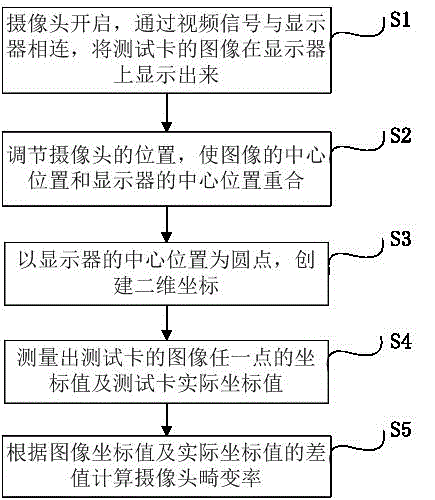

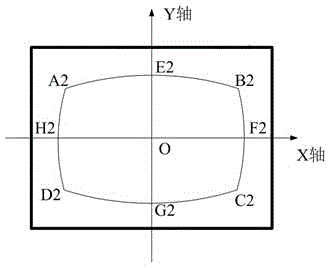

Method and system for testing distortion rate of camera

InactiveCN105120258AReduce time to correctSimple methodTelevision systemsContinuous measurementDisplay device

The invention provides a method and a system for testing the distortion rate of a camera, and belongs to the field of camera correction. The method for testing the distortion rate of the camera comprises the steps of turning on the camera, connecting the camera to a display through video signals, and displaying an image of a test card on the display; adjusting the position of the camera, and enabling the central position of the image to be overlapped with the central position of the display; establishing a two-dimensional coordinate system by taking the central position of the display as a dot; measuring coordinate values of any point of the image of the test card and actual coordinate values of the test card; and calculating the distortion rate of the camera according to the difference between the image coordinate values and the actual coordinate values. The method provided by the invention is simple, efficient, effective and low in cost. In addition, multiple times of continuous measurement online can be realized, the work efficiency is improved, and the time is saved, thereby greatly shortening the correction time in a research and development period of the camera.

Owner:SHENZHEN HANGSHENG ELECTRONICS

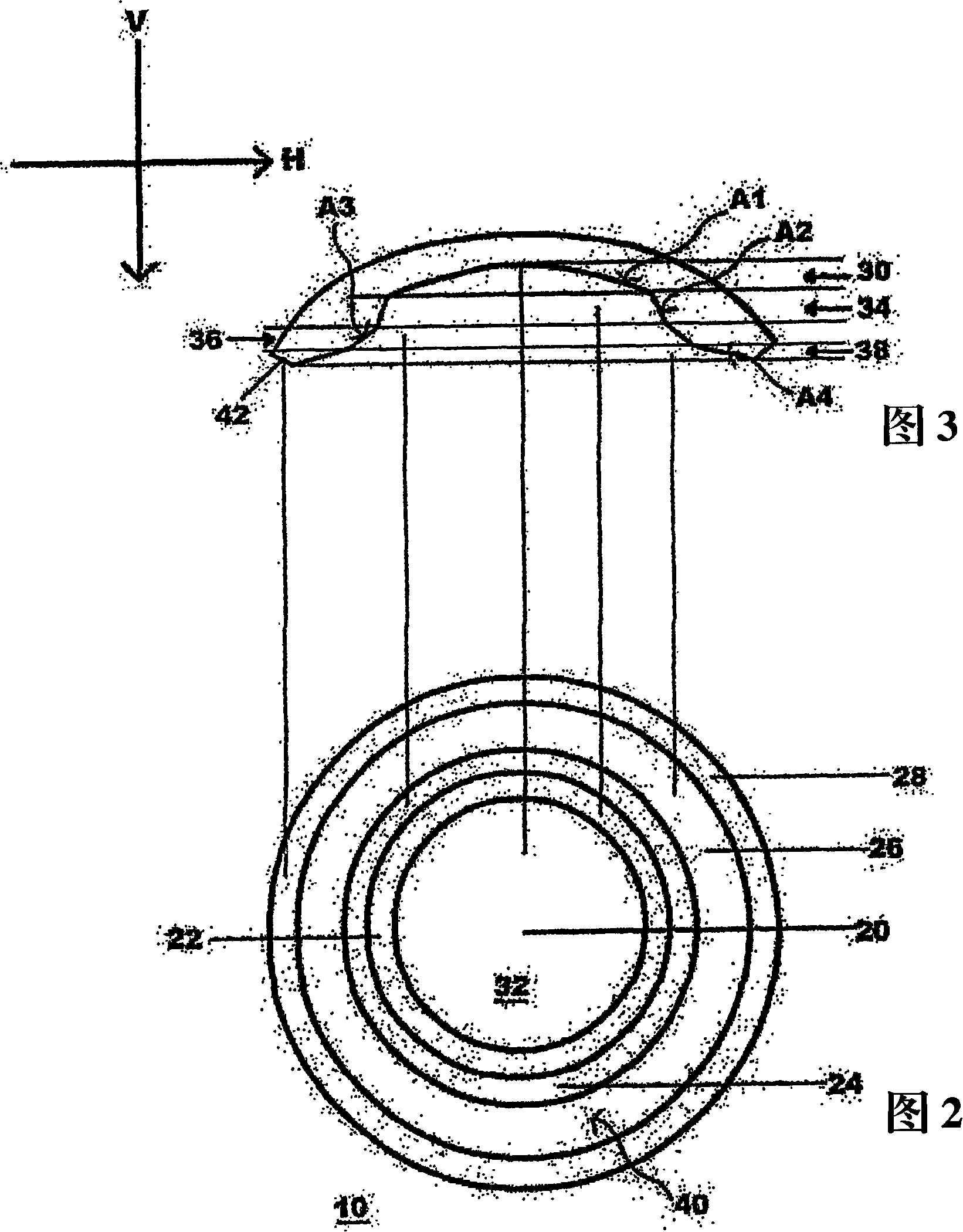

Orthokeratology contact lens

InactiveCN1474957AIncrease the degree of myopia correctionReduce time to correctOptical partsFar-sightednessOrthokeratology contact lens

A contact lens is fitted to a cornea of a patient's eye to gradually alter the patient's cornea during continued wear to reshape the cornea to reduce the hyperopia and / or presbyopia condition. The contact lens has a plurality of zones that includes one or two optical zones, a plateau zone, a fitting zone, an alignment zone and a peripheral zone. The one or more optical zones are utilized to redistribute cornea tissue to cause the cornea to have a steepened central portion surrounded by a flat mid-peripheral ring The plateau zone helps steepening the central cornea by two ways: a positive molding effect of pushing the cornea tissue inward to pile up and a negative molding effect to flatten the mid-peripheral cornea for enhancing.

Owner:董晓青

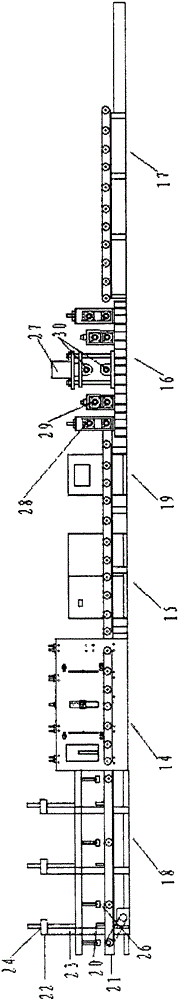

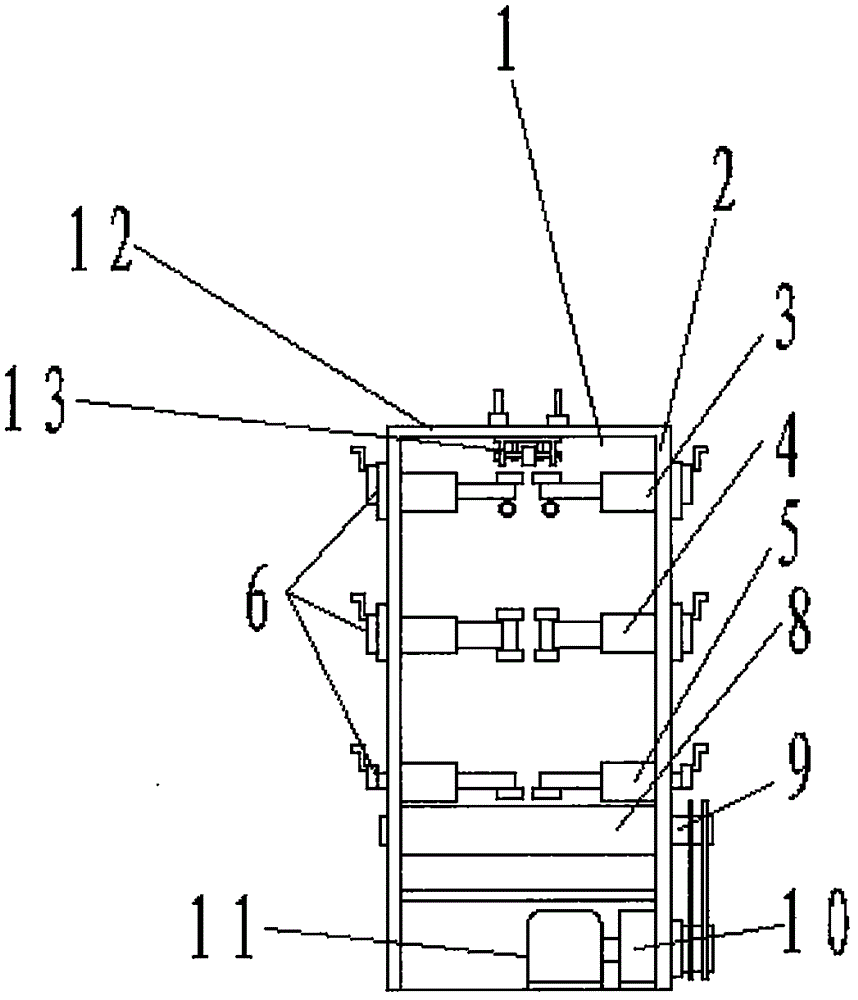

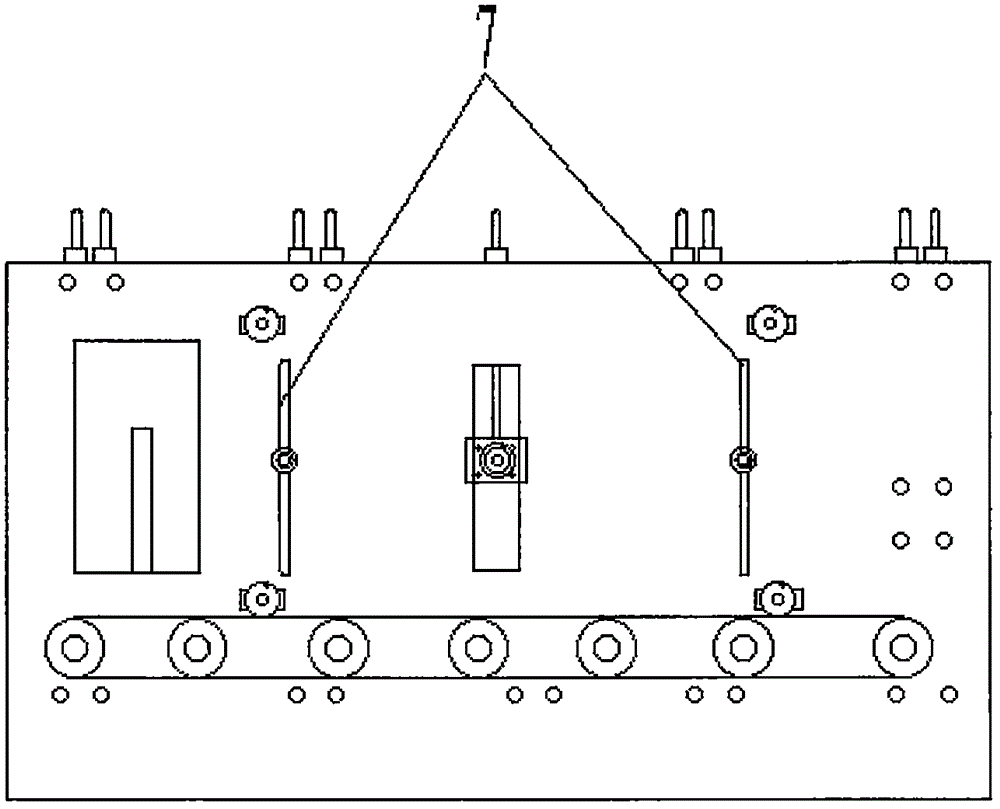

Integrated unit capable of automatically welding and cutting T-type steel through laser

ActiveCN106001925ARealize continuous productionStable righting and compacting effectLaser beam welding apparatusEngineeringLaser

The invention relates to the technical field of sectional material equipment, in particular to an integrated unit capable of automatically welding and cutting T-type steel through laser. The integrated unit comprises a feeding mechanism, a centralizing and pressing mechanism, a laser welding and cutting mechanism, a discharging mechanism and a correcting and inspecting mechanism. The integrated unit has the beneficial effects that welding and cutting equipment of H-type steel and welding and correcting equipment of the T-type steel are integrated, welding is directly carried in the feeding process, full-automatic production and continuous production of the T-type steel are realized, and the production efficiency is greatly improved.

Owner:唐山纵横联合板带有限公司

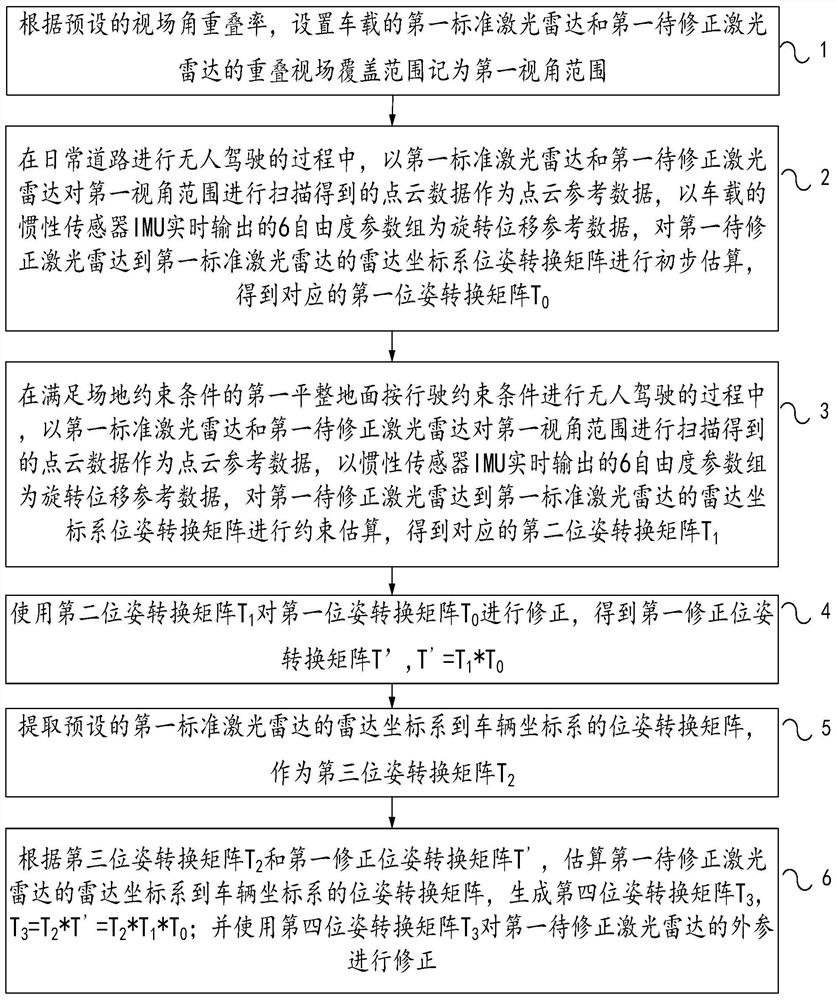

Method for correcting external parameters of laser radar in unmanned driving

InactiveCN113552559AAvoid Fixing InefficienciesReduce Corrective CostsElectromagnetic wave reradiationRadarComputer science

The embodiment of the invention relates to a method for correcting external parameters of a laser radar in unmanned driving. The method comprises the steps of setting a first standard laser radar, and recording the coverage range of an overlapped view field of the to-be-corrected laser radar as a first view angle range, performing preliminary estimation on a pose conversion matrix from the first to-be-corrected laser radar to the first standard laser radar on a daily road to obtain a first pose conversion matrix T0, performing constraint estimation on the first to-be-corrected laser radar to first standard laser radar pose conversion matrix on the first flat ground to obtain a second pose conversion matrix T1, correcting the first pose conversion matrix T0 to obtain a first corrected pose conversion matrix T', extracting a third pose conversion matrix T2, estimating a pose conversion matrix of the first to-be-corrected laser radar to generate a fourth pose conversion matrix T3, and correcting the external parameters of the first to-be-corrected laser radar. Through the method, the correction cost can be saved, the correction time is shortened, and the correction effect is improved.

Owner:BEIJING QINGZHOUZHIHANG TECH CO LTD

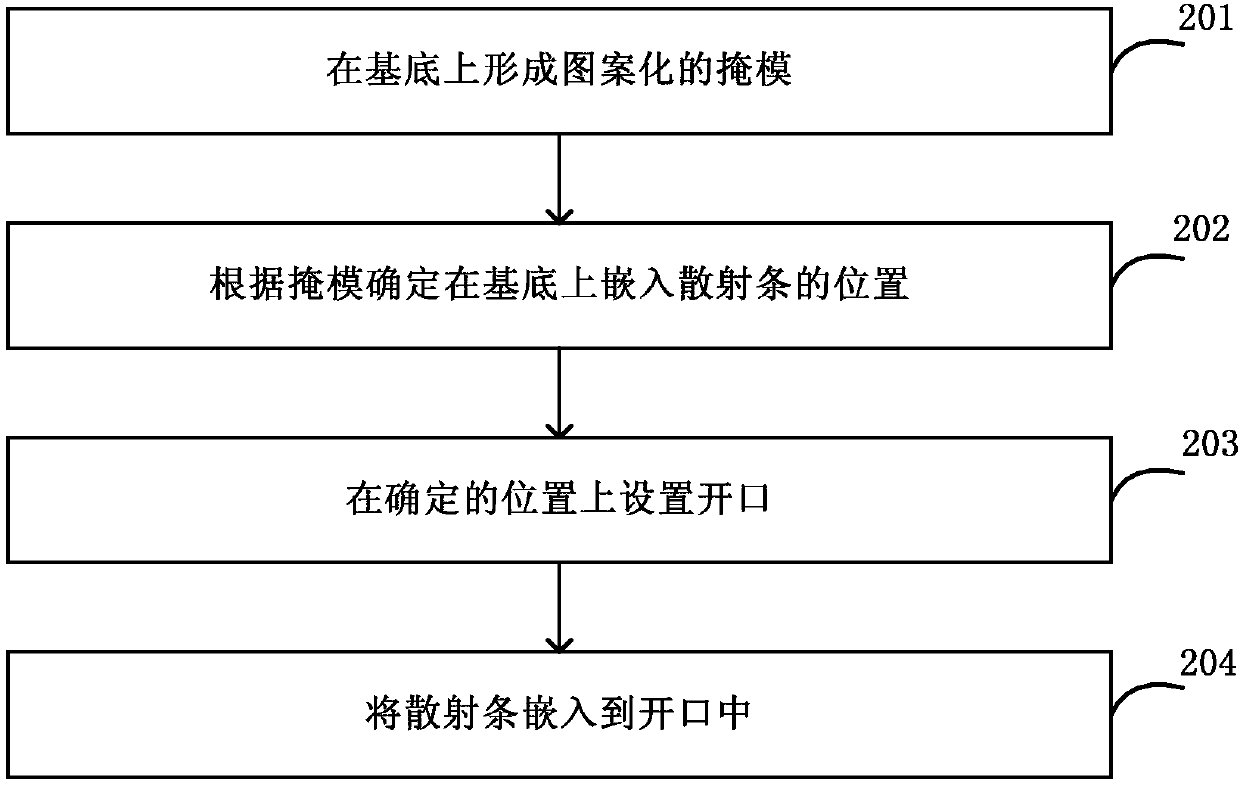

OPC method for reducing correction iterations

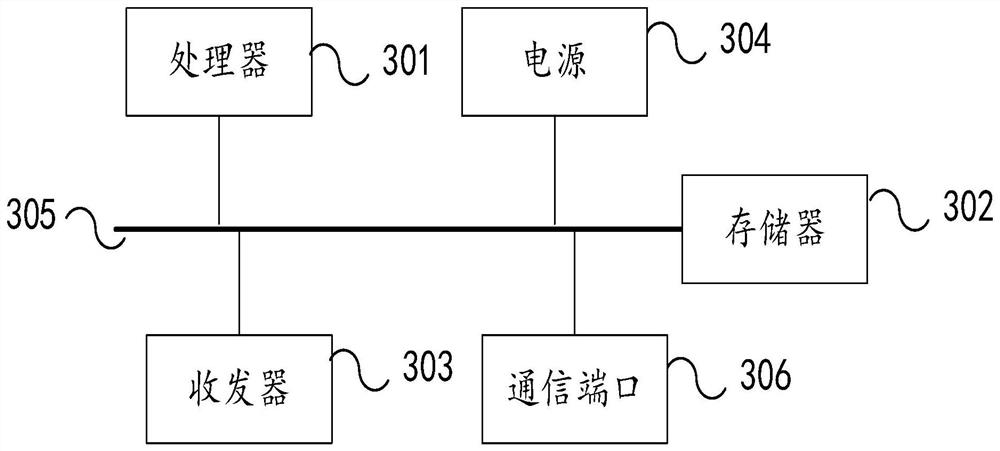

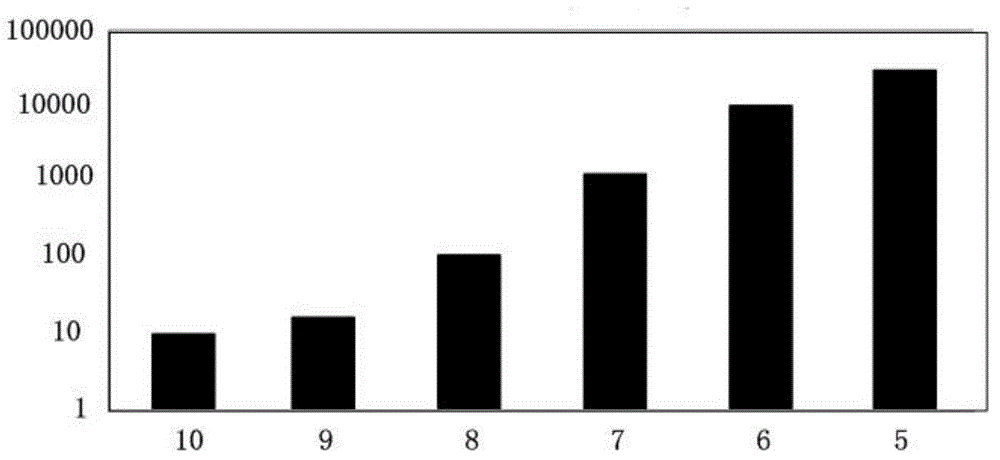

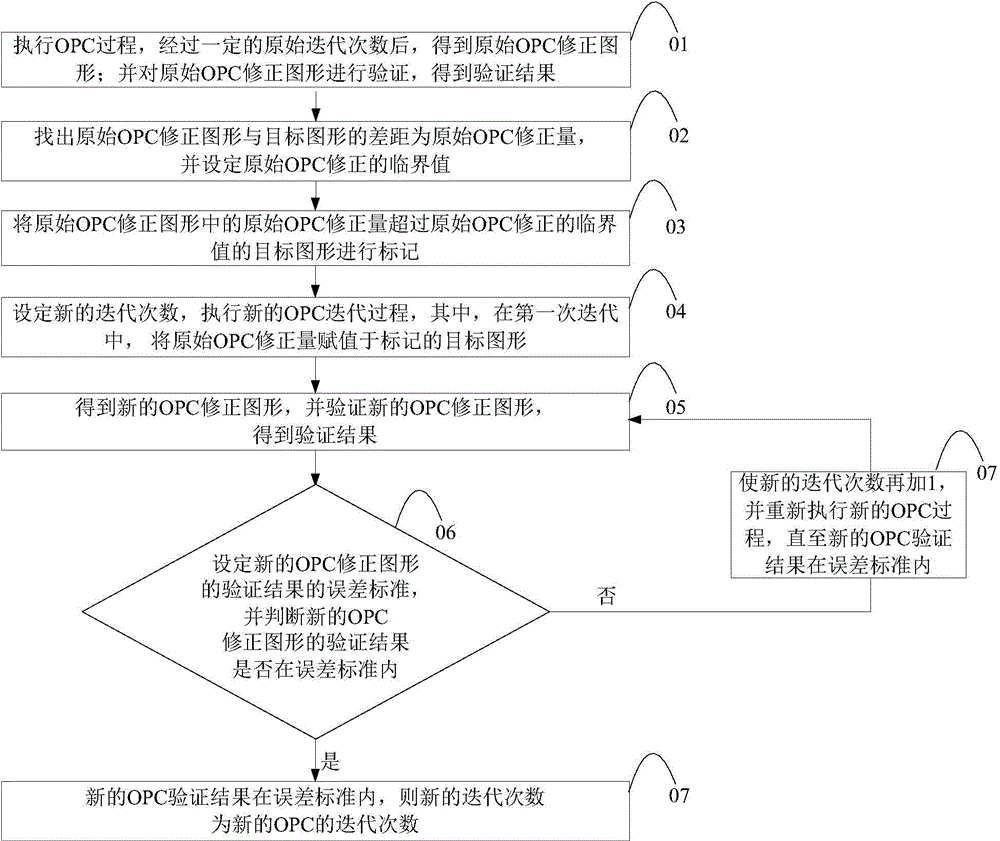

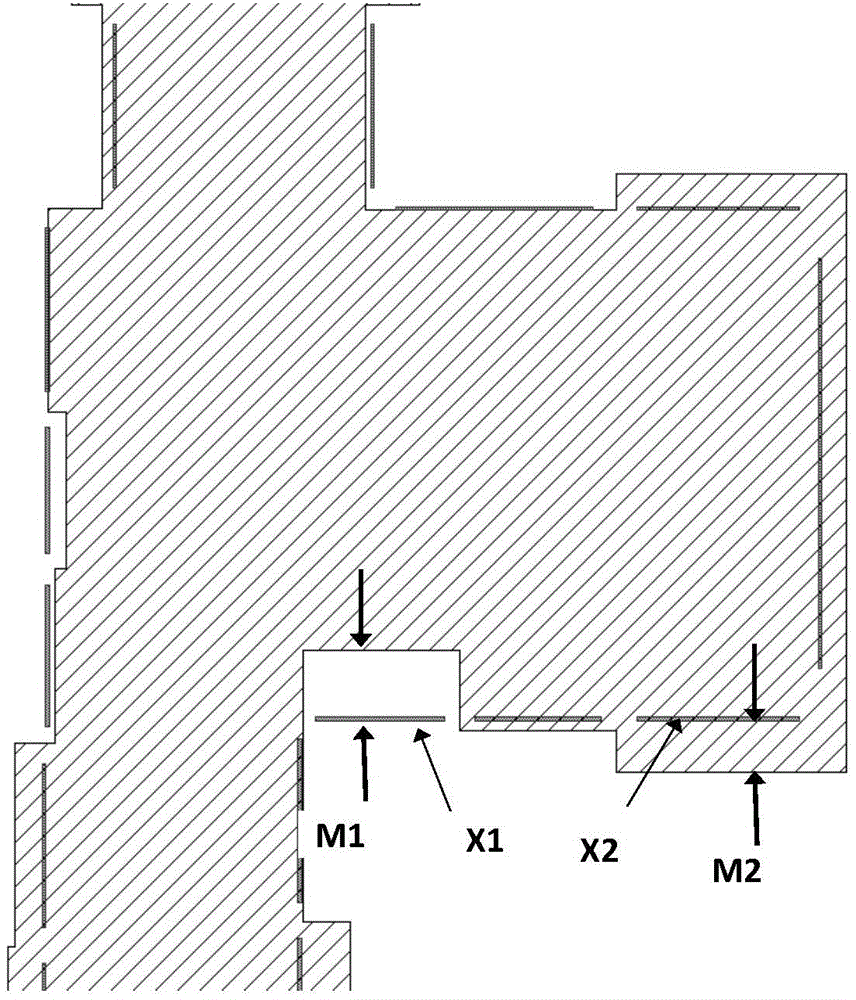

ActiveCN104166305AReduce the number of iterationsReduce time to correctOriginals for photomechanical treatmentAlgorithmIteration process

The invention provides an OPC method for reducing correction iterations. The OPC method comprises the following steps: executing an OPC process, thereby obtaining an original OPC correction diagram via original iterations; verifying the original OPC correction diagram; finding out the difference between the original correction diagram and a target diagram as the original OPC correction quantity, and setting the supercritical value of the original OPC correction; marking a target diagram with the original OPC correction quantity exceeding the critical value of the original OPC correction in the original OPC correction diagram; setting new iterations, executing the new OPC iteration process, and assigning the original OPC correction quantity to the marked target diagram in the first time of iteration; acquiring and verifying the new OPC correction diagram; and judging whether the verification result of the OPC correction diagram is within the error standard, if yes, taking the new iterations as the new OPC iterations, and if not, adding one to the new iterations, and executing the new OPC process again until the verification result of the new OPC is within the error standard, so that the OPC precision is ensured, and the time is saved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

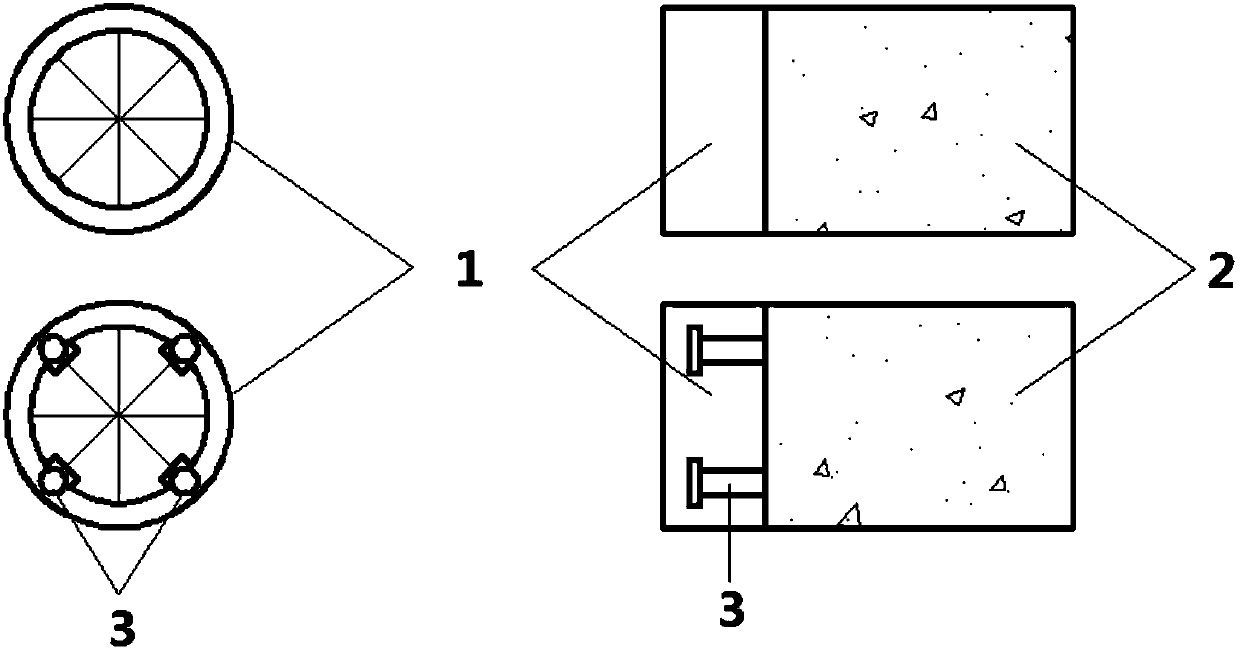

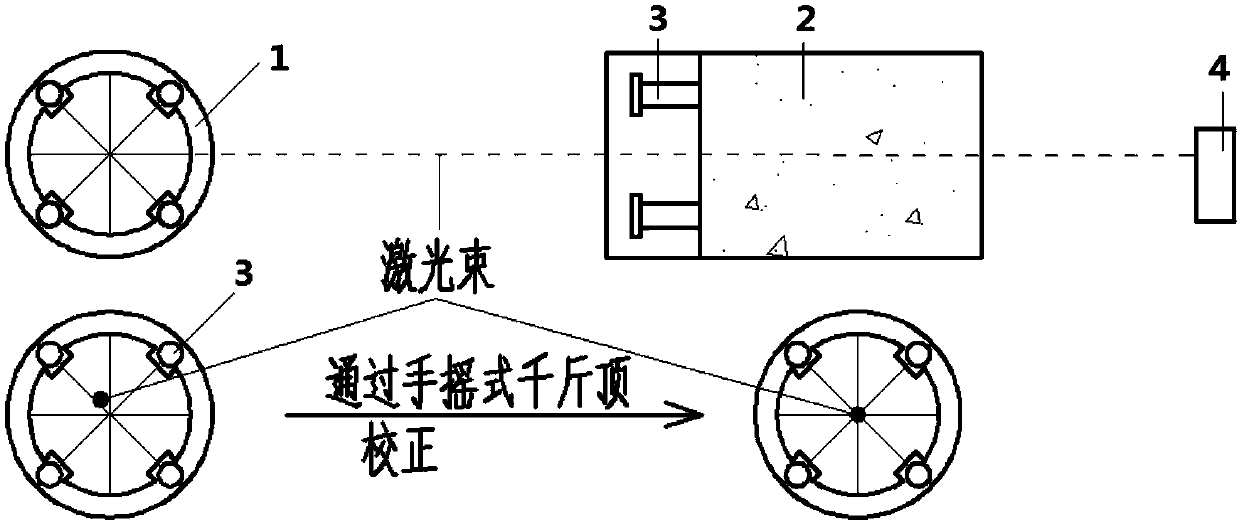

Device and method for correcting cutterhead jacking direction in real time during manual pipe jacking construction

InactiveCN107725892AReduce the difficulty of correctionRealize integrationPipe laying and repairEngineeringBuilding construction

The invention discloses a device and method for correcting the cutterhead jacking direction in real time during manual pipe jacking construction, and relates to the field of municipal road drain pipeline construction. The method comprises the following steps that four hand-operated jacks are uniformly arranged and fixed to the inner side of the circumference of a cutterhead, a protection barrel ofthe cutterhead extends to cover the four hand-operated jacks, and the cutterhead is connected with a pipeline through the four hand-operated jacks; and when the cutterhead is jacked into a first pipeline section, in the deviation correcting process, the center line and the elevation are measured every time the cutterhead is jacked in by 20-30 cm, the hand-operated jacks are operated manually to slightly adjust the angle of the cutterhead according to the measurement results so that the pipeline jacking direction can be corrected. Through the device and method for correcting the cutterhead jacking direction in real time during manual pipe jacking construction, the constructed pipeline can be precisely positioned, the underground extending deviation of the pipeline is corrected in real time, and the jacking direction in the whole pipeline jacking process is effectively controlled.

Owner:WUHAN HANYANG MUNICIPAL CONSTR GRP CO LTD

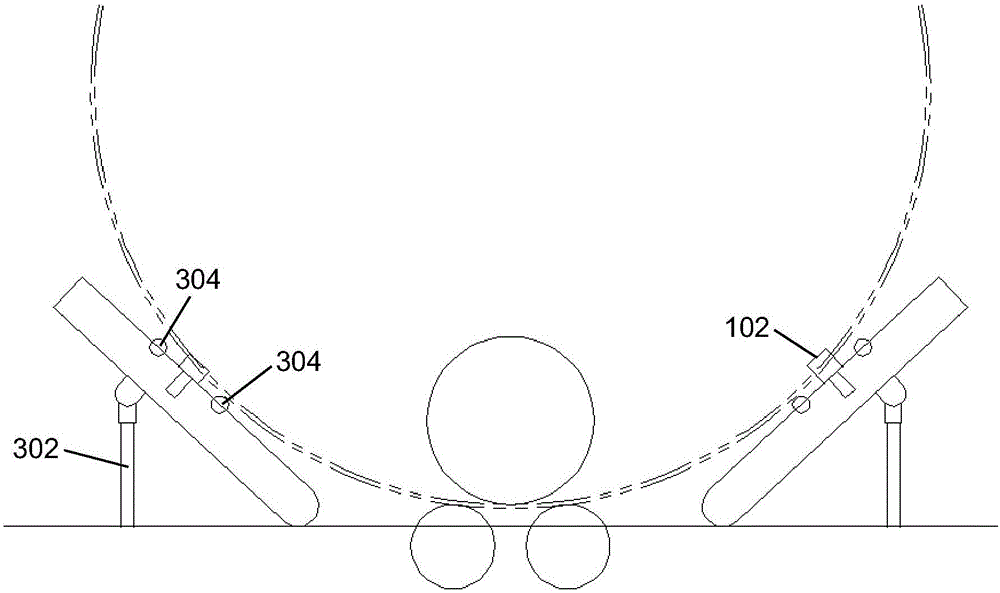

T-shaped steel machining device and T-shaped steel straightening method

InactiveCN107042250AIncrease productivityGuaranteed uptimeShaping toolsWelding apparatusAssembly lineMachining

The invention relates to the technical field of welding, in particular to a T-shaped steel machining device and a T-shaped steel straightening method. According to the T-shaped steel straightening method, flame straightening is conducted on T-shaped steel during assembly line welding operation of the T-shaped steel. The T-shaped steel straightening method comprises the following steps that the height of a flame heating gun is adjusted according to the height of the T-shaped steel; the T-shaped steel is welded; when the initial end of a weld joint of the T-shaped steel is aligned to the straightening device, the flame heating gun needing to work is started; and when the terminal end of the weld joint of the T-shaped steel is aligned to the straightening device, the started flame heating gun is stopped. By the adoption of the T-shaped steel machining device and the T-shaped steel straightening method, the straightening time can be effectively shortened, the production efficiency of the T-shaped steel is improved, an assembly line is prevented from being stopped, and the utilization rate of a machining plant is increased.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

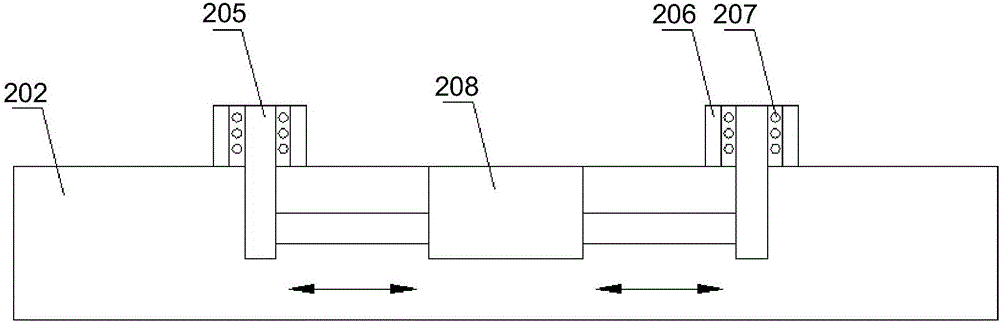

Misaligned rectifying and dragging device of plate rolling machine

InactiveCN106734414AIncrease the level of automationAvoid deformationMetal-working feeding devicesPositioning devicesMechanical engineering

The invention discloses a misaligned rectifying and dragging device of a plate rolling machine. The misaligned rectifying and dragging device comprises a dragging base plate, a longitudinal rectifying mechanism and a radial rectifying mechanism, wherein the longitudinal rectifying mechanism is arranged on the dragging base plate for carrying out longitudinal rectifying on a plate which is being rolled; the radial rectifying mechanism is arranged on the dragging base plate for carrying out radial rectifying on the plate which is being rolled; the longitudinal rectifying mechanism comprises a beam, a clamping rod and a drive mechanism; the beam is arranged on the dragging base plate and is provided with a lateral groove; the clamping rod is arranged on the beam, and the clamping rod is arranged in the lateral groove and can laterally move along the groove; the drive mechanism is arranged on the beam and drives the clamping rod to laterally move along the groove; the clamping rod is in contact with the plate which is being rolled, and the plate is driven to laterally move to carry out longitudinal rectifying on the plate; the radial rectifying mechanism comprises a jacking mechanism and support rollers; the jacking mechanism is connected with the dragging base plate and adjusts the inclination angle of the dragging base plate; and the support rollers are arranged on the dragging base plate to support the plate which is being rolled.

Owner:SHANGHAI ZHENHUA HEAVY IND

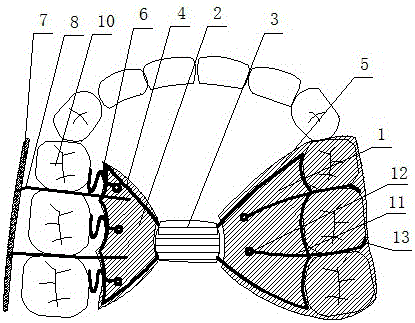

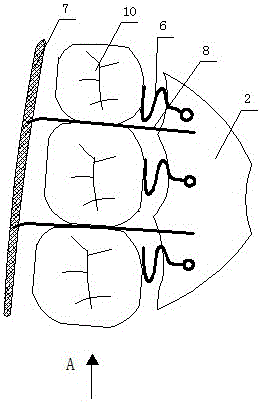

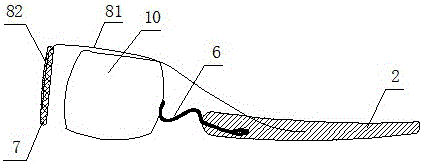

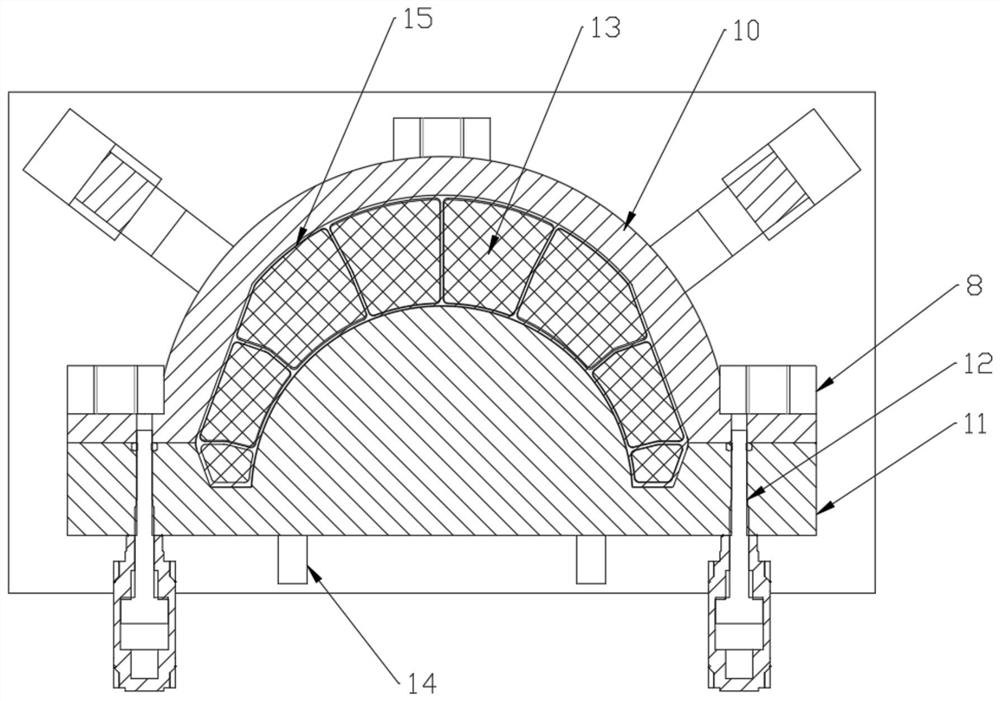

Unilateral posterior tooth reverse occlusion orthodontic apparatus

The invention provides a unilateral posterior tooth reverse occlusion orthodontic apparatus which comprises a jaw pad, a base bracket, a spiral expander, a first anti-crack component, a second anti-crack component, adjacent hooks, an outward pushing assembly, a cheek screen and at least two jaw crossing steel wires. Two ends of the spiral expander are connected with the first anti-crack component and the second anti-crack component, the first anti-crack component is arranged in the jaw pad, the second anti-crack component is arranged in the base bracket, each jaw crossing steel wire comprises a jaw-direction portion and a cheek-direction portion, one end of each jaw-direction portion is arranged in the base bracket, the other end of the each jaw-direction portion crosses the sulcus vestibularis of a corresponding reverse occlusion tooth to be connected with the corresponding cheek-direction portion, each cheek-direction portion is arranged on a cheek side of the corresponding reverse occlusion tooth and is arranged in the cheek screen, and the outward pushing assembly comprises more than one hyperbolic tongue spring for providing outward thrust for the reverse occlusion teeth. The unilateral posterior tooth reverse occlusion orthodontic apparatus has the advantages that effective and quick orthodontic treatment can be carried out on the reverse occlusion teeth by the aid of the unilateral posterior tooth reverse occlusion orthodontic apparatus, and the orthodontic time can be shortened to a great extent, can be shortened from the existing orthodontic time of 4-6 months and is 1-2 months.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

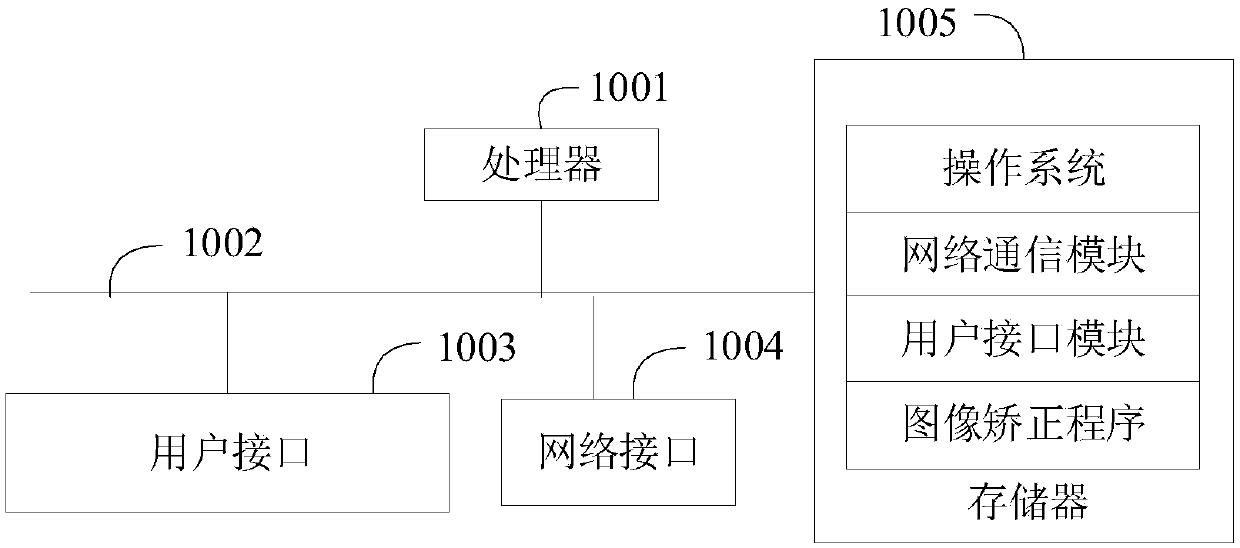

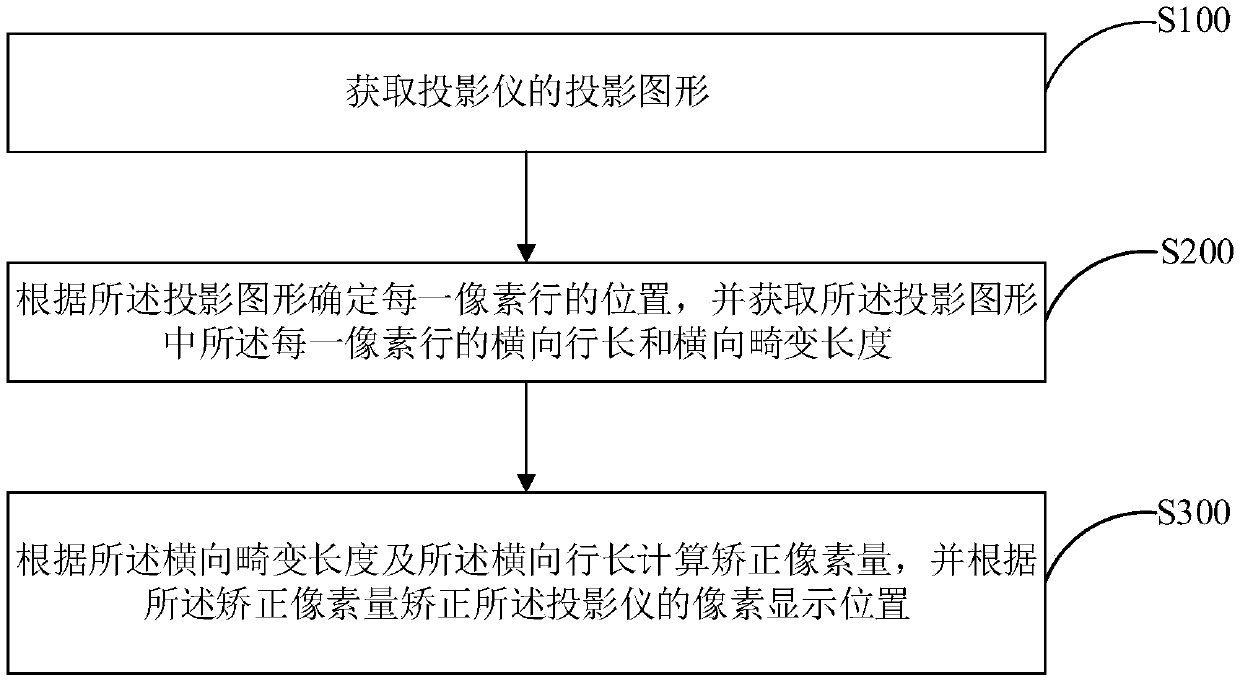

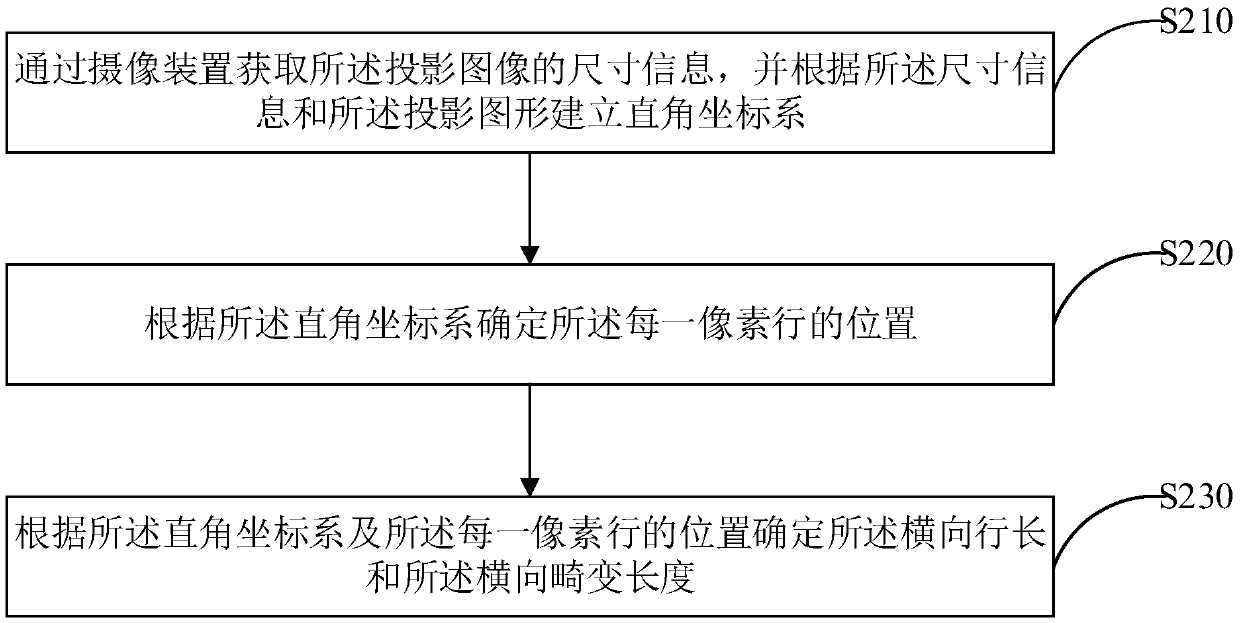

Projector image distortion correction method and device and computer readable storage medium

ActiveCN109523481AImprove correction efficiencyReduce time to correctImage enhancementGeometric image transformationLaser beamsComputer science

The invention discloses a method for correcting image distortion of a projector. The method comprises the following steps: obtaining a projection graph of the projector; Determining the position of each pixel row according to the projection graph, and obtaining the transverse row length and the transverse distortion length of each pixel row in the projection graph; And calculating a correction pixel quantity according to the transverse distortion length and the transverse row length, and correcting the pixel display position of the projector according to the correction pixel quantity. The invention also discloses a projector image distortion correction device and a computer readable storage medium. The technical problems of long inherent distortion correction time and low correction efficiency of a projection graph output by a laser beam scanning projector are solved.

Owner:GOERTEK OPTICAL TECH CO LTD

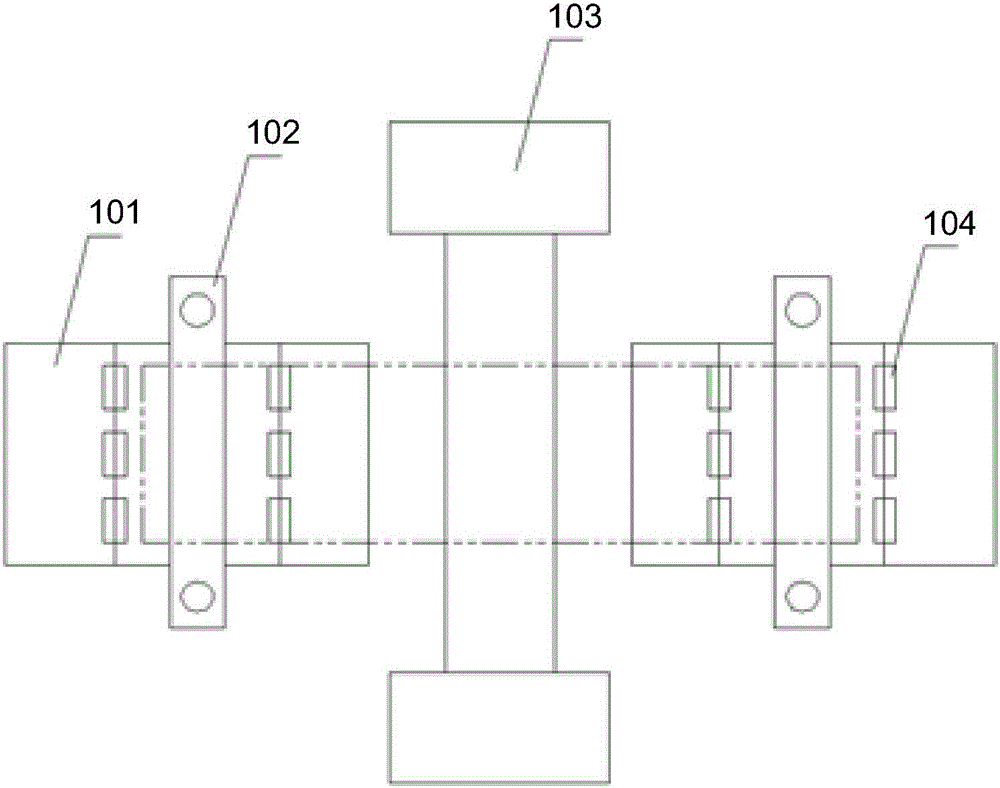

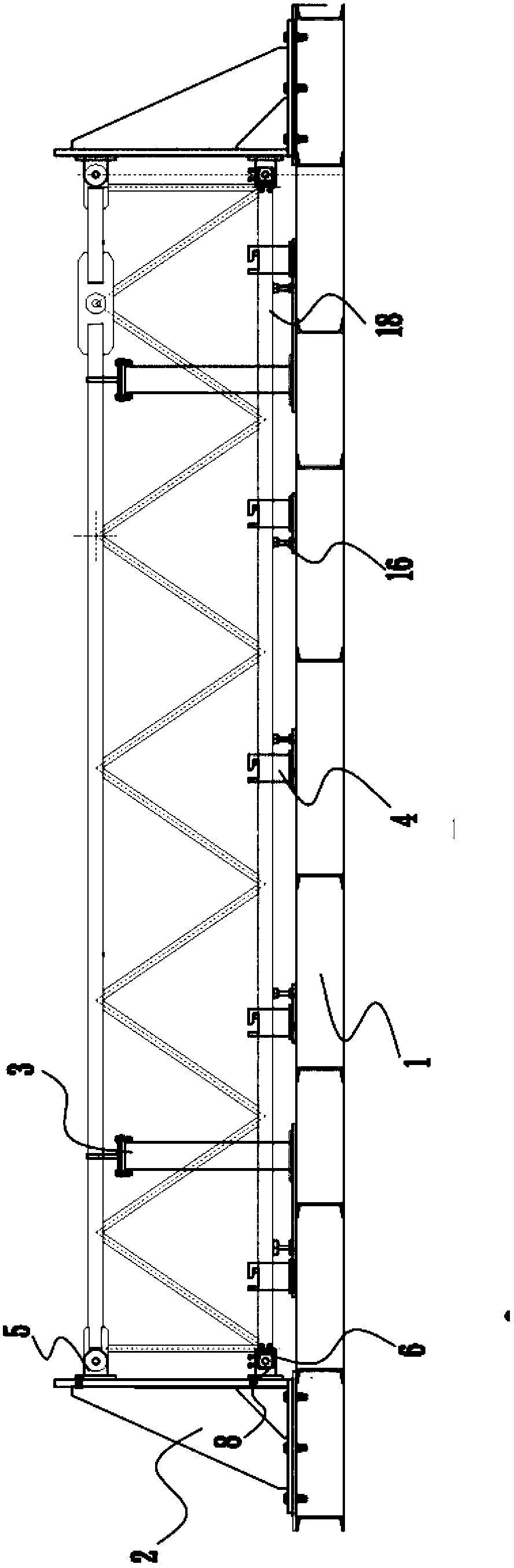

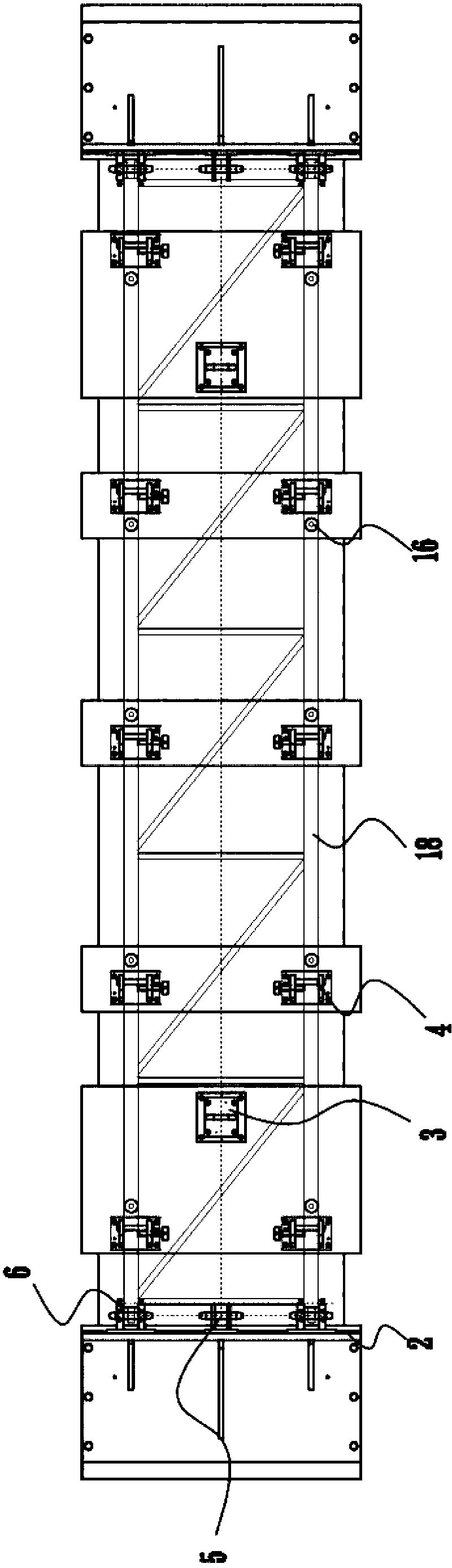

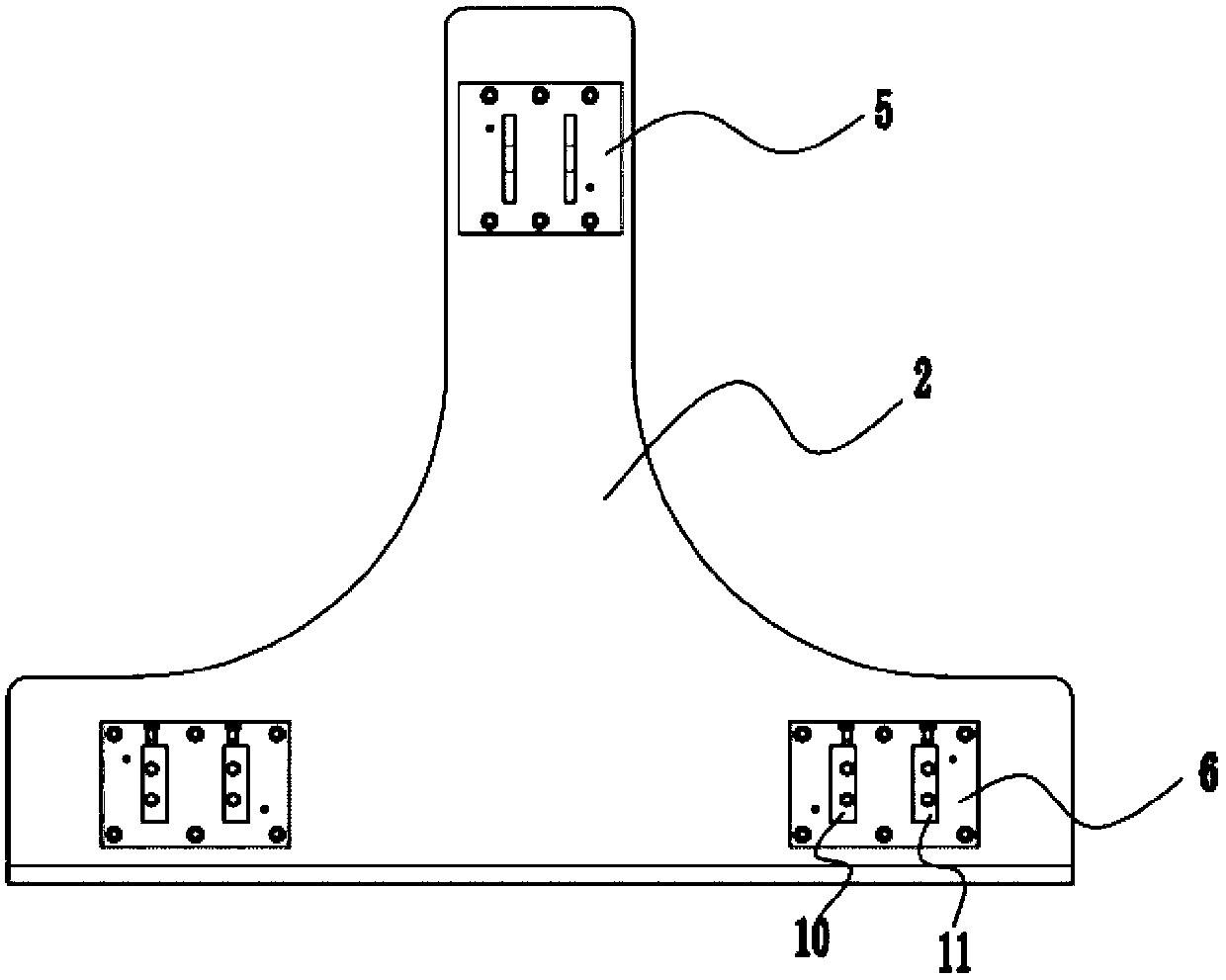

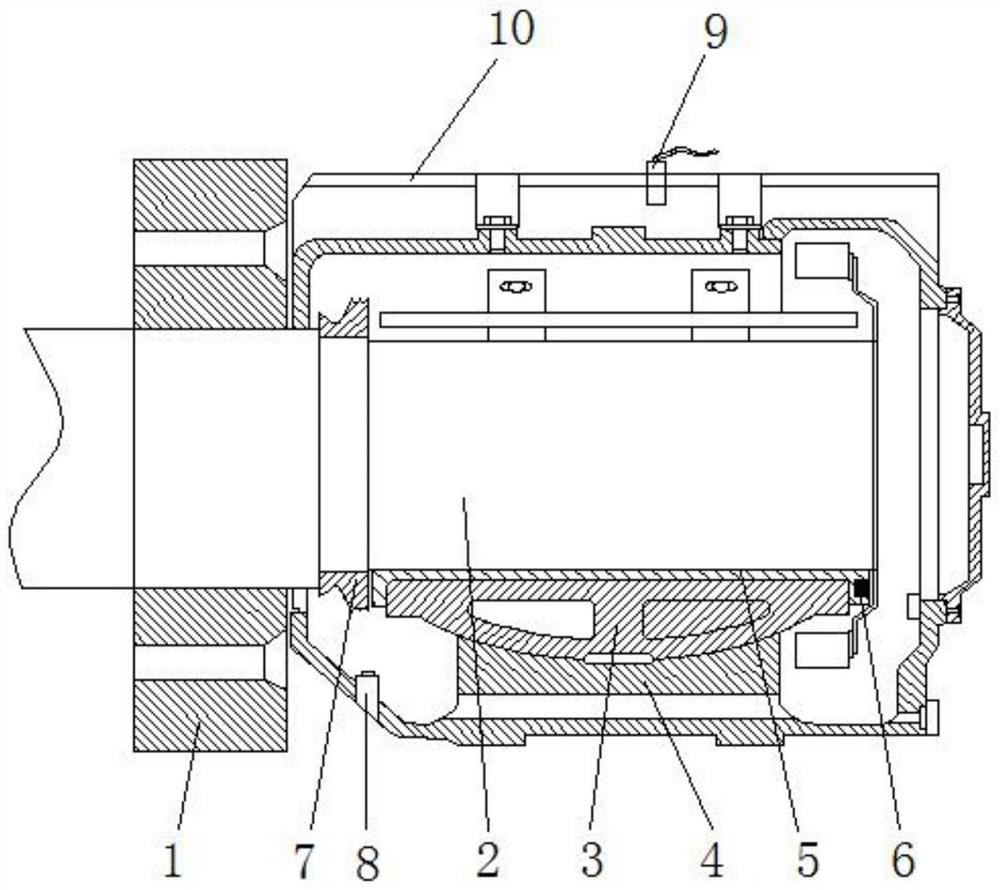

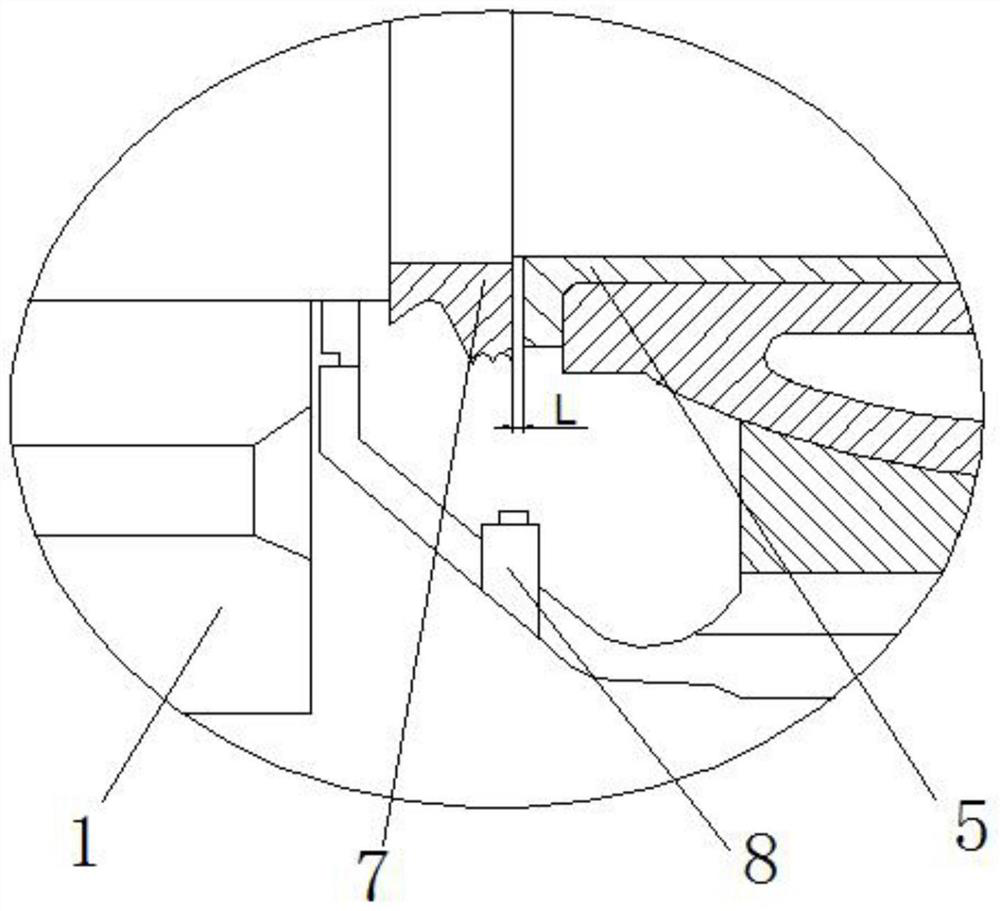

Tower crane boom tool

ActiveCN103128474ASmooth transitionPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesButt jointUpper joint

A tower crane boom tool comprises a framework platform (1), wall plate components (2), a plurality of upper chord tube positioning supports (3), and a plurality of lower chord square tube positioning supports (4), wherein the wall plates components are detachably fixed on the left side and the right side of the framework platform (1). The tower crane boom tool is characterized in that upper joint positioning supports (5) and lower joint positioning supports (6) which are structured in left and right double side plates are arranged on the wall plate components, pin shaft holes are correspondingly arranged on the double side plates of the upper joint positioning supports, and square holes (7) are correspondingly arranged on the double side plates of the lower joint positioning supports and used for fixedly holding standardized modules (8) in different specifications. On one hand, precise positioning and butt jointing of variable cross sections of lower joints can be realized, on the other hand, deformation of the outer side surface and the upper surface of lower chord square tubes during splicing process of a tower crane boom is well controlled, good running conditions for amplitude-variable cars are provided, straightness of integral butt joint of the crane boom is effectively guaranteed, correcting workload is greatly reduced, and producing efficiency is improved.

Owner:ANHUI CONSTR MACHINERY

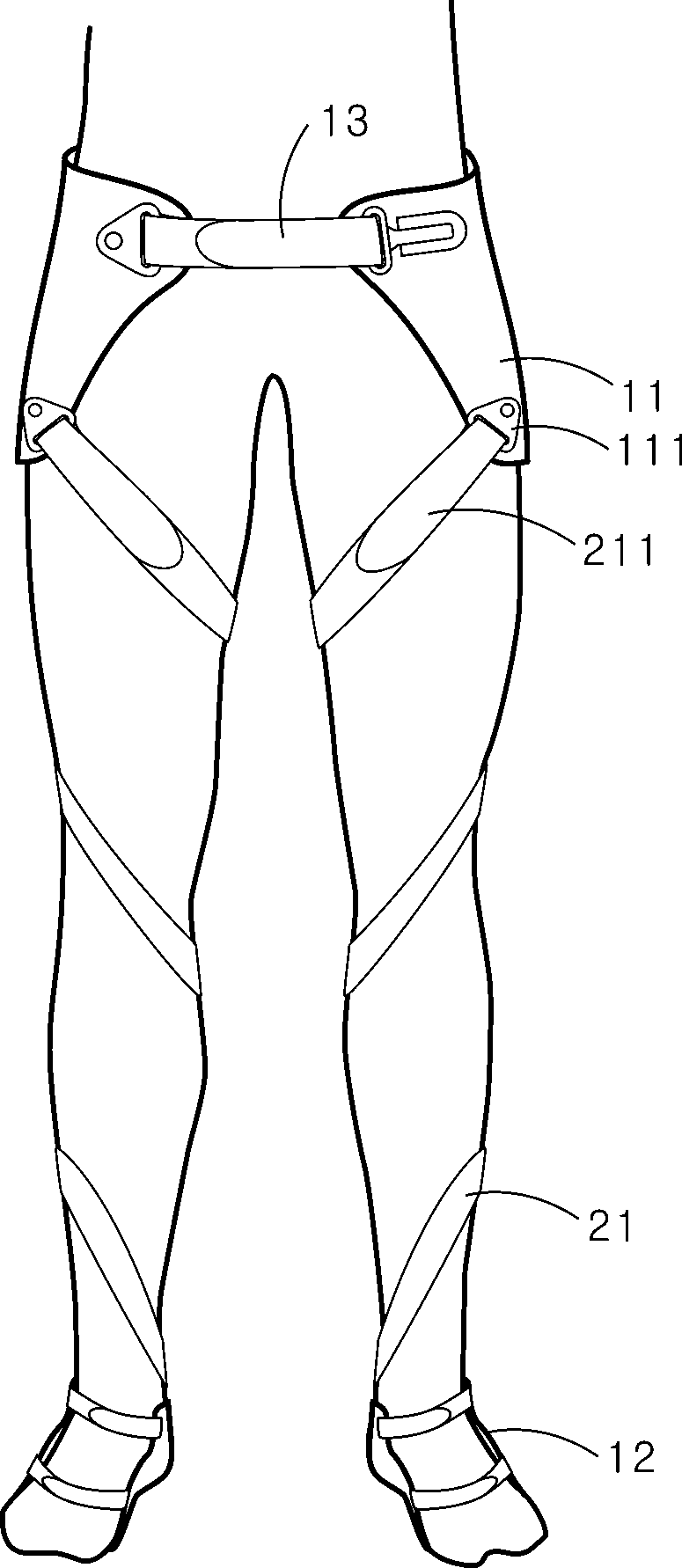

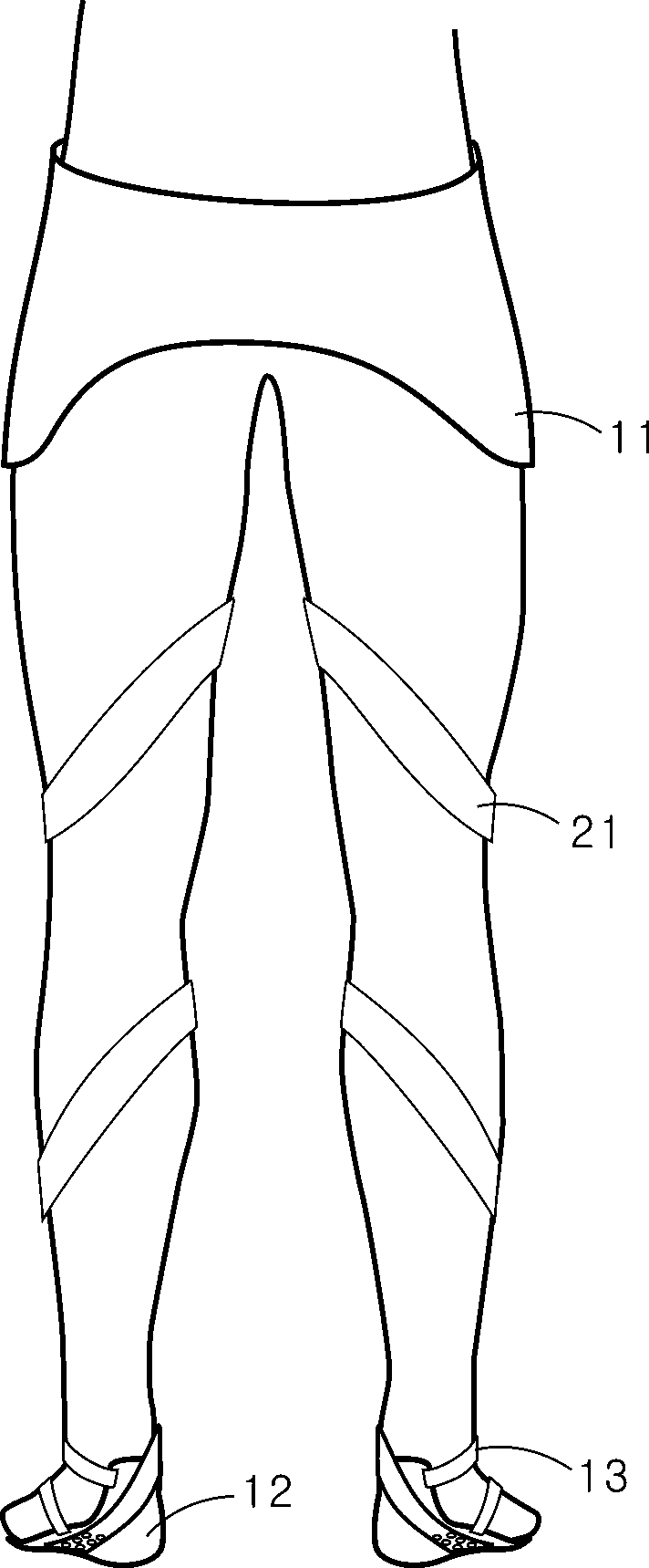

Lower limb intorsion orthosis device

The invention discloses a lower limb intorsion orthosis device which consists of a protective tool assembly and a binding belt assembly. The protective tool assembly comprises a pelvis portion and foot supporters, wherein protective tool binding belts are arranged at an opening of the pelvis portion and an opening of the foot supporters. Binding belts are fixedly installed on the outer sides of the foot supporters, and the upper ends of the binding belts are connected with rubber buckles and locking buckles installed on the outer side of the lower end of the pelvis portion. The binding belts are spirally wounded in the rubber buckles from the outer side of the pelvis portion to the upper portions of heels to be locked. A use method of the lower limb intorsion orthosis device comprises thefollowing steps that the pelvis portion is worn; the foot supporters are worn; the binding belts are spirally wound; a lower limb intorsion orthosis range is adjusted. The binding belts having the peculiar flexibility of spiral winding are utilized as joints, the lower limbs can be fixed to extorsion positions, orthosis is conducted on lower limb intorsion caused by tibia intorsion or excess frontinclination angles of thighbones, the abnormal phenomenon of in-toeing gait is avoided, and meanwhile the flexibility of the joints is also not affected. Therefore, the lower limb intorsion orthosisdevice can be used in the daytime and at night, the orthosis time is greatly shortened, an orthosis effect is improved, and the lower limb intorsion orthosis device is safe and comfortable.

Owner:深圳市福尔泰医疗科技有限公司

Scribing wheel and method for manufacturing the scribing wheel

InactiveCN105291271AReduce bendingReduce time to correctOther manufacturing equipments/toolsStone-like material working toolsBand shapeMachining

The invention relates to a scribing wheel and a method for manufacturing the scribing wheel. The scribing wheel ensures high strength in end face of segmented substrate obtained by severing brittle material-made substrate scribed by the scribing wheel. A diamond film is formed on the periphery of the scribing wheel by grinding the periphery of the scribing wheel into V-shaped. The band-shaped part of the ridge with the V-shaped front end forms a grinding surface (15) through rough grinding in the vertex angle (Alpha 2) mode. Moreover, the band-shaped part including the ridge in the grinding surface (15) is grinded through finish machining so that a grinding surface (16) with a vertex angle (Alpha 3) is formed. The grinding width (w) for the edge through rough grinding and finish machining for the ridge is more than 20mum. Therefore, the concave-convex of the ridge and the inclined surface at the front end of a knife is reduced and the strength in end face plane of the severing brittle material-made substrate scribed is improved.

Owner:MITSUBOSHI DIAMOND IND CO LTD

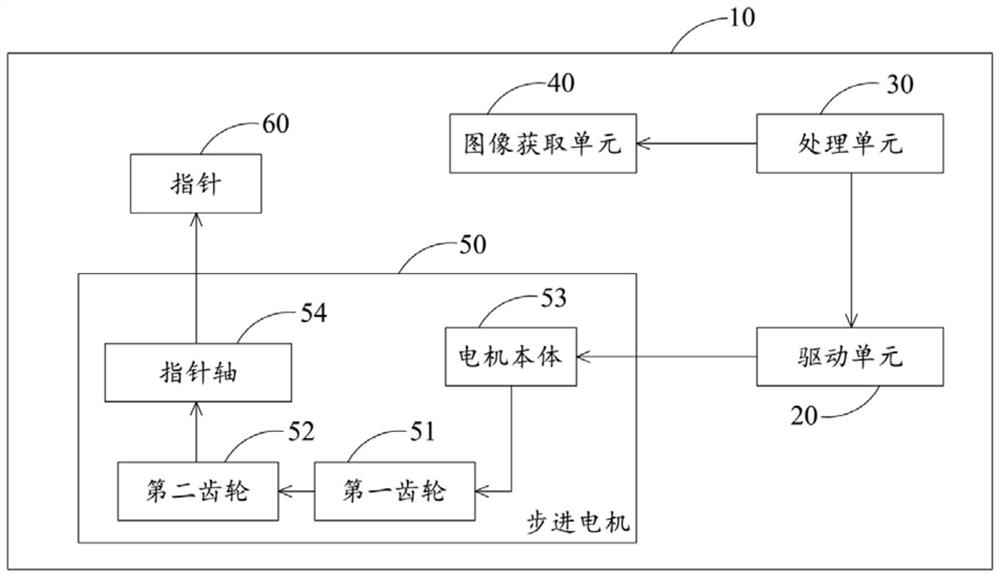

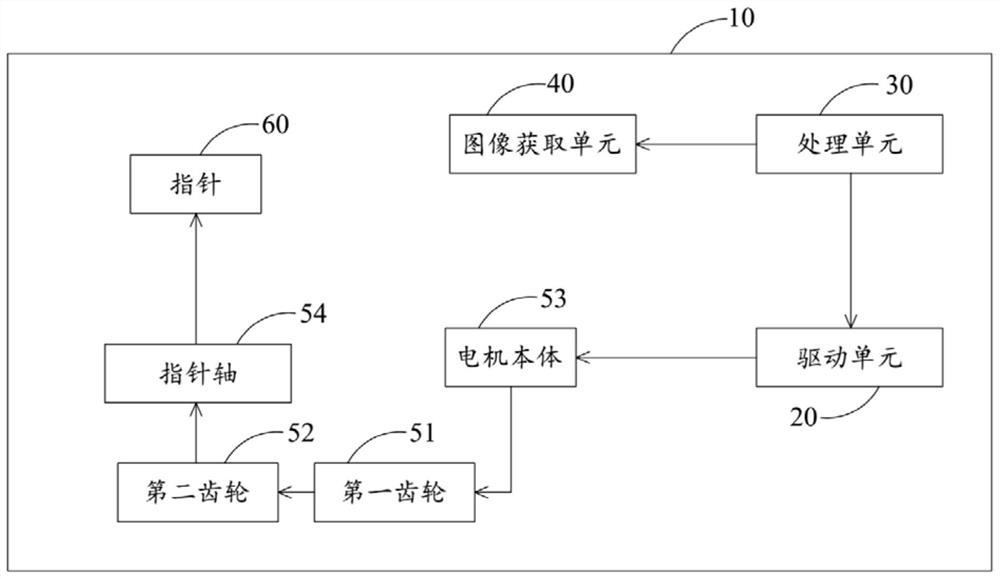

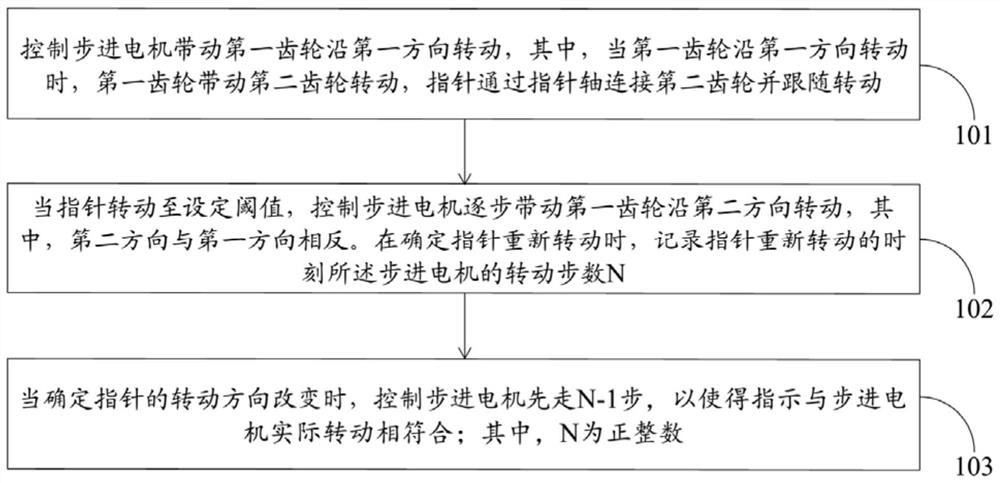

Method for eliminating gear clearance error influence and related product

InactiveCN111917347AReduce time to correctEliminate display inaccuraciesDynamo-electric converter controlGear driveElectric machine

The invention relates to a method for eliminating gear clearance error influence and a related product. The method comprises the steps of controlling a stepping motor to drive a first gear to rotate in a first direction, wherein the first gear drives a second gear to rotate when the first gear rotates along the first direction, meanwhile, enabling a pointer connected with the second gear through apointer shaft to rotate along with the second gear; when the pointer rotates to a set threshold value, controlling the stepping motor to gradually drive the first gear to rotate along the second direction, wherein the second direction is opposite to the first direction; when it is determined that the pointer rotates again, recording the rotating step number N of the stepping motor at the moment that the pointer rotates again; and when it is determined that the rotation direction of the pointer is changed, controlling the stepping motor to move (N-1) steps firstly, so that indication is consistent with the actual rotation of the stepping motor. According to the present invention, instrument indication errors caused by gear inherent clearances can be eliminated, and instrument display is more accurate.

Owner:SHANGHAI OUFEI INTELLIGNET VEHICLE INTERNET TECH CO LTD

Gamma correction system and gamma correction method

ActiveCN108182914BSave storage resourcesThe calibration method is simpleStatic indicating devicesGray levelComputer science

The invention provides a gamma correction system and a gamma correction method. The gamma correction method includes: acquiring the color coordinates and the brightness values of a R sub-pixel, a G sub-pixel, and a B sub-pixel; calculating the target brightness values of the R sub-pixel, the G sub-pixel, and the B sub-pixel according to the color coordinates and the brightness values of the R sub-pixel, the G sub-pixel, and the B sub-pixel, and calculating the brightness value of each sub-pixel at each grayscale according to the brightness value of each of the R sub-pixel, the G sub-pixel, andthe B sub-pixel; determining whether a difference between the brightness value of each sub-pixel of the R sub-pixel, the G sub-pixel, and the B sub-pixel at each grayscale and the target brightness value of each sub-pixel is smaller than a threshold corresponding to the sub-pixel; if so, storing the grayscale value and corresponding brightness value of the sub-pixel. The gamma correction method saves storage resources, greatly shortens correction time and improves correction efficiency.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

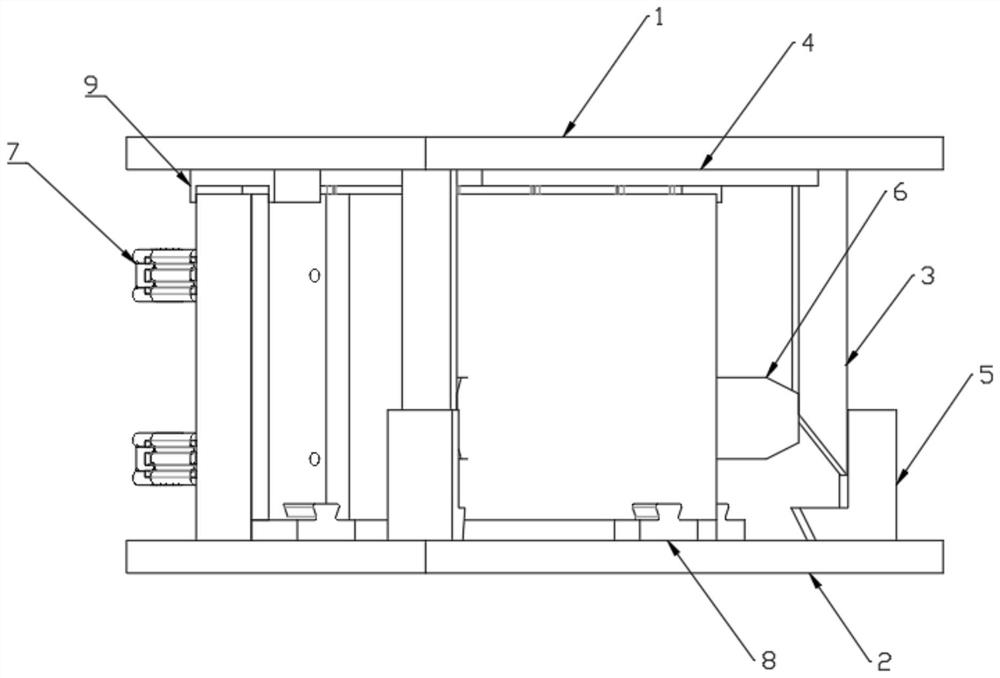

Device and method for correcting multi-cavity special-shaped double-layer thin-wall section pipe through rubber and plastic soft dies

ActiveCN112474899ASolve efficiency problemsTroubleshoot technical issues with poor performanceShaping toolsGeneral water supply conservationHydraulic cylinderEngineering

The invention discloses a device and method for correcting a multi-cavity special-shaped double-layer thin-wall section pipe through rubber and plastic soft dies. The correcting device comprises an upper bottom plate, a lower bottom plate, a circumferential bulging die, a fixing assembly, a pressure suction assembly and a rubber sealing plate. The circumferential bulging die is used for containingthe to-be-machined multi-cavity special-shaped double-layer thin-wall section pipe and can be attached to the formed multi-cavity special-shaped double-layer thin-wall section pipe. The pressure suction assembly comprises hydraulic cylinders and rubber soft dies. The multiple hydraulic cylinders are arranged on one side of the circumferential bulging die in a surrounding mode and provide deformation restoring force for the circumferential bulging die. According to the shape of the to-be-machined multi-cavity special-shaped double-layer thin-wall section pipe, the multiple rubber soft dies aresequentially placed in the circumferential bulging die, and the to-be-machined multi-cavity special-shaped double-layer thin-wall section pipe is extruded after pressing and expansion. The multi-cavity special-shaped double-layer thin-wall section pipe is corrected through the device and method, the defects such as recesses and protrusions on the surface of the thin-wall section pipe can be overcome, manual correction is avoided, the correction time is shortened, and the correction efficiency, quality and precision are improved.

Owner:HEFEI UNIV OF TECH

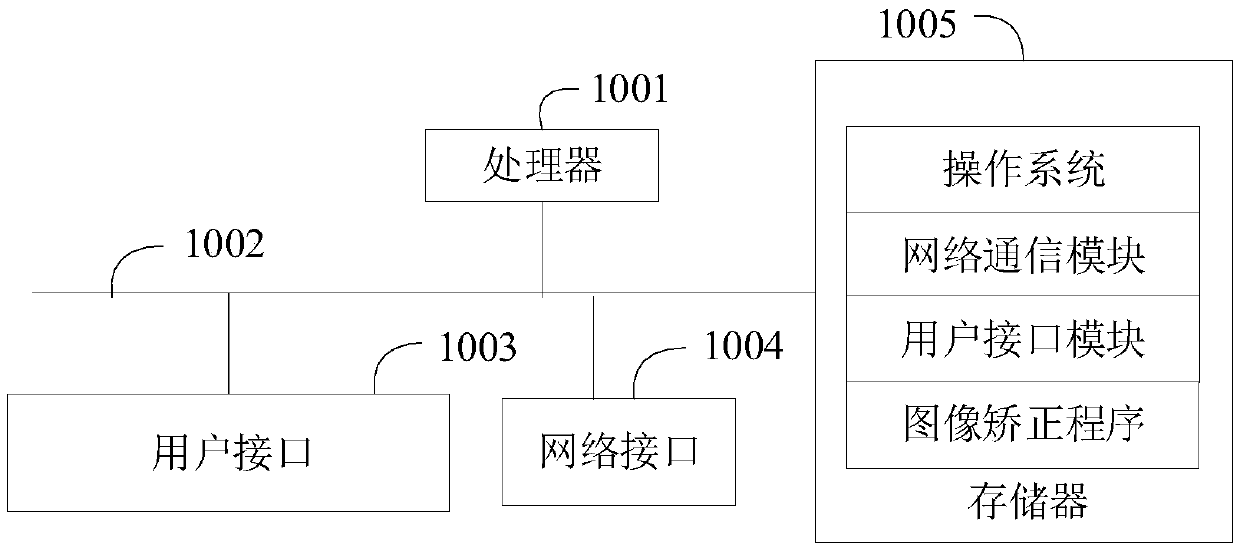

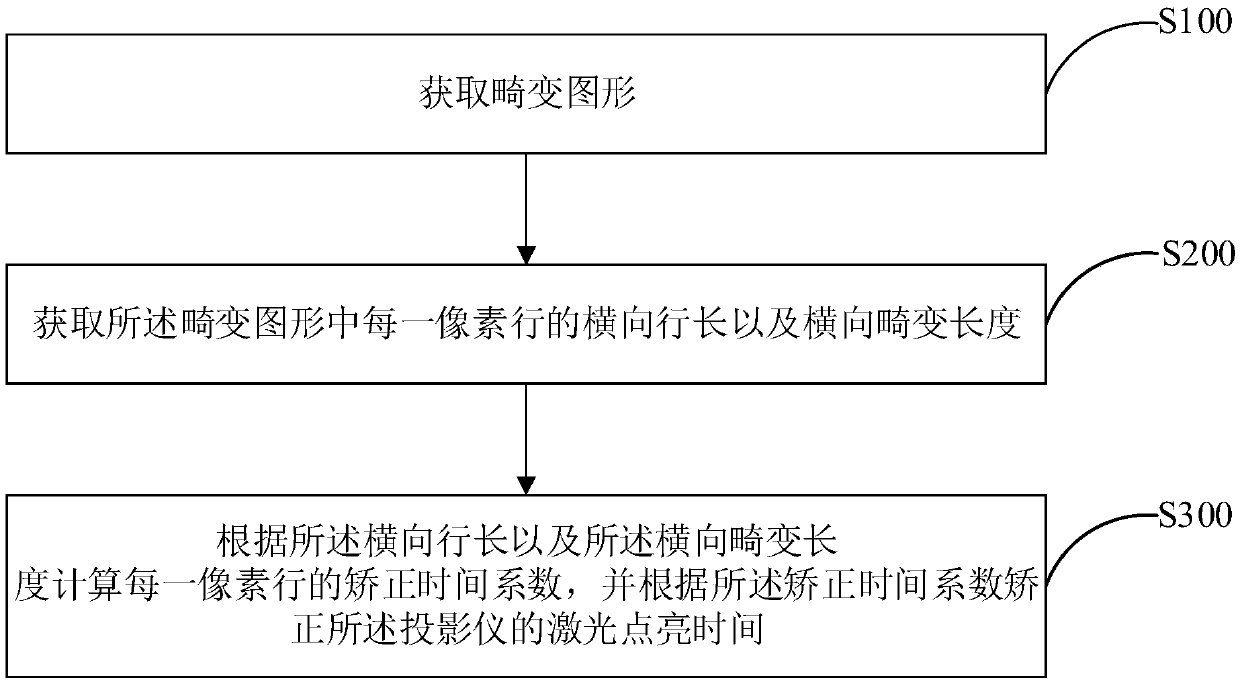

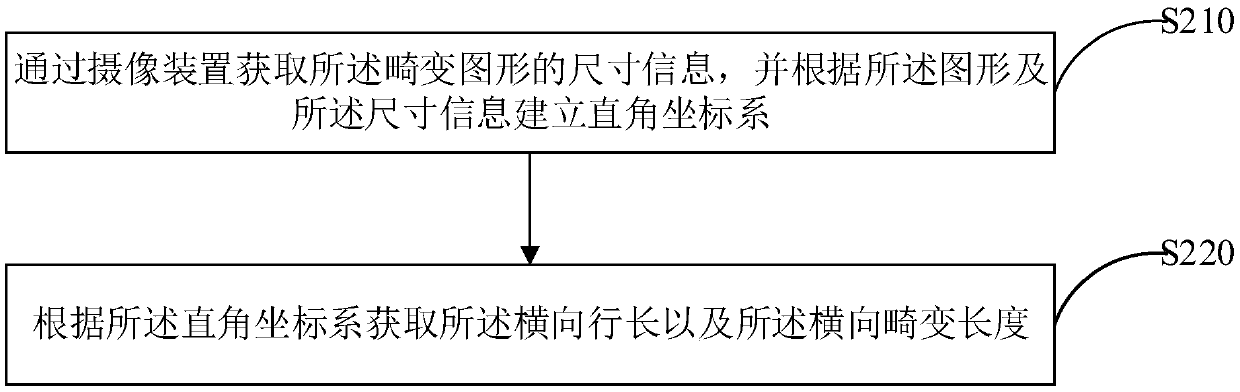

Projector image distortion correction method and device and medium

InactiveCN109600590ANo manual operationImprove correction efficiencyPicture reproducers using projection devicesGraphicsComputer vision

The invention discloses a projector image distortion correction method. The method comprises the following steps: obtaining a distorted image; o btaining a transverse row length and a transverse distortion length of each pixel row in the distorted image; and calculating a correction time coefficient of each pixel row according to the transverse row length and the transverse distortion length, andcorrecting the laser lighting time of the projector according to the correction time coefficient. The invention also discloses a projector image distortion correction device and a computer readable storage medium. The invention provides the projector image distortion correction method, and solves the technical problems of long correction time and low correction efficiency of a distorted image in the prior art.

Owner:GOERTEK OPTICAL TECH CO LTD

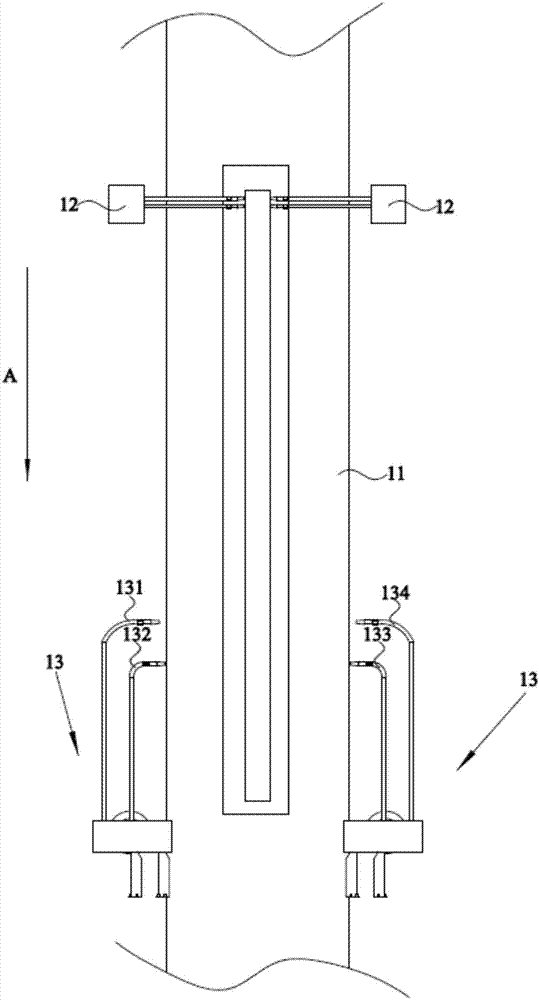

Manual jacking pipe control method and control system

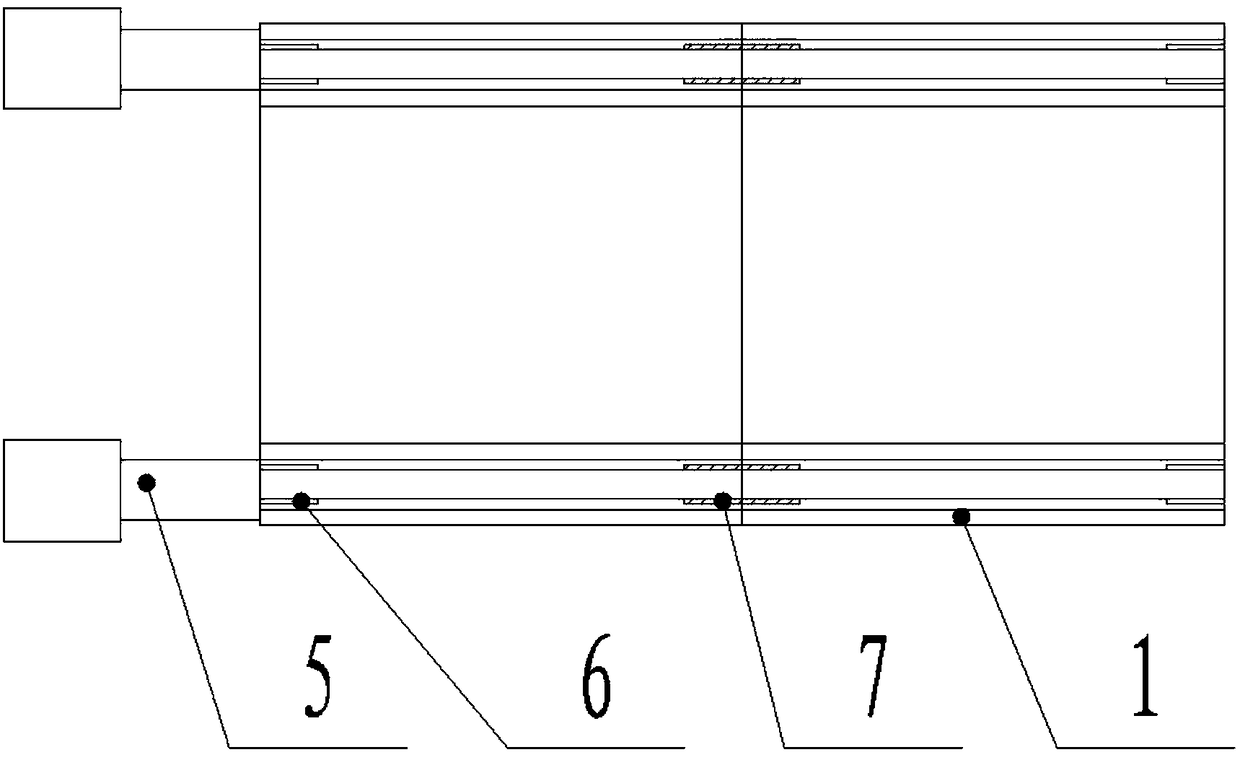

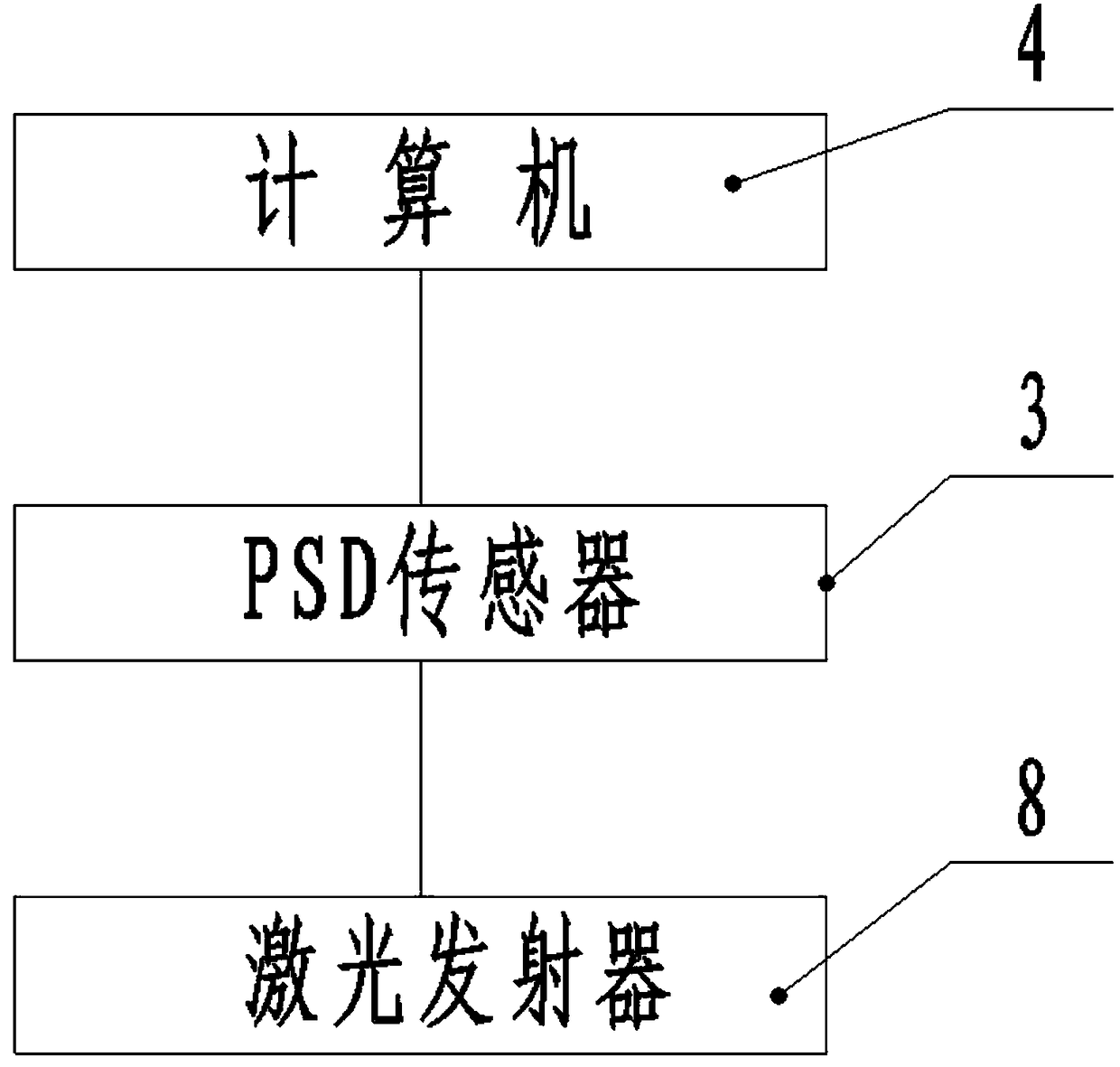

ActiveCN108458164AImprove securityReduce difficultyPipe laying and repairUsing optical meansLaser transmitterStructural engineering

The invention discloses a manual l jacking pipe control method and control system. Two laser detection pipes are symmetrically arranged in the wall of each cement concrete pipe, a PSD sensor is arranged at the position, on the front end of a jacking pipe, in each laser detection pipe of each cement concrete pipe, a computer connected with the PSD sensors are arranged outside each cement concrete pipe, and laser emitters are arranged at the position, on the outer end of the jacking pipe, in the laser detection pipes of one cement concrete pipe, laser emitted by the laser emitters is irradiatedon the PSD sensors to form light spots, the PSD sensors collect and record information of light spot position changes, and the computer analyzes collected data, the straightness error of the cement concrete pipes can be evaluated. Through manual adjusting of a jack, the jacking direction of the cement concrete pipes can be adjusted; in the manual jacking pipe construction process, the extension deviation of a pipeline underground can be corrected, the jacking direction is effectively controlled, a deviation correcting control system and a jacking device are integrated, safety is improved, thedifficulty of pipeline deviation correcting in the pipeline jacking process can be effectively reduced, and the comprehensive cost is reduced.

Owner:CHINA MCC5 GROUP CORP

Children amblyopia vision correction method

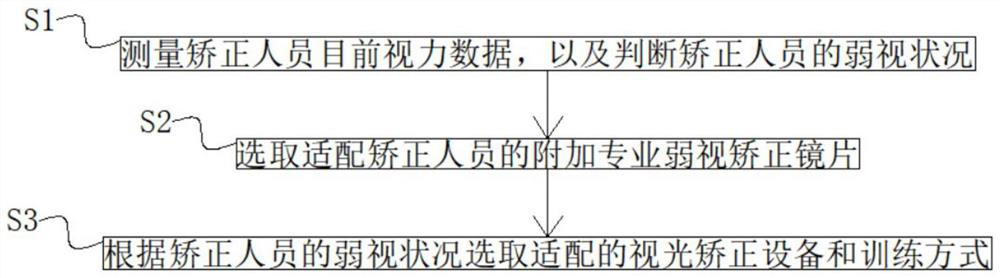

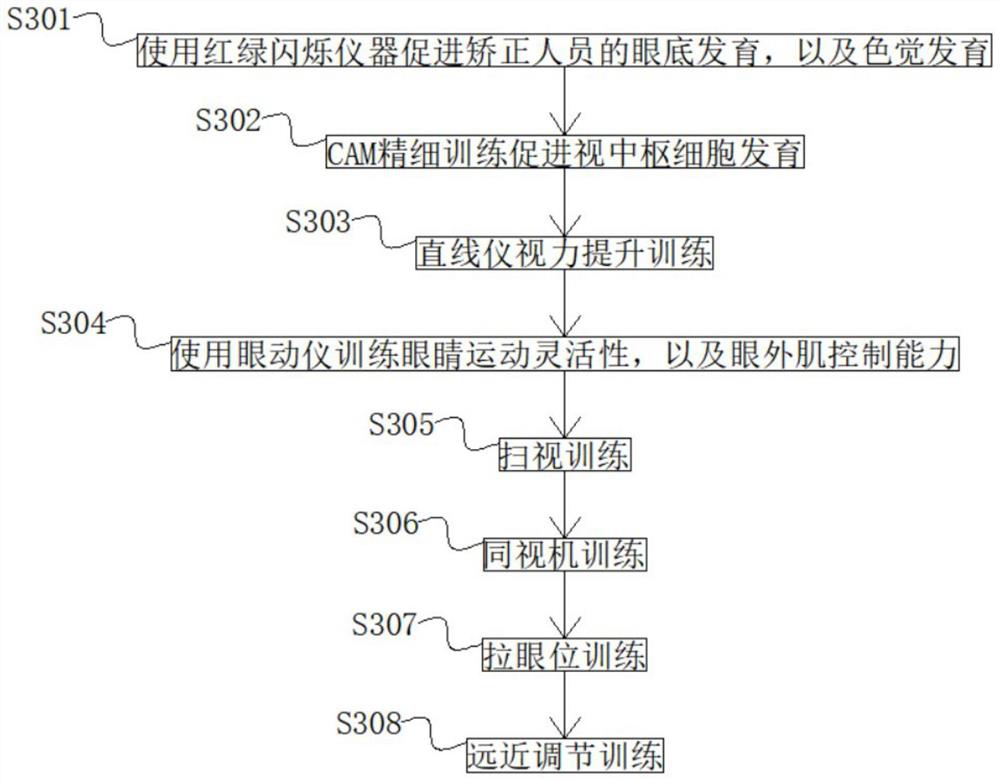

PendingCN113679580AReduce time to correctSpeed up the ascensionEye exercisersEye treatmentChromatic visionCorrective lens

The invention discloses a children amblyopia vision correction method, and relates to the technical field of children amblyopia vision correction, in particular to a children amblyopia vision correction method, which comprises the following steps: S1, measuring the current vision data of a correction person, and judging the amblyopia condition of the correction person; S2, selecting additional professional amblyopia correction lenses matched with correction person; and S3, selecting adaptive vision light correction equipment according to the amblyopia condition of the correction person. The arranged red and green scintillation instrument promotes fundus development and color vision development; CAM fine training is used for promoting development of visual center cells, fine eye training is used for promoting eyes to focus on eye use, and the eye use amount is increased; the straightener vision improvement training is used for improving and strengthening the adjusting force of eyes for seeing near and far, and improving near vision and far vision; an eye tracker is used for improving the eye movement flexibility and improving the extraocular muscle control ability; and the glancing training is used for improving the concentration of eyes and removing the crowding phenomenon.

Owner:付珊

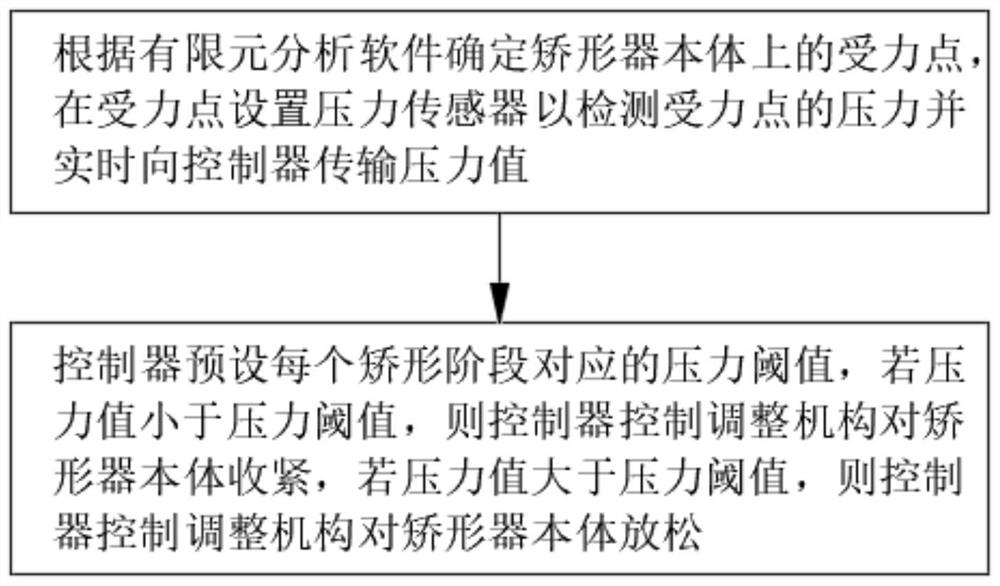

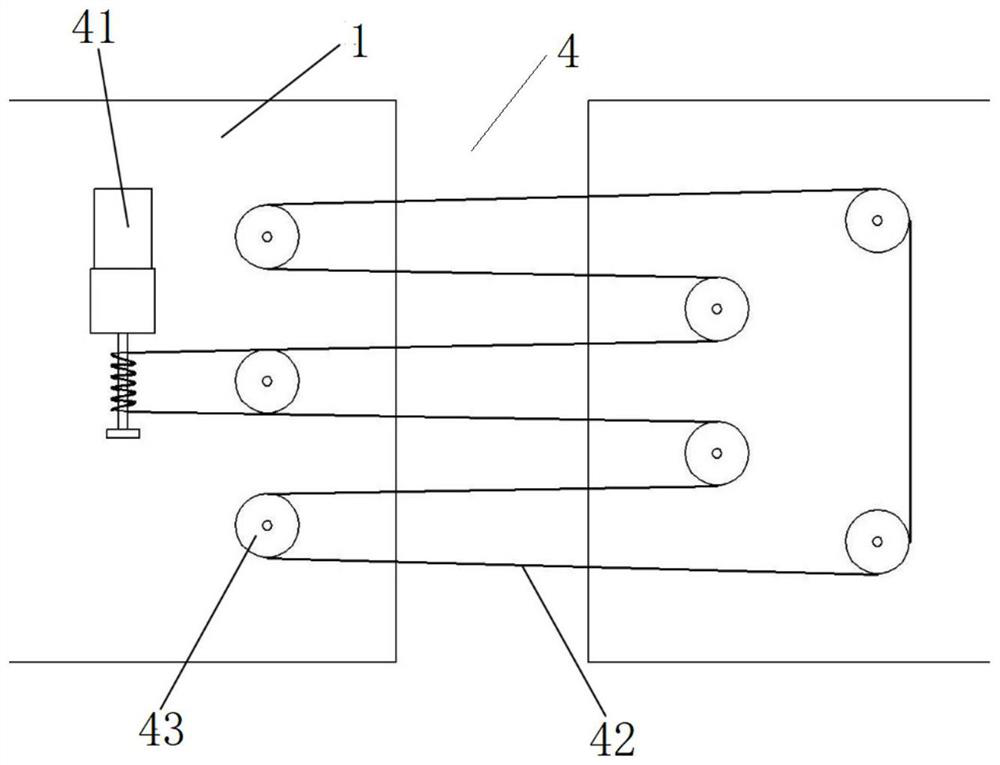

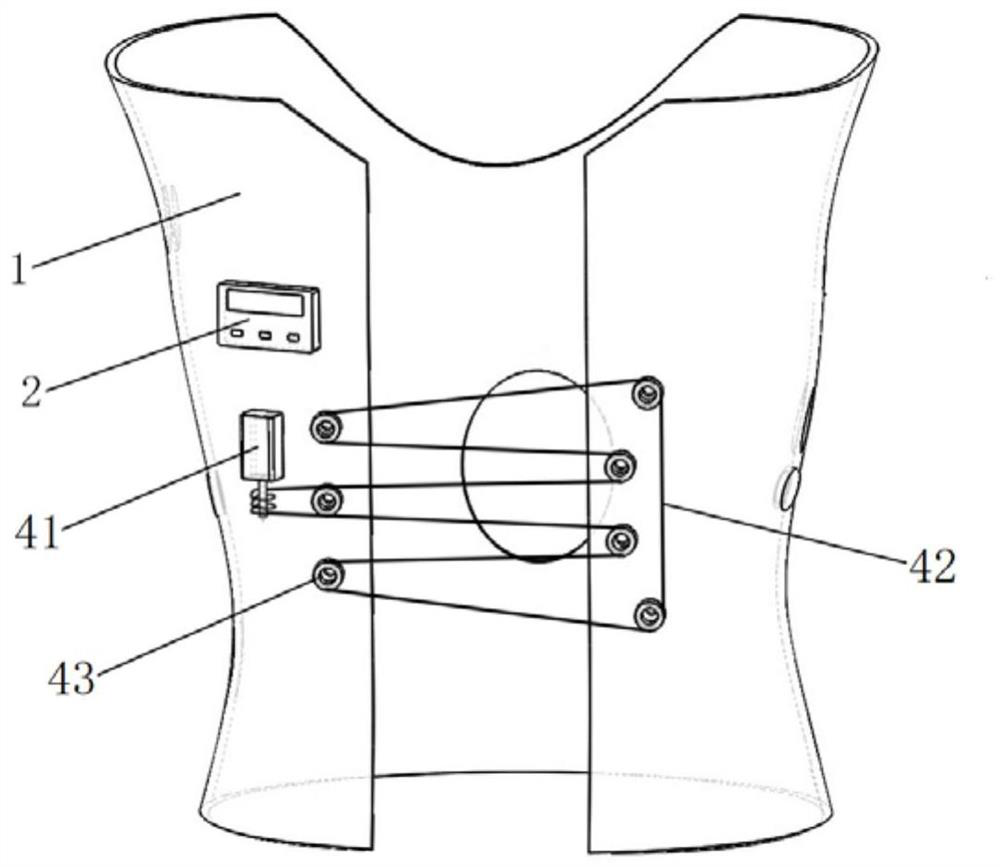

Automatic orthopedic method of spine orthosis

PendingCN113143563ARealize automatic adjustmentGuaranteed corrective effectAdditive manufacturing apparatusOrthopedic corsetsSpinal columnFinite element analysis software

The invention discloses an automatic orthopedic method of a spine orthosis. The orthosis comprises an orthosis body, wherein the orthosis body is provided with a controller and an adjusting mechanism which plays a role in tightening the orthosis body, a force bearing point on the orthosis body is determined according to finite element analysis software, and a pressure sensor is arranged at the force bearing point to detect the pressure of the force bearing point and transmit a pressure value to the controller in real time; and the controller presets a pressure threshold value corresponding to each orthopedic stage, if the pressure value is smaller than the pressure threshold value, the controller controls the adjusting mechanism to tighten the orthosis body, and if the pressure value is larger than the pressure threshold value, the controller controls the adjusting mechanism to loosen the orthosis body. The adjusting mechanism is controlled by the controller to automatically tighten the orthosis, so that the automatic adjustment of the orthopedic force in each stage is realized, the orthopedic effect is guaranteed, and the orthopedic time is greatly shortened.

Owner:HANGZHOU DIANZI UNIV

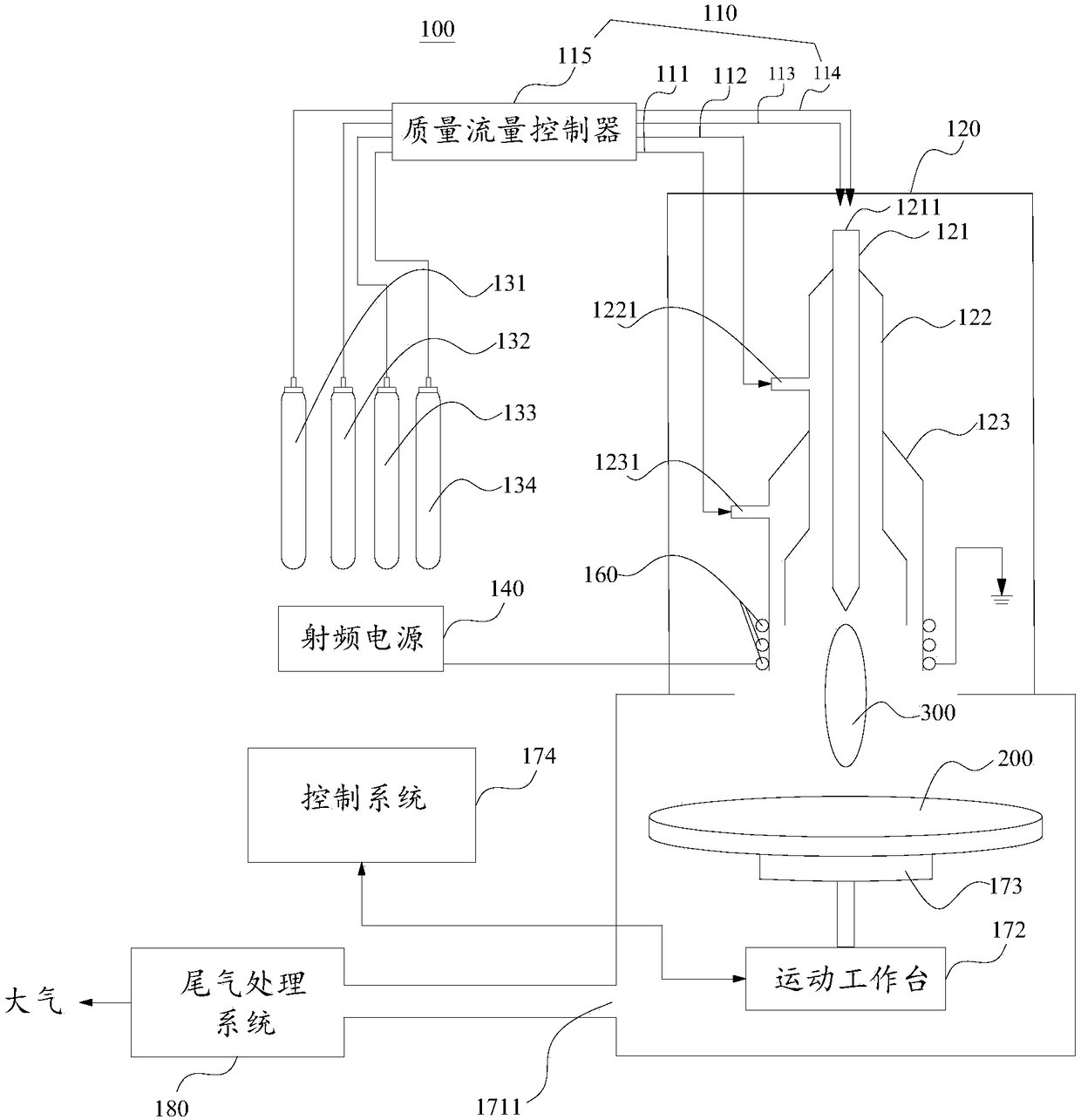

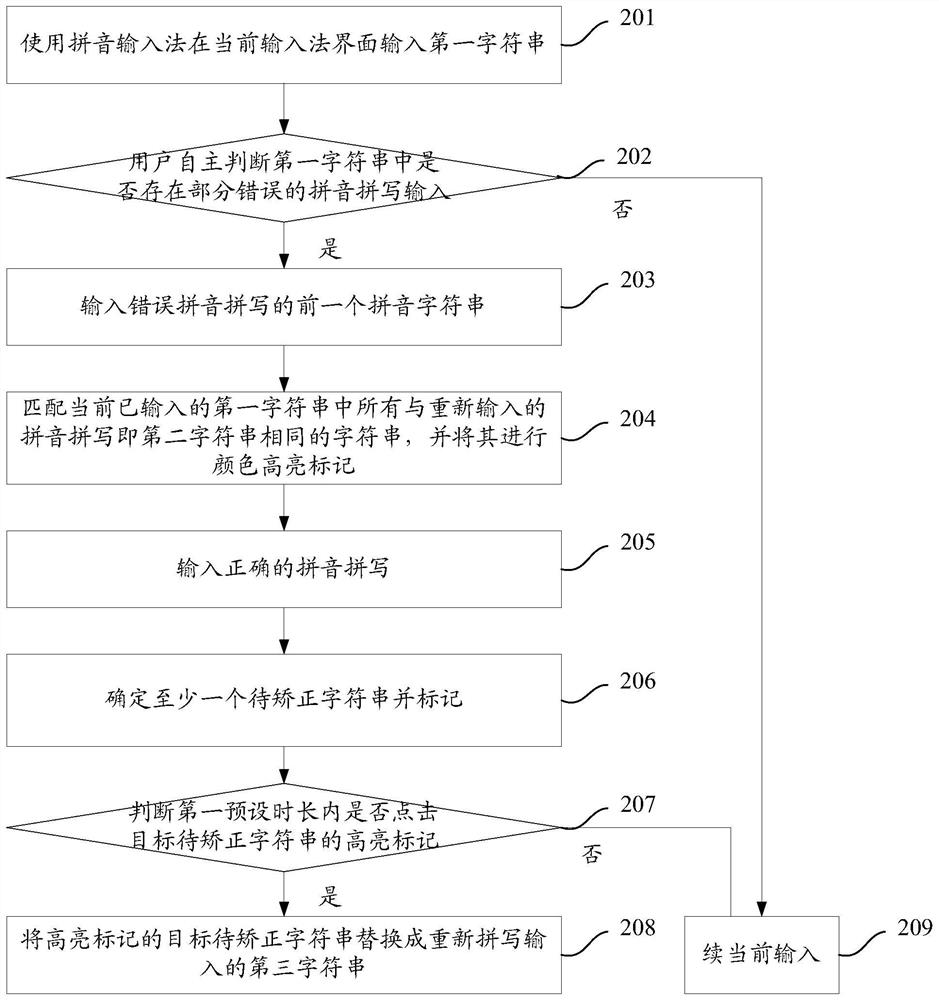

Processing method and non-spherical surface optical element

InactiveCN108972163AAvoiding Subsurface Damage ProblemsShorten the timeOptical surface grinding machinesPlasma jetEngineering

The embodiment of the invention provides a processing method and a non-spherical surface optical element. According to the processing method, the non-spherical surface optical element is processed through plasma jet, wherein the plasma jet is spaced from the non-spherical surface optical element by a predetermined distance. The non-contact jet processing manner can avoid the introduction of subsurface damage during processing and saves the subsequent process and time of removing the subsurface damage.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

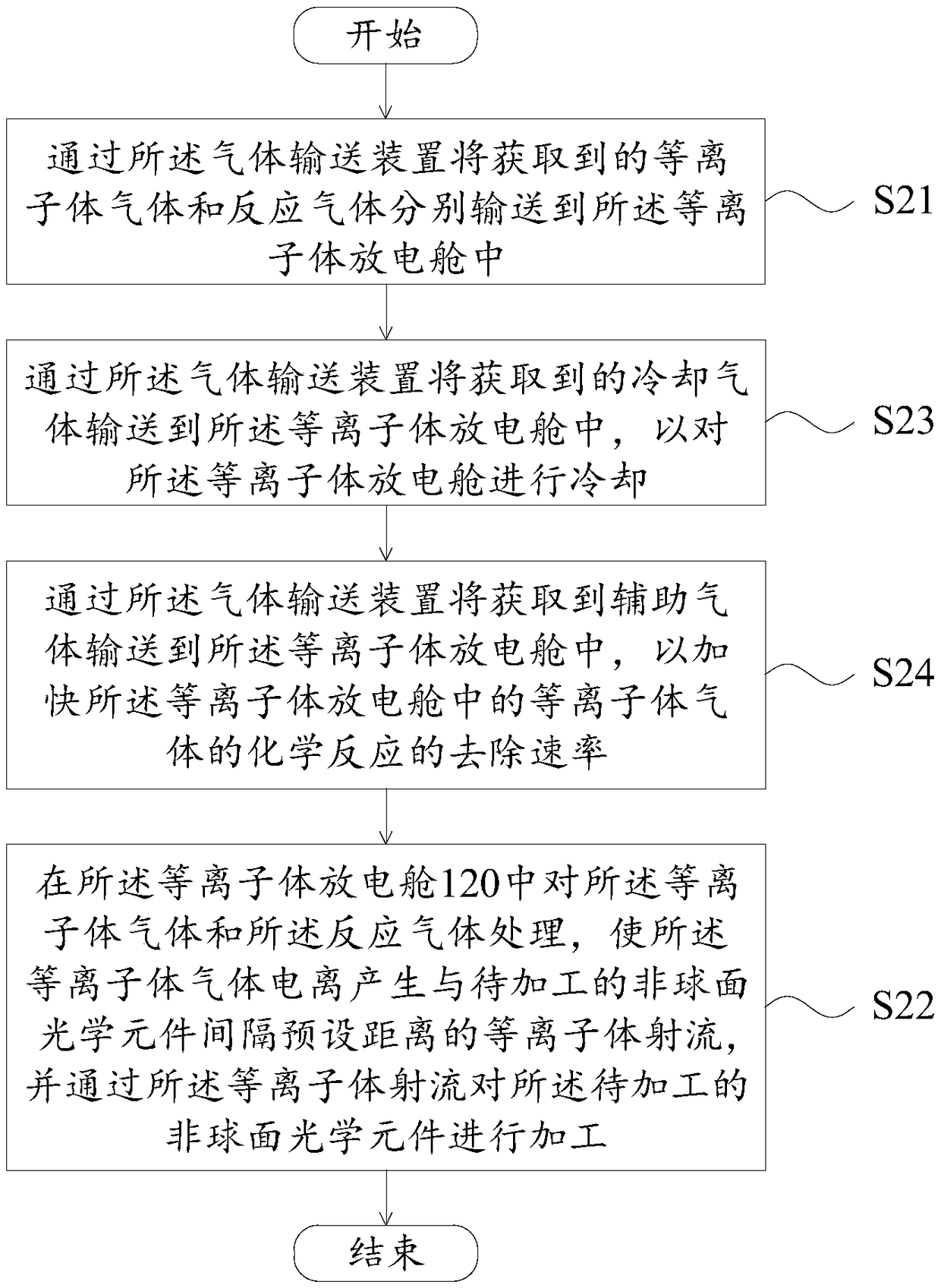

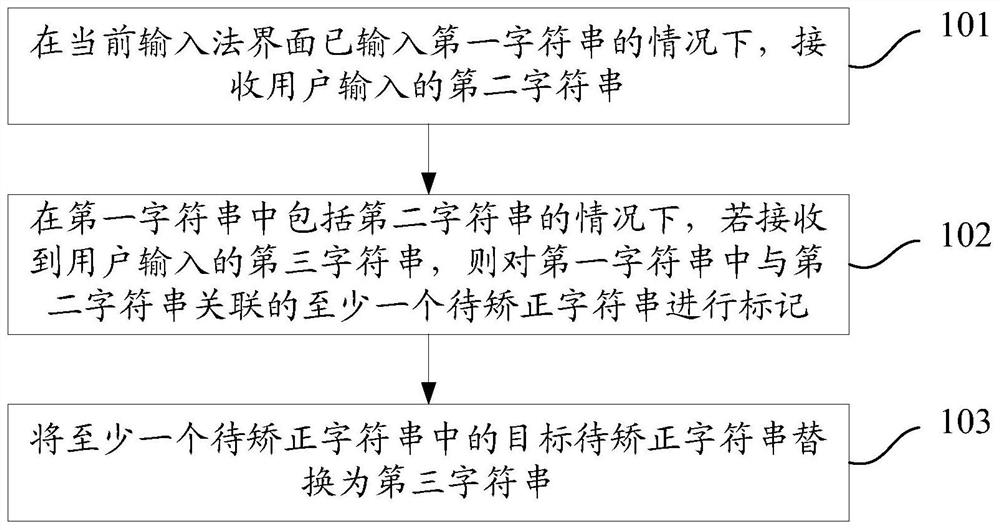

Input correction method and device

PendingCN113190125AImprove experienceImplement inputNatural language data processingInput/output processes for data processingProgramming languageAlgorithm

The invention discloses an input correction method and device, and belongs to the technical field of communication. The method comprises the steps of receiving a second character string input by a user under the condition that a first character string is input in a current input method interface; under the condition that the first character string comprises the second character string, if a third character string input by a user is received, marking at least one to-be-corrected character string associated with the second character string in the first character string; and replacing a target character string to be corrected in the at least one character string to be corrected with the third character string.

Owner:VIVO MOBILE COMM HANGZHOU CO LTD

Photoetching plate and mask correction method

ActiveCN109901357AReduce deposition lossImprove the correction effectOriginals for photomechanical treatmentClassical mechanicsCorrection method

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

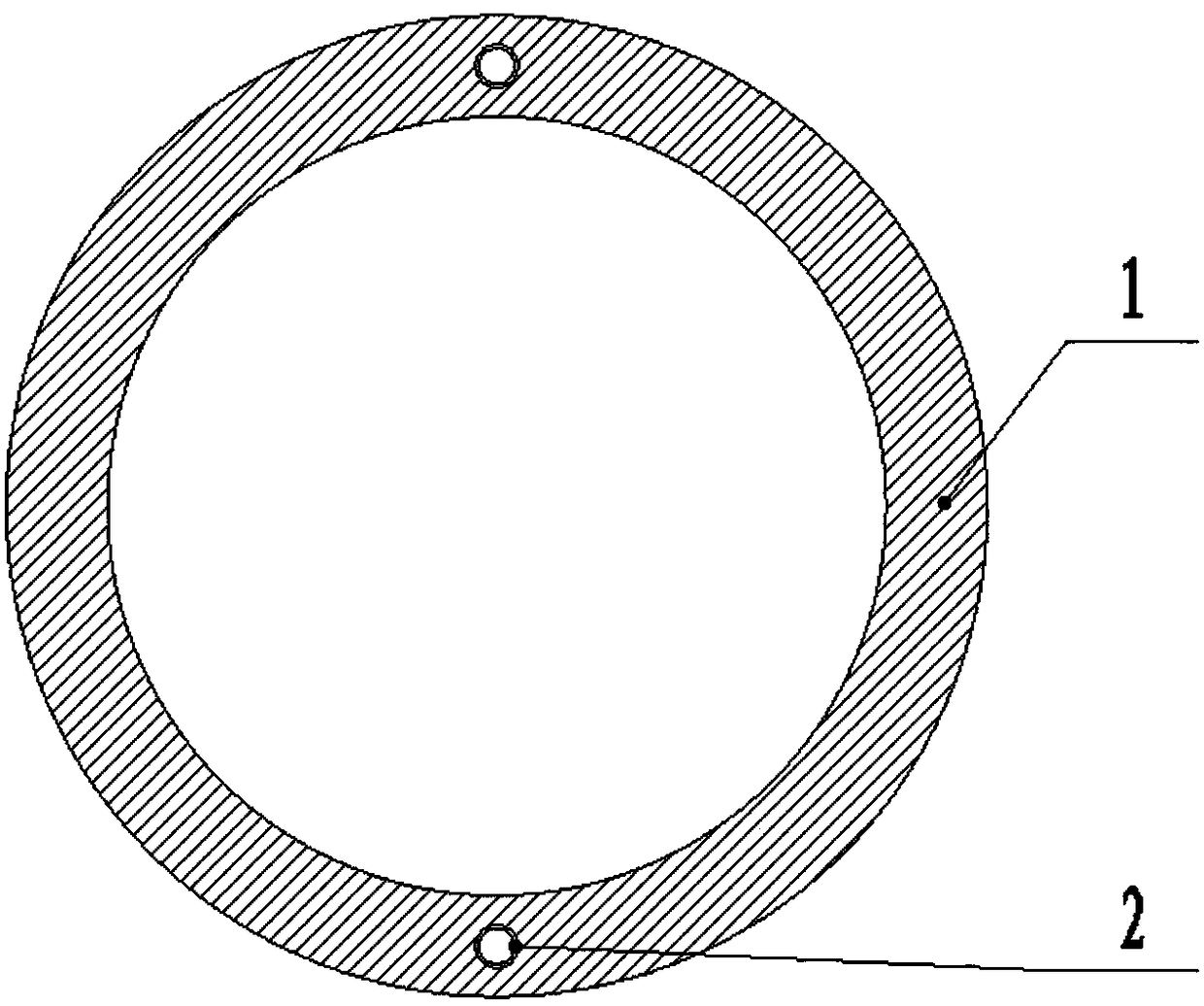

Tooling and grinding method thereof

ActiveCN102717319AReduce wearAvoid clamping fit gapsAbrasive surface conditioning devicesGrinding machinesEngineeringGrinding wheel

The invention relates to a special tooling for grinding a product. The special tooling comprises a core shaft which is formed by integral fixed connection of a plurality of stations. The stations are cylindrical stations which are axially distributed along the core shaft and extend radially along the core shaft, and the outer diameters of the stations are reduced gradually; the stations comprise a fastening station, a dressing-grinding wheel clamping station, a dressing-grinding wheel locking station, a grinding-wheel retracting station, a product clamping station and a product locking station.. The invention also relates to a grinding method of the tooling. The method adopted for processing a thin-wall ring product has the characteristics of high resetting accuracy, stability and long service life. The invention has the advantages that the assembly and the disassembly of the product are convenient, the one-time qualification rate and the processing efficiency can be obviously increased, and the accuracy requirement for batched grinding of high-accuracy thin-wall ring products is better met.

Owner:ZIGONG CEMENTED CARBIDE CORP

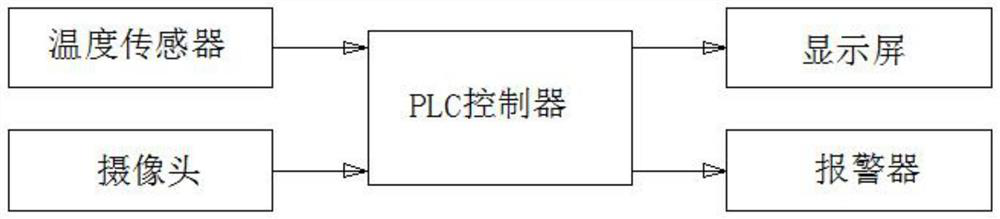

Digital monitoring system and adjusting method for rotary kiln riding wheel shaft bearing bush

InactiveCN113670063ARealize transmissionCompare and view in timeRotary drum furnacesInterference fitSlider bearing

The invention discloses a digital monitoring system and adjusting method for a rotary kiln riding wheel shaft bearing bush. The digital monitoring system comprises a riding wheel, a riding wheel shaft, sliding bearings and bearing pedestals, wherein the two bearing pedestals are symmetrically arranged, the bearing pedestals are fixed to a supporting base, the sliding bearings are arranged in the bearing pedestals, the riding wheel is connected to the riding wheel shaft in an interference fit mode; and the riding wheel shaft acts on the sliding bearings, so that the riding wheel shaft and the riding wheel rotate freely; a thrust plate and an oil spoon are arranged on the two sides of the riding wheel shaft, a temperature sensor is arranged on the sliding bearing, a camera is arranged on the bearing seat, the camera corresponds to the thrust plate in position, and the temperature sensor and the camera are electrically connected with a PLC of the rotary kiln. The digital adjustment method for the rotary kiln riding wheel shaft bearing bush mainly comprises the three steps of monitoring data acquisition, data analysis and riding wheel adjustment, real-time monitoring is achieved, feedback is timely, adjustment is rapid, and normal operation of production is effectively guaranteed.

Owner:重庆召全科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com