Tower crane boom tool

A technology of tower cranes and jibs, which is applied to auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve problems such as large correction workload, reduced straightness, and low running quality of luffing trolleys, so as to reduce correction time , Guarantee the effect of straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

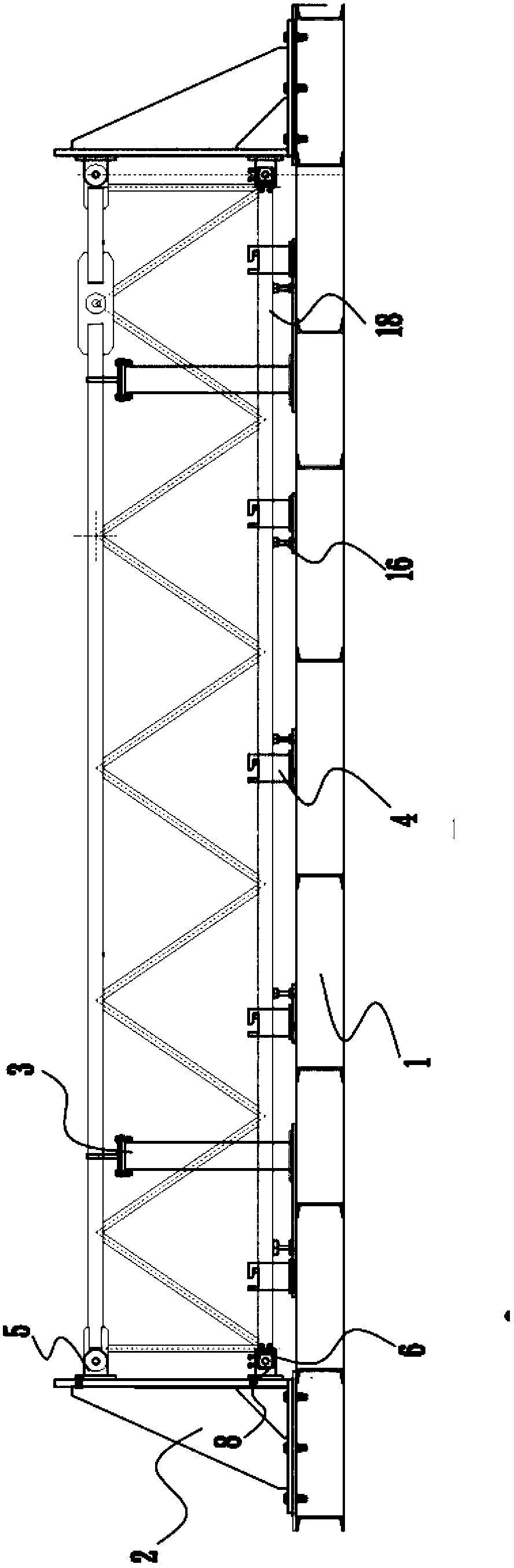

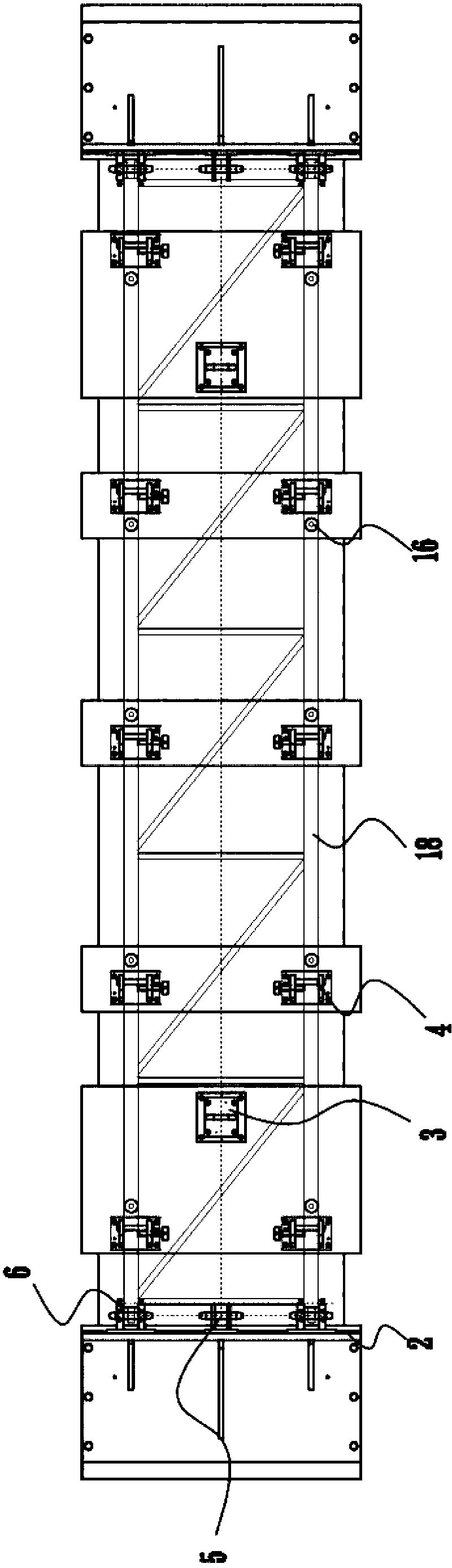

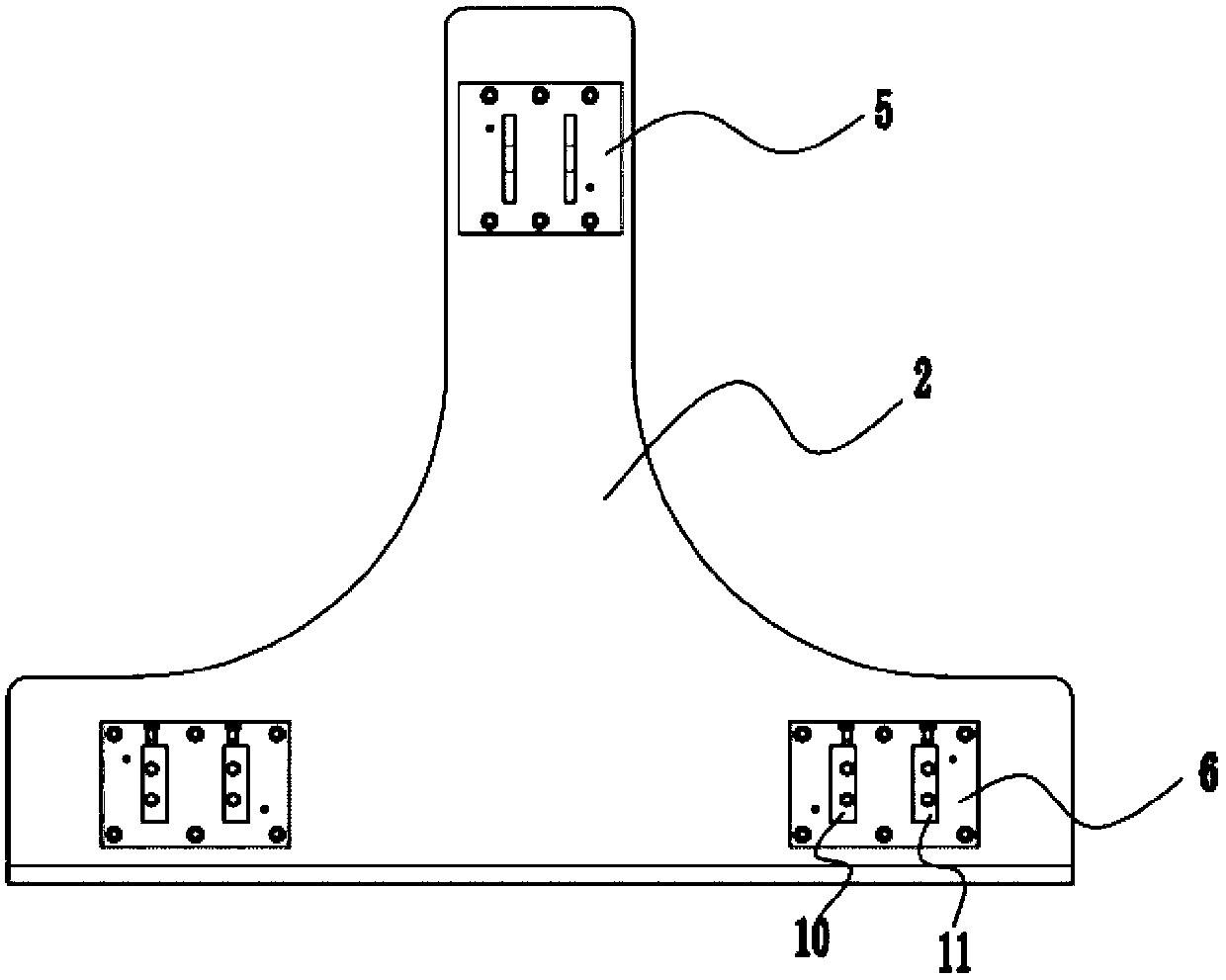

[0021] As shown in the figure, the jib tooling of the crane includes a frame platform 1, a wall panel assembly 2 detachably fixed on the left and right sides of the horizontal frame platform 1, a plurality of upper chord tube positioning supports 3, and a lower chord square tube positioning support 4 , the wall panel assembly 2 is provided with the upper and lower joint positioning supports 5, 6 of the left and right double side plate structure, the double side plates of the upper joint positioning support are correspondingly provided with pin holes, and the double side plates of the lower joint are corresponding A square hole 7 is provided, and the square hole 7 is used for fixedly installing standardized modules 8 of different specifications. The different specifications of the standardized modules mean that different modules are provided with pin holes of different heights. The standardized modules are embedded in the square holes and pressed with bolts. Tightly fixed, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com