Misaligned rectifying and dragging device of plate rolling machine

A plate rolling machine and wrong side technology, applied in the field of wrong side deviation correction, can solve the problems of increasing the workload of deviation correction, the difficulty of rounding, the existence of safety hazards, and poor cylinder forming, so as to shorten the time of deviation correction, avoid the deformation of the lower ra Improvement effect of ellipse phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

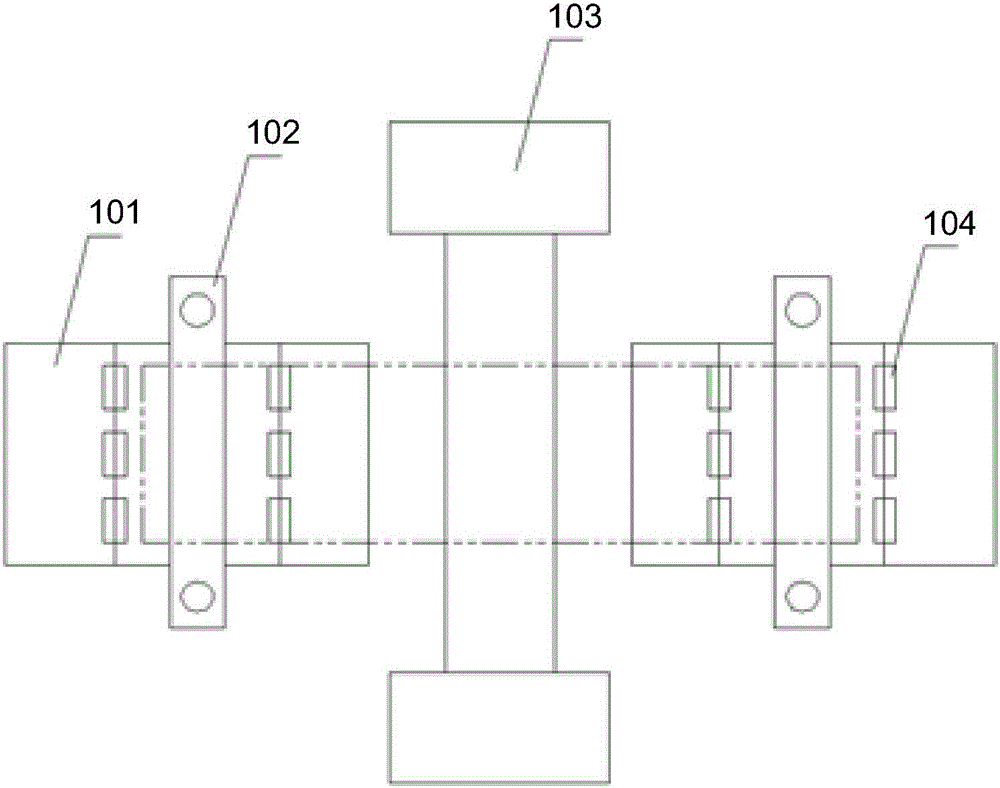

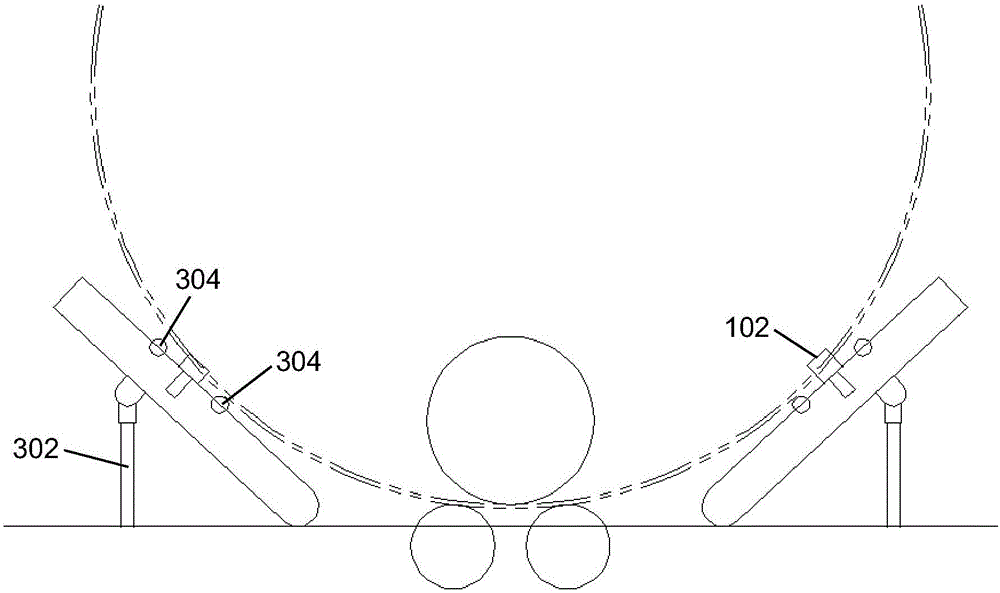

[0017] refer to figure 1 as shown, figure 1 Disclosed is a structural diagram of a misalignment correcting and dragging device of a plate bending machine according to an embodiment of the present invention. The misalignment correcting and dragging device of the plate bending machine includes: a dragging chassis 101 , a longitudinal deviation correcting mechanism 102 and a radial deviation correcting mechanism 104 . The longitudinal deviation correction mechanism 102 is installed on the dragging chassis 101, and the longitudinal deviation correction mechanism 102 performs longitudinal deviation correction on the plate being rolled. The radial deviation correction mechanism 104 is installed on the dragging chassis 101, and the radial deviation correction mechanism 104 performs radial deviation correction on the plate being rolled. The misalignment correction and dragging devices of the plate bending machine are arranged in pairs, and the misalignment correction and dragging de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com