Tooling and grinding method thereof

A tooling and station technology, applied in the field of tooling, can solve problems affecting the reset accuracy of the tailstock top, affecting the coaxiality of batch products, and injury to operators of leftover materials, so as to improve the first pass rate and processing efficiency, and avoid clamping and matching Clearance, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. However, this should not be construed as limiting the scope of the above-mentioned subject matter of the invention to only the following examples.

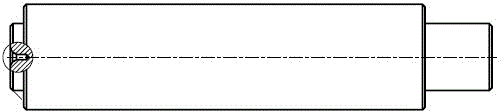

[0025] figure 1 Shown is a prior art micro-cone mandrel, the outer conicity of the micro-cone mandrel is 1:6000.

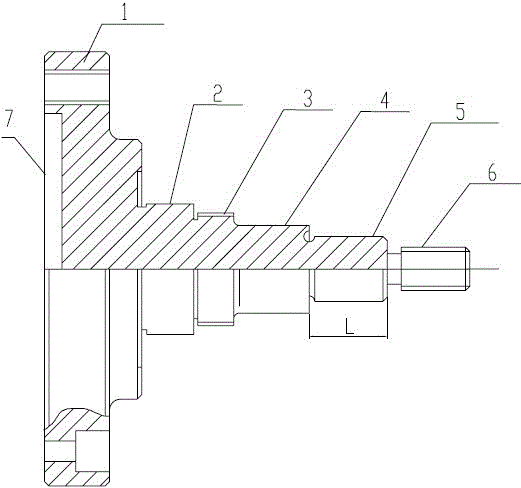

[0026] Such as figure 2 The shown tooling of the present invention includes a mandrel integrally connected by a plurality of stations, the above-mentioned stations are cylindrical stations distributed along the axial direction of the mandrel, and the outer diameter extending radially along the mandrel gradually decreases; In turn, it includes clamping station 1, trimming wheel clamping station 2, dressing wheel locking station 3, grinding wheel retracting station 4, product clamping station 5, and product locking station 6. The product locking station and the dressing wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com