Scribing wheel and method for manufacturing the scribing wheel

A manufacturing method and scoring wheel technology, applied to other manufacturing equipment/tools, manufacturing tools, stone processing equipment, etc., can solve the problems of general products without suitable structure, large changes in the shape of abrasive materials, and time-consuming, etc., to achieve shortening Grinding stone correction time, less warping, and improved manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and structure of a scoring wheel and its manufacturing method according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail below.

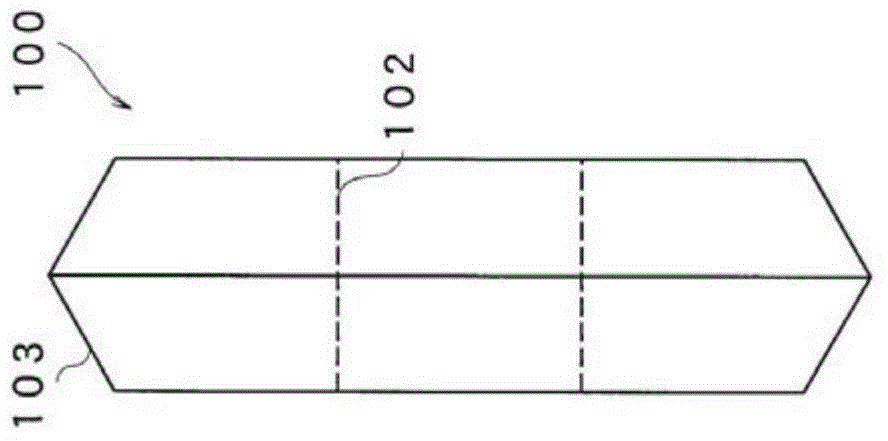

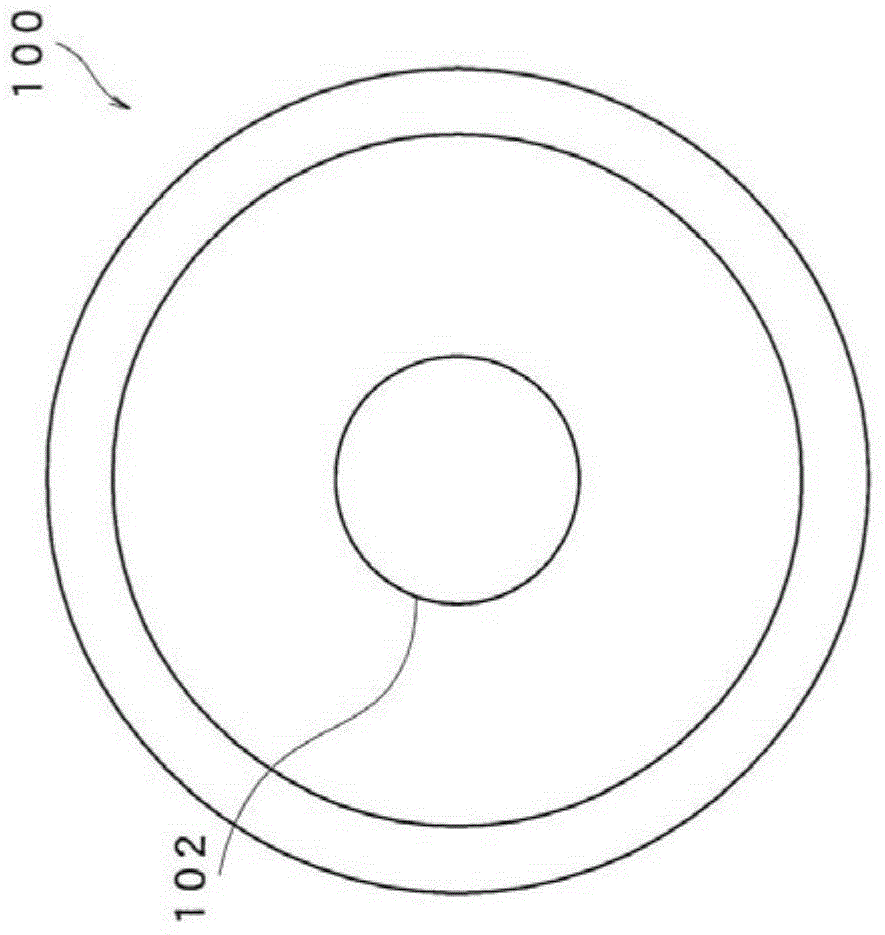

[0038] Figure 2A is a front view of a scoring wheel according to an embodiment of the present invention, Figure 2B is its side view. also, Figure 3A -D is a side view which shows the manufacturing process of the scribing wheel of this embodiment. When manufacturing scoring wheel 10, for example, at first in the center of disc 11 of the scoring wheel substrate made of superhard alloy or ceramics such as Figure 3B A through hole 12 serving as a shaft hole is formed as shown.

[0039] Next, the shaft of a motor or the like is connected to the through ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com