Integrated unit capable of automatically welding and cutting T-type steel through laser

An automatic welding and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as low production efficiency and yield, poor automation, and dispersion, and achieve filling automation and continuous production. Labor cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A specific implementation of the invention will be described below in conjunction with the drawings.

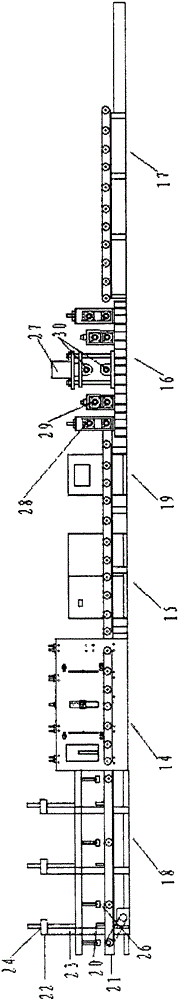

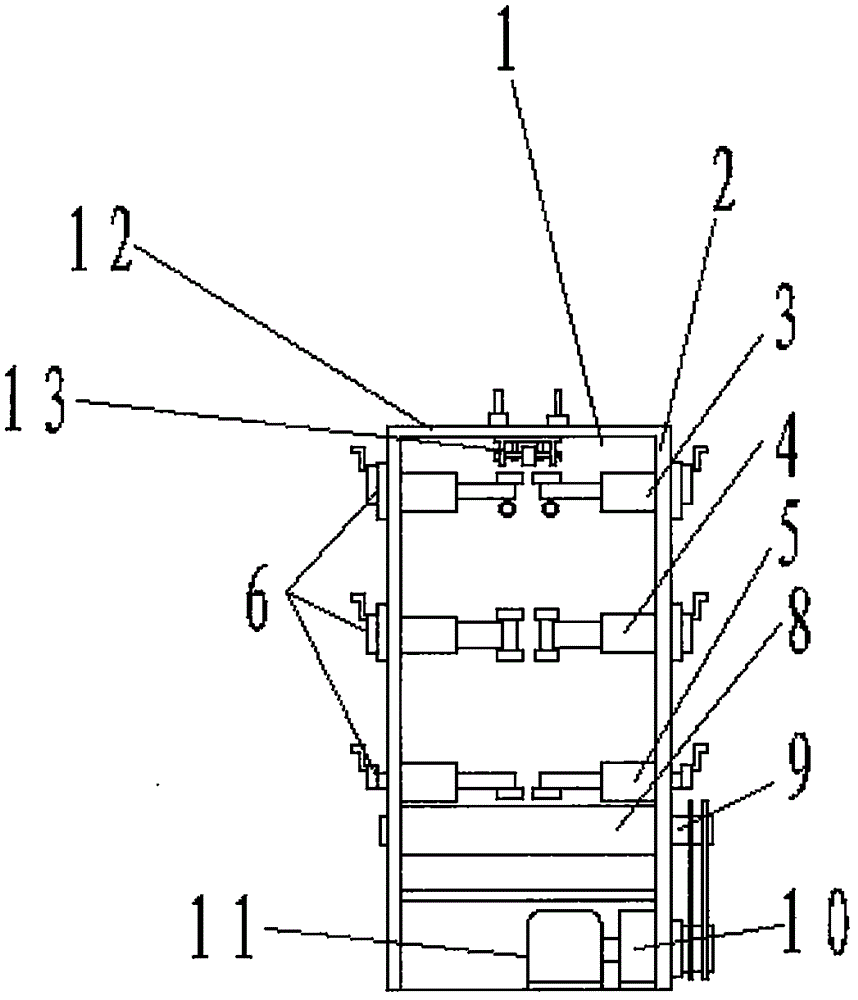

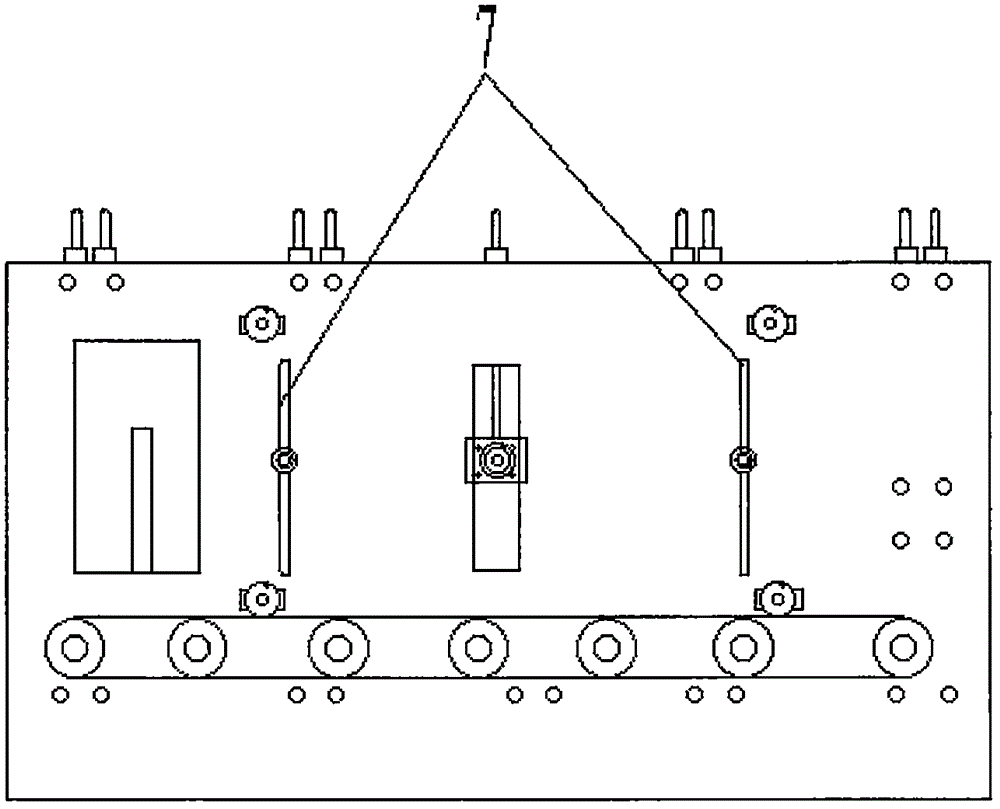

[0038] Figure 1-6 Among them, 1 is the main frame body, 2 is the wall panel, 3 is the upper compression and centralization unit group, 4 is the middle compression and centralization unit group, 5 is the lower compression and centralization unit group, 6 is the screw-in adjustment mechanism, and 7 is the strip Hole position, 8 is the load-bearing support conveyor roller, 9 is the transmission mechanism, 10 is the reducer, 11 is the motor, 12 is the fixed plate, 13 is the pressing unit, 14 is the centralizing and pressing mechanism, 15 is the laser welding and splitting mechanism , 16 is the correction inspection mechanism, 17 is the blanking rack of the baler, 18 is the automatic feeding mechanism, 19 is the electrical control mechanism, 20 is the assembly centralizing mechanism, 21 is the feeding roller table, 22 is the beam, 23 is the feeder column , 24 is the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com