Device and method for correcting multi-cavity special-shaped double-layer thin-wall section pipe through rubber and plastic soft dies

A special-shaped, double-layer technology, applied in the correction device, the rubber-plastic soft mold correction device for multi-cavity special-shaped double-layer thin-walled section pipes, and the rubber-plastic soft mold correction for multi-cavity special-shaped double-layer thin-walled section pipes can solve the correction efficiency. Low, poor effect and other problems, to achieve the effect of good correction effect, prevent deformation, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

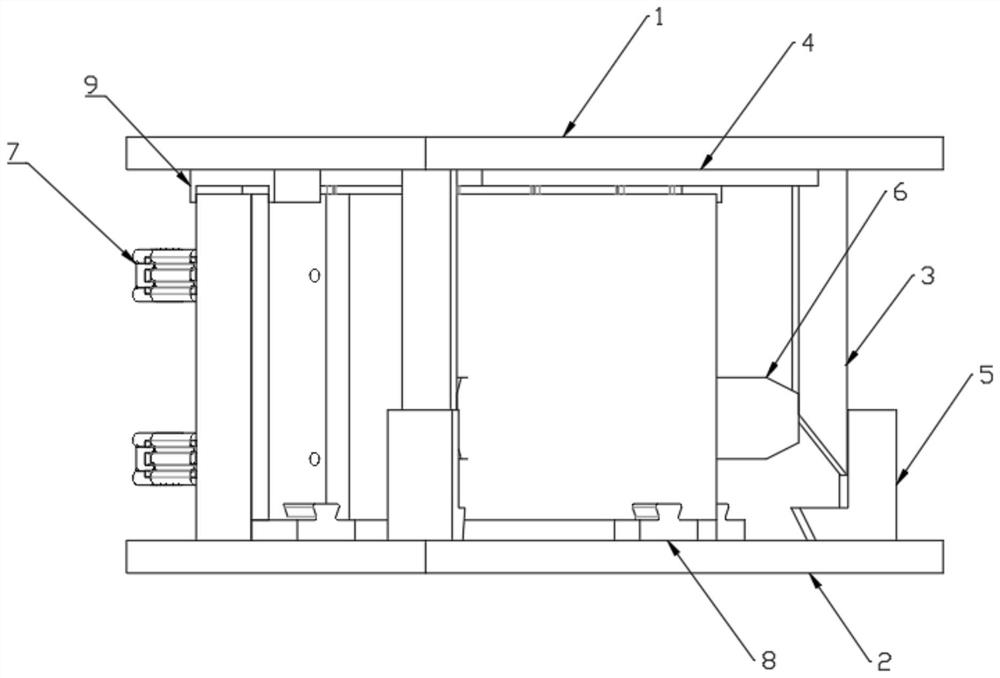

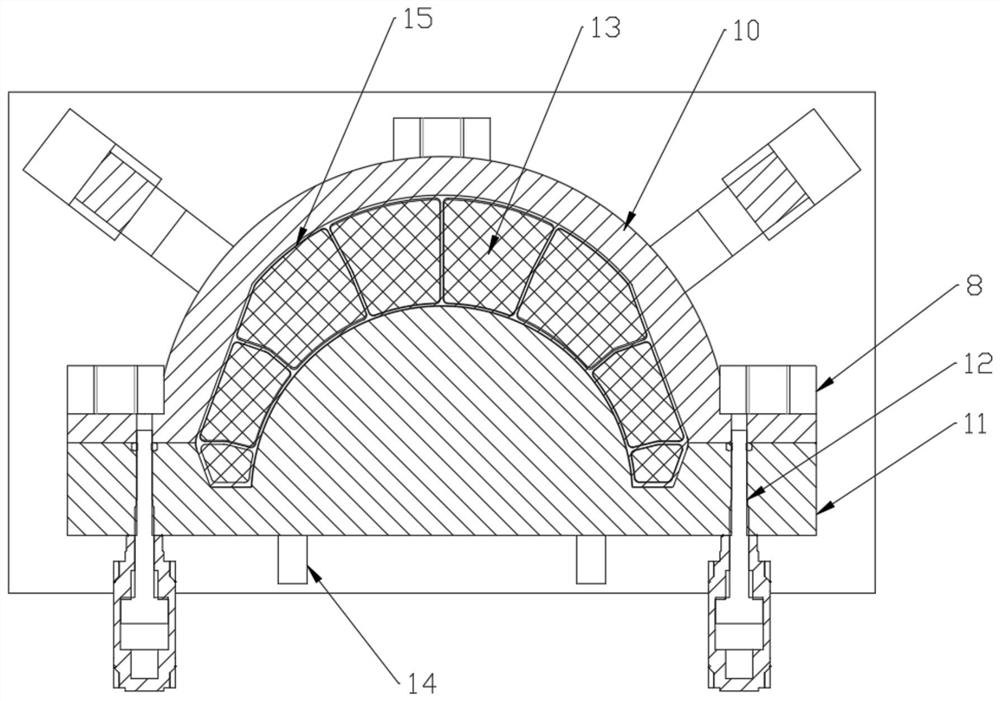

[0044] see figure 1 with figure 2, this embodiment provides a multi-cavity special-shaped double-layer thin-walled cross-section pipe rubber-plastic soft mold correction device, which is used to correct the multi-cavity special-shaped double-layer thin-walled cross-section pipe 15 to be formed into a multi-cavity special-shaped double-layer thin pipe. wall section tube. Among them, the multi-cavity special-shaped double-layer thin-walled cross-section pipe 15 to be processed can be a multi-cavity special-shaped double-layer thin-walled cross-section pipe that has been corrected for the first time, or a multi-cavity special-shaped double-layer thin-walled cross-section pipe that needs secondary processing, and formed The multi-cavity special-shaped double-layer thin-walled cross-section pipe is the corrected formed pipe and is a qualified product that meets the standards. The rectification device includes an upper bottom plate 1 , a lower bottom plate 2 , a circumferential b...

Embodiment 2

[0058] This embodiment provides a multi-cavity special-shaped double-layer thin-walled cross-section pipe rubber-plastic soft mold correction device, and the correction device is based on the embodiment 1 with additional pressure-applying equipment. Wherein, the pressing device may be the hydraulic press mentioned in Embodiment 1, or other existing equipment capable of applying pressure to the upper base plate 1 . In addition, the pressure applying device can display the size of the pressing pressure. When the pressure exceeds a threshold, the pressing device will stop applying pressure, so as to ensure that there will be no damage to the circumferential bulging mold and the soft rubber mold, and at the same time avoid damage caused by Excessive pressure will damage the multi-cavity special-shaped double-layer thin-walled cross-section tube to ensure the safety of correction.

Embodiment 3

[0060] This embodiment provides a production line for aviation multi-cavity special-shaped double-layer thin-wall cross-section pipes. The production line guarantees the production equipment and the rubber-plastic soft mold correction device for multi-cavity special-shaped double-layer thin-wall cross-section pipes in Embodiment 1 or 2. The production equipment can produce the multi-cavity special-shaped double-layer thin-wall cross-section pipe 15 to be processed (unqualified production) or the formed multi-cavity special-shaped double-layer thin-wall cross-section pipe (qualified product), and the unqualified product will be corrected by the correction device. Make it finally become a qualified product. Since the use of the straightening device can be streamlined, the straightening efficiency can be greatly improved, thereby improving the production efficiency of the entire production line, improving the yield rate of products, and reducing the burden on enterprises.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com