Output correction method of image forming device and image forming appts.

An image reading device and image technology, applied in printing devices, image communication, printing and other directions, can solve the problems of difficult correction, density dispersion, and large position, so as to reduce density unevenness, improve correction accuracy, reduce Determining the effect of discrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

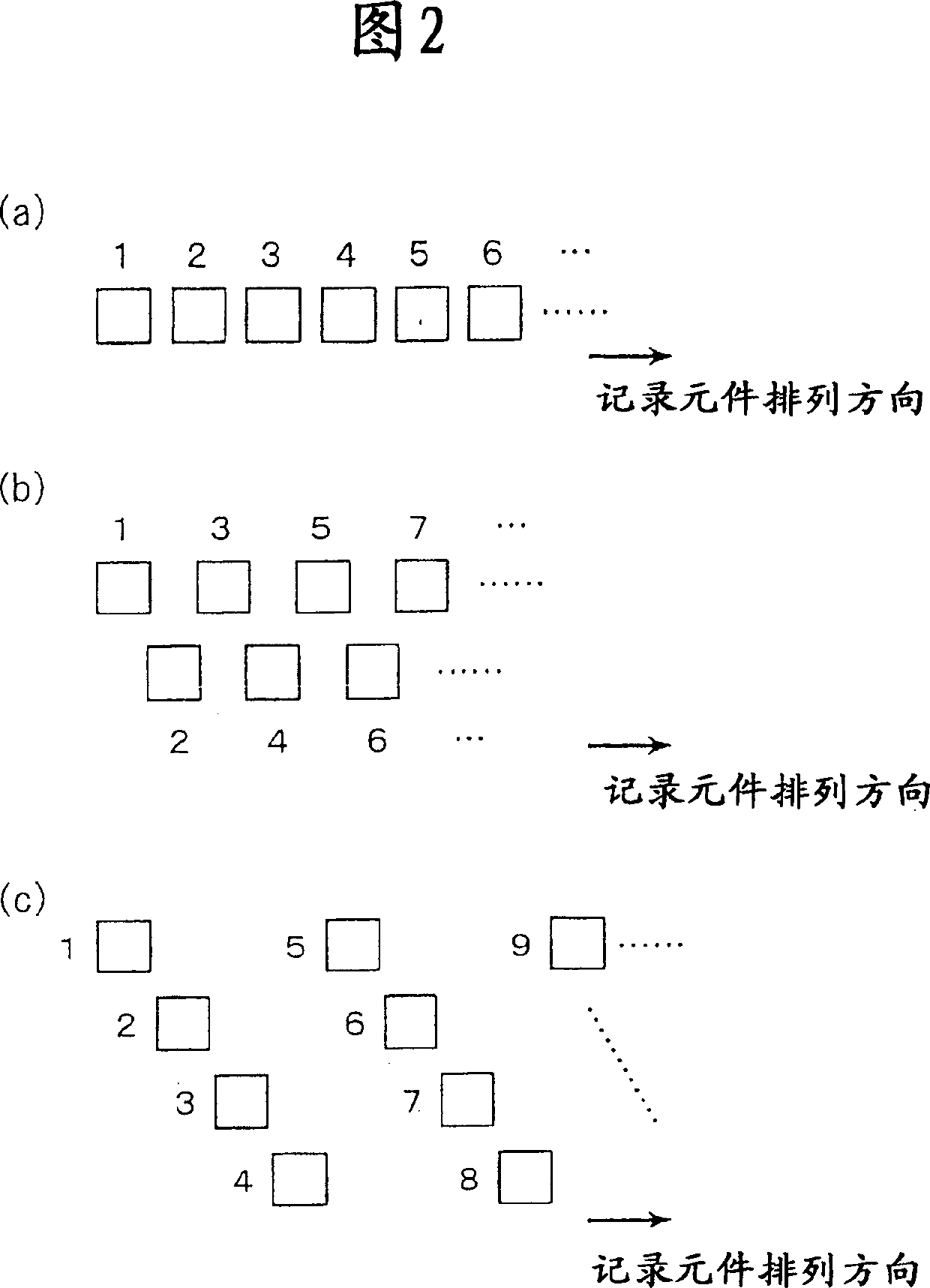

[0252] Hereinafter, Embodiment 1 of the present invention will be described in detail with reference to the drawings. However, the scope of the invention is not limited by the illustrated examples.

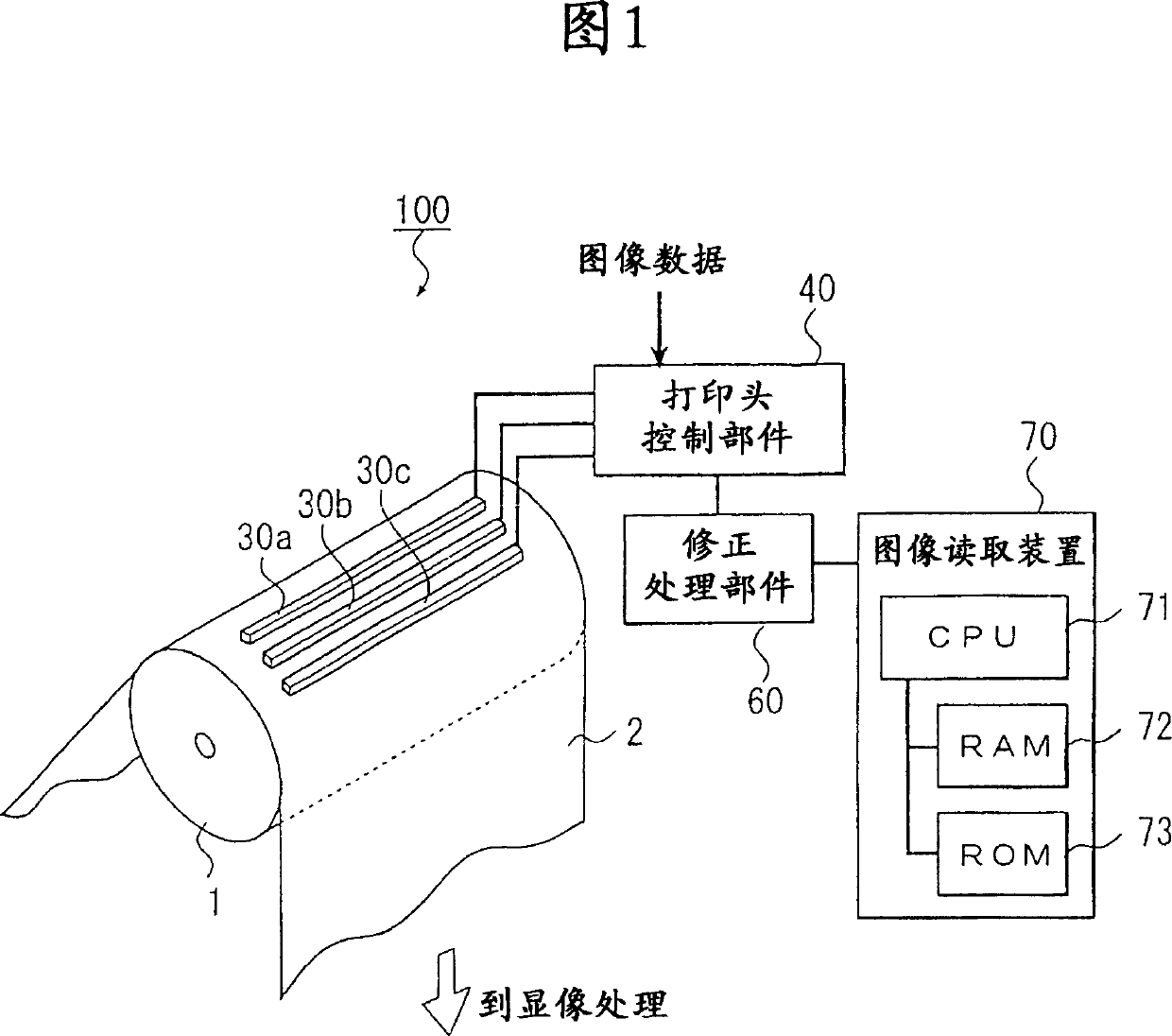

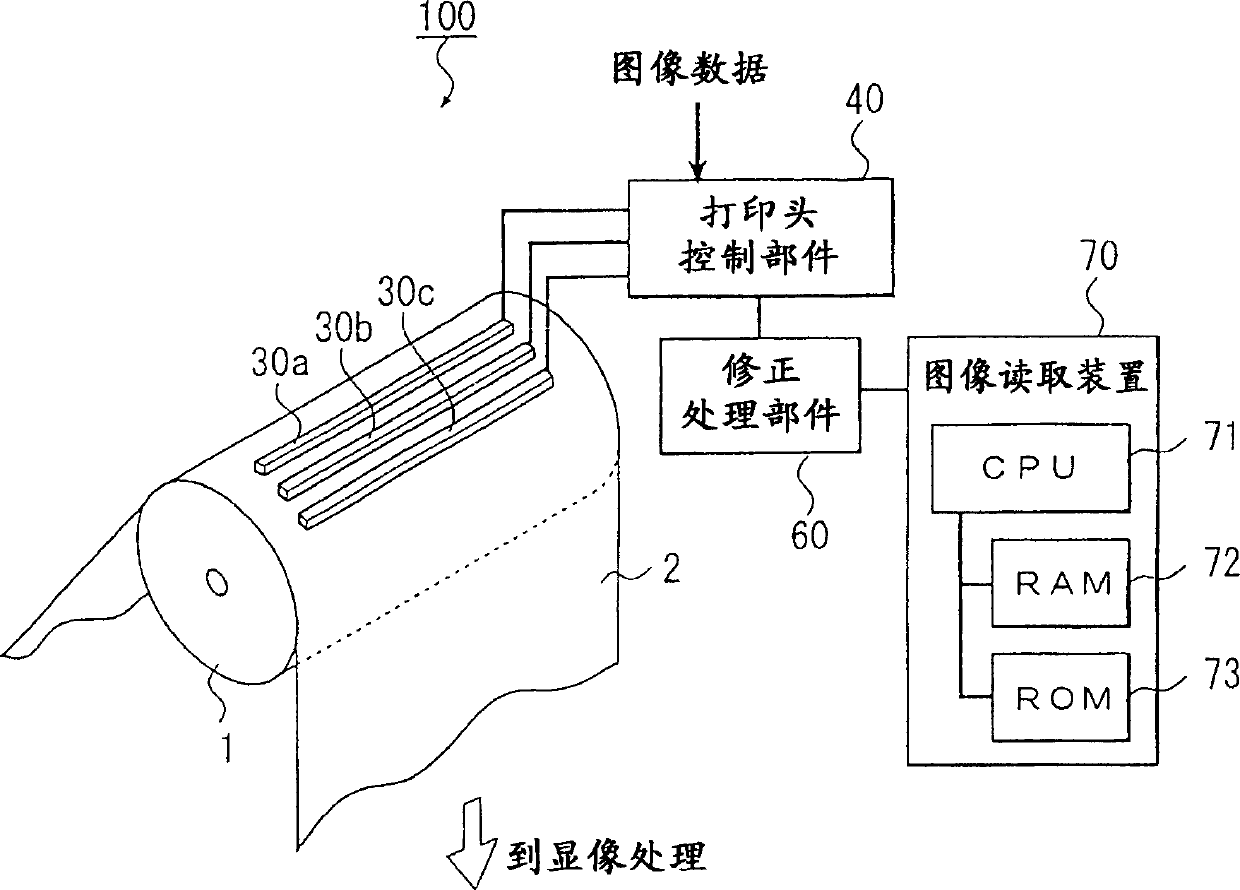

[0253] FIG. 1 shows a schematic configuration diagram of an image forming apparatus 100 in this embodiment.

[0254] As shown in FIG. 1, the image forming apparatus 100 includes a support drum 1, a red print head 30a, a green print head 30b, a blue print head 30c, a print head control unit 40, a correction processing unit 60, an image reading device 70, and the like. is constituted. In this embodiment, photosensitive paper for color photography (hereinafter referred to as photosensitive paper) that is a silver halide photosensitive material is used as a recording material.

[0255] The support drum 1 is a conveyor that is rotated by an unillustrated drive source. The support drum 1 conveys the photosensitive paper 2 conveyed from a roller (not shown) in the direction of the arr...

Embodiment 2

[0428] Next, Embodiment 2 of the present invention will be described in detail with reference to the drawings. The image forming apparatus 300 related to the second embodiment differs from the first embodiment in the light flux correction processing method of the recording element performed by the image forming apparatus 300 and the recording material used. Therefore, when describing the second embodiment, the same configurations as those of the above-mentioned first embodiment are given the same reference numerals, and description thereof will be omitted.

[0429] The image forming apparatus 300 includes a support drum 1, a red printhead 30a, a green printhead 30b, a blue printhead 30c, a printhead control unit 40, a correction processing unit 60, an image reading device 80, and the like. In this embodiment, as a recording material, color photographic photosensitive paper (hereinafter referred to as photosensitive paper) 22 which is a silver halide photosensitive material is ...

Deformed example 1

[0498] For example, one correction image can be generated, one image can be set twice in different directions, and read in two times. In FIG. 30 , one graph 33A is installed in the image reading device twice, and a modification 1 is given as a reading method.

[0499] Fig. 30(a) is the installation direction for the first time, and (b) is the installation direction for the second time.

[0500] As shown in (a), first, the arrangement direction of the corrected image included in the graph 33A is arranged so as to be the first direction in the forward direction of the arrangement direction of the recording elements, read in this state, and obtain the first read. fetch information.

[0501] Next, as shown in (b), first, the alignment direction of the corrected image in the graph 33A is arranged so that it becomes the opposite direction to the alignment direction of the recording elements, that is, as the second direction opposite to the first direction, and the second reading is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com