Rotary correcting device for gem machining row body

A gemstone and arrangement technology, applied in stone processing equipment, fine work devices, work accessories, etc., can solve the problems of labor time-consuming and gemstone processing cost increase, achieve a wide range of use, reduce the difficulty of correction, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

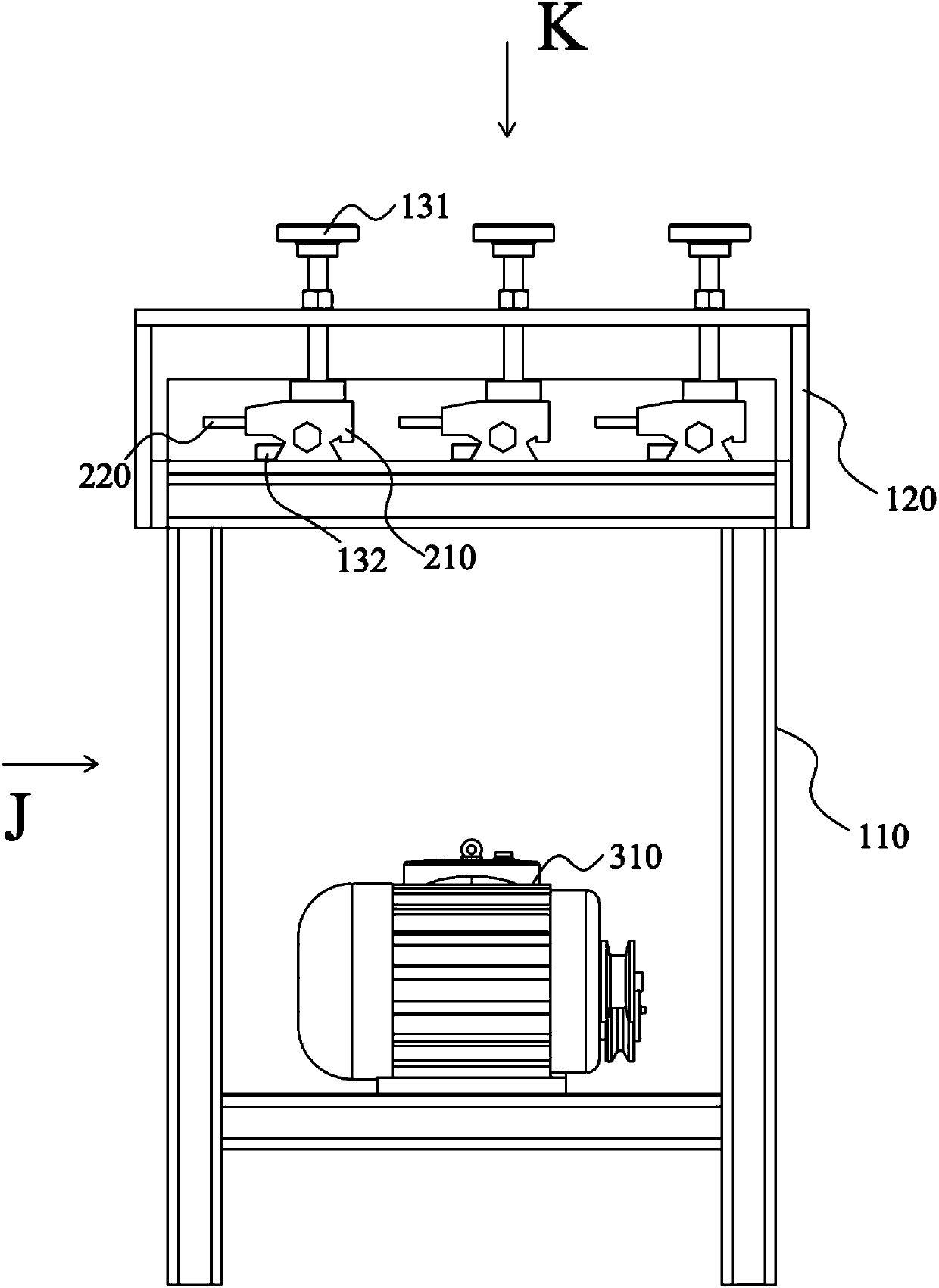

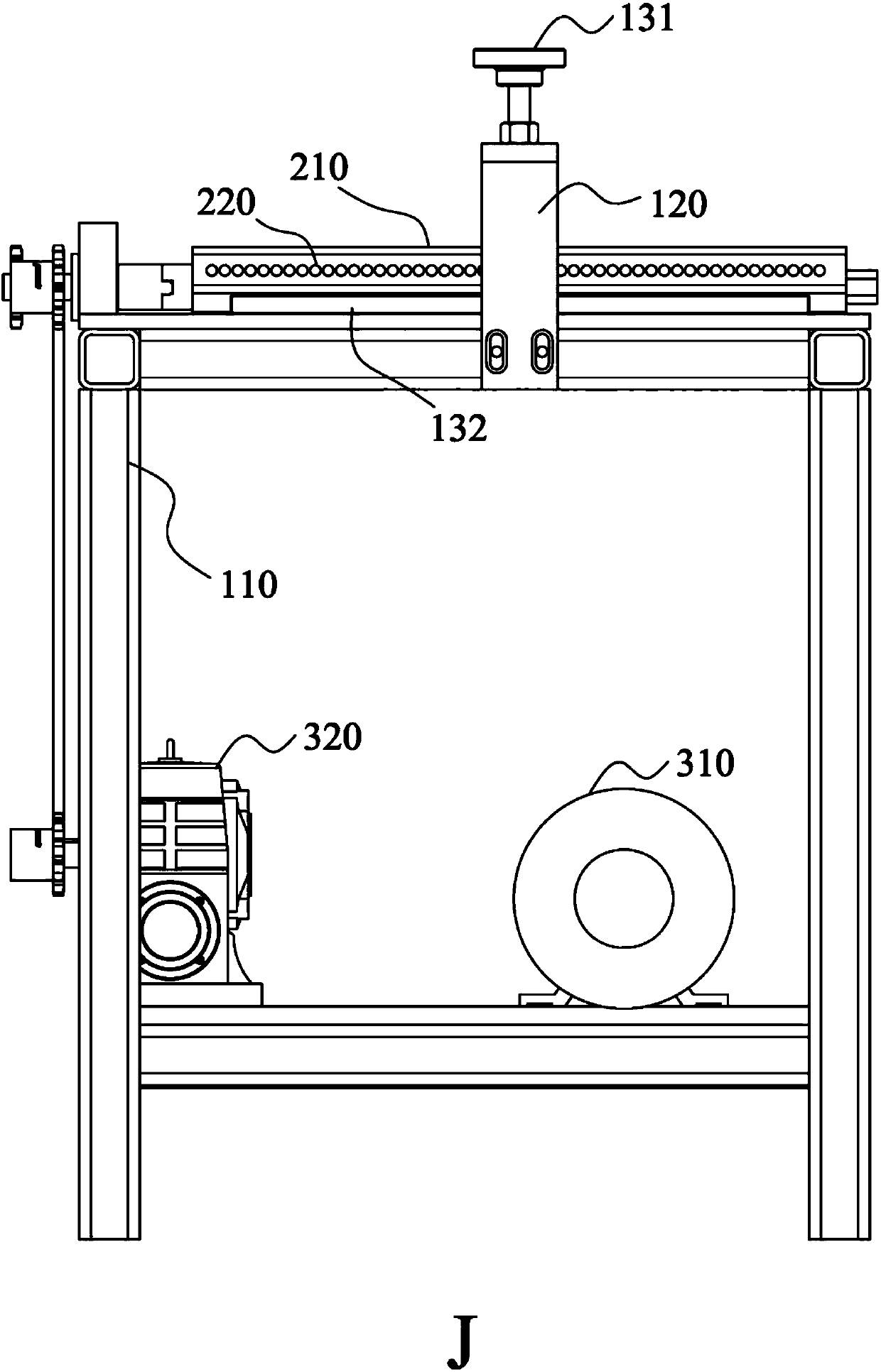

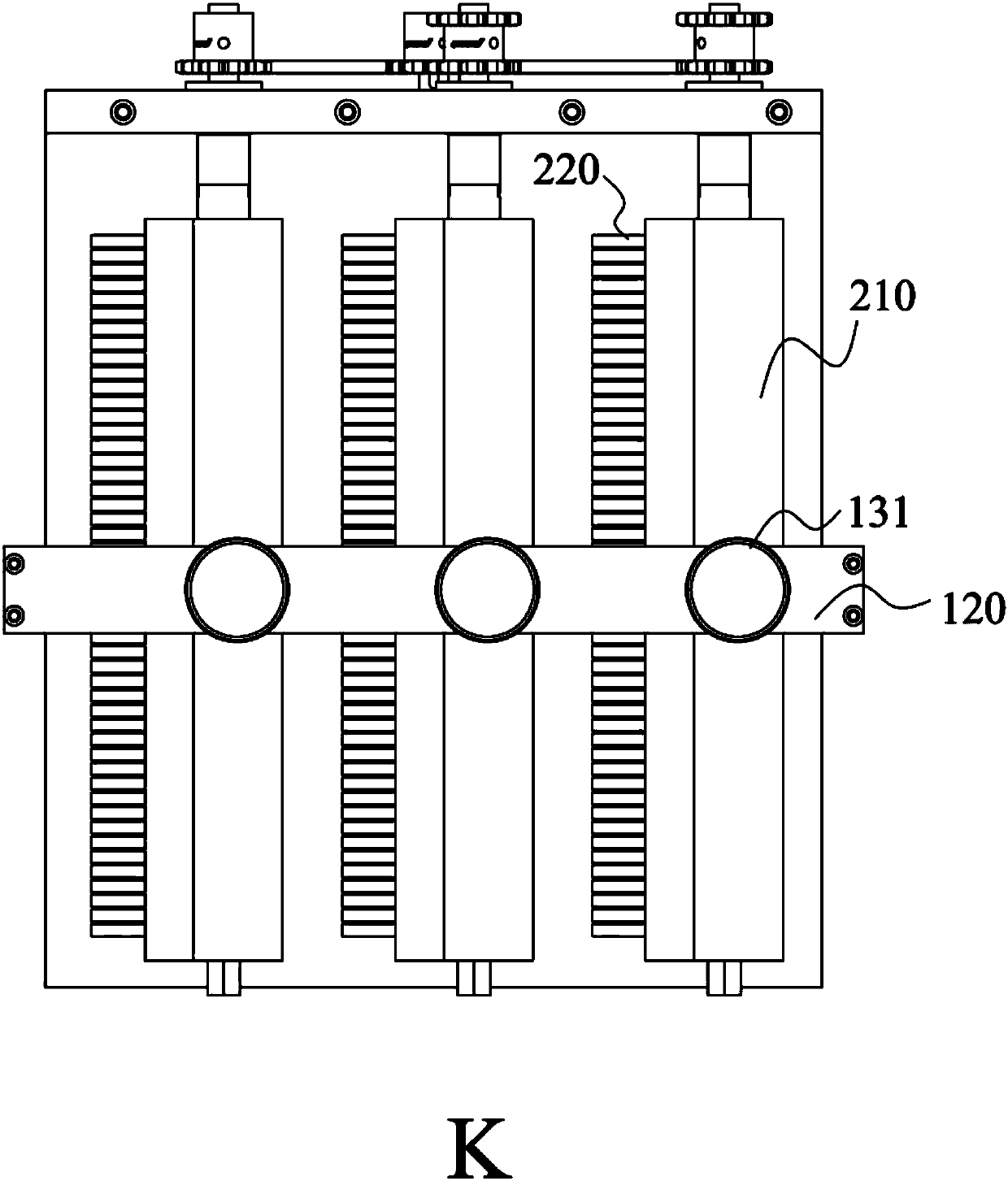

[0017] Such as Figure 1-3 As shown, the rotation correction device of a gemstone processing row body according to the present invention mainly includes a frame body 110 of a hollow rectangular frame structure, a motor 310 and a reduction box 320 arranged inside the frame body 110, and a It is used to assist in pressing the pressing bar support part 120 and the threaded pressing bar 131 of each grouping body 210 .

[0018] The upper end surface of the frame body 110 is provided with a plurality of installation stations for row bodies 210 , one installation station corresponds to a group of row bodies 210 , and the installation stations are detachably connected to the row body 210 through dovetail strips 132 . The dovetail strip 132 enables technicians to quickly disassemble and install any row body 210 without affecting the correction work of other row bodies 210 . After each group of row bodies 210 is installed, they are parallel to each other and horizontally arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com