A method and system for manual pipe jacking control

A control method and pipe jacking technology, applied in radio wave measurement system, satellite radio beacon positioning system, pipeline laying and maintenance, etc., can solve problems such as inability to monitor and adjust in time, pipeline direction deviation, etc., and achieve shortening correction time, The effect of reducing overall cost and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] like Figure 1-3 As shown, an artificial pipe jacking control method of the present invention includes the steps:

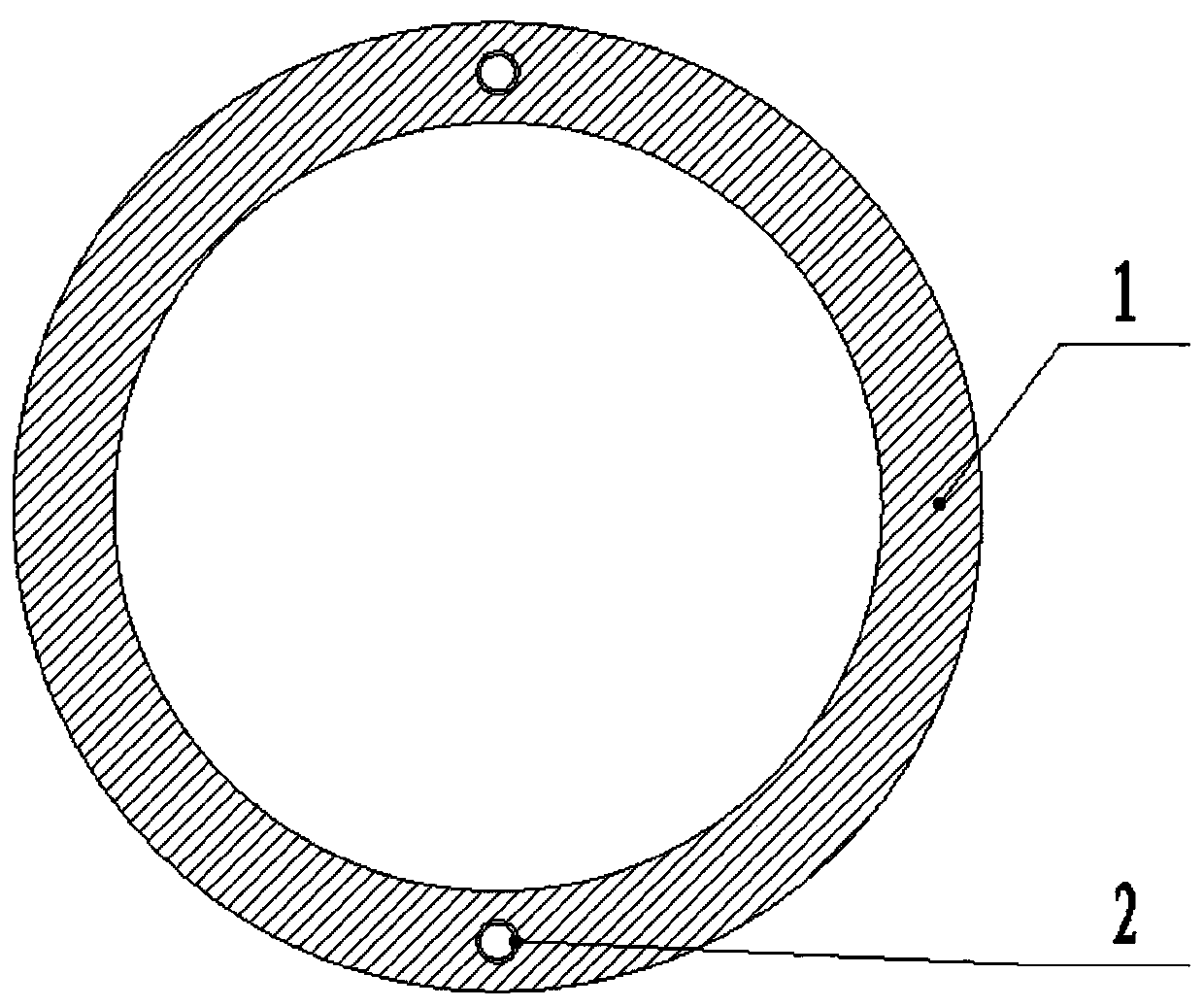

[0036] Step 1) There are two laser detection pipes 2 symmetrically in the pipe wall of each cement concrete pipe 1, and the laser detection pipes 2 can be formed by pre-embedded pipes (seamless steel pipes), or they can be formed by casting through molds;

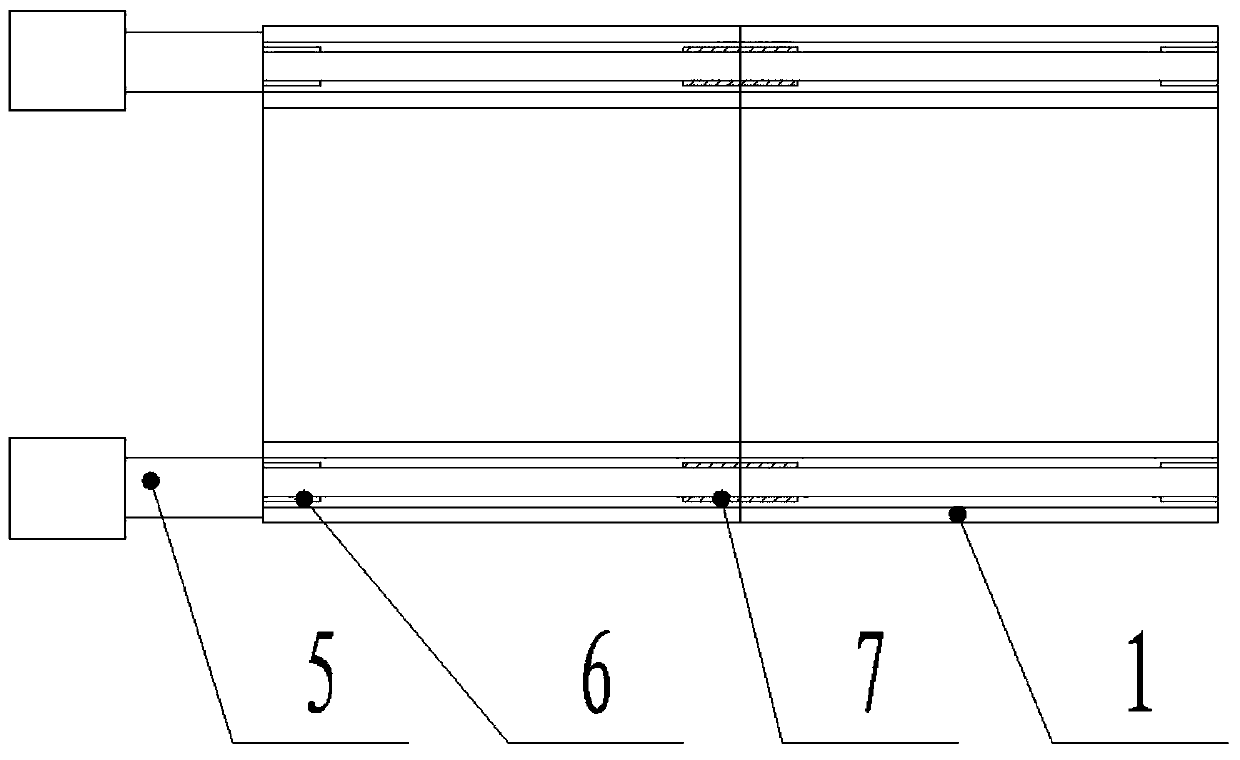

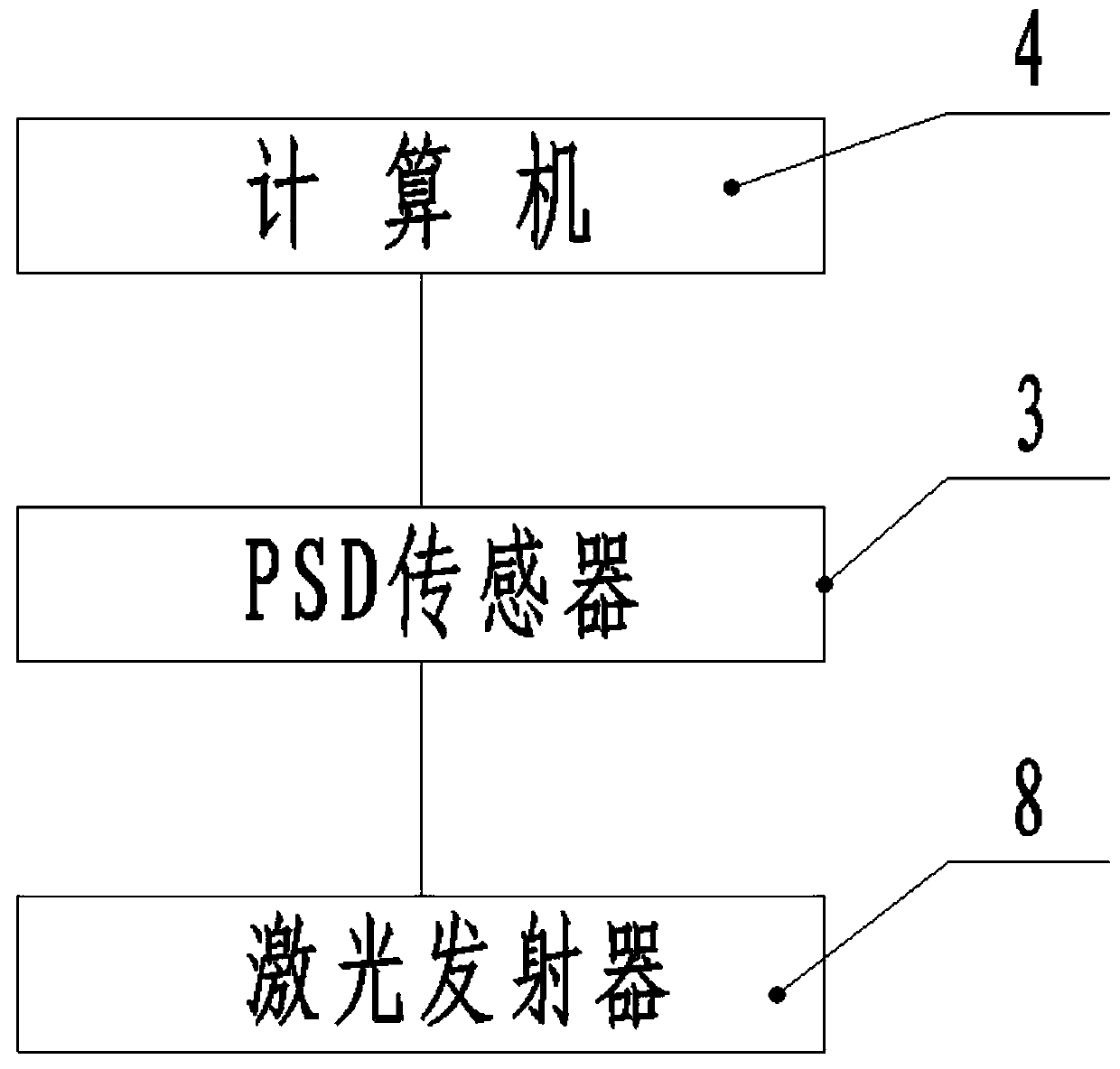

[0037] Step 2) A PSD sensor 3 is arranged in each laser detection tube 2 of the cement concrete pipe 1 at the front end of the pipe jacking, and a computer 4 connected to the PSD sensor 3 is arranged outside the cement concrete pipe 1. The computer 4 is arranged in the caisson, which is convenient for Workers monitor the jacking direction of the pipe jacking in real time;

[0038] Step 3) Connect the cement concrete pipe 1 that is subsequently jacked with the end of the cement concrete pipe that has been jacked in, and the laser detection pipes of the two connected cement concrete pipes are aligned wit...

Embodiment 2

[0049] like Figure 1-3 As shown in the figure, an artificial pipe jacking control system of the present invention includes a jack and a cement concrete pipe, and is characterized in that: two laser detection pipes are symmetrically arranged in the pipe wall of each cement concrete pipe; A PSD sensor is set in each laser detection tube of the , PSD (Position Sensitive detector) is a position sensitive detector. It is divided into one-dimensional PSD and two-dimensional PSD two types of products. PSD is a PIN photodiode composed of one or two surfaces with uniform impedance, which has the advantages of high position resolution, simple reaction current, and fast (depending on the position of the light spot) compared with discrete element detectors.

[0050] There is a computer connected to the PSD sensor outside the cement concrete pipe; the cement concrete pipe that is subsequently jacked is butted with the end of the cement concrete pipe that has been jacked in, and the laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com