Automatic paper web deviation rectifying device

An automatic deviation correction device and paper web technology, applied in transportation and packaging, thin material processing, winding strips, etc., can solve the problems of deviation correction effect records, few deviation correction mechanical frame position detection feedback, unfavorable paper web control, and deviation correction accuracy Low-level problems, to achieve the effect of easy real-time monitoring, simple structure, and high accuracy of deviation correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

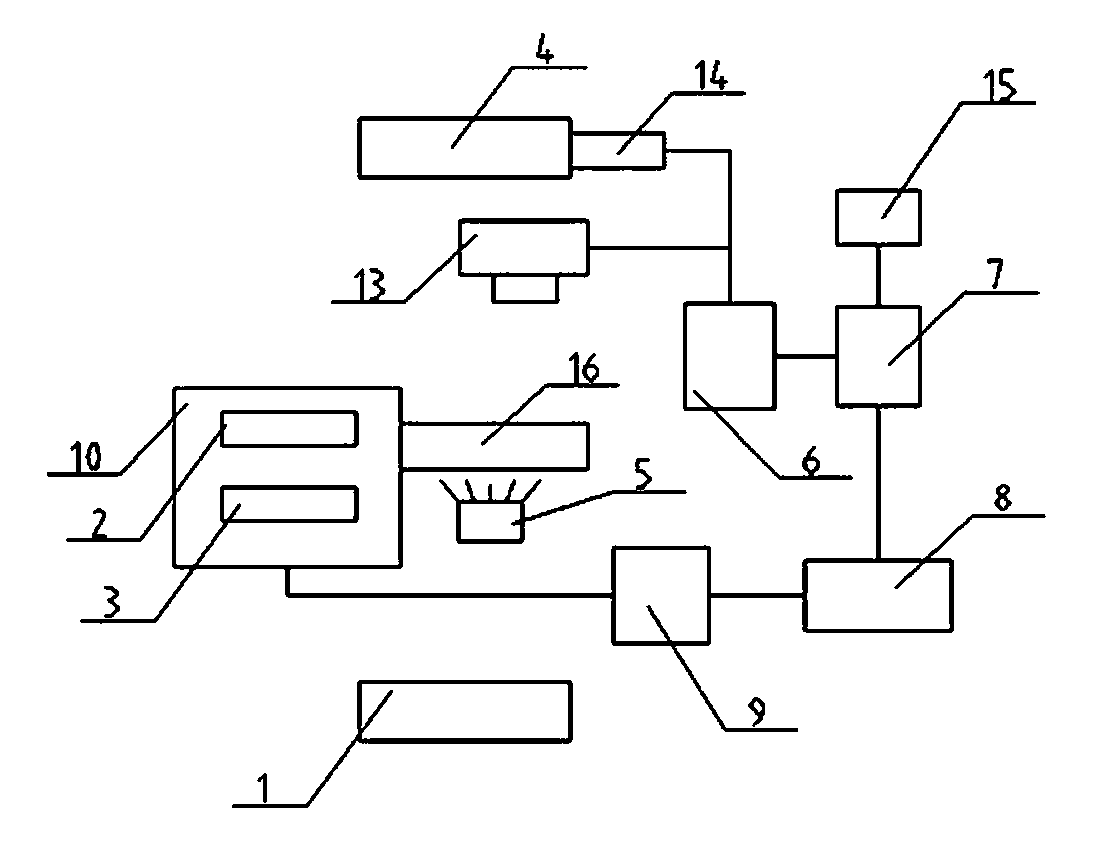

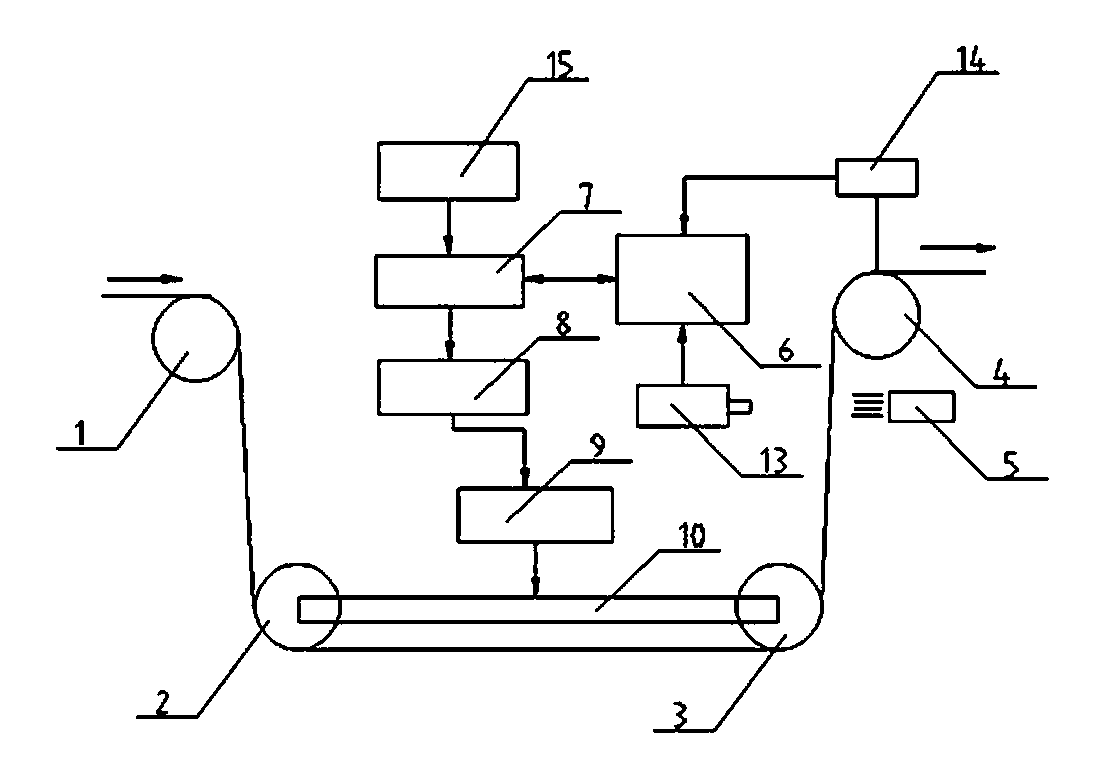

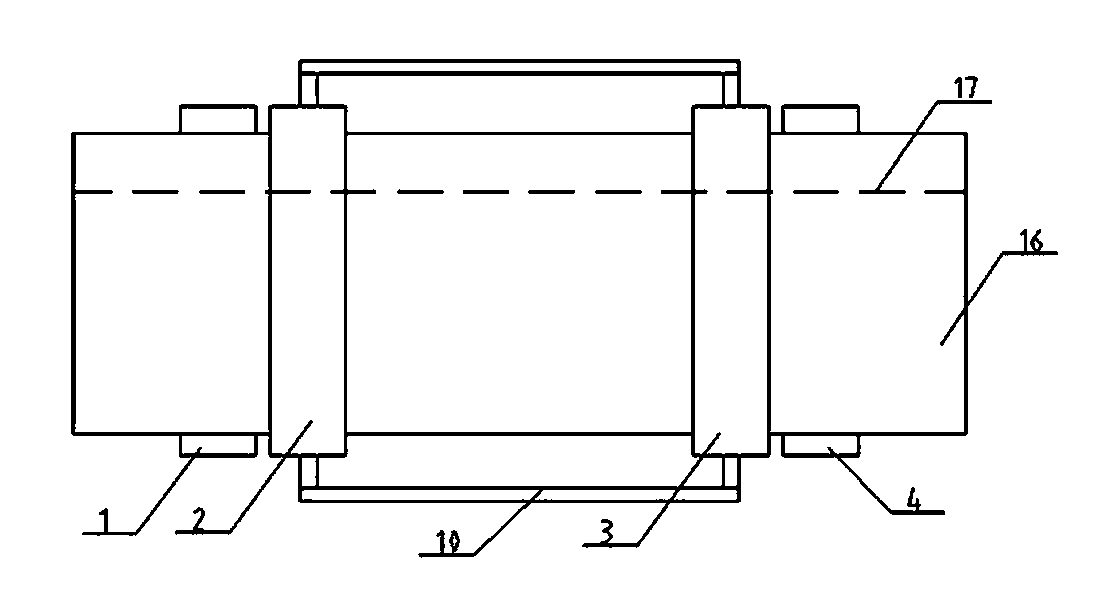

[0023] Embodiment: An automatic paper web deviation correction device, including a front threading roller 1, a front threading roller 2, a rear threading roller 3, a rear threading roller 4, a light source 5, an imaging device, and a slitting cursor position analysis and deviation calculation module 6 and the main control module 7 for deviation correction, the paper web is introduced by the front guiding roller 1, passes through the front guiding roller 2 and the rear guiding roller 3 in turn, and finally is led out by the rear guiding roller 4, the front guiding roller 2 and the rear guiding roller The roller 3 tensions the paper web, and the light source 5 illuminates the paper web surface between the rear deviation-correcting roller 3 and the rear threading roller 4, and the imaging device can image the paper web irradiated by the light source 5 and send a signal to the slitting cursor The position analysis and deviation calculation module 6, the slitting cursor position ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com