Charge coupled device (CCD) feedback correction closed-loop control method, control device and control system

A closed-loop control and deviation correction technology, which is applied in the fields of final product manufacturing, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve problems such as inaccurate detection, affecting detection and correction accuracy, and pole piece offset, so as to improve correction The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

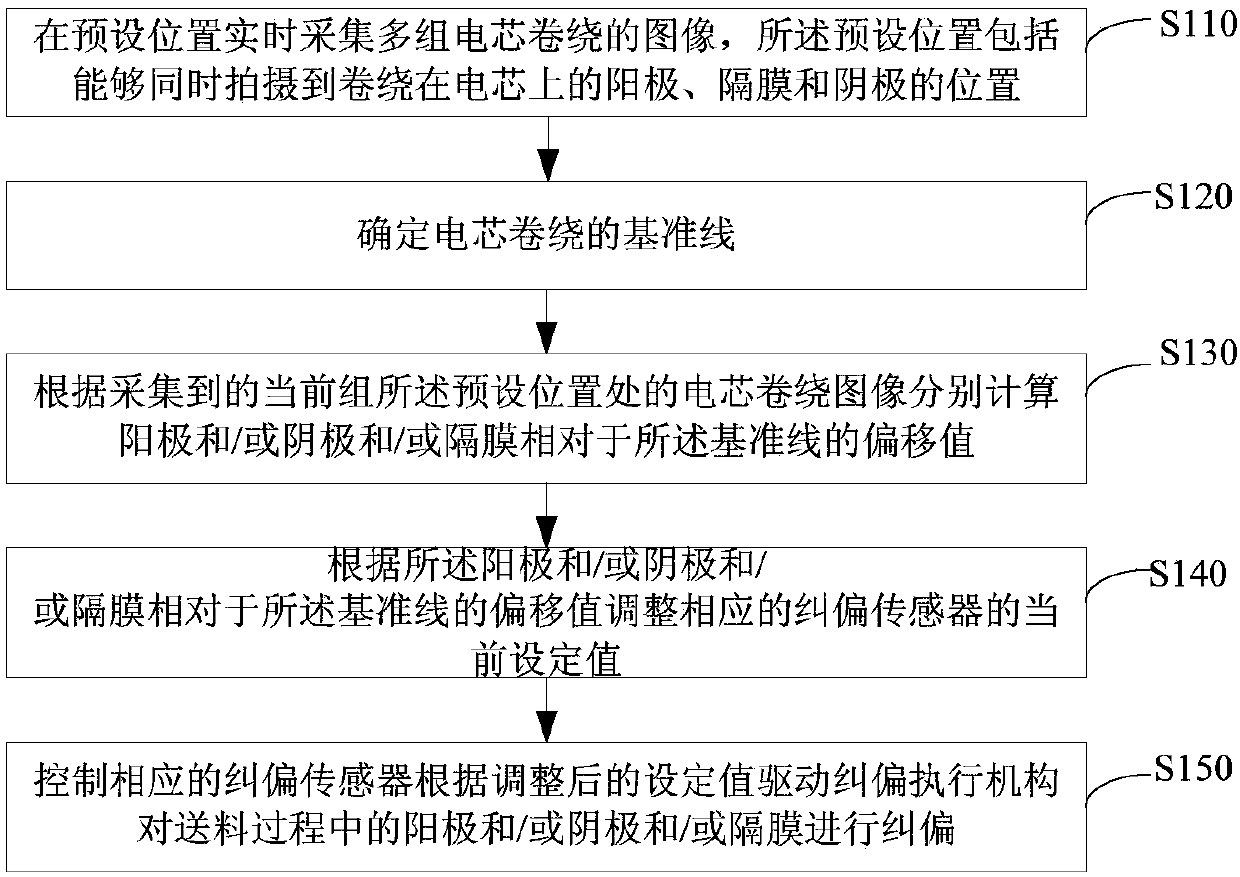

[0070] As the first aspect of the present invention, a kind of CCD feedback correction closed-loop control method is provided, wherein, such as figure 1 As shown, the CCD feedback correction closed-loop control method includes:

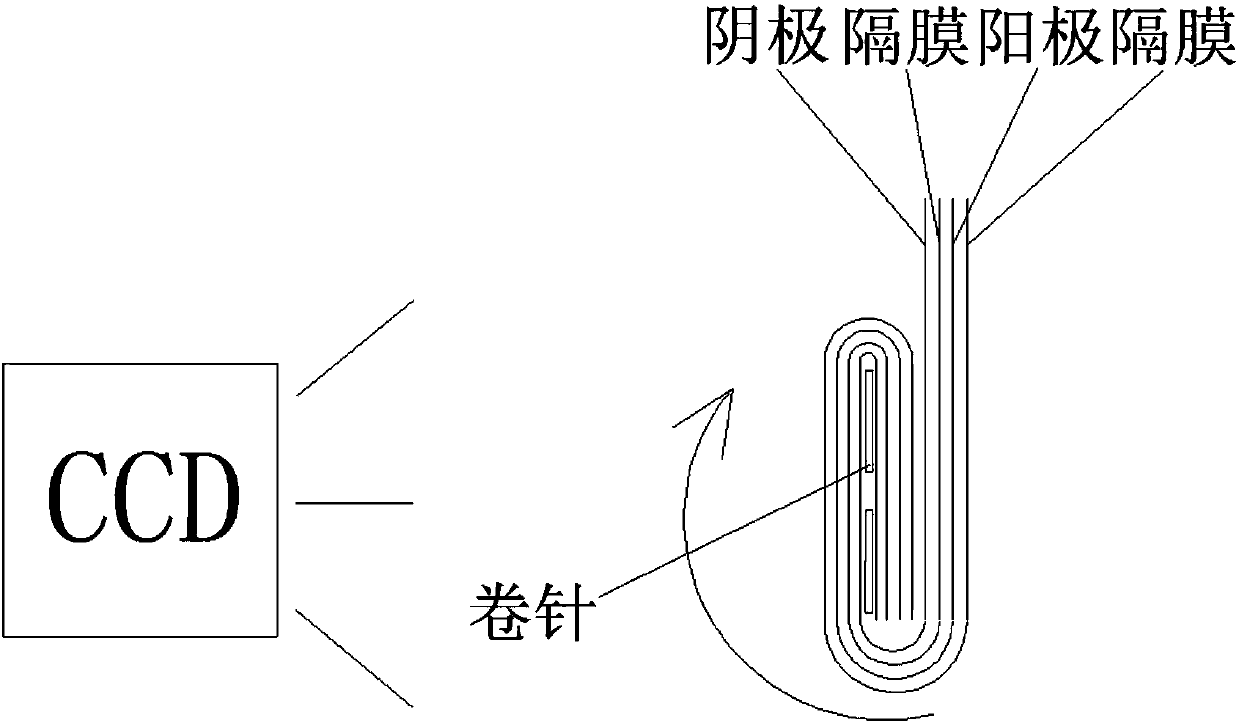

[0071] S110. Collect multiple groups of images of battery core winding in real time at a preset position, where the preset position includes a position where the anode, diaphragm, and cathode during the battery core winding process can be photographed;

[0072] S120. Determine the reference line for winding the battery core;

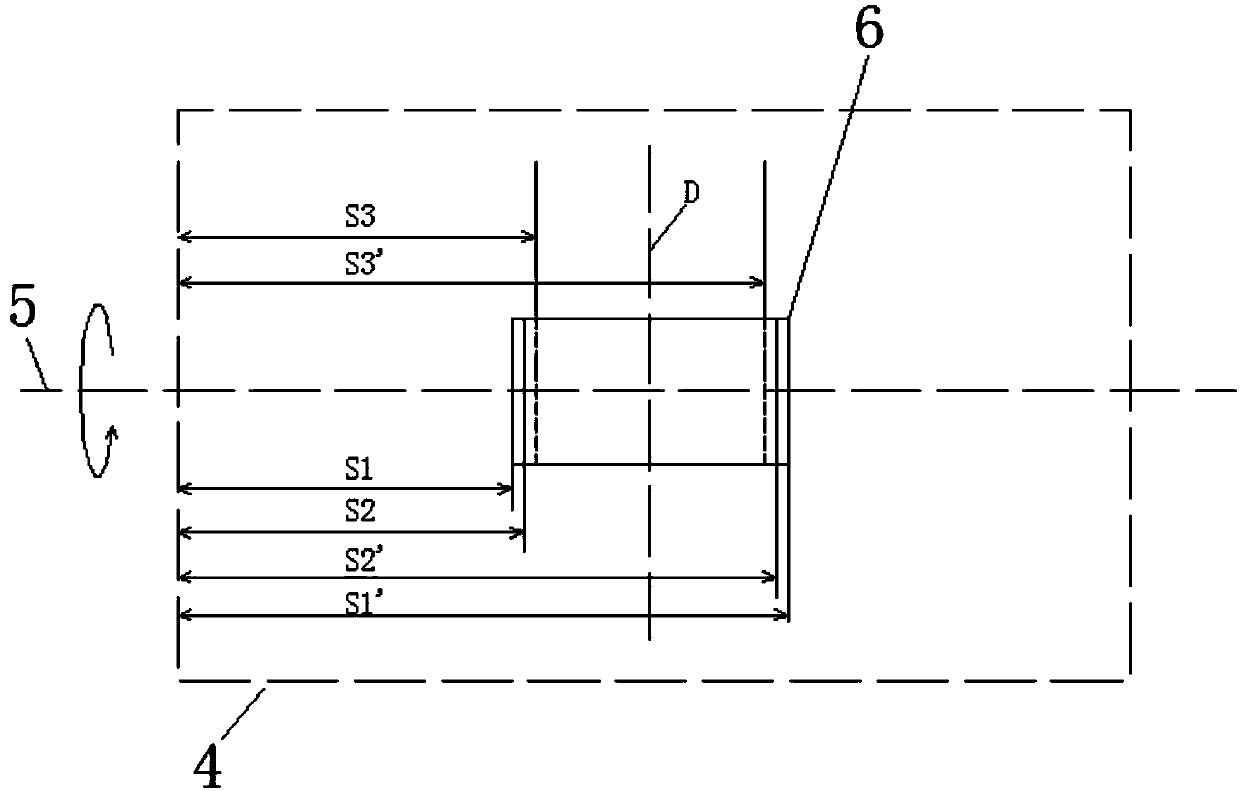

[0073] S130. Calculate respectively the offset values of the anode and / or cathode and / or diaphragm relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com