Strip steel non-roller correcting error method and apparatus

A deviation correction device and strip deviation technology, applied in transportation and packaging, coiling strips, use feedback control, etc., can solve the problems of increased strip scratches, low deviation correction ability, complex system maintenance, etc., to achieve easy Effects of computer control, improved surface quality, and high accuracy of deviation correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

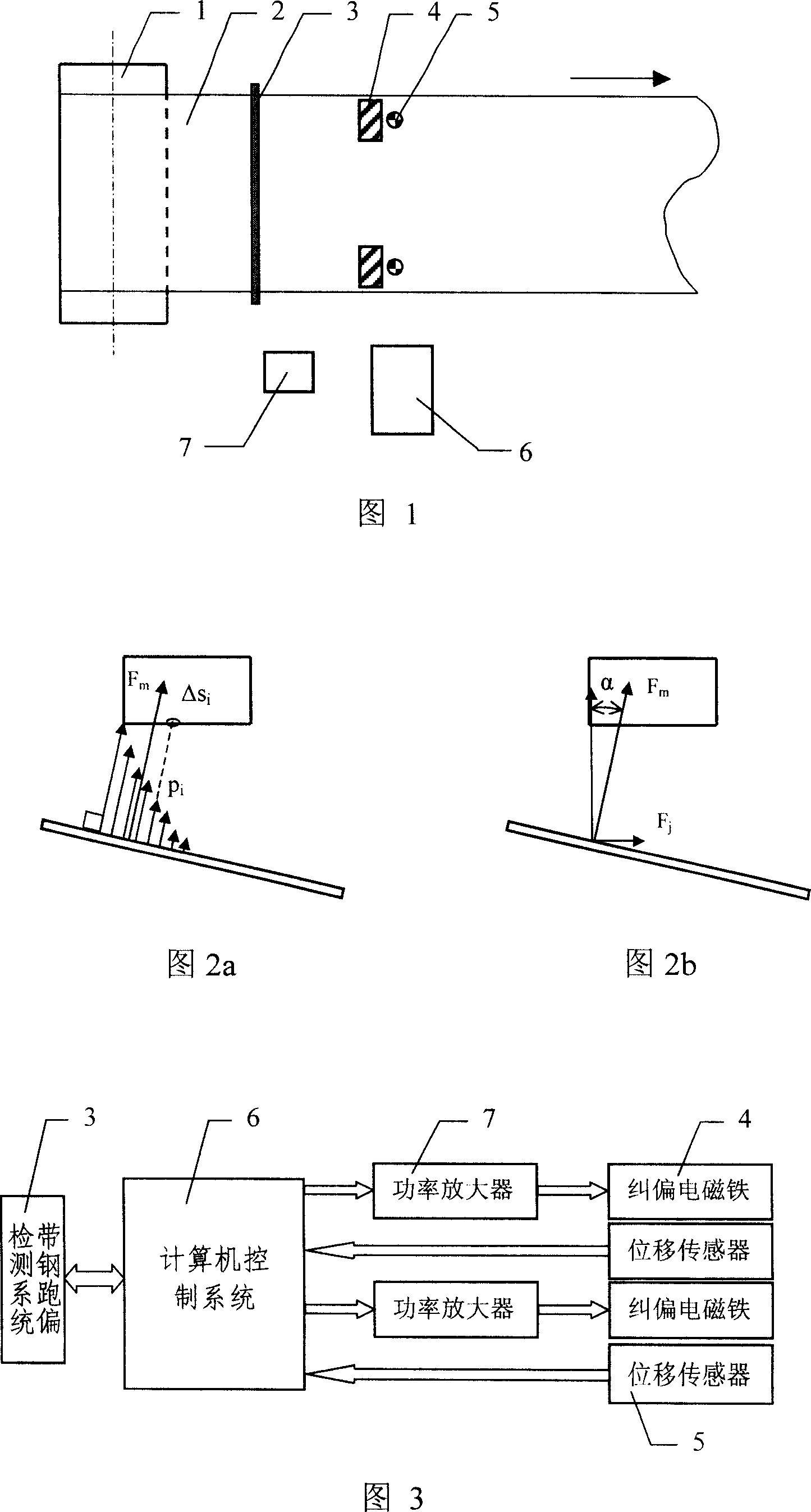

[0041] Referring to Fig. 4, for a strip steel 2 with a width of 1400mm, a pair of rectifying electromagnets 4 with a bottom surface size of 150mm×150mm are symmetrically arranged on both sides of the running center line of the strip steel 2, and the outer distance between the two electromagnets 4 is 1300mm . When there is no excitation current, the vertical distance from the bottom surface of the electromagnet 4 to the surface of the strip steel 2 is 30 mm. An eddy current displacement sensor 5 is arranged at the center of each electromagnet 4 to measure and control the distance from the electromagnet 4 to the steel strip 2 .

[0042] The area of the electromagnet 4 facing the strip steel 2 should be as large as possible, so that on the one hand, a larger electromagnetic correction force can be obtained; Detrimental effects of force concentration on strip 2 surface shape and other surface qualities. After testing, the deviation correction control accuracy can reach ±1mm, o...

Embodiment 2

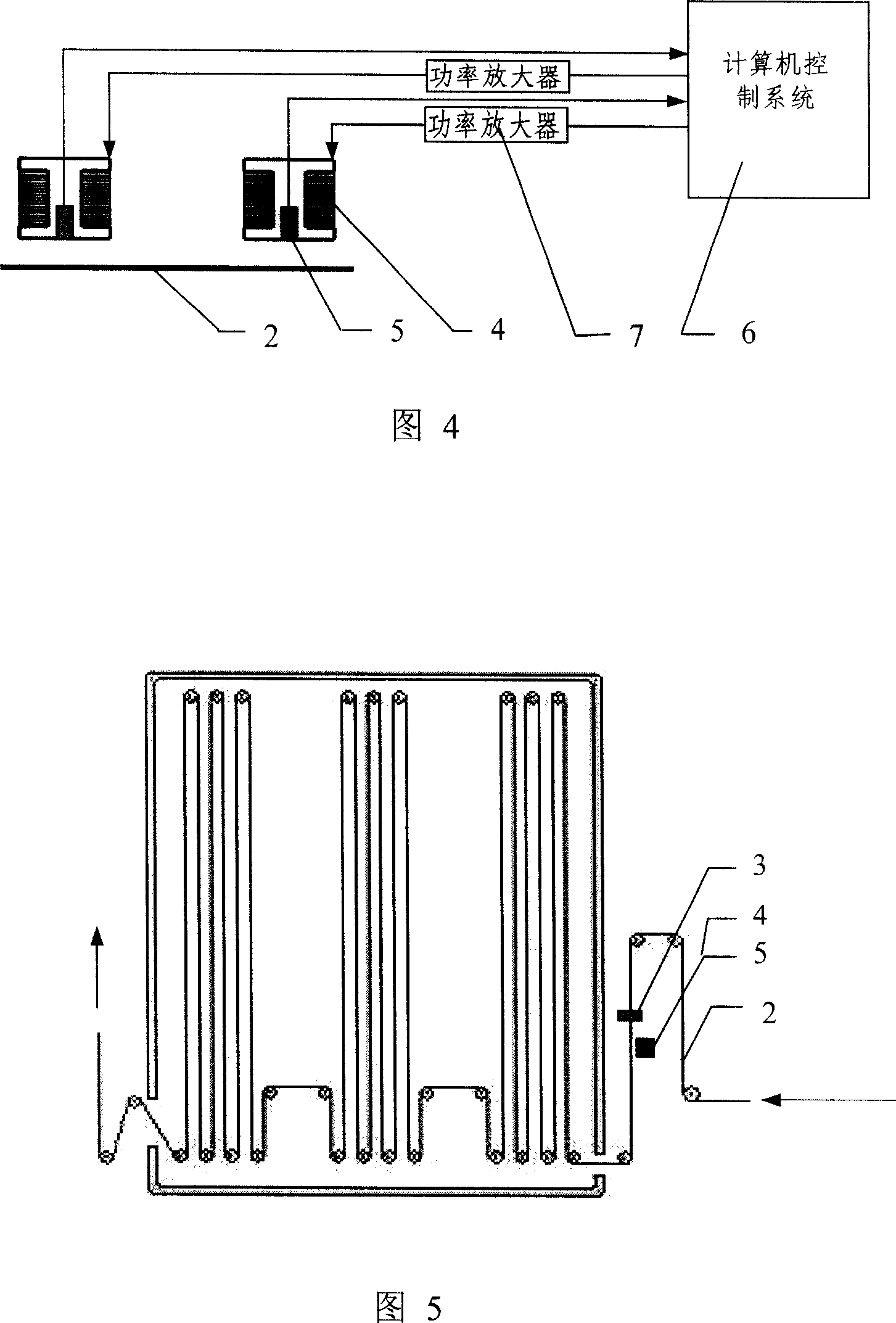

[0044] Referring to Fig. 5, before the continuous annealing processing production line (CAPL) steel strip enters the looper, the deviation of the strip steel is corrected by using a roller-less correction method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com