Composite membrane machine for manufacturing flat membrane

A technology of composite membrane and flat membrane, applied in membrane technology, semi-permeable membrane separation, textile processing machine accessories, etc., can solve problems such as undeveloped devices or equipment, and achieve high accuracy of deviation correction, reasonable structure setting, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

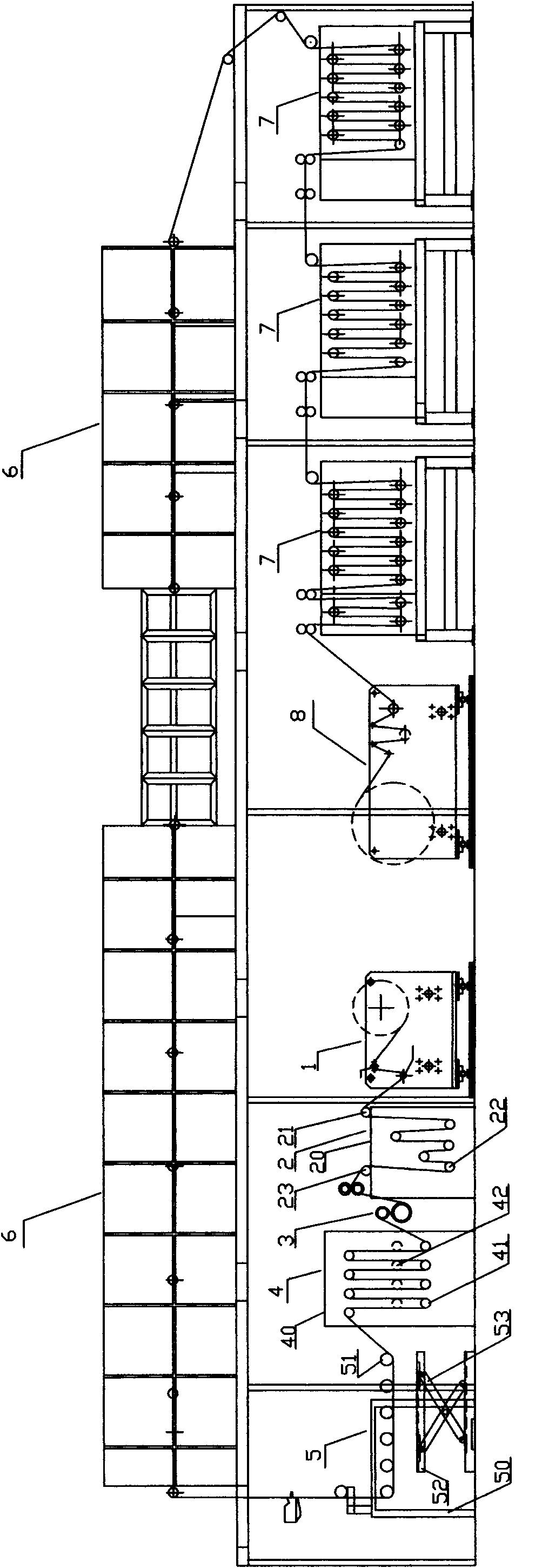

[0037] Such as figure 1 As shown, a flat film composite film machine of the present invention includes an unwinding cloth feeding unit 1, a liquid immersion unit 2, a conveying unit 3, a ventilation regulating unit 4, a film making unit 5, a drying unit 6, a washing unit 7, Rolling and receiving unit 8. Among them, the unwinding and feeding unit 1, the immersion unit 2, the ventilation adjustment unit 4, the film making unit 5, the drying unit 6, the washing unit 7, and the rolling and receiving unit 8 are installed in sequence in an assembly line, and the conveying unit 3 is installed On the above-mentioned functional units, the conveying track is mainly composed of several groups of fabric guide rollers, so that the base fabric (non-woven fabric) can run stably on the conveying track, and the base fabric (non-woven fabric) can pass through the above-mentioned functions without interruption. unit is processed.

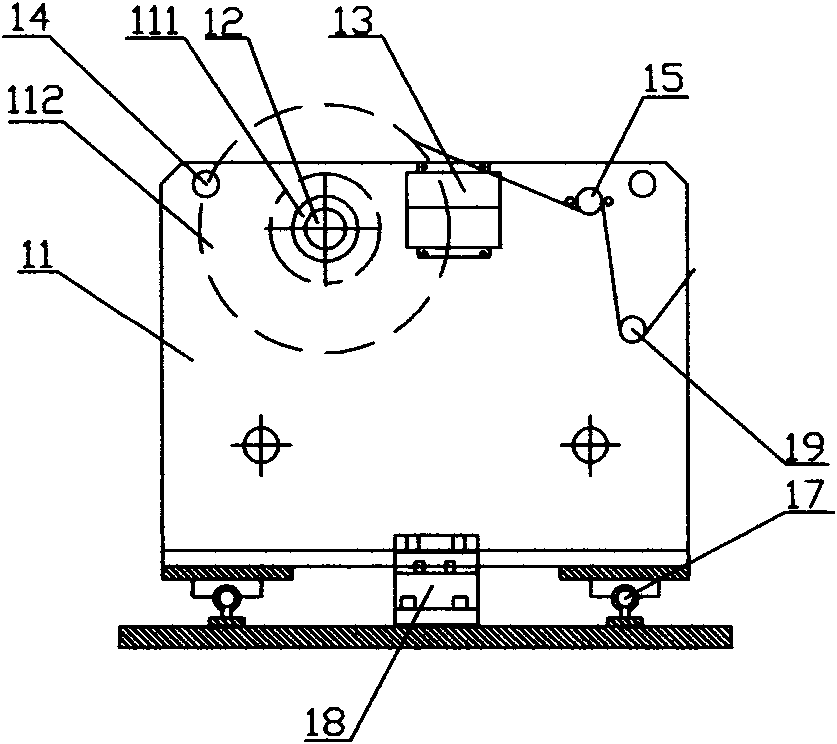

[0038] Unwinding and feeding unit 1 such as figure 2 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com