Monitoring and measuring method of culvert jacking deviation rectification

A measurement method and culvert technology, applied in the field of monitoring and measurement of culvert jacking correction, can solve problems such as poor visibility conditions, influence of obstacles, and inaccurate data, so as to solve measurement problems, improve jacking accuracy, and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

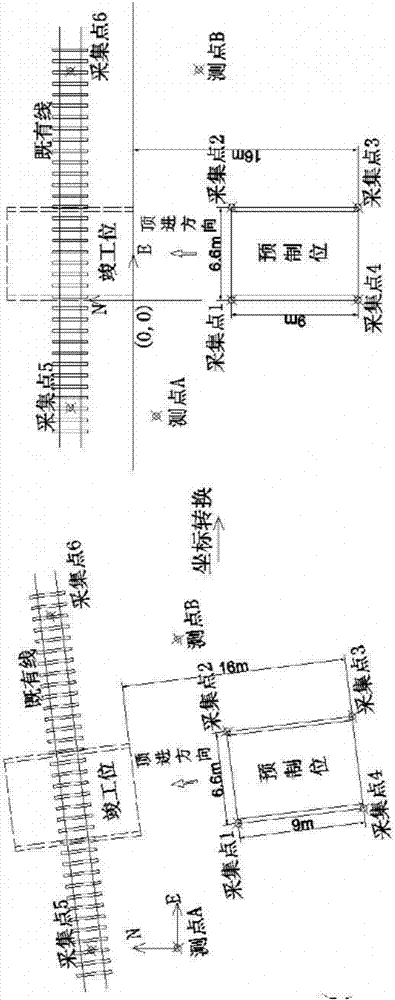

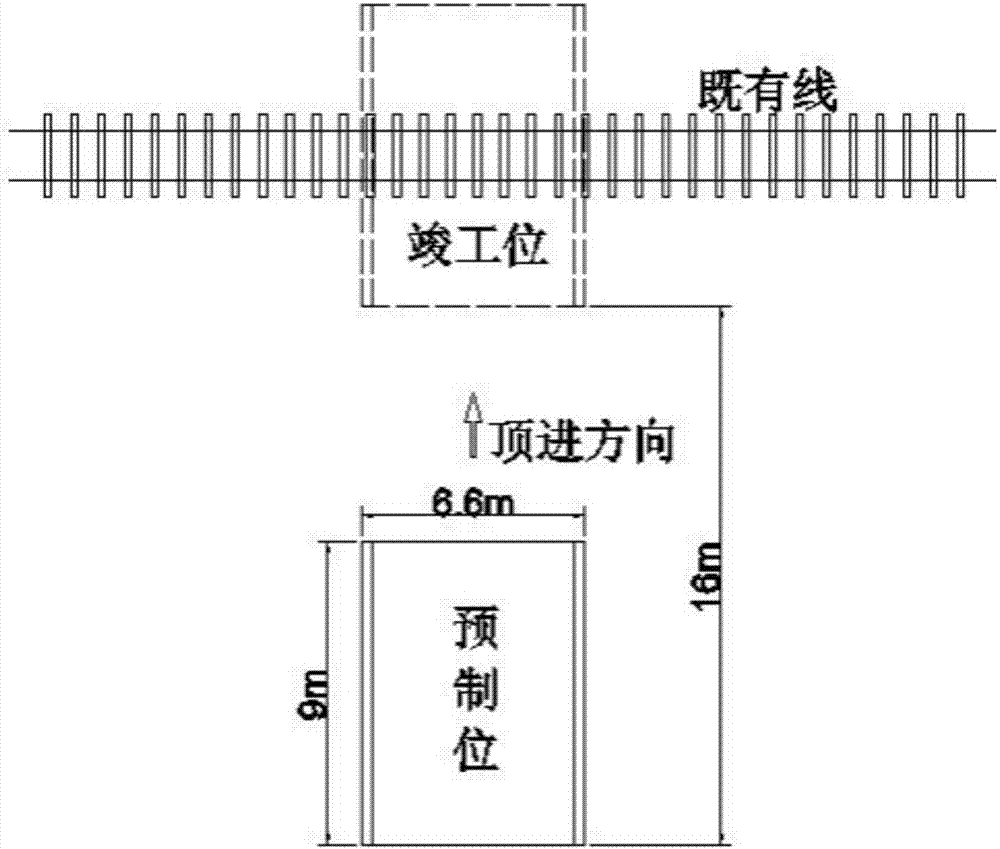

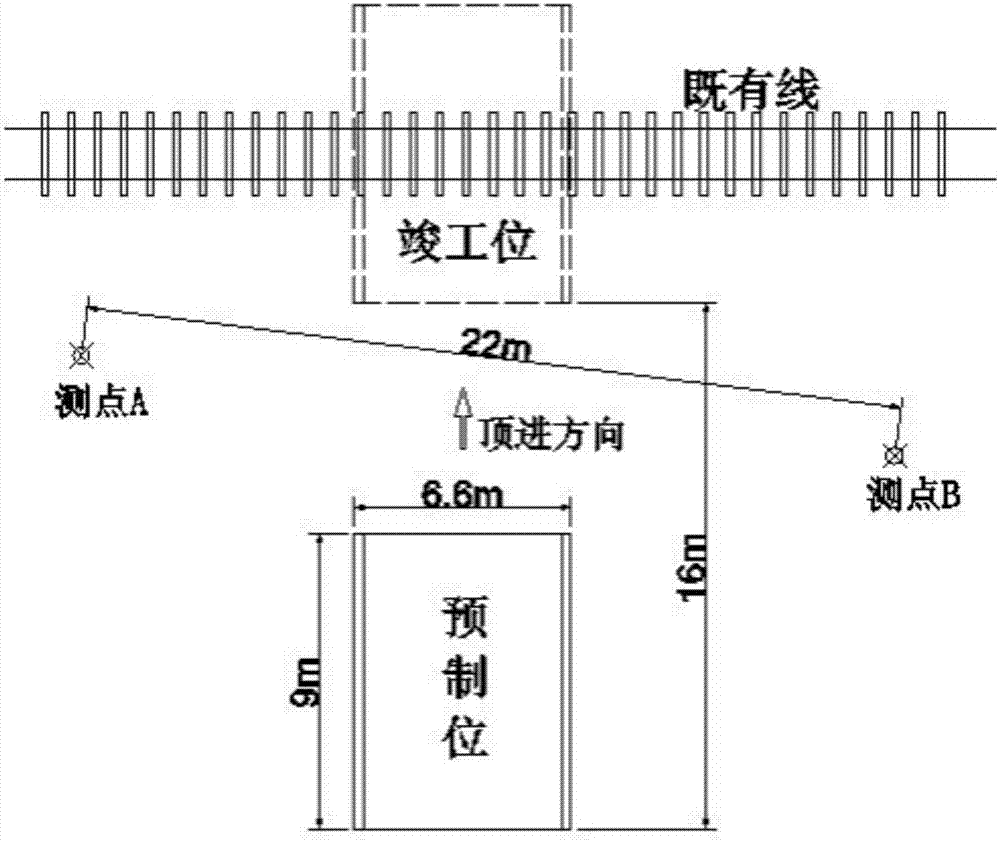

[0012] Before the jacking construction of the existing line culverts, the culverts are prefabricated on the side of the line. Therefore, the culvert has a prefabricated position before jacking and an as-built position after jacking. A local coordinate system can be established within the scope of the construction site. In theory, the coordinate system can be established arbitrarily, but for the convenience of coordinate calculation during monitoring, the coordinate system is established using the completed position of the culvert, so that the X-axis and Y-axis of the coordinate system are parallel to the culvert The vertical and horizontal axes of the as-built position.

[0013] As shown in the attached figure, the following example is used to illustrate the establishment of the coordinate system. For example, the lateral dimension of the culvert is 6.6m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com