Solar cell cutting system

A solar cell and cutting system technology, applied in the field of solar cells, can solve problems such as cell short circuit, lack of solar cell rectification, failure of cell qualified inspection, etc., and achieve the effects of improving production efficiency, small error, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

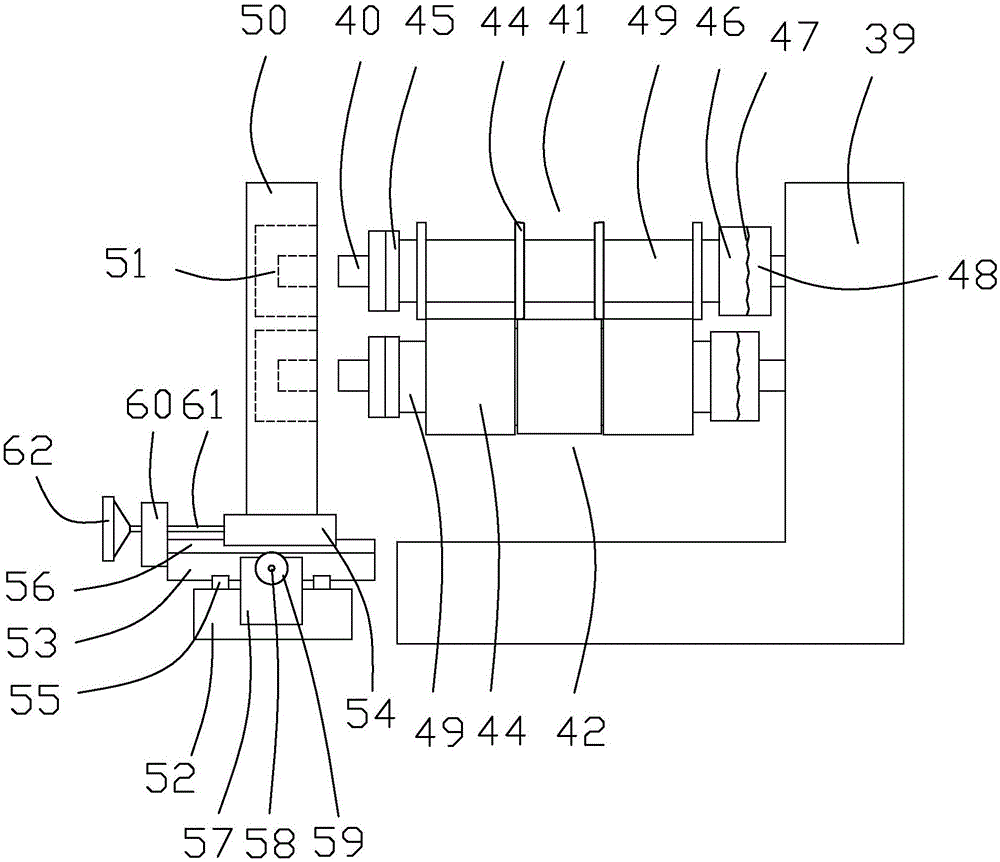

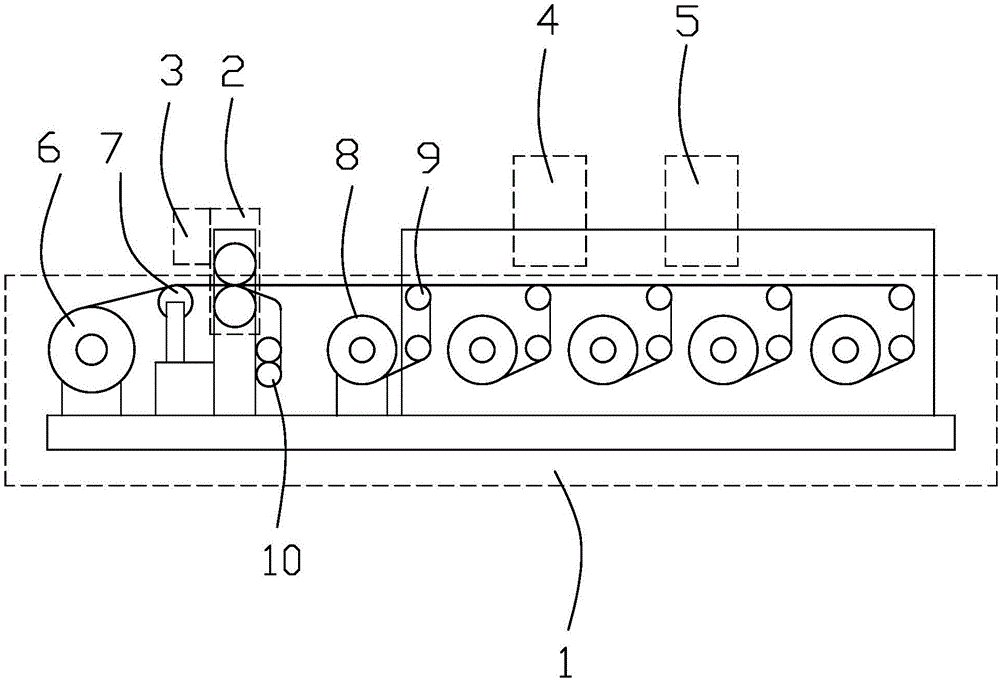

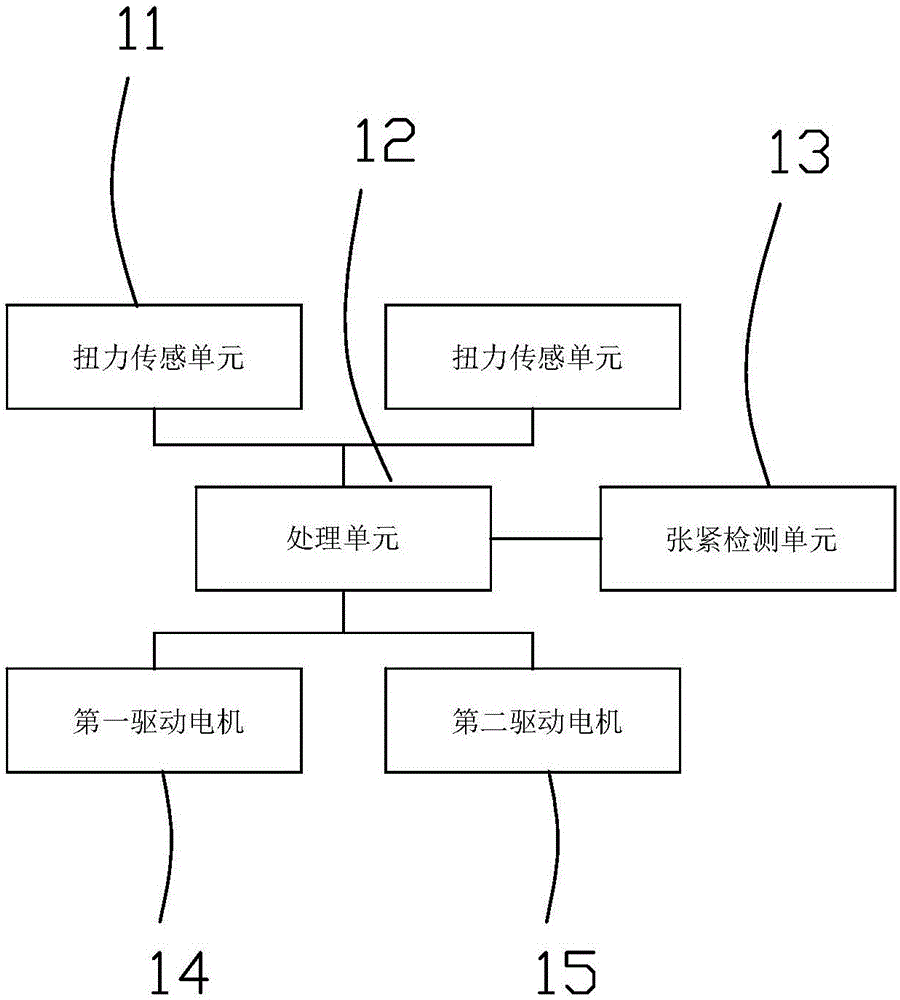

[0041] A solar cell cutting system in this embodiment, such as figure 1 shown, including

[0042] A conveying device 1 for conveying flexible battery rolls from roll to roll;

[0043] Installed in the middle section of the conveying device, the cutting device 2 roll-cuts the battery roll, and the cutting device includes a cutter that cuts up and down and can be disassembled as a whole;

[0044] Installed in the front section of the conveying device, the intelligent dual-mode deviation correction device 3 is used to correct the deviation of the battery roll transmission. The intelligent dual-mode deviation correction device collects the edge of the battery roll and the grid line image including the deviation correction light spot, and determines the battery volume by detecting the deviation correction light spot in the image. offset position;

[0045] The voltage testing device 4 and the surface testing device 5 are installed in the rear section of the conveying device for pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com