Double-layer sheet transverse cutting machine

A cross-cutting machine and sheet material technology, applied in lamination, lamination device, winding strip, etc., can solve the problems of multi-manual operation links, inconsistent size of corrugated paper and bubble paper, inability to place and move, etc., to achieve The effect of high guiding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

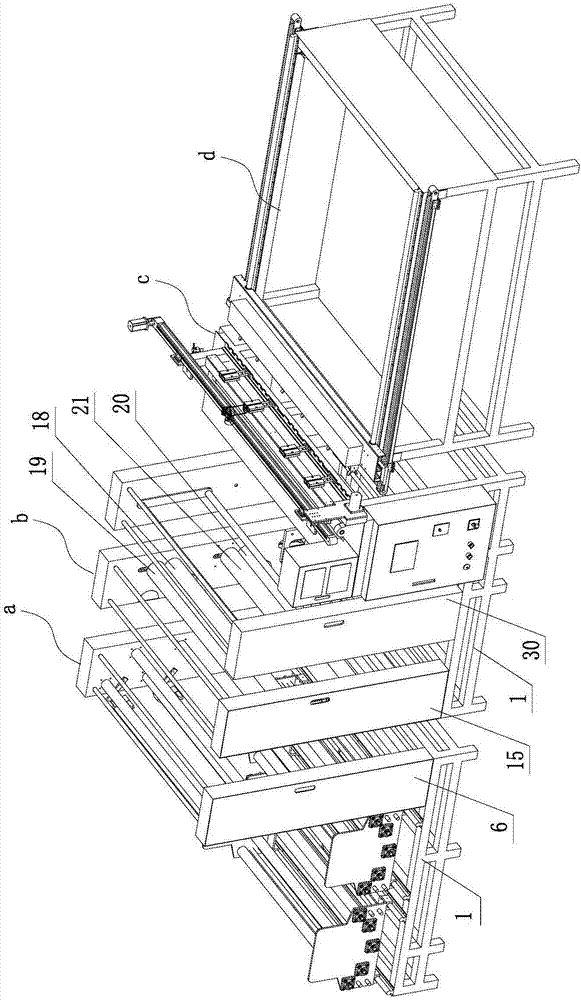

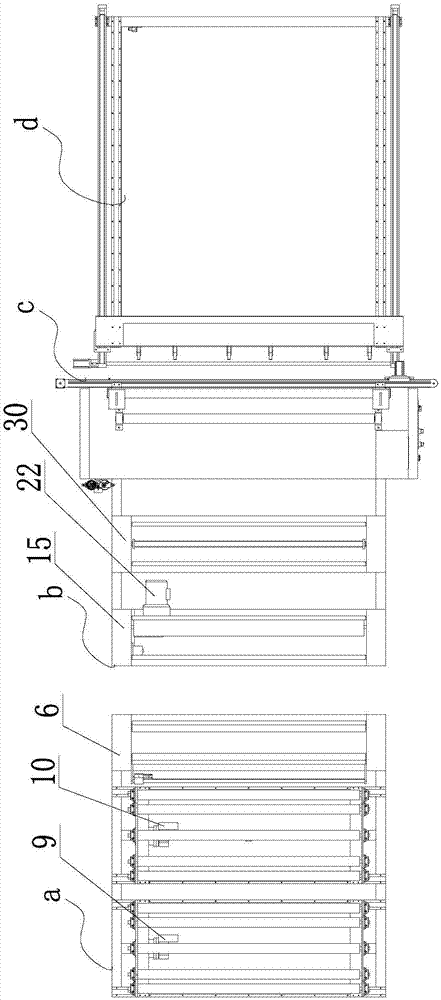

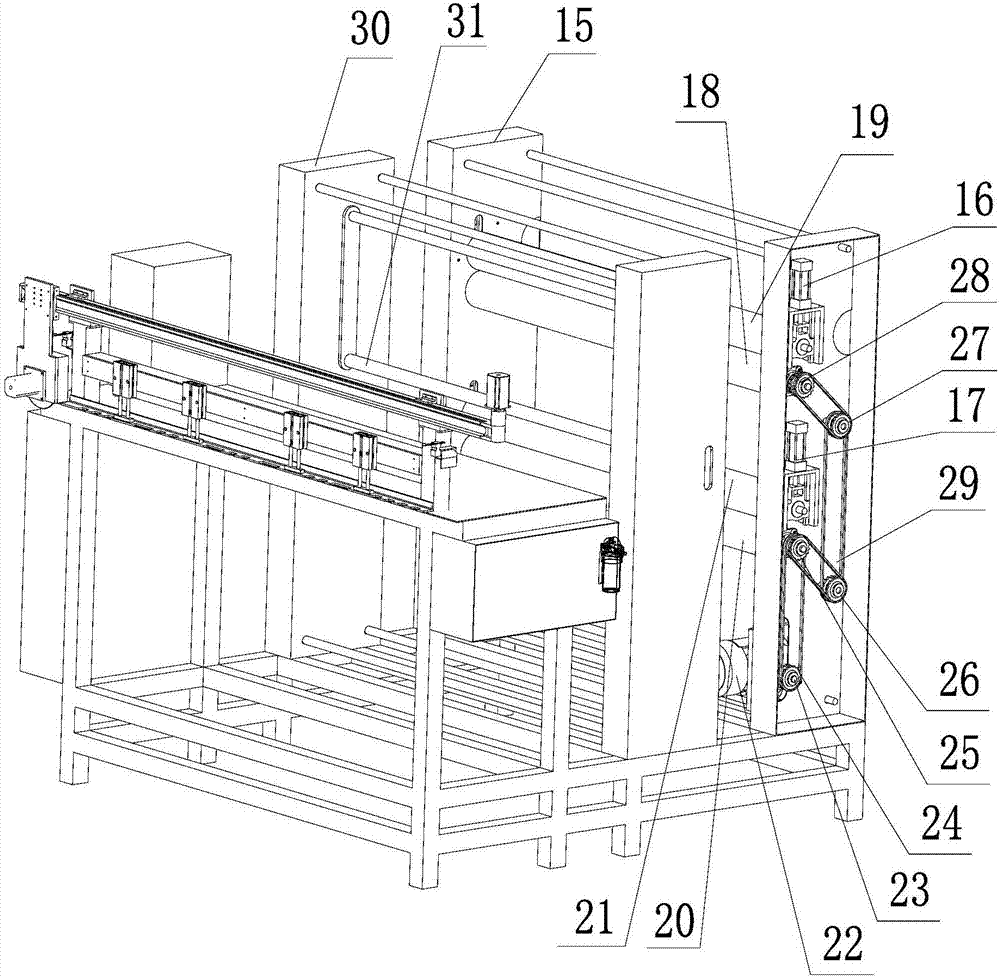

[0044] A kind of double-deck sheet cross-cutting machine of present embodiment, as figure 1 or figure 2 As shown, it includes a support 1, a feeding mechanism a, a traction mechanism b, a cutting mechanism c and a receiving hopper d. According to the conveying direction of the photo material, the discharging mechanism, the drawing mechanism, the cutting mechanism and the receiving hopper are successively arranged on the support; the cutting The mechanism includes a front clamping assembly, a rear clamping assembly, a cross-cutting guide assembly and a circular knife assembly. The front clamping assembly is installed on the bracket, and the rear clamping assembly is installed on the receiving hopper and moves reciprocatingly on the receiving hopper along the sheet conveying direction. The cutting guide assembly is arranged above the front clip assembly, and the circular knife assembly is arranged on the cross-cut guide assembly and moves back and forth along the cross-cut guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com