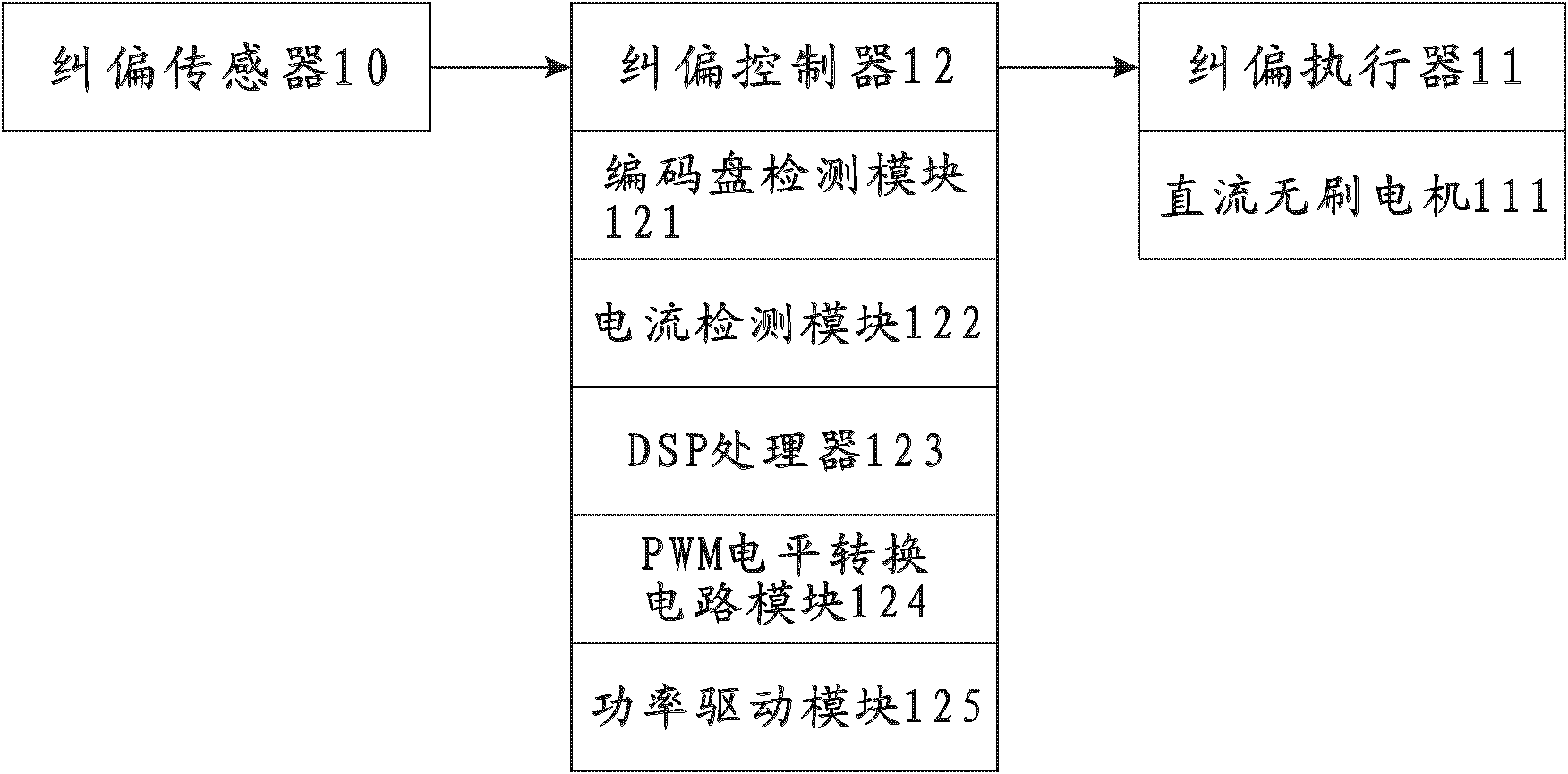

Device and system for controlling deviation correction of brushless direct current (DC) motor

A brushless DC motor and control device technology, applied in the field of electronics, can solve the problems of non-standard motors that need to be customized, closed-loop control of position following, inconvenient installation, etc., and achieves the effect of overcoming easy wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

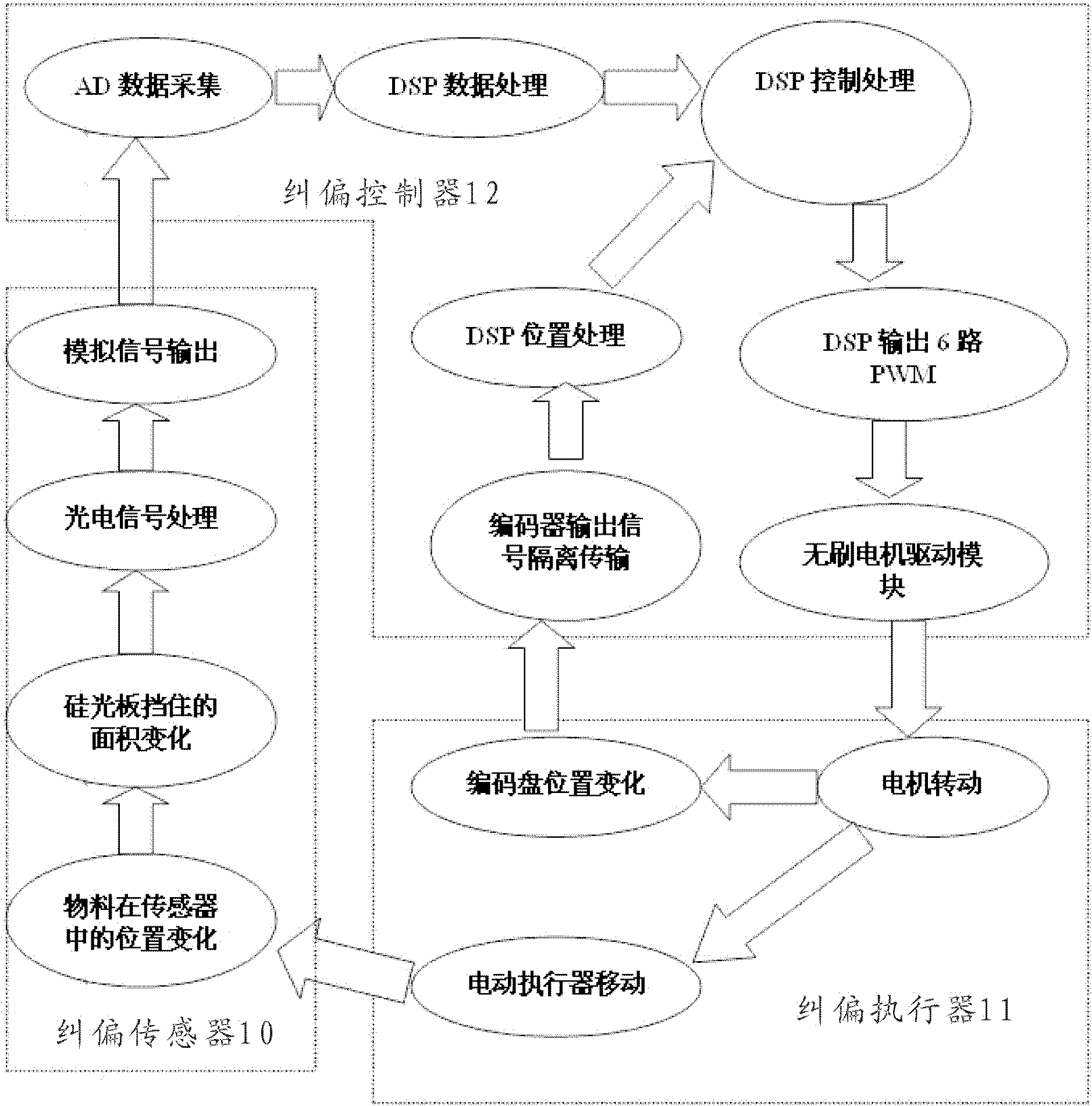

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0023] DSP processor refers to digital signal processor.

[0024] PWM, pulse width modulation, is the abbreviation of "Pulse Width Modulation" in English, referred to as pulse width modulation. It is a very effective technology that uses the digital output of a microprocessor to control analog circuits. It is widely used in measurement, communication into many areas of power control and conversion.

[0025] The stepper motor control system meets high-end requirements by using an external encoder, which is only used for positioning. The main problems are: the non-standard motor needs to be customized; the price of an additional encoder is close to the price of a brushless motor; it is only used for positioning and cannot achieve position f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com