Biaxially-oriented polyester film and preparation method thereof

A biaxially stretched polyester and film technology, applied in chemical instruments and methods, other household appliances, household components, etc., can solve the problems of antistatic effect decline, large film haze, environmental pollution, etc., and achieve long-lasting antistatic effect , reduce haze, improve the effect of optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

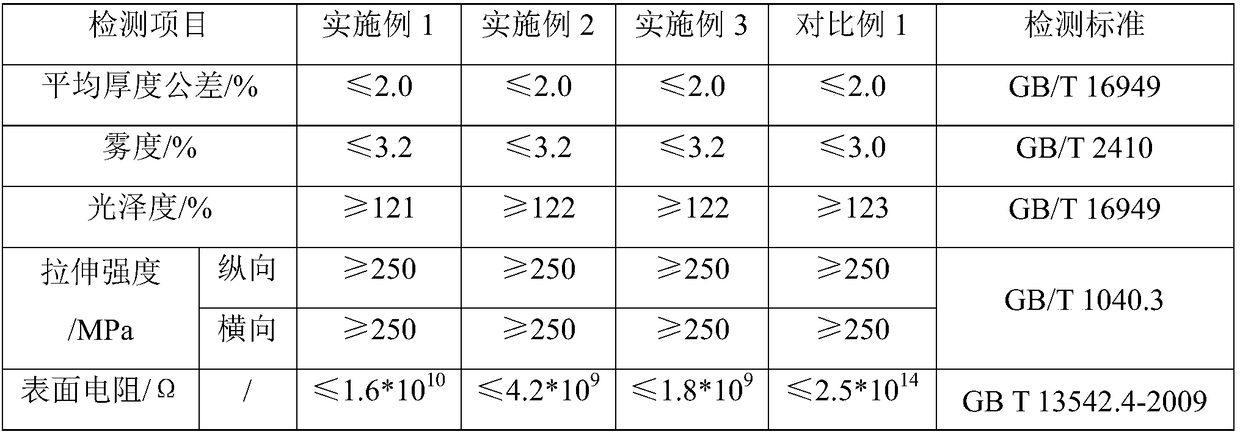

Examples

Embodiment 1

[0032] A BOPET film with a thickness of 15 μm is composed of an upper surface layer, a core layer and a lower surface layer, wherein the thicknesses of the upper surface layer and the lower surface layer are respectively 12% of the total thickness of the BOPET film.

[0033] The core layer is composed of 100wt% polyester chips;

[0034] The upper surface layer is an anti-adhesive layer, and the anti-adhesive layer is composed of 40wt% polyester chips and 60wt% glass microbead anti-adhesive masterbatch, wherein the glass microbead anti-adhesive masterbatch is made of a particle size of 2.0 μm, Consists of glass microspheres and polyester chips with a content of 3000ppm.

[0035] The lower surface layer is an antistatic layer, and the antisticking layer is made of 85wt% polyester chips and 15wt% antistatic masterbatch, wherein the antistatic masterbatch is made of nonionic ethoxylated alkylamine, anionic alkane Sodium sulfonate and polyester chips are blended, extruded and drie...

Embodiment 2

[0043] A kind of BOPET film, its thickness is 12 μm, is made of upper surface layer, core layer and lower surface layer, wherein the thickness of upper surface layer and lower surface layer is respectively 15% of the total thickness of described biaxially stretched polyester film.

[0044] The core layer is composed of 100wt% polyester chips;

[0045] The upper surface layer is an anti-adhesive layer, and the anti-adhesive layer is composed of 45wt% polyester chips and 55wt% glass microbead anti-adhesive masterbatch, wherein the glass microbead anti-adhesive masterbatch is made of a particle size of 2.2 μm, Consists of glass microspheres and polyester chips with a content of 3000ppm.

[0046] The lower surface layer is an antistatic layer, and the antisticking layer is made of 90wt% polyester chips and 10wt% antistatic masterbatch, wherein the antistatic masterbatch is made of nonionic ethoxylated alkylamine, anionic alkyl Sodium sulfonate and polyester chips are blended, ext...

Embodiment 3

[0054]A kind of BOPET film, its thickness is 20 μm, is made of upper surface layer, core layer and lower surface layer, wherein the thickness of upper surface layer and lower surface layer is respectively 13% of the total thickness of described biaxially stretched polyester film.

[0055] The core layer is composed of 100wt% polyester chips;

[0056] The upper surface layer is an anti-adhesive layer, and the anti-adhesive layer is composed of 50wt% polyester chips and 50wt% glass microbead anti-adhesive masterbatch, wherein the glass microbead anti-adhesive masterbatch is made of a particle size of 2.5 μm, Consists of glass microspheres and polyester chips with a content of 3000ppm.

[0057] The lower surface layer is an antistatic layer, and the antisticking layer is 95wt% polyester chips and 5wt% antistatic masterbatch, wherein the antistatic masterbatch is made of nonionic ethoxylated alkylamine, anionic alkyl Sodium sulfonate and polyester chips are blended, extruded and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com