Belt drive

A transmission, main vibration technology, used in transmissions, valve drives, valve devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

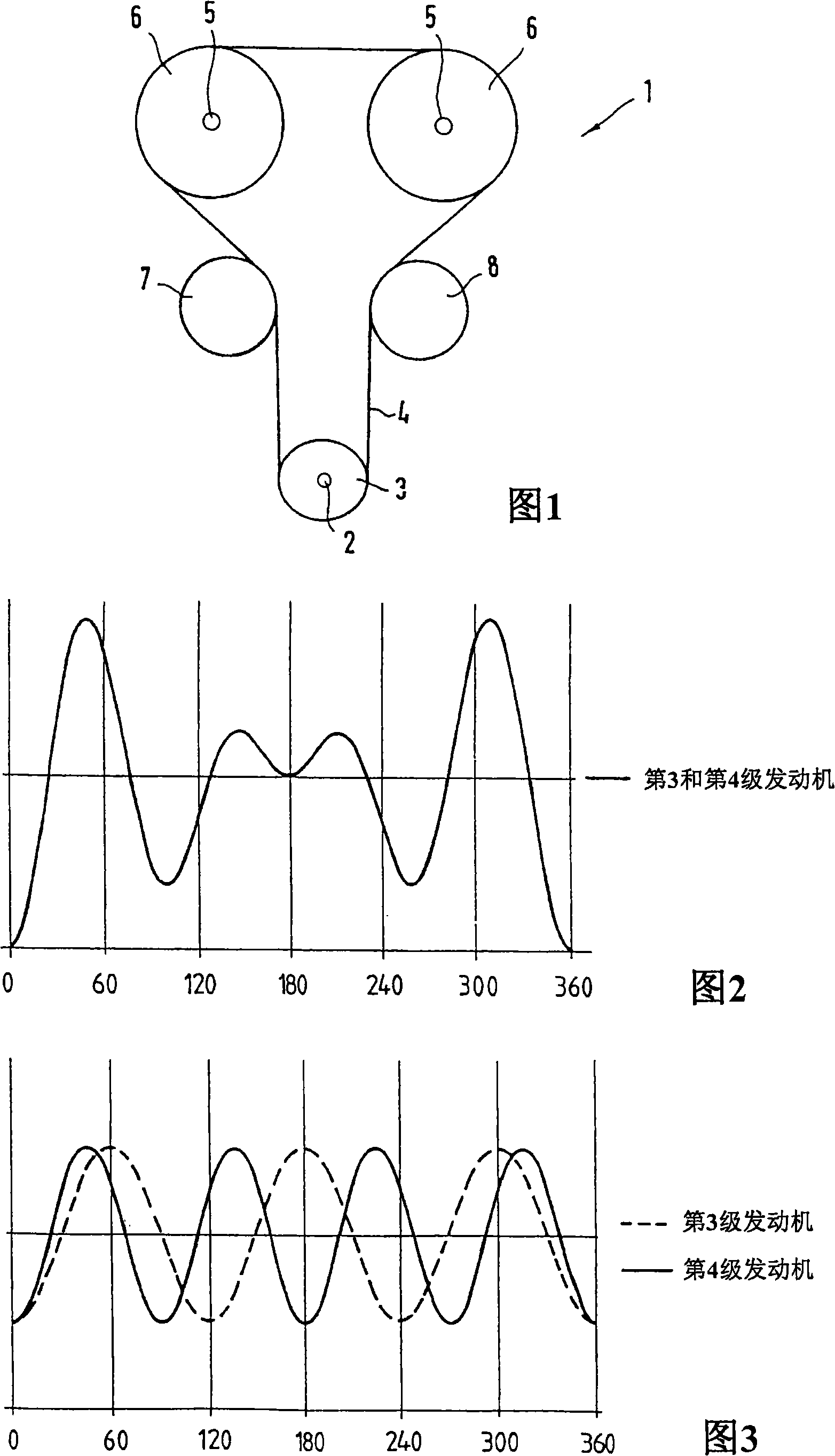

[0019] FIG. 1 shows a schematic diagram of a conventional winding transmission 1 , such as is found, for example, in internal combustion engines of motor vehicles. Located on the crankshaft 2 is a first pulley 3 which is wound by a traction element 4 (belt or chain). On each of the two camshafts 5 is seated a wheel 6 which is likewise wound by the traction element 4 . Furthermore, there is a tensioning device 7 which can be a tensioning pulley if the traction means 4 is a belt. If the traction means 4 is a chain, the tensioning device 7 is designed as a tensioning disk. On the opposite return section of the traction element 4 there is a guide 8 by which the traction element 4 is guided. On a belt, the guide 8 is a deflection wheel, in the case of a chain it is a guide rail. The basic structure of the winding drive is already known and does not need to be described in detail.

[0020] During operation, disturbing vibrations are transmitted to the winding drive 1 or the trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com