Winding device for wire material with rectangular section

A technology of rectangular cross-section and winding device, applied in the field of winding technology, can solve problems such as cost increase, product appearance deterioration, complex winding device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

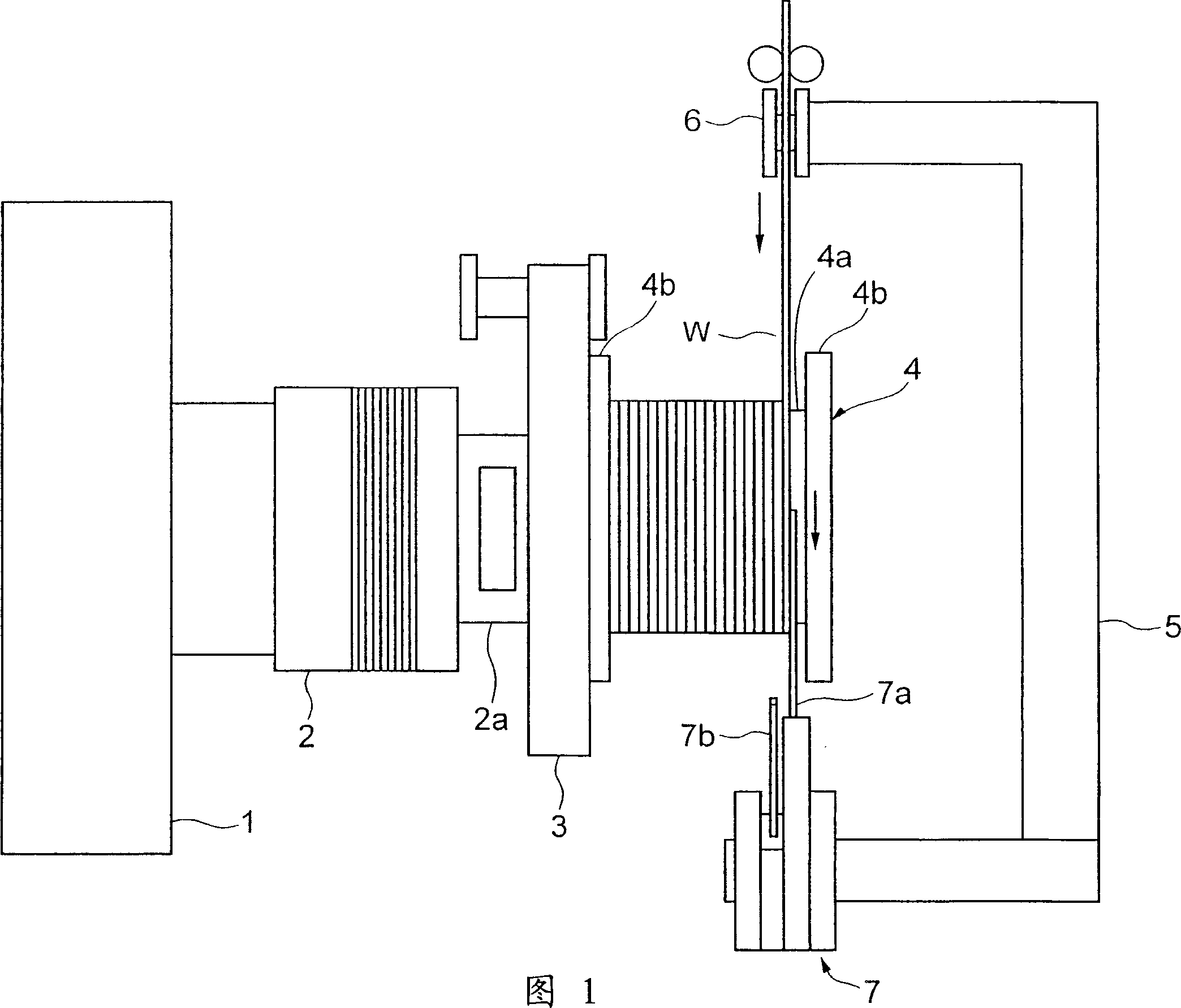

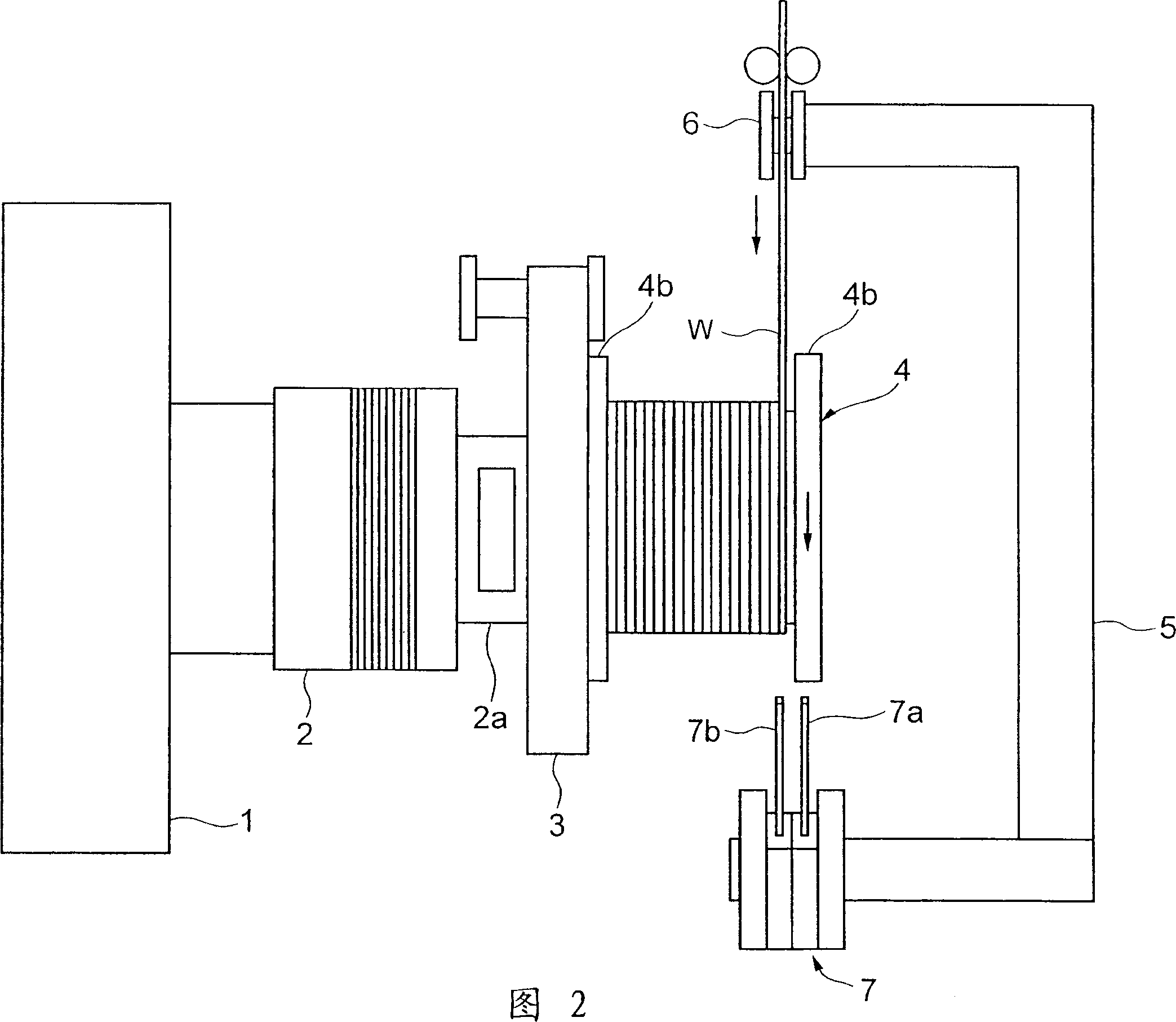

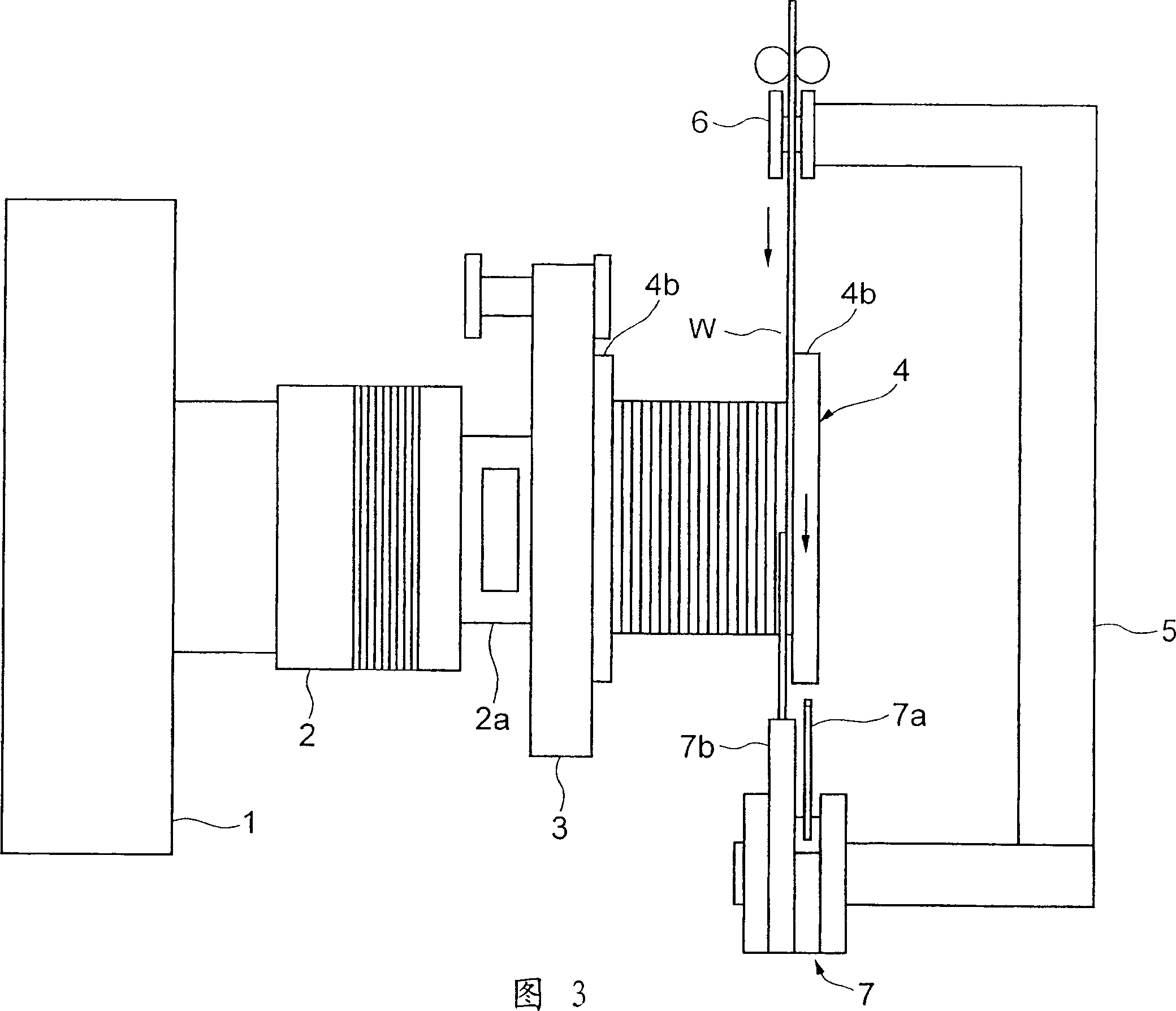

[0053] Hereinafter, various embodiments of the present invention will be described with reference to the accompanying drawings. 1 to 3 are top views illustrating a wire winding device according to an embodiment of the present invention. In each figure, the motor 3 is fixed to the first bracket 1 . The holding portion 3 is mounted to the rotating shaft 2a of the motor 2, which serves as a driving portion. The holding portion 3 holds the bobbin 4 concentrically with the rotation shaft 2a. The bobbin 4 has a cylindrical portion 4a as a winding portion, and flange portions 4b, 4b formed at both ends in the axial direction. In this regard, in the present invention, the length of the cylindrical portion 4a of the bobbin 4 is approximately six times the width of the regular square wire (see Figures 4A to 4K ).

[0054] Meanwhile, contrary to the first bracket, the second bracket 5 is movably provided by a driving source not shown. The tensioning wheel 6 is supported by the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com