Process and device for rewinding feed spools

A yarn and yarn guide technology is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing. It can solve problems such as reducing yarn quality, reduce yarn breakage, improve process conditions, and achieve high winding speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

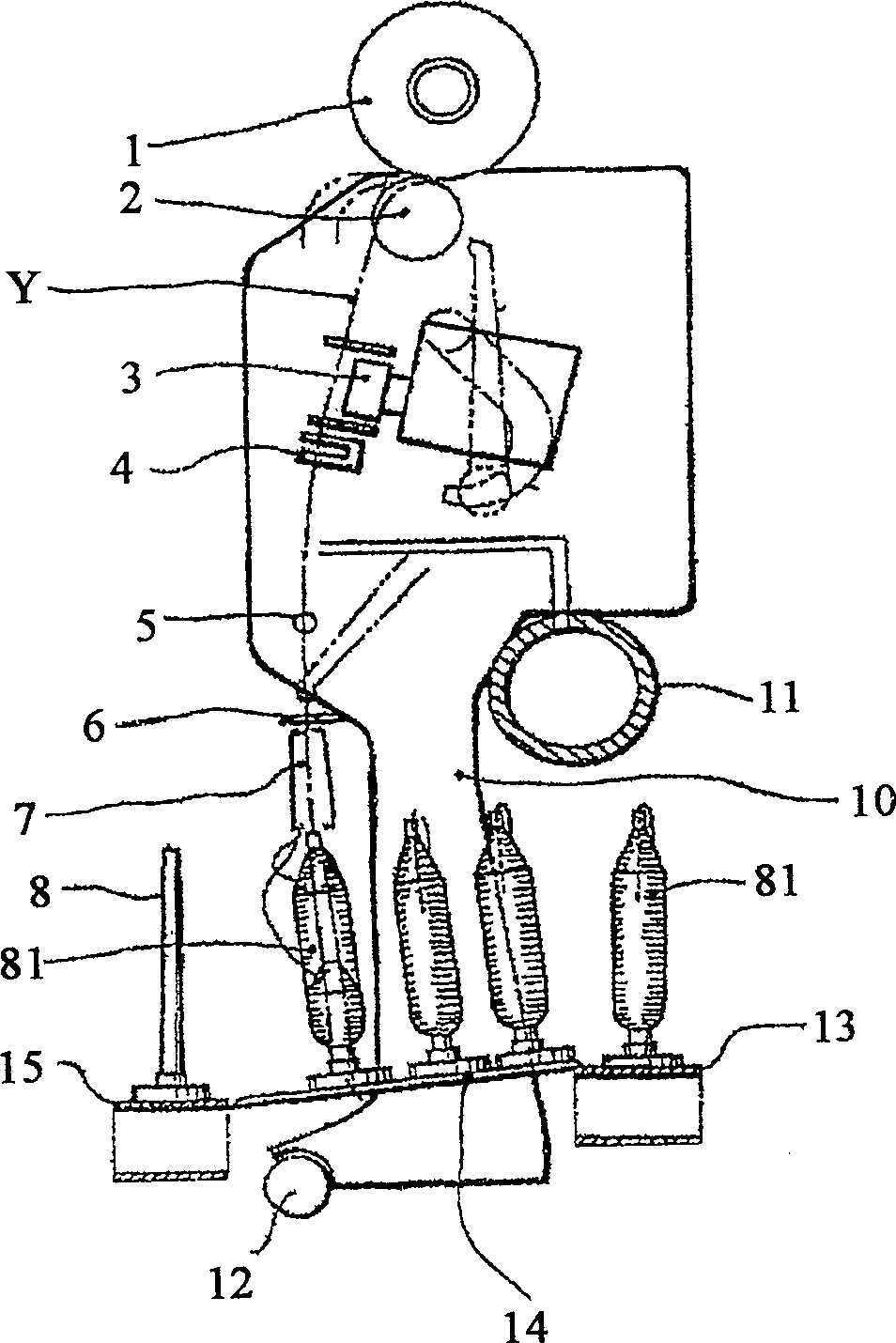

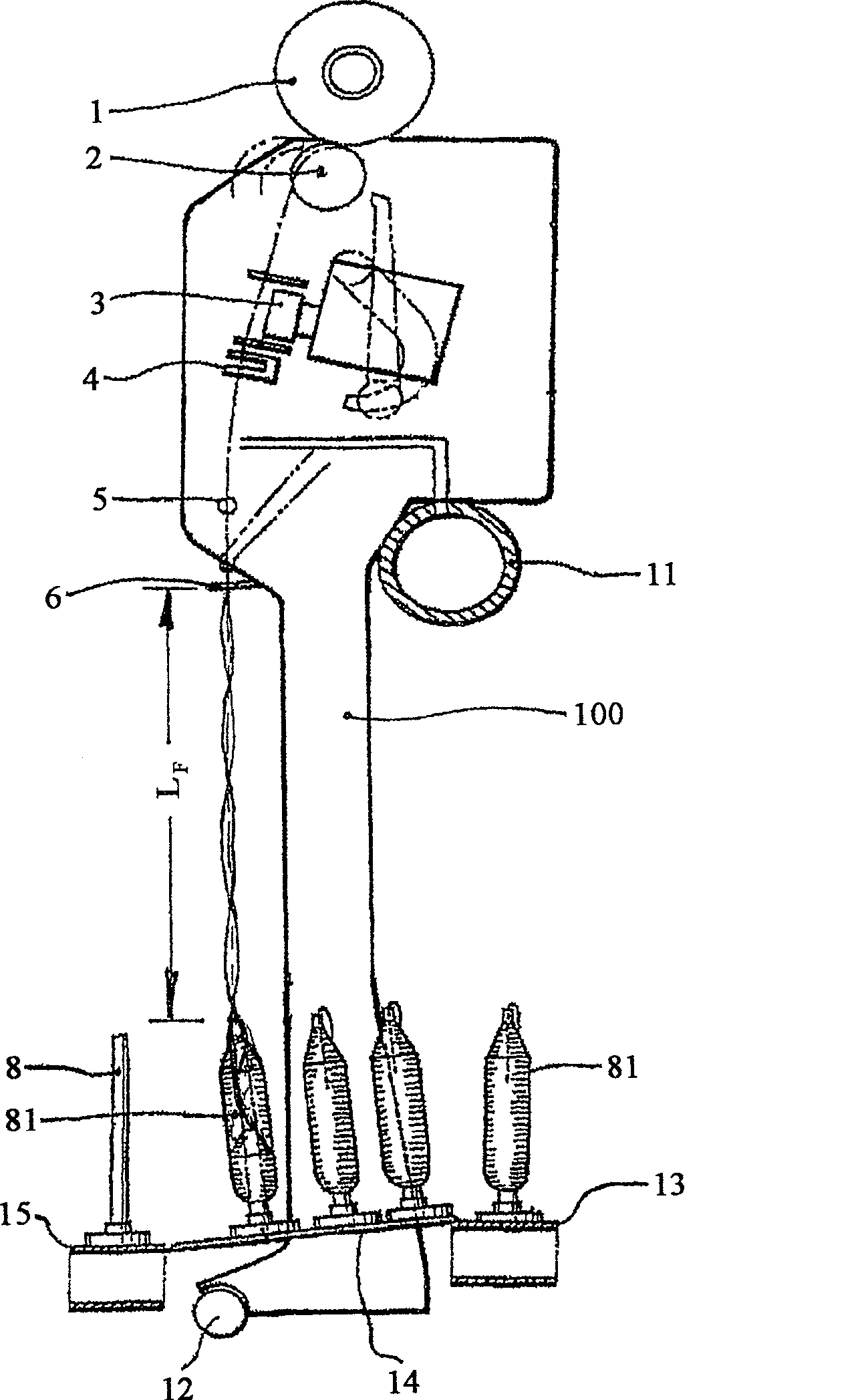

[0020] figure 1 A conventional design is shown in the winding state, with a winding spool 1 , which is generally configured as a conical or cylindrical crossing spool and is driven by a winding roller or grooved drum 2 . Here, the yarn Y is withdrawn from the weft tube or from the yarn supply shaft 81 via the top of the yarn tube 8 . Between the top of the bobbin 8 and the winding bobbin 1, a yarn guide 6, a tensioning device 5, a slub defect detector 4 and a splicing device 3 are generally arranged. Between the yarn Y take-off point at the weft tube 81 and the yarn guide 6 a yarn balloon is formed which, due to the centrifugal force of the yarn Y linked to the unwinding speed, causes a very high yarn tension and thus limits the unwinding speed. Therefore, if figure 1 As shown in , the balloon breaking device 7 is arranged above the weft tube 81 in front of the yarn guide 6 to prevent the formation of a larger balloon. The weft tubes 81 are conveyed by means of the supply ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com