Energy-saving yarn-singeing burner

A combustion device and energy-saving technology, applied in singeing, textile and papermaking, fabric surface trimming, etc., can solve problems such as low efficiency and reduced consumption of liquefied petroleum gas, so as to reduce consumption and save consumption ,Singeing effect and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The features of the present invention can be illustrated by the following structural diagrams and examples.

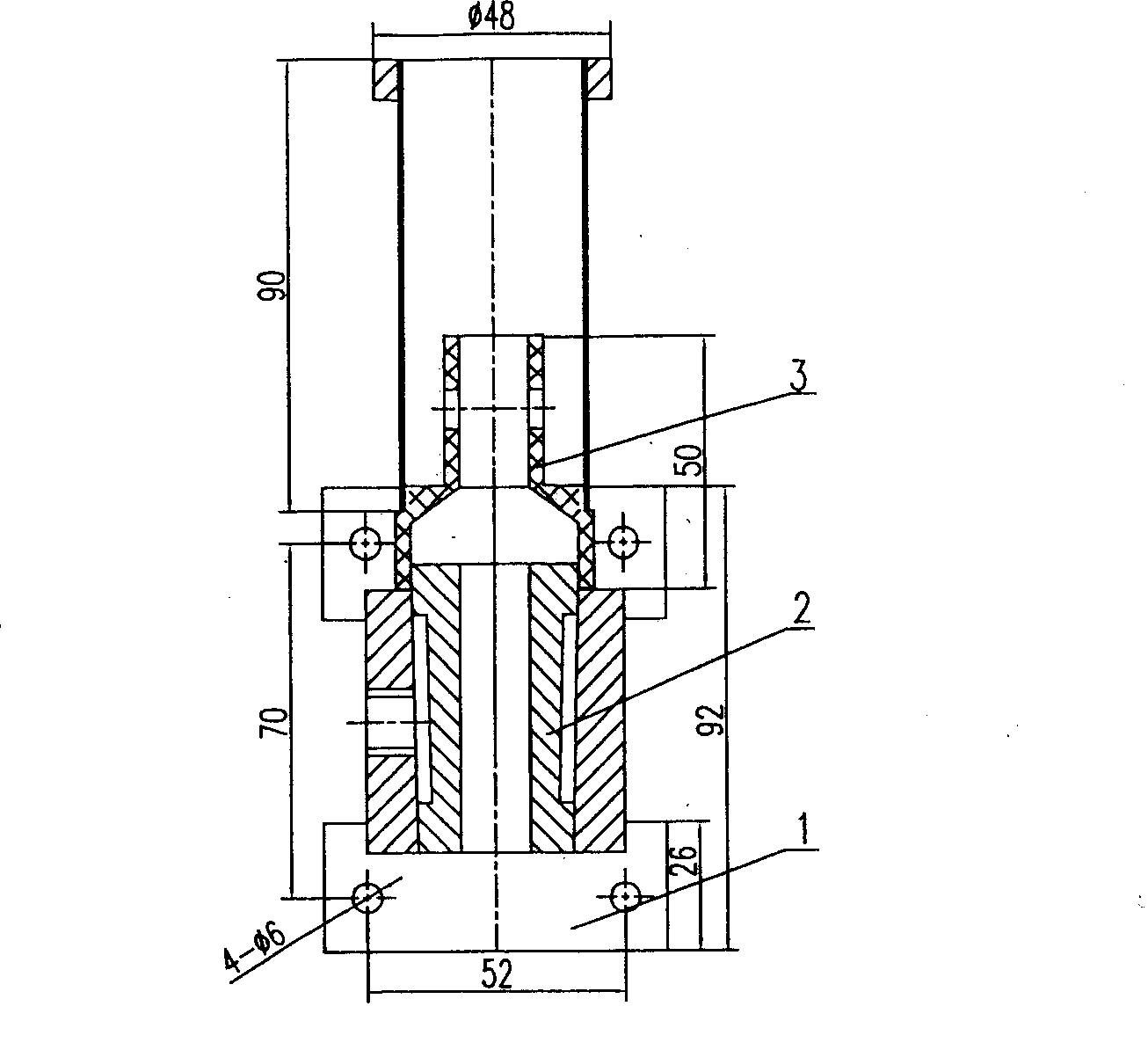

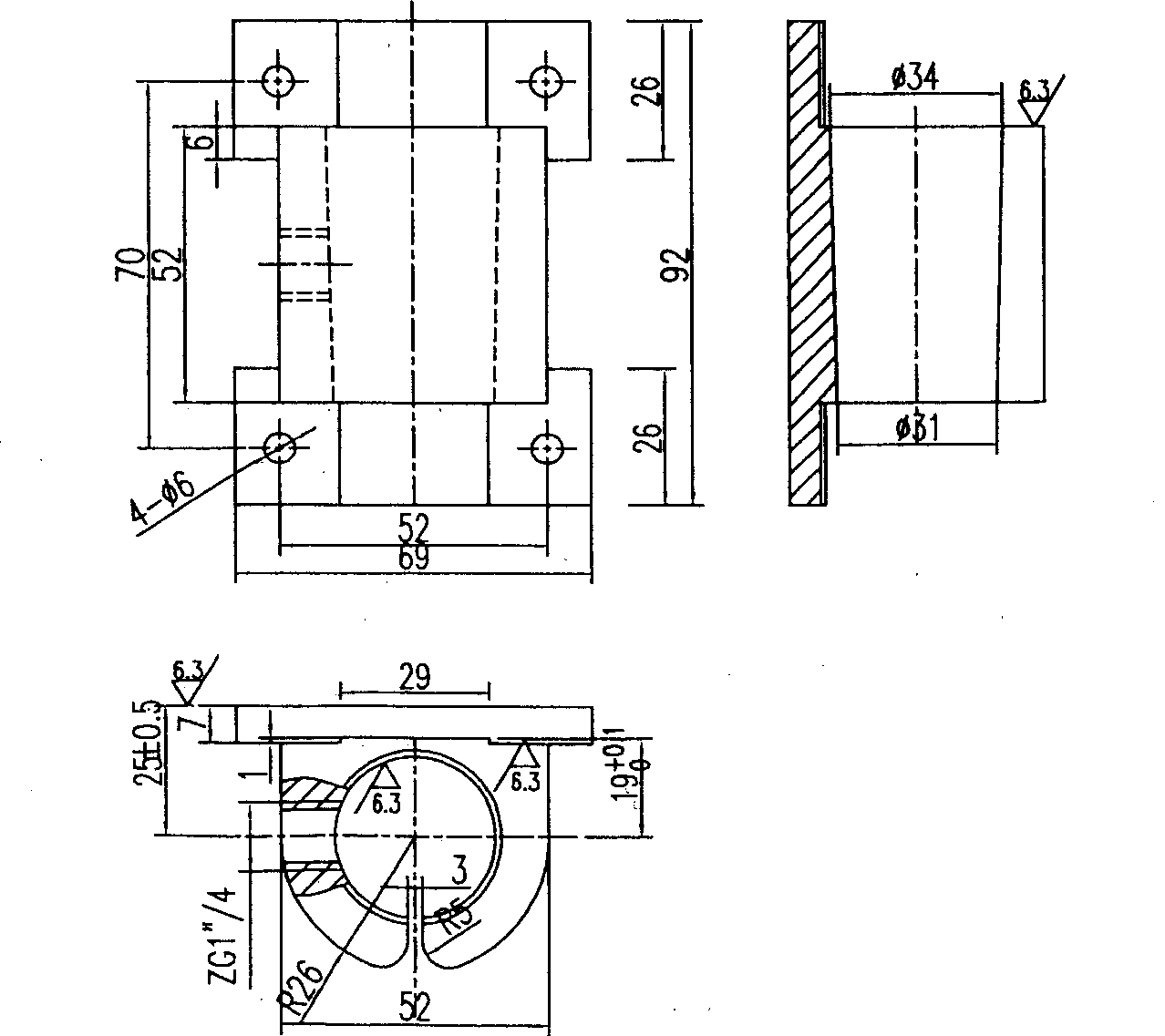

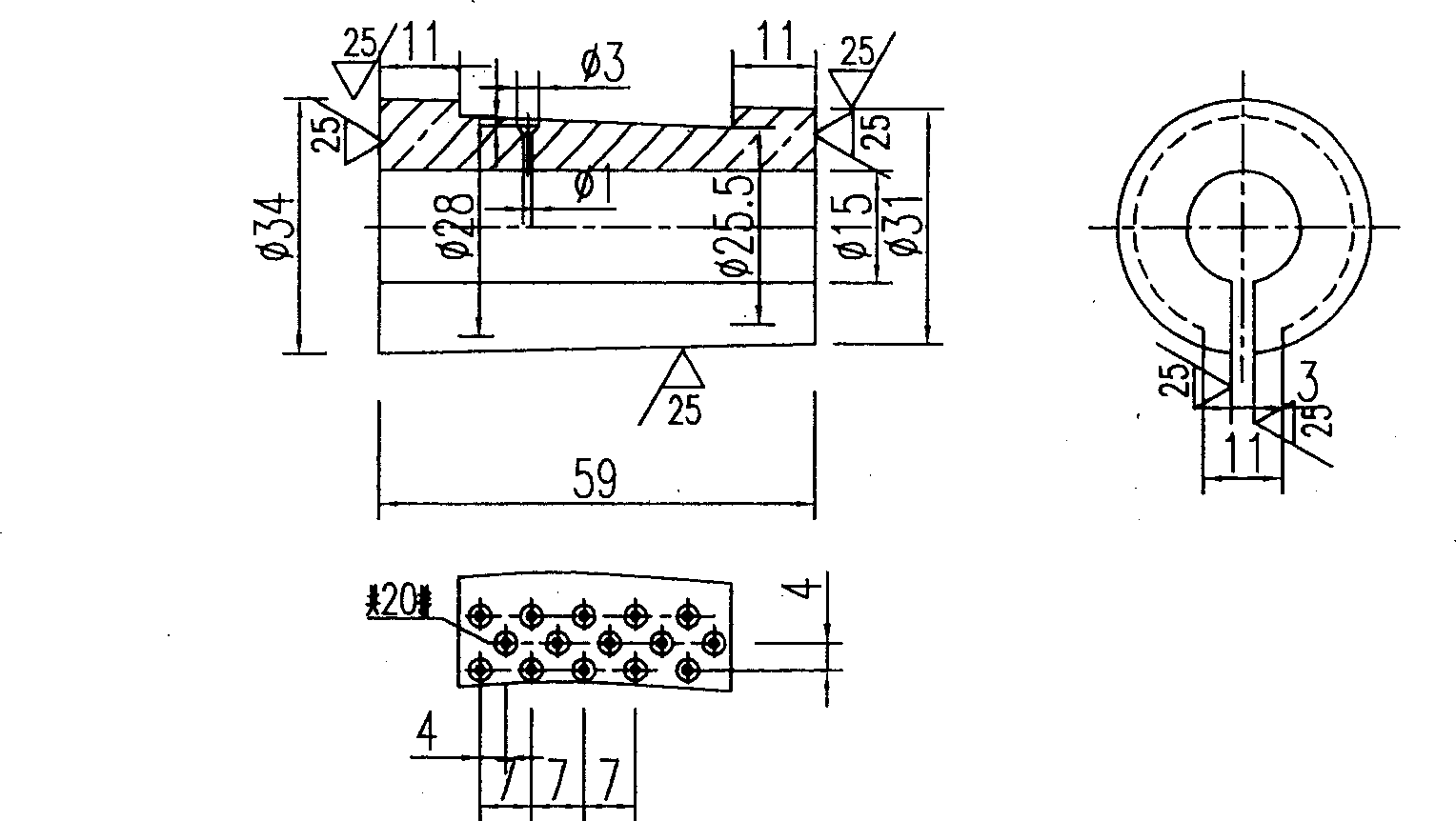

[0019] figure 1 It shows the sectional view of the assembly of the yarn singeing combustion device in this embodiment; among the figures, 1 is the burner seat, 2 is the combustion tube, and 3 is the combustion cover. figure 2 It shows the structure diagram of the burner seat of the yarn singeing combustion device in this embodiment; image 3 It shows the structural diagram of the combustion tube of the yarn singeing combustion device in this embodiment.

[0020] The steps of the embodiment are: on the yarn singeing machine, the mixed gas of air and liquefied petroleum gas (mixed gas for short) enters from the entrance next to the burner seat; because the upper and lower parts of the burner seat and the combustion tube are basically sealed , so the mixed gas first enters the cavity of the burner seat and the middle part of the combustion tube, and enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com