Peanut shelling device for agricultural production

A peanut and agricultural technology, applied in the field of peanut shelling devices for agricultural production, can solve the problems of single shelling method and unshelled peanuts, etc., and achieve the effects of improving screening effect, increasing functionality, and good shelling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

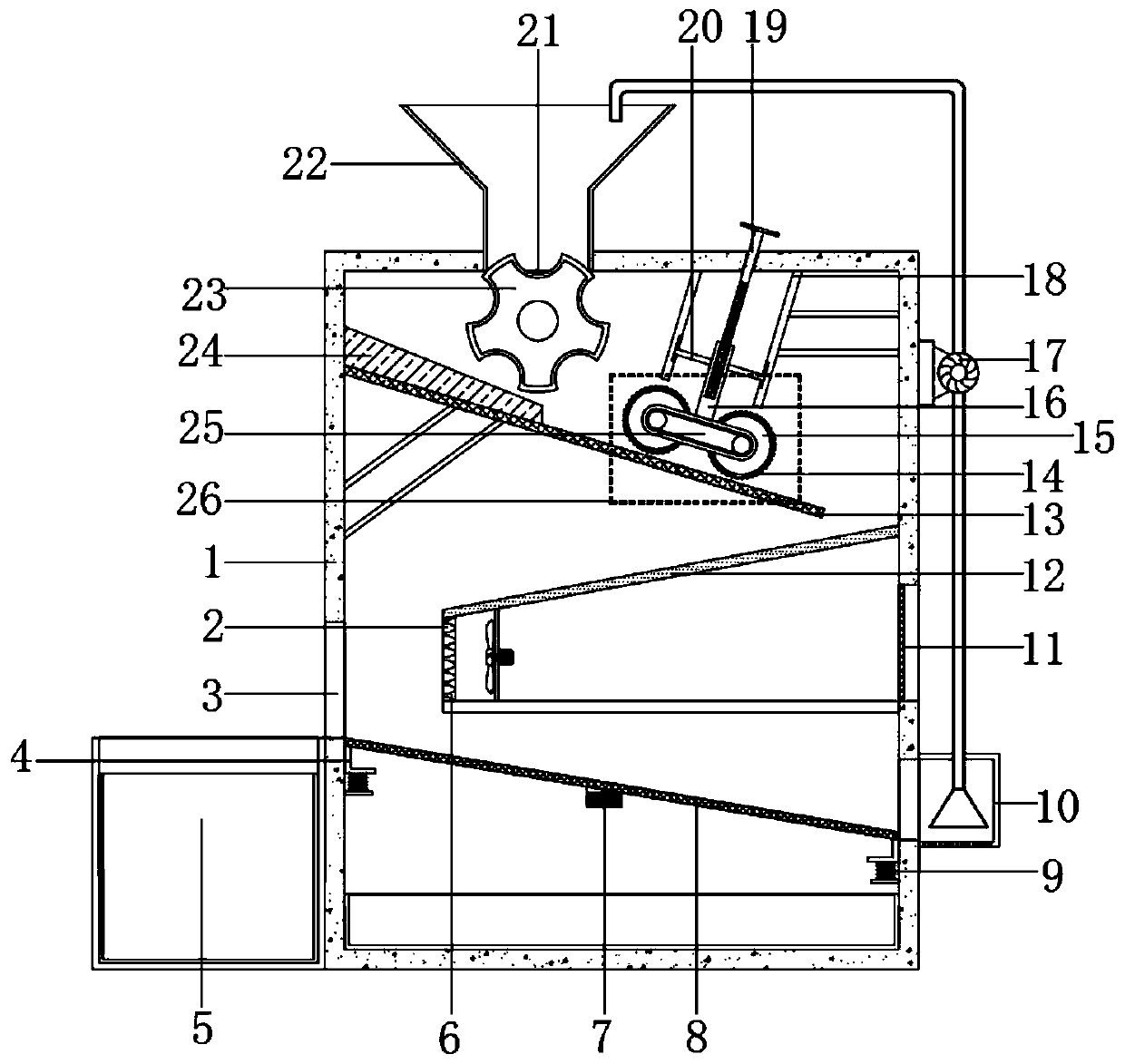

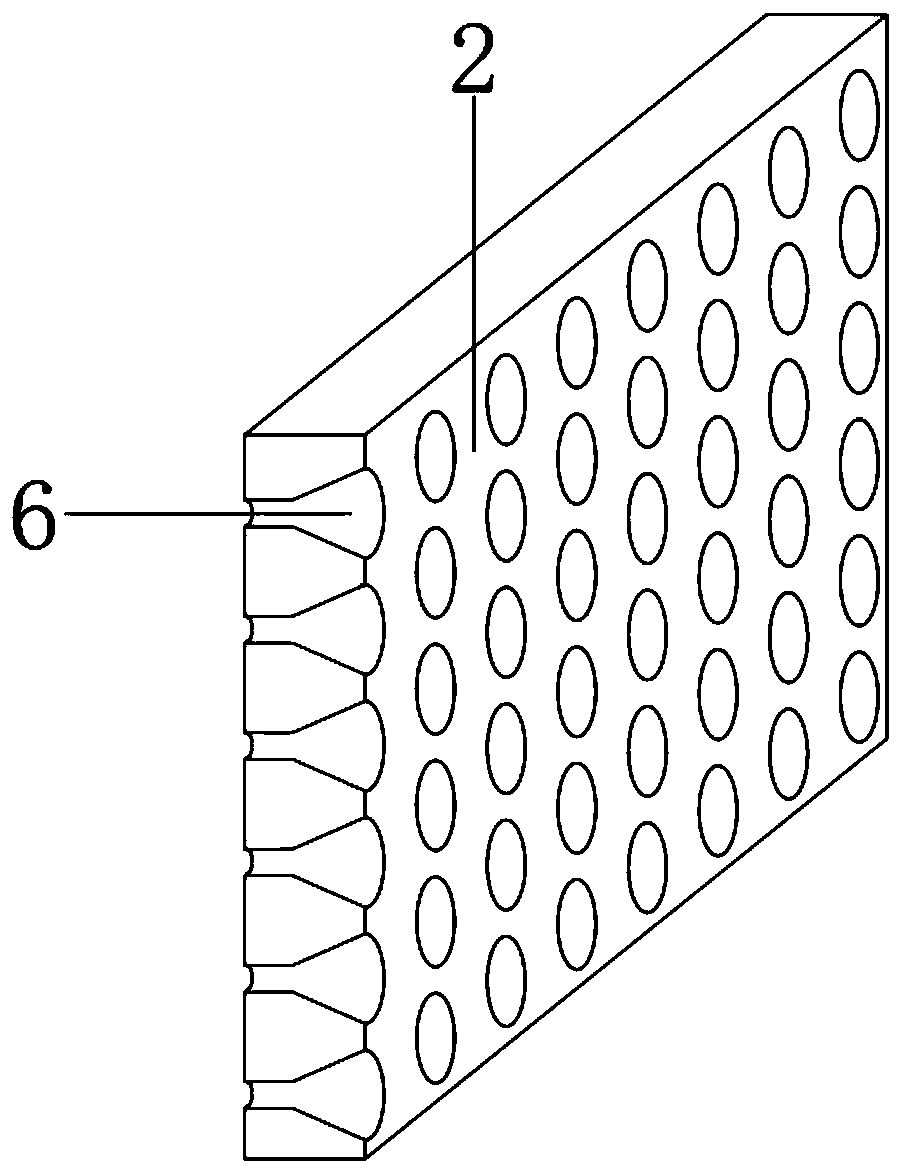

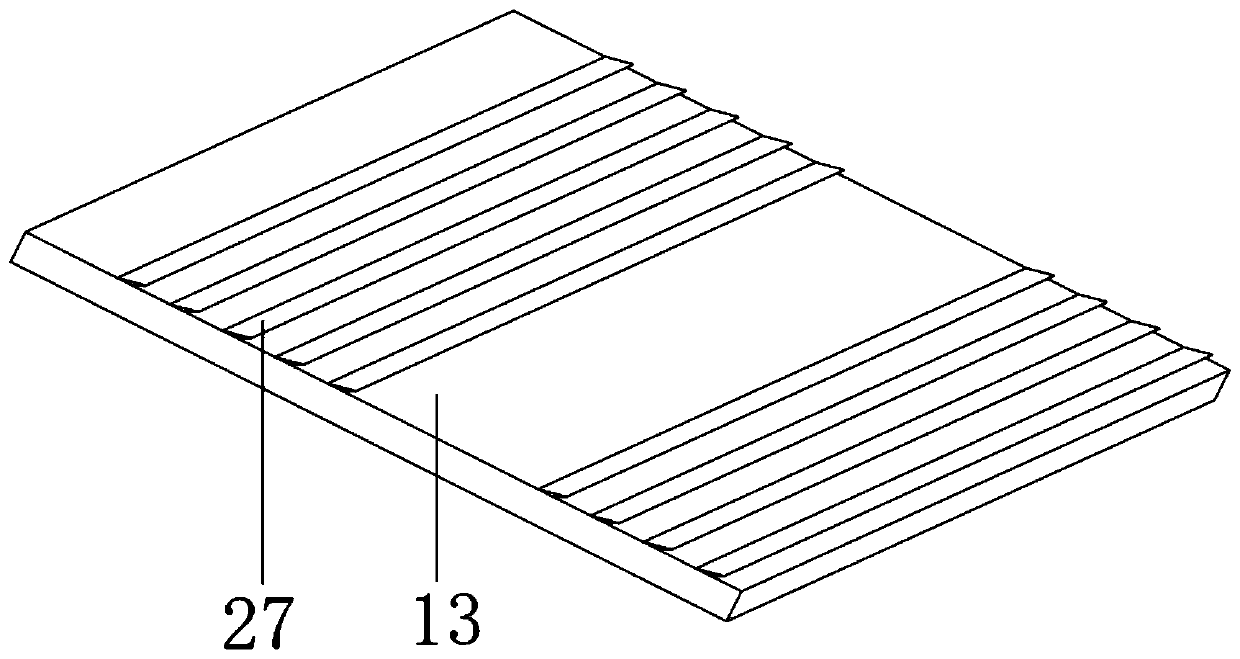

[0030] refer to Figure 1-5 , a peanut shelling device for agricultural production, comprising a box body 1 and a hopper 22 welded to the top side of the box body 1, the side of the box body 1 close to the hopper 22 is rotatably connected with a feeding roller 23 through a bearing, and One end of the unloading roller 23 is connected with a deceleration motor through a coupling, and the outer wall of the unloading roller 23 is provided with arc-shaped unloading grooves 21 distributed equidistantly, and the side of the box body 1 close to the unloading roller 23 is welded with an inclined The set blanking plate 13, the end of the blanking plate 13 is welded with equidistantly distributed triangular strip plates 27, and one end of the blanking plate 13 is fixed with a rolling block 24 by bolts, and the rolling block 24 is close to one end of the blanking roller 23 The arc surface strips 28 distributed equidistantly are bonded, and the prediction of the box body 1 close to the tri...

Embodiment 2

[0041] refer to figure 1 , a peanut shelling device for agricultural production. Compared with Embodiment 1, this embodiment also includes a blanking plate 13, a fixed inclined bar 18 and a reinforcing bar fixed on the opposite side of the box body 1 by bolts, and the box body 1 A transparent observation window 26 is fixedly installed near the side of the shell grinding mechanism.

[0042] When the present invention is in use: utilize reinforcing bar to effectively improve the structural strength of blanking plate 13, fixed inclined bar 18, through the setting of transparent observation window 26, convenient operator observes the distance between grinding roller 15 and blanking plate 13, with It is convenient for the operator to rotate the screw mandrel 19 for adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com