Flying fork type winding machine and working method thereof

A technology of winding machine and winding mechanism, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of large wear and tear of enameled wires, affecting product quality, and damage to enameled wires, so as to improve the accuracy of wiring and winding. The effect of speed, improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

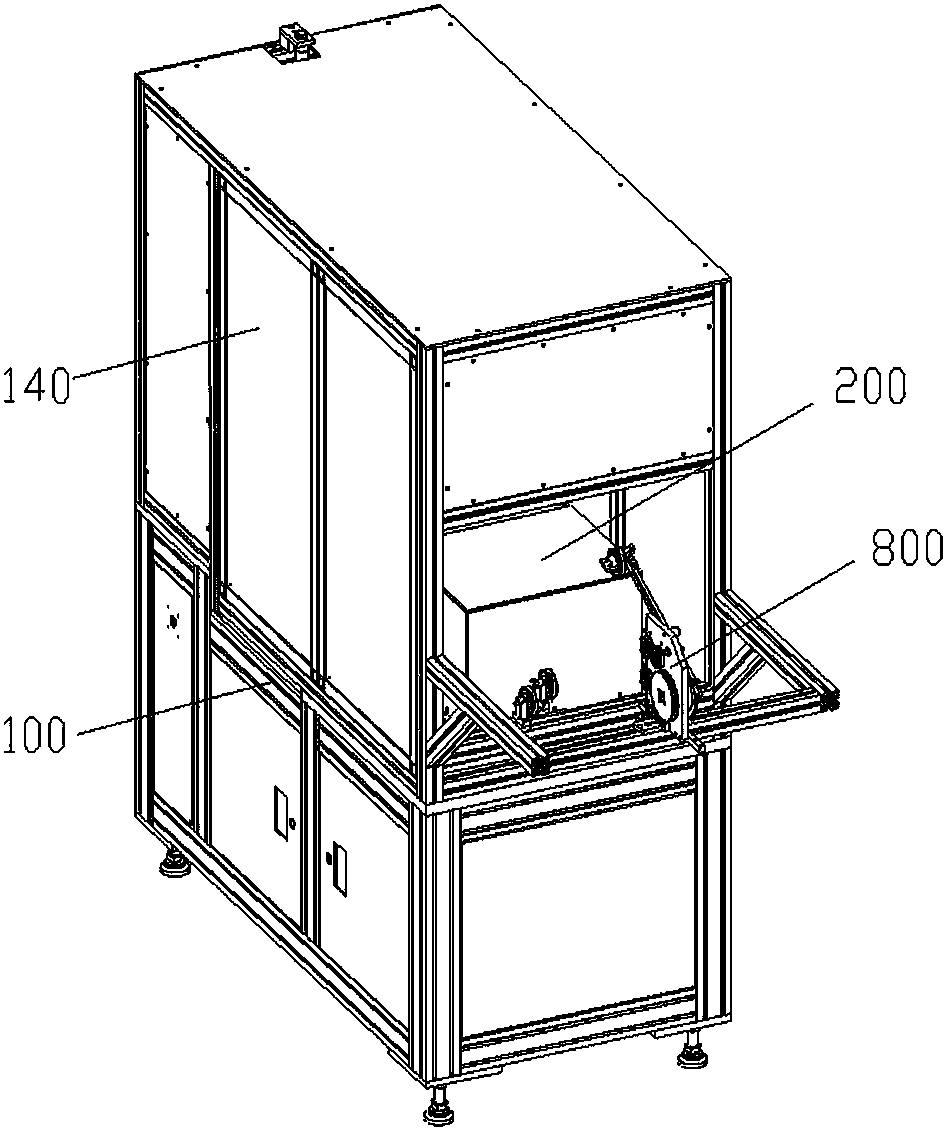

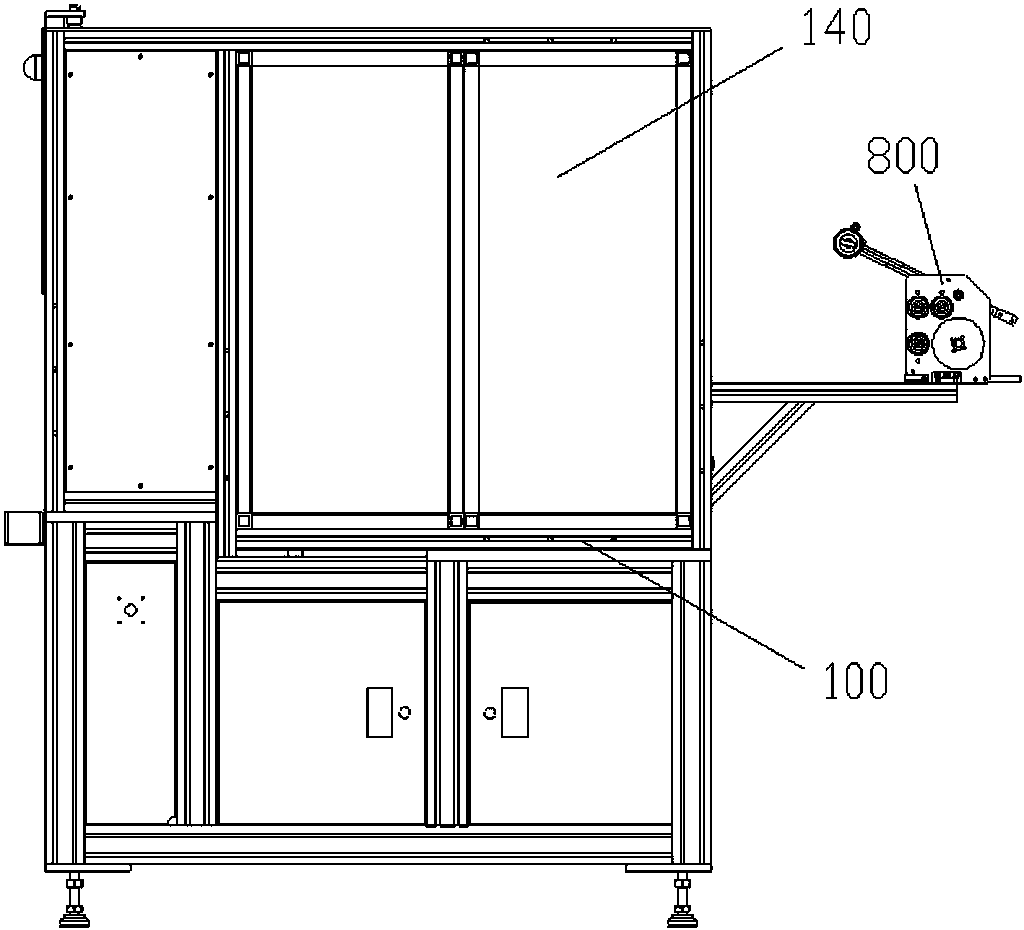

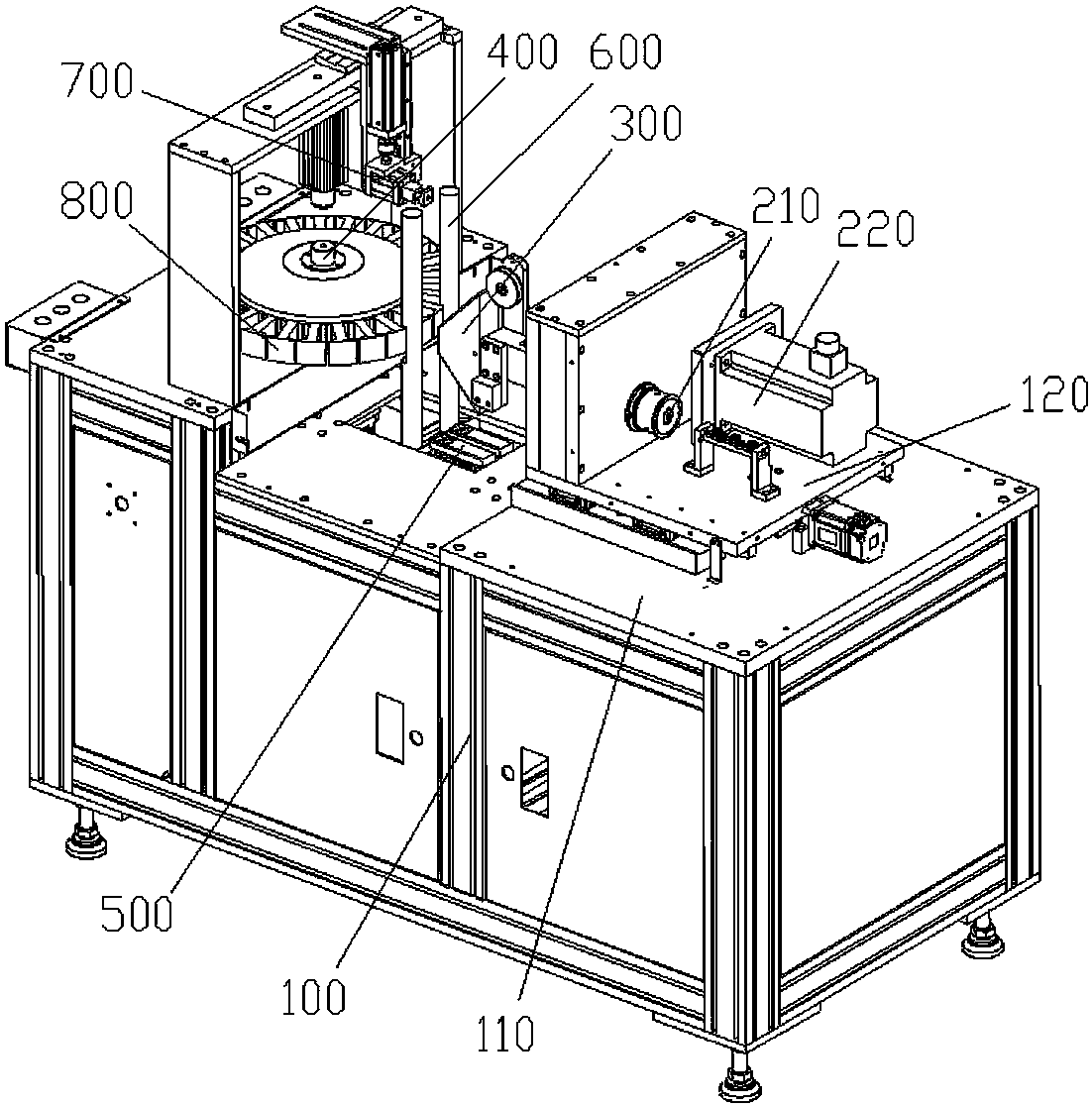

[0030] Such as Figure 1~10 As shown, a flying fork type winding machine includes a body 100 with a table 110, a headstock 200 capable of moving back and forth is installed on the table 110 of the body 100, and a center with a threading hole is installed in the headstock 200 The main shaft 210, the front end of the main shaft is equipped with a winding mechanism 300 for winding, and the table 110 of the body 100 is also equipped with an installation mechanism 400 located in front of the winding mechanism 300 for installing the stator core. The winding mechanism 300 includes a flying fork 310 installed at the front end of the main shaft and a trapezoidal wire slider 320 with a small front and a large rear for forcing the enameled wire to slide into the teeth of the stator core. The liftable positioning mechanism 500, the front of the winding mechanism 300 is provided with a pair of wire protection rods 600 used to block between the stator core and the winding mechanism to preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com