High-sulfating chondroitin sulfate (CS) and preparing method and application thereof

A technology of chondroitin sulfate and high sulfuric acid, applied in the biological field, to achieve mild reaction conditions, strong anti-tumor metastasis activity, and high market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A preparation method of highly sulfated chondroitin sulfate, comprising the steps of:

[0058] (1) After crushing 1 kg of American red squid (Dosidicus Gigas) cartilage, add 3 times the volume of absolute ethanol to dehydrate and degrease for 24 hours, filter, repeat the steps of dehydration and degreasing 3 times, then dry and weigh at 50°C to obtain defatted cartilage ;

[0059] (2) Submerge the degreased cartilage prepared in step (1) with water, treat it in a water bath at 100°C for 30 minutes, cool to room temperature and filter, add 20 times the volume of calcium chloride borate buffer solution (0.1M boric acid, 10mM calcium chloride , pH8.0) and mix well, add Aspergillus niger protease (purchased from TCI company) with a dry weight of 2‰ of raw materials, react at 60°C for 72h, add enzyme once every 24h, and the amount of enzyme added is gradually reduced to the last enzyme added 0.5 times the amount, add twice in total, inactivate the enzyme at 100°C for 10 min...

Embodiment 2

[0062] The purity analysis of embodiment 2, DG-CS

[0063] 2.1 Analysis of protein and glycosaminoglycan content

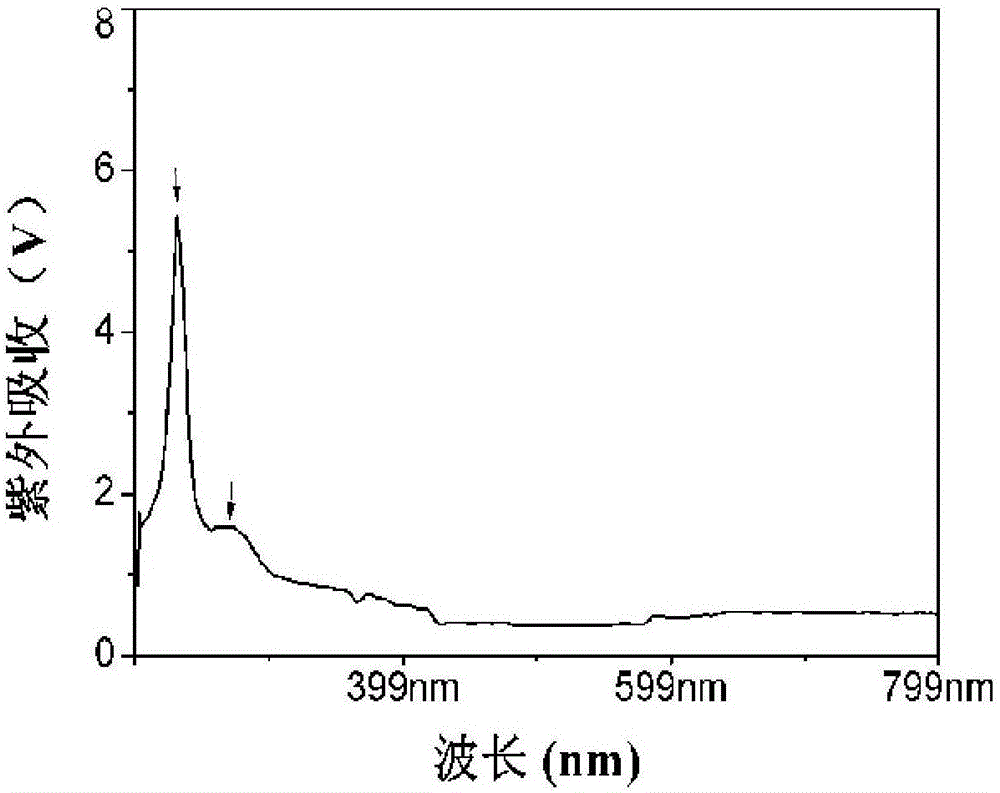

[0064] Using carbazole reaction, BCA protein assay kit, full-wavelength scanning and other technical means to test the purity of the prepared DG-CS, it was found that the protein content in the sample was less than 2%, and the protein absorption peak near 280nm was extremely small, such as figure 1 Shown; The glycosaminoglycan content measured by the carbazole reaction is more than 97%, and the recovery rate is 20%.

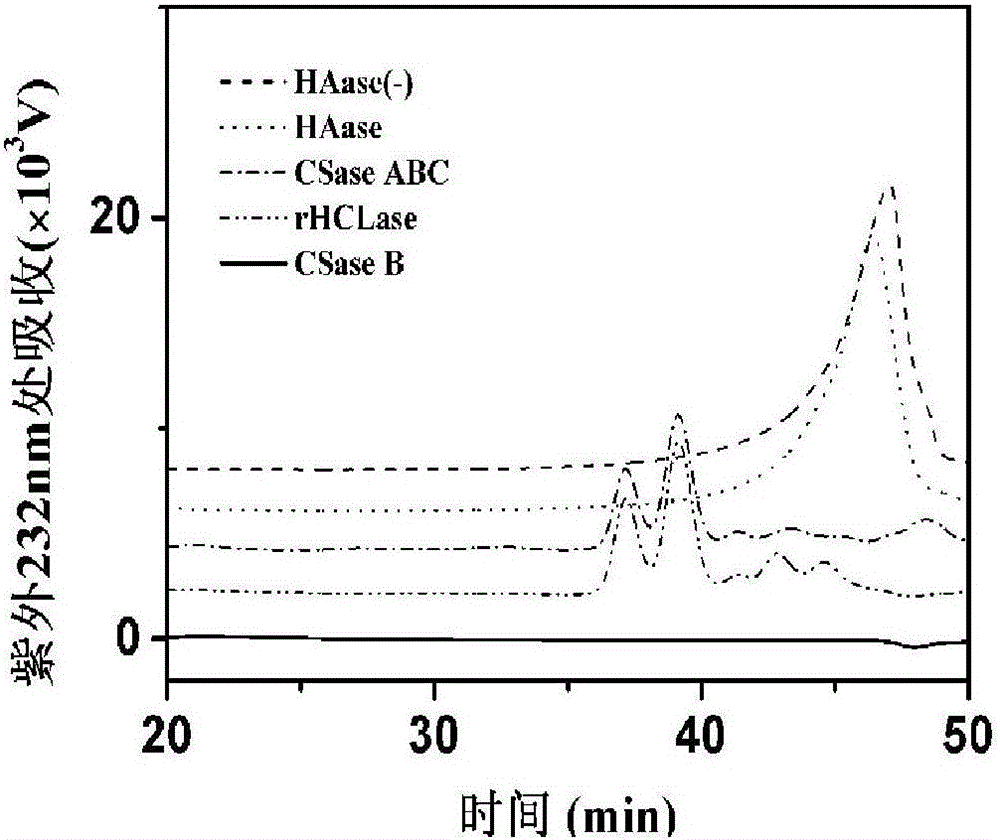

[0065] 2.2 Content analysis of other glycosaminoglycans

[0066] It is well known that the types of polysaccharide samples can be determined by using properties such as substrate specificity of biological enzymes. Chondroteinase ABC mainly degrades chondroitin sulfate, and Chondroteinase B can specifically degrade dermatan sulfate (DS), a glycosaminoglycan lyase disclosed by Chinese patent document CN103923899A (Patent No. 201410160095.3) rHCLase ...

Embodiment 3D

[0068] The molecular weight analysis of embodiment 3DG-CS

[0069] Average molecular weight is respectively the dextran standard of 11.6KD, 48.6KD, 147KD, 273KD, 409.8KD and the highly sulfated chondroitin sulfate DG-CS (mass concentration 1%) that embodiment 1 makes, get 100 μ l respectively and carry out HPLC analysis .

[0070] HPLC analysis conditions for gel column: Ultrahydrogel TM 100 7.8×300mm (Water); mobile phase: 0.02MNa 2 HPO4, 0.02M NaH 2 PO 4 , 0.02% NaN 3 , pH 7.0; flow rate: 0.6mL / min; detection condition: Shimadzu differential detector (RID-10A).

[0071] The result is as image 3 shown, according to image 3 It can be calculated that the average molecular weight of the prepared DG-CS is about 623.2KD.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com