Aqueous enzymatic method for preparing protein peptide powder from soybean hydrolysate

A technology of soybean hydrolyzate and protein peptide, applied in the field of soybean product processing, can solve the problems of limited composition and functional properties, and little research on protein peptide powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

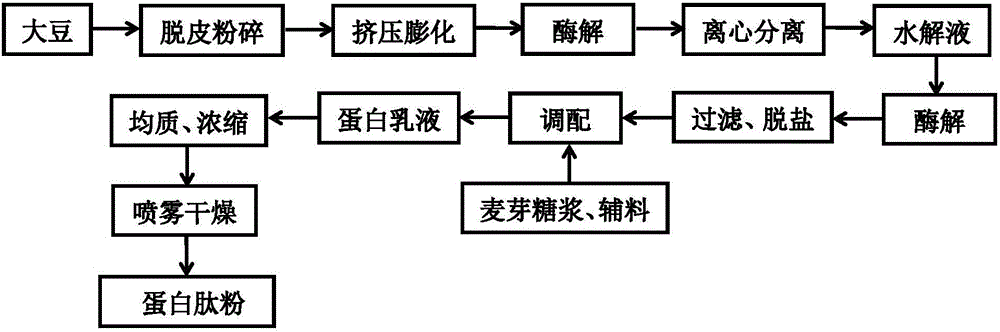

Image

Examples

Embodiment 1

[0023] Dehulled and crushed soybeans are extruded and puffed to obtain puffed products. Water is poured into the enzymolysis reaction tank, and steam at 55°C is introduced for heating. The puffed products are added to the heated water and mixed to obtain a mixed solution, using 2mol / L NaOH solution to adjust the pH of the mixed solution to 9.0, add 2% alkaline protease to the mixed solution for 3 hours under the condition that the ratio of solid to liquid is 1:6, and carry out enzymatic hydrolysis for 3 hours. Obtain emulsified oil, hydrolyzate Ⅰ and residue Ⅰ; add soybean protein isolate to hydrolyzate Ⅰ to make its solid content reach 30% of its total mass, adjust its pH value to 2, add pepsin for enzymolysis, enzymolysis The time is 1.5h, the enzymolysis temperature is 40°C, and after enzymolysis, soybean oil, hydrolyzate II and residue II are obtained by centrifugation, adding alkali to the hydrolyzate II to neutralize the pH, and desalting through the ultrafiltration membr...

Embodiment 2

[0025] Dehulled and crushed soybeans are extruded and puffed to obtain puffed products. Water is poured into the enzymolysis reaction tank, and steam at 55°C is introduced for heating. The puffed products are added to the heated water and mixed to obtain a mixed solution, using 2mol / L NaOH solution to adjust the pH of the mixed solution to 9.0, add 2% alkaline protease to the mixed solution for 3 hours under the condition that the ratio of solid to liquid is 1:6, and carry out enzymatic hydrolysis for 3 hours. Obtain emulsified oil, hydrolyzate Ⅰ and residue Ⅰ; add soybean protein isolate to hydrolyzate Ⅰ to make its solid content reach 30% of its total mass, adjust its pH value to 2, add pepsin for enzymolysis, enzymolysis The time is 1.5h, the enzymolysis temperature is 40°C, and after enzymolysis, soybean oil, hydrolyzate II and residue II are obtained by centrifugation, adding alkali to the hydrolyzate II to neutralize the pH, and desalting through the ultrafiltration membr...

Embodiment 3

[0027]Dehulled and crushed soybeans are extruded and puffed to obtain puffed products. Water is poured into the enzymolysis reaction tank, and steam at 55°C is introduced for heating. The puffed products are added to the heated water and mixed to obtain a mixed solution, using 2mol / L NaOH solution to adjust the pH of the mixed solution to 9.0, add 2% alkaline protease to the mixed solution for 3 hours under the condition that the ratio of solid to liquid is 1:6, and carry out enzymatic hydrolysis for 3 hours. Obtain emulsified oil, hydrolyzate Ⅰ and residue Ⅰ; add soybean protein isolate to hydrolyzate Ⅰ to make its solid content reach 30% of its total mass, adjust its pH value to 2, add pepsin for enzymolysis, enzymolysis The time is 1.5h, the enzymolysis temperature is 40°C, and after enzymolysis, soybean oil, hydrolyzate II and residue II are obtained by centrifugation, adding alkali to the hydrolyzate II to neutralize the pH, and desalting through the ultrafiltration membra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com