Method for processing egg bean curd with three-grinding and slurry punching machine technology

A technology of egg tofu and process processing, applied in the field of egg tofu, can solve the problems of loose and weak products, poor taste of tofu, and difficulty in uniform reaction, etc., and achieve texture and elasticity with good strength and toughness, fine and smooth taste, and glossy color good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

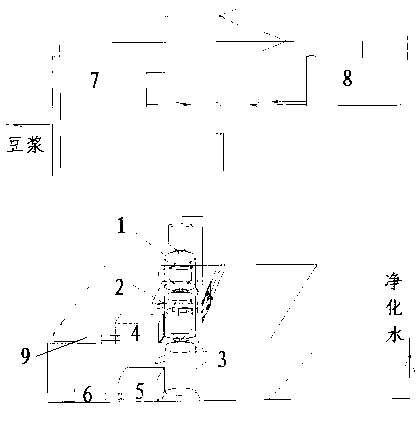

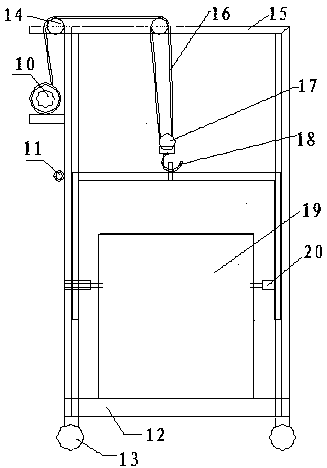

[0031] First, choose 40kg of high-quality soybeans and wash them with water, soak them in purified water 1.5 times that of soybeans, and soak for 12 hours at a water temperature of 5 degrees Celsius. Then use a triple mill to extract high-quality soybean milk, and promptly lift the soybean milk through the water pump to the cooking tank for heating, use high-pressure and high-temperature steam to heat the soybean milk in the cooking tank to above 120 degrees Celsius, and then put the cooked soybean milk into the A large iron hot pot. Use a large iron hot pot to boil the soybean milk, filter the boiled soybean milk through a filter in time, and then put it into the pulping machine. At the same time, first put 8kg of egg liquid that has been beaten into the slurry tank after being filtered through the filter screen, and adjust the protein coagulant according to the concentration of soybean milk, and use 0.6-1kg of food additive calcium sulfate to filter through the filter screen...

Embodiment 2

[0033] First, select 40kg of high-quality black beans, wash them with water, soak them in purified water 1.5 times that of black beans, and soak for 12 hours at a water temperature of 5 degrees Celsius. Then use a triple mill to extract high-quality soybean milk, and promptly lift the soybean milk through the water pump to the cooking tank for heating, use high-pressure and high-temperature steam to heat the soybean milk in the cooking tank to above 120 degrees Celsius, and then put the cooked soybean milk into the A large iron hot pot. Use a large iron hot pot to boil the soybean milk, filter the boiled soybean milk through a filter in time, and then put it into the pulping machine. At the same time, firstly pour 7kg of egg liquid that has been beaten into the slurry tank after filtering through the filter screen, and adjust a certain proportion of protein coagulant according to the concentration of soybean milk, and pour 0.75kg of lactone into the slurry tank after filtering...

Embodiment 3

[0035] First, select 40kg of high-quality soybeans and wash them with water, then soak them in purified water 1.5 times that of soybeans. The soaking time is 7 hours when the water temperature is 15 degrees Celsius. Then use a triple mill to extract high-quality soybean milk, and promptly lift the soybean milk through the water pump to the cooking tank for heating, use high-pressure and high-temperature steam to heat the soybean milk in the cooking tank to above 120 degrees Celsius, and then put the cooked soybean milk into the A large iron hot pot. Use a large iron hot pot to boil the soybean milk, filter the boiled soybean milk through a filter in time, and then put it into the pulping machine. At the same time, 6 kg of egg liquid that has been beaten is first filtered through a filter screen and poured into the slurry tank, and the protein coagulant is adjusted according to the concentration of the soybean milk. Specifically, 1 kg of edible additive magnesium chloride is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com