Whole milk and production method thereof

A production method and technology of whole milk, applied in milk preparations, dairy products, applications, etc., can solve the problems of heat-sensitive nutrients and taste influence, complex process, etc., to achieve extended shelf life, fine and smooth taste, and avoid bacterial contamination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

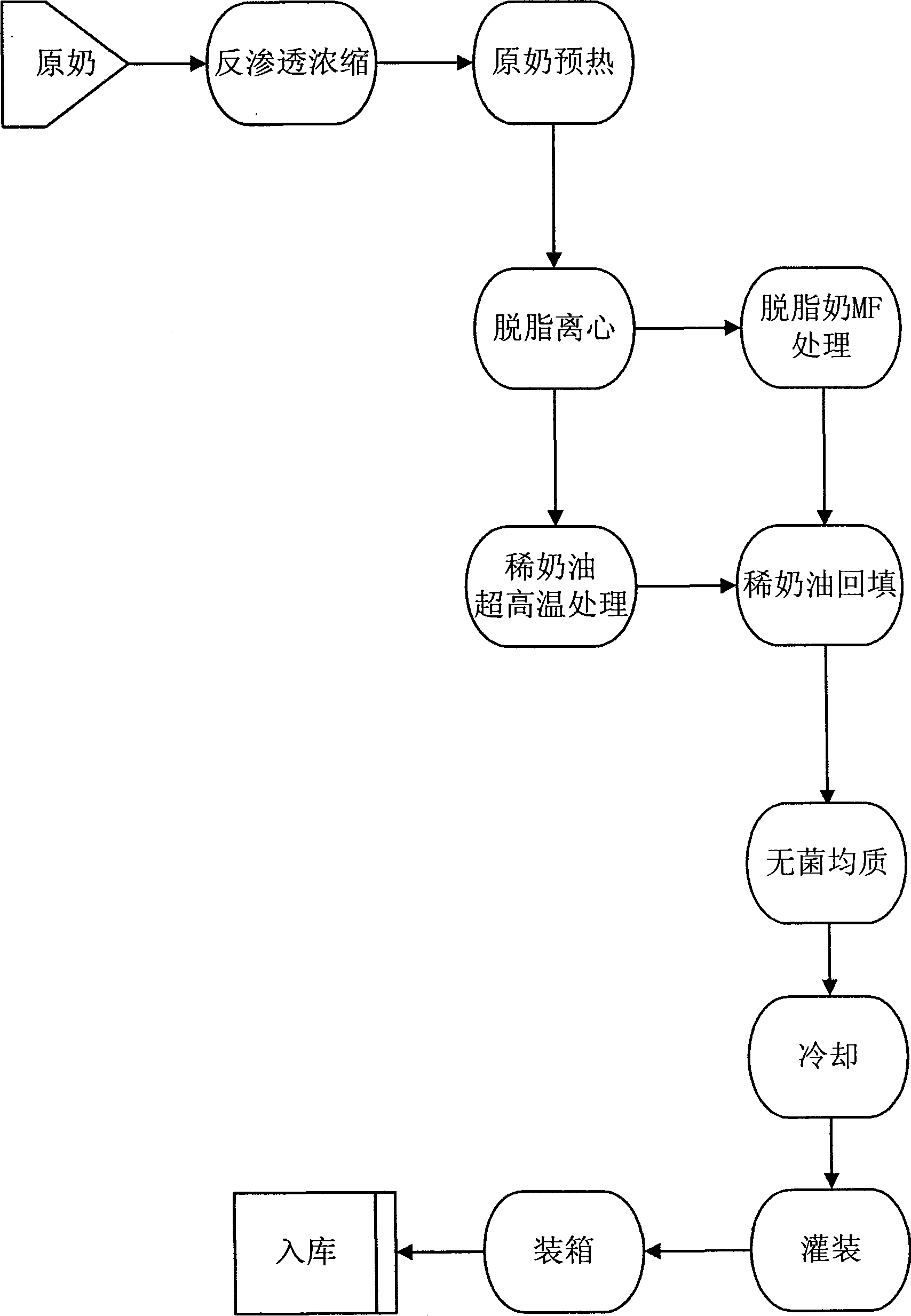

[0032] refer to figure 1 , follow the steps below to produce whole milk:

[0033] (1) Raw milk: the total number of bacteria and microorganisms is less than 5×104cfu / g, the fat content is more than 3.5%, and the non-fat solids are more than 8.3%. The raw milk is concentrated by reverse osmosis through the organic roll-type membrane of reverse osmosis until the dry matter content in the concentrated liquid reaches more than 13.0%, and the concentrated liquid is obtained. The reverse osmosis condition is: the pressure difference is 17Kg / cm 2 , The temperature is 10 ℃.

[0034] (2) Heat the concentrated solution to 50°C to facilitate degreasing and separation. Centrifuge the concentrated solution at about 50°C to skim the fat in a centrifuge to obtain cream and skim milk until the milk fat content in the skim milk is 0.4%.

[0035] (3) Microfiltration treatment of skimmed milk: At a temperature of 50°C, the skimmed milk is microfiltered through a ceramic membrane device with a...

Embodiment 2

[0041] Follow the steps below to produce whole milk:

[0042] (1) Raw milk: the total number of bacteria and microorganisms is less than 1×105cfu / g, the fat content is more than 3.5%, and the non-fat solids are more than 8.3%. Pass the raw milk through the reverse osmosis organic roll-type membrane, carry out reverse osmosis concentration, carry out reverse osmosis concentration, concentrate until the dry matter content in the concentrate reaches more than 13.0%, and obtain the concentrate. The reverse osmosis condition is: the pressure difference is 15Kg / cm 2 , The temperature is 6 ℃.

[0043] (2) Heat the concentrated solution to 55°C to facilitate degreasing and separation. Centrifuge the concentrated solution at about 55°C to skim the fat in a centrifuge to obtain cream and skim milk until the milk fat content in the skim milk is 0.4%.

[0044] (3) Microfiltration treatment of skimmed milk: at a temperature of 55°C, microfiltration of skimmed milk through a ceramic membr...

Embodiment 3

[0050] Follow the steps below to produce whole milk:

[0051] (1) Raw milk: the total number of bacteria and microorganisms is less than 1×105cfu / g, the fat content is more than 3.5%, and the non-fat solids are more than 8.3%. Pass the raw milk through the reverse osmosis organic roll membrane, carry out reverse osmosis concentration, carry out reverse osmosis concentration, concentrate until the dry matter content in the concentrated solution reaches 13.0% or more, and obtain the concentrated solution. The reverse osmosis condition is: the pressure difference is 25Kg / cm 2 , The temperature is 8 ℃.

[0052] (2) Heat the concentrated solution to 55°C to facilitate degreasing and separation. The concentrated liquid is centrifuged and degreased in a centrifuge at about 55° C. to obtain cream and skim milk until the milk fat content in the skim milk is 0.2%.

[0053] (3) Microfiltration treatment of skimmed milk: at a temperature of 55°C, the skimmed milk is microfiltered throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com