Processing method of soaking-free mixed beans

A processing method and non-soaking technology, which is applied in the field of intensive grain processing, can solve the problems of reduced cooking hardness, difficulty in absorbing water from miscellaneous beans, and long cooking time, so as to improve water absorption performance, promote staple food consumption, and have a soft and delicate taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

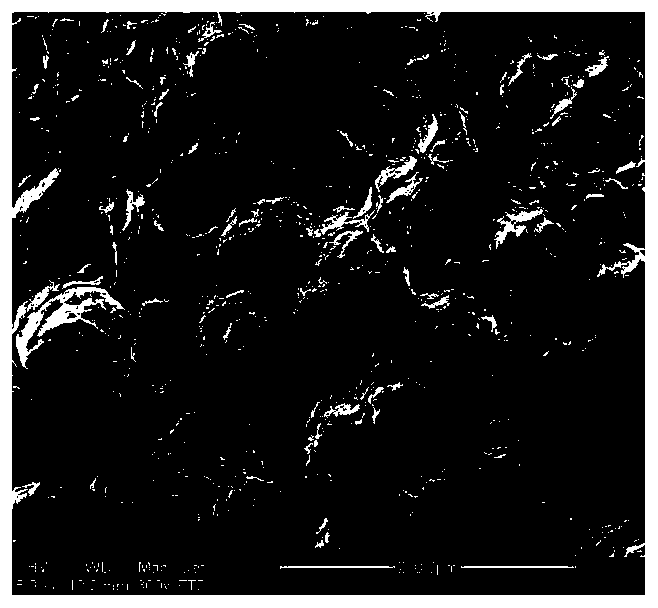

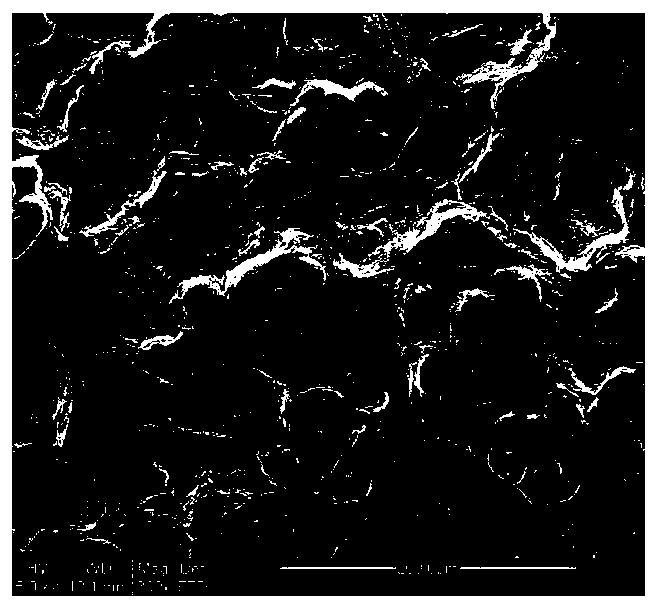

Image

Examples

preparation example Construction

[0036] (1) Preparation of standard sample: Accurately weigh 250 mg of raffinose, dissolve it in 10 mL of pure water, and then dilute to 25 mL with 15 mL of acetonitrile, which is the 10 g / L stock solution. Accurately pipette a certain amount from the stock solution into a 10mL volumetric flask, and prepare standard samples of a series of concentrations after constant volume with the mobile phase. The solution is filtered through a 0.45μ syringe filter for later use.

[0037] (2) Preparation of sample: Accurately weigh 1.000 g of soybean powder sample through a 100-mesh sieve, dissolve it with 10 mL of 70% ethanol, extract with microwave extraction, microwave extraction for 2 minutes, and place the extract in a high-speed refrigerated centrifuge Centrifuge at 4000r / min for 10min. The supernatant was filtered through a 0.45 μ filter membrane, and 10 μL of the sample solution was taken for HPLC detection.

[0038] Hypersil-amino column (4.6mm×150mm, 5μm); mobile phase (degassed ...

Embodiment 1

[0042] A kind of processing method of soaking-free red bean, the method comprises following processing steps:

[0043] (1) First, add water to the red bean raw material 10:2 (red bean / water, m / m);

[0044] (2) Then red bean raw material is carried out fluidization treatment, fluidization temperature 235 ℃, feed rate 47kg / h;

[0045] (3) The product is obtained after cooling and packaging;

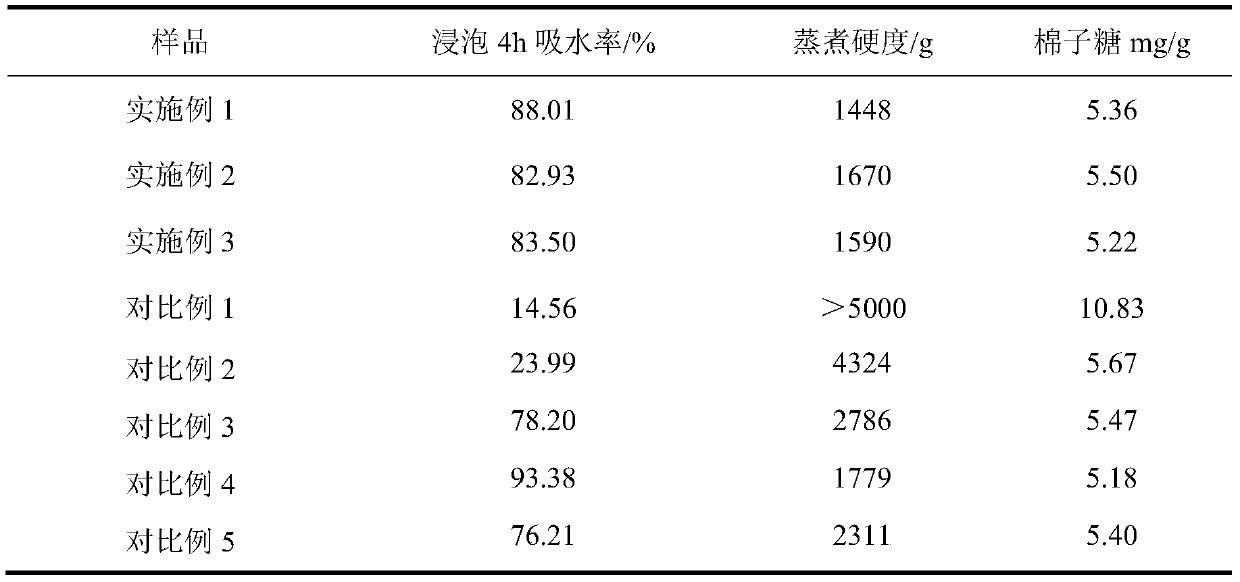

[0046](4) Finally, wash the product and white rice, add tap water according to a certain quality of rice-water ratio, cook for a period of time and keep warm for a certain period of time to obtain rice with red bean miscellaneous grains. See Table 1 for product water absorption, raffinose content, and cooking hardness test results.

Embodiment 2

[0048] A kind of processing method of soaking-free red bean, the method comprises following processing steps:

[0049] (1) First, add water to the red bean raw material 10:1.5 (red bean / water, m / m);

[0050] (2) Then red bean raw material is carried out fluidization treatment, fluidization temperature 225 ℃, feed rate 77kg / h;

[0051] (3) The product is obtained after cooling and packaging;

[0052] (4) Finally, wash the product and white rice, add tap water according to a certain quality of rice-water ratio, cook for a period of time and keep warm for a certain period of time to obtain rice with red bean miscellaneous grains. See Table 1 for product water absorption, raffinose content, and cooking hardness test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com