Patents

Literature

84results about How to "Save slurry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yarn foam sizing process and device

ActiveCN102733194AImprove wear resistanceLow running costFibre treatmentLiquid/gas/vapor textile treatmentChemistrySizing

The invention provides a yarn foam sizing process which is characterized in that: a sizing agent comprises polyvinyl alcohol, modified starch, acrylic acid, water and a foaming agent, wherein the ratio of the total mass of the polyvinyl alcohol, the modified starch and the acrylic acid to the mass of the water is 1:(3-20), and the ratio of the volume of the foaming agent to the total volume of the other four components is (1-3):100. The sizing agent is heated to 90-120 DEG C and then cooled to 40-60 DEG C and filled into a foam maker, then the foam is sprayed from top to bottom in a position between two sizing-agent pressing rollers which rotate oppositely, and the yarn penetrates through the position between the two sizing-agent pressing rollers from bottom, wherein the pressure between the two sizing-agent pressing rollers is 12,000-20,000N. According to the process, the yarn penetrates through the position between the two sizing-agent pressing rollers from bottom, then the form is attached to the warp yarn before being properly squeezed by the sizing-agent pressing rollers, and after the foam bursts, a proper amount of sizing agent is attached to the surface of the warp yarn to form a sizing-agent film. The sizing agent is saved, the strength of the yarn is increased, the sizing agent can be well attached to the hairness on the surface of the yarn, and the wear resistance of the yarn is improved.

Owner:LUTAI TEXTILE

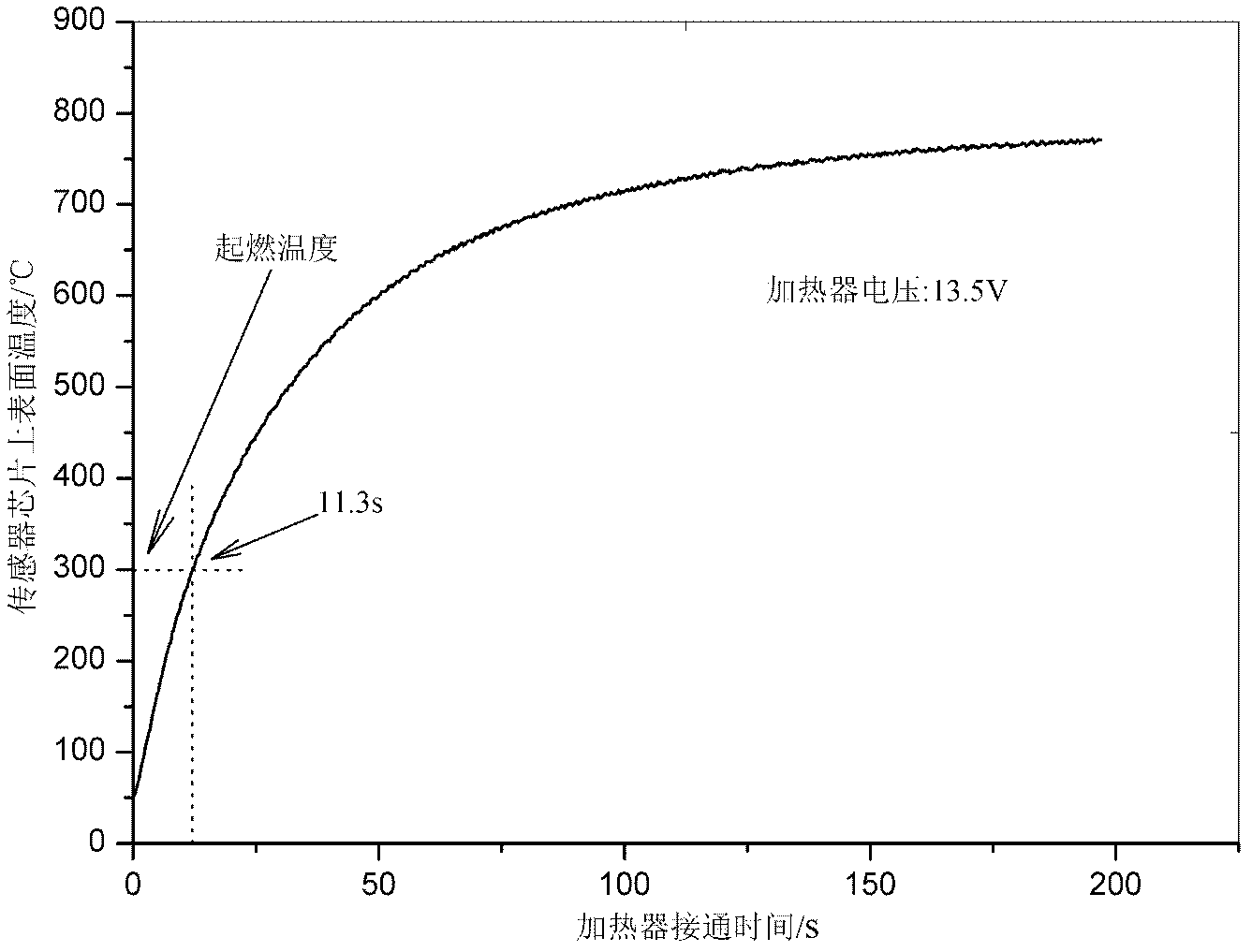

Flat oxygen sensor and preparation method thereof

ActiveCN102608193AHigh strengthSpeed up dryingMaterial analysis by electric/magnetic meansSignal functionInsulation layer

The invention discloses a flat oxygen sensor and a preparation method thereof. The flat oxygen sensor comprises a sensor chip prepared by seven layers of zirconium oxide ceramic raw pieces which are 0.2 to 0.25 mm thick, wherein the chip sequentially comprises a signal functional layer consisting of the first and second layers of ceramic raw pieces, a reference channel functional layer consistingof the third, fourth and fifth layers of ceramic raw pieces and a heating functional layer consisting of the sixth and seventh layers of ceramic raw pieces; an outer electrode and a signal electrode pin are arranged on the upper surface of the first layer of ceramic raw piece; a porous protection layer is arranged on the outer electrode; a lead protection layer is arranged on the signal electrodepin; a reference electrode is arranged between the second and third layers of ceramic raw pieces; a heater is arranged between the fifth and sixth layers of ceramic raw pieces; an upper heater insulation layer and a lower heater insulation layer are arranged on and below heater respectively; and a heating electrode pin is connected to the heater. The preparation method comprises the following steps of preparing, forming, printing and stacking the ceramic raw pieces and sintering the sensor.

Owner:WUXI LONGSHENG TECH

Interconnection structure between solar laminated cells and solar laminated cell

ActiveCN106531829AReliable interconnectionInterconnection is stablePhotovoltaic energy generationSemiconductor devicesElectrical connectionEngineering

The present invention belongs to the technical field of solar cells, and particularly relates to an interconnection structure between solar laminated cells and a solar laminated cell. The interconnection structure is used for sequentially bonding at least two cells and forming a good electrical connection. A front electrode and / or a back electrode of the cell are / is of a hollow structure. The back electrode of the previous cell is connected with the front electrode of the next adjacent cell by using conductive glue, so that a lot of front and back electrode paste is saved, and the cost of the laminated cell is lowered. For a back fragmented hollow design, the interconnection structure also can help reduce the amount of the used conductive glue and the cost of the laminated cell.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

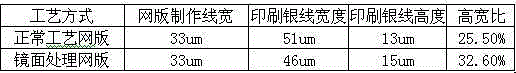

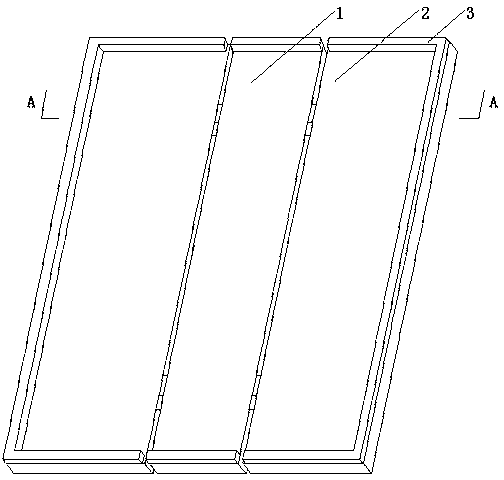

Smooth mirror surface processing technology based on composite screen printing plate

InactiveCN105269995AImprove flatnessPrevent spillageOther printing apparatusScreen printingEngineering

The invention discloses a smooth mirror surface processing technology based on a composite screen printing plate. The smooth mirror surface processing technology comprises the steps of screen pulling, that is, the composite screen printing plate is manufactured from a screen plate, a silk screen and a hot melt adhesive film; pretreatment, that is, the composite screen printing plate is cleaned, and grease and impurities on the surface of the composite screen printing plate are removed; distribution and film attaching, that is, sensitive emulsion and a release attaching film are attached to the composite screen printing plate in sequence; plate burning, that is, a pattern is transferred to the composite screen printing plate from a film through ultraviolet irradiation; and developing, that is, non-cured sensitive emulsion on the composite screen printing plate is removed, and a finished product is obtained. By means of the smooth mirror surface processing technology based on the composite screen printing plate, the flatness of the printing surface of the composite screen printing plate is greatly improved, pulp can be effectively prevented from overflowing, the pulp is saved, lines can be printed thinner and straighter, and therefore a better printing silver line height-width ratio is obtained, the photoelectric conversion efficiency of products is improved, and the product competitiveness is improved.

Owner:赫日光电(苏州)有限公司

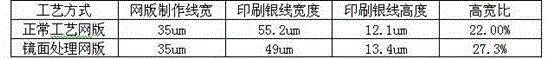

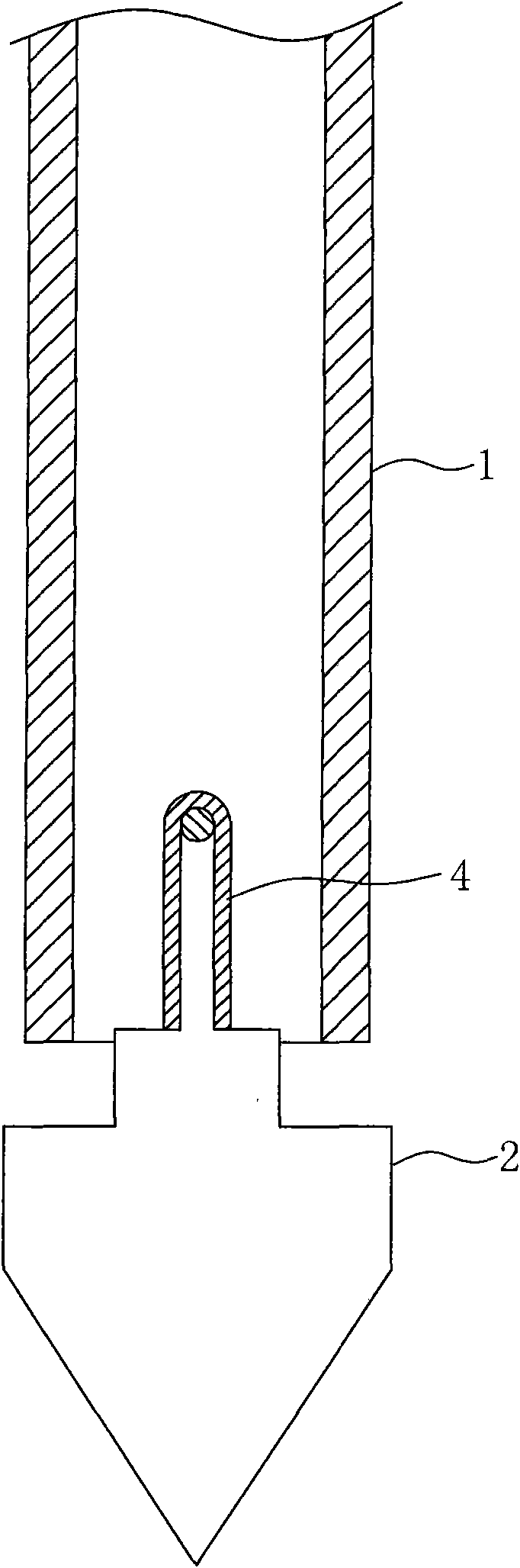

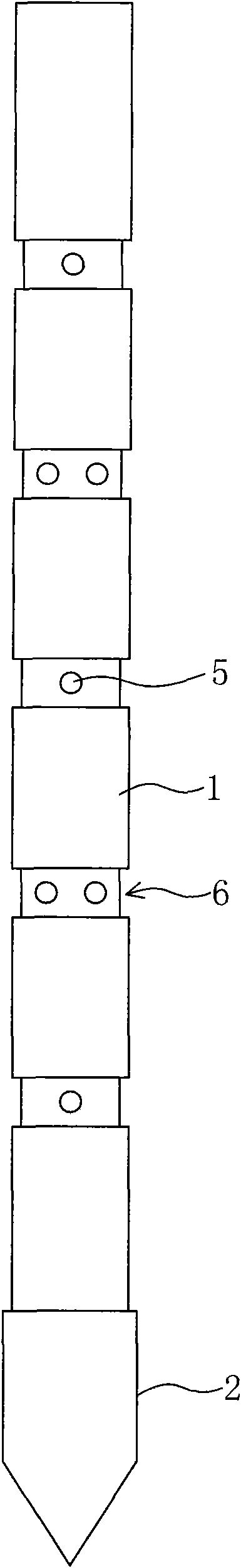

Casting head for compact casting

ActiveCN101614008AReduce partial leakageControl pulping problemsSoil preservationBiomedical engineeringDrill bit

The invention discloses a casting head for compact casting, which comprises a hollow drilling rod and a drilling head arranged at one end of the drilling rod. One side of the drilling rod is provided with at least three injection holes; the injection holes are arrayed at intervals relative to the drilling head from near to far; annual grooves are arranged on the outer wall of the drilling rod corresponding to the position of various injection holes; the widths of the grooves are larger than the diameters of the injection holes; and outlets of the injection holes are positioned in the grooves. The casting head limits the casting in a certain range, prevents the mortar escape, not only saves the mortar, but also has excellent casting effect.

Owner:ZHONGYIFENG CONSTR GRP

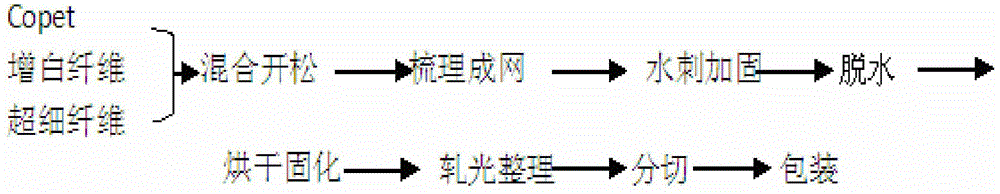

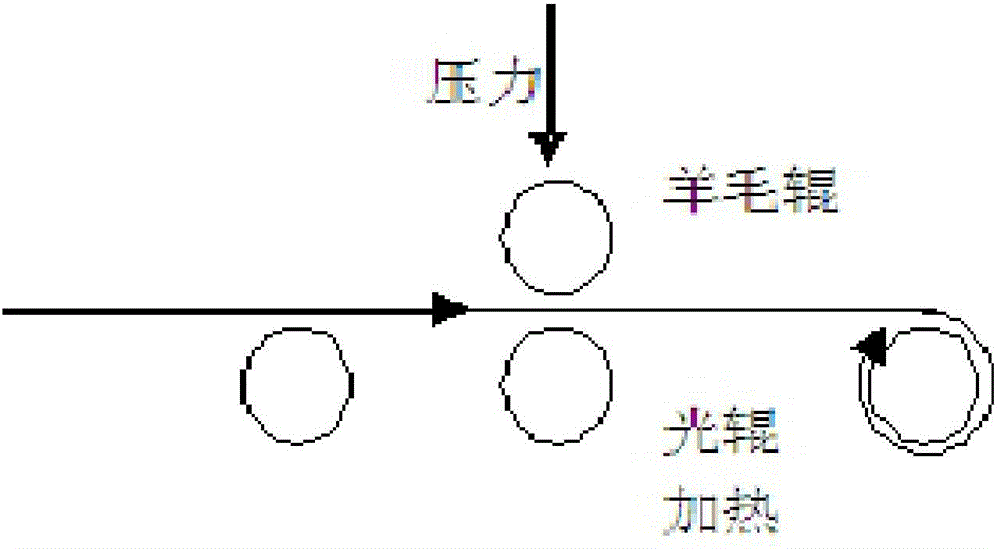

Spunlaced nonwovens and machining method for composite fiber curtain filtration

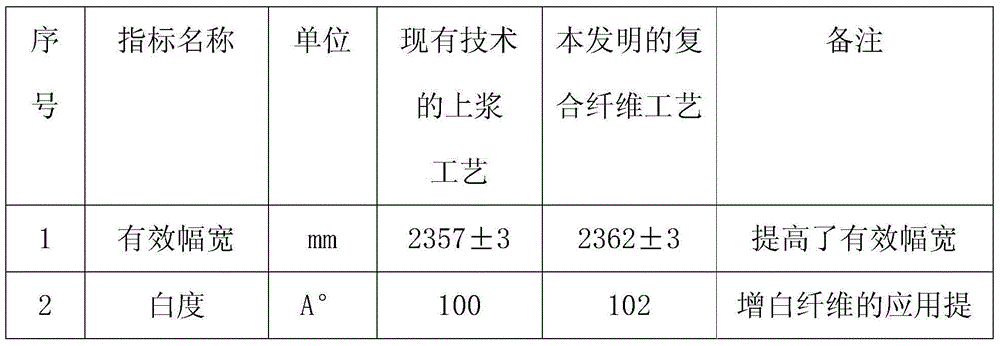

The invention discloses spunlaced nonwovens and a machining method for composite fiber curtain filtration. According to the method, copet composite fiber, whitening polyester fiber and superfine polyester fiber in the weight proportion 1.5: 2.5:1 are subjected to the following steps to form the spunlaced nonwovens, 1, the copet composite fiber, the whitening polyester fiber and the superfine polyester fiber are mixed in the weight proportion 1.5: 2.5:1; 2, the mixed material is conveyed to an air pressure cotton box carding machine through a draught fan after being subjected to mixing opening; 3, the mixed fiber is subjected to carding to form a mesh, and the mesh is conveyed to a spunlace machine; 4, spunlace machining is conducted on the mixed fiber on a spunlace machine; 5, dehydration treatment is conducted; 6, the mixed fiber is transferred to a dryer to be subjected to continuous drying solidification after the spunlace machining, the solidification temperature of a first drying oven is 160+-3 DEG C, the solidification temperature of a second drying oven is 170+-3 DEG C, and the speed is 45-50 m / min; 7, calendering finish is conducted; 8, the working procedures of slitting and packaging are conducted. The spunlaced nonwovens and machining method for the composite fiber curtain filtration has the advantages that the effects of printing and dyeing, bending and polishing are achieved, no sizing agent exists, and the cost is low.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

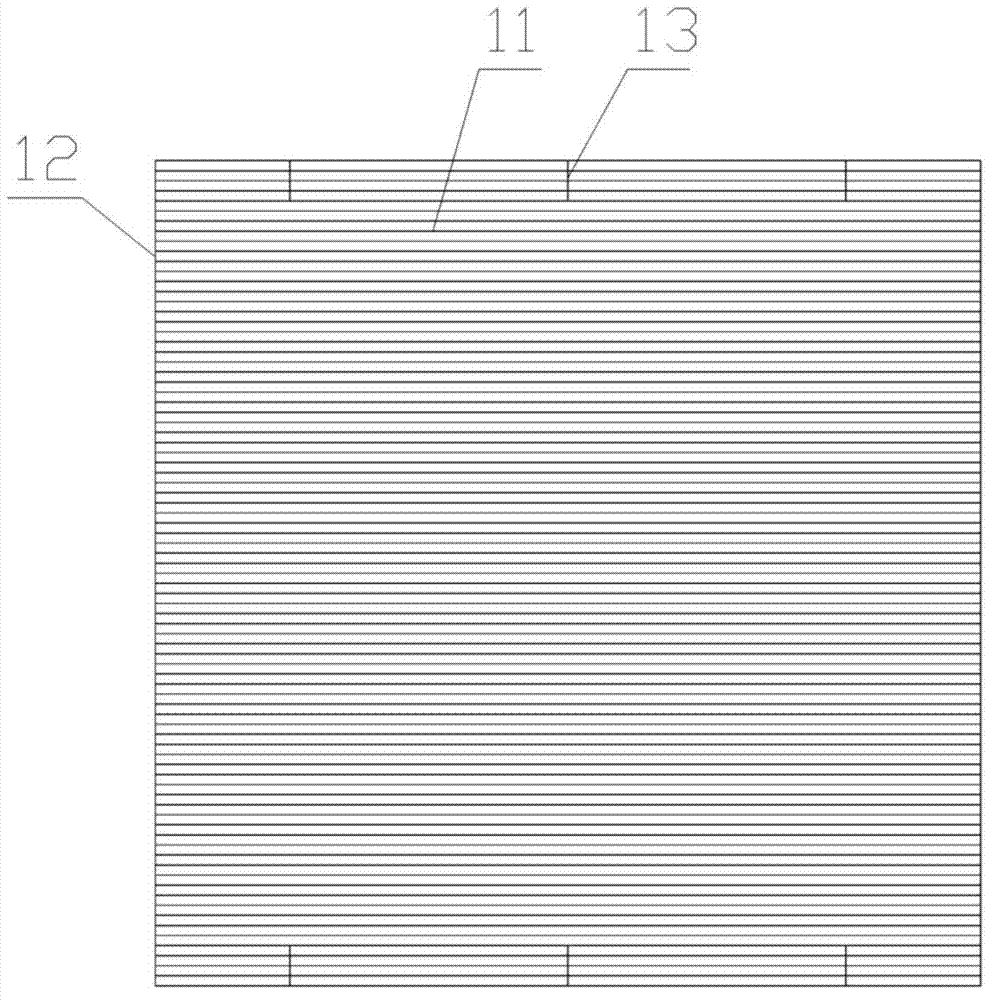

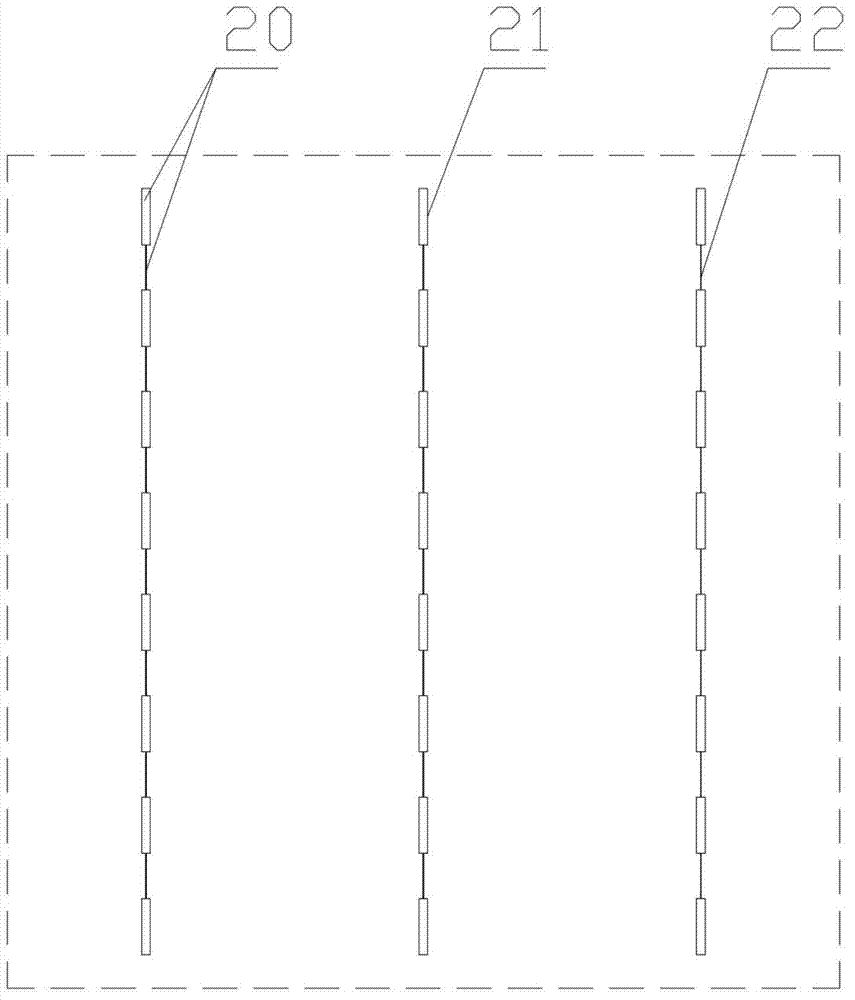

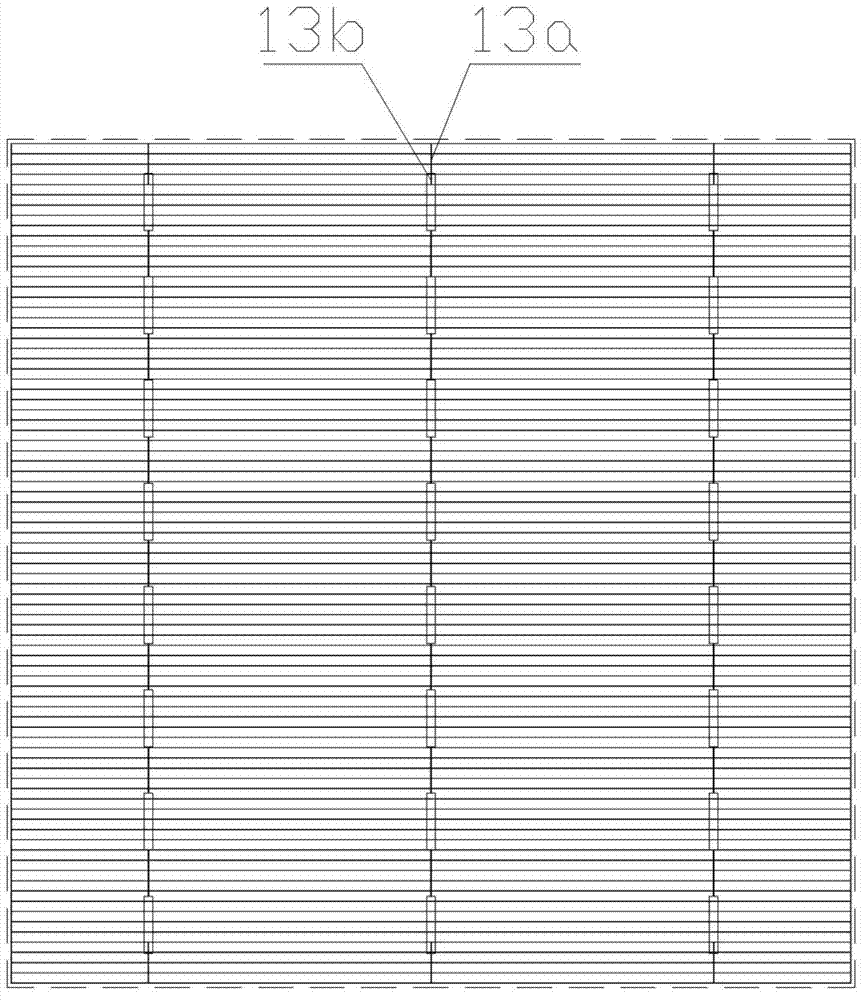

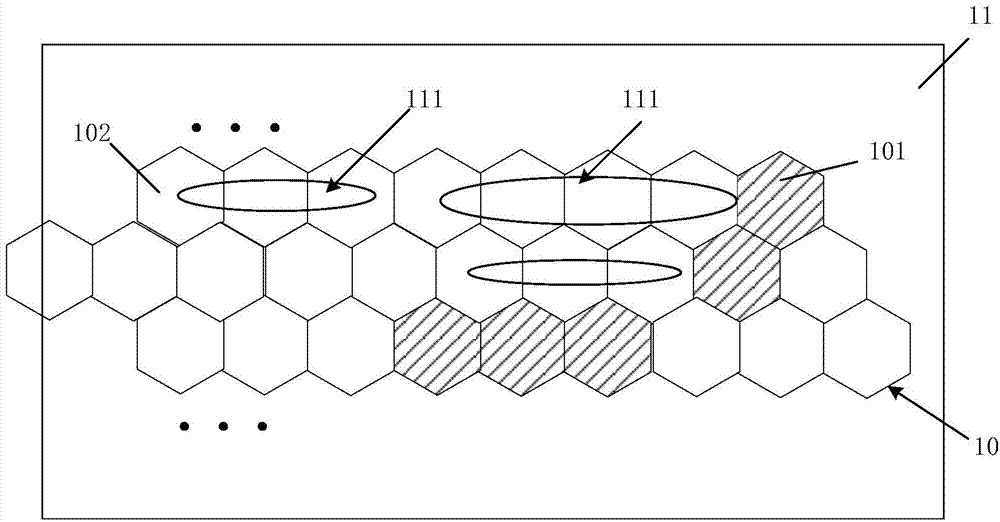

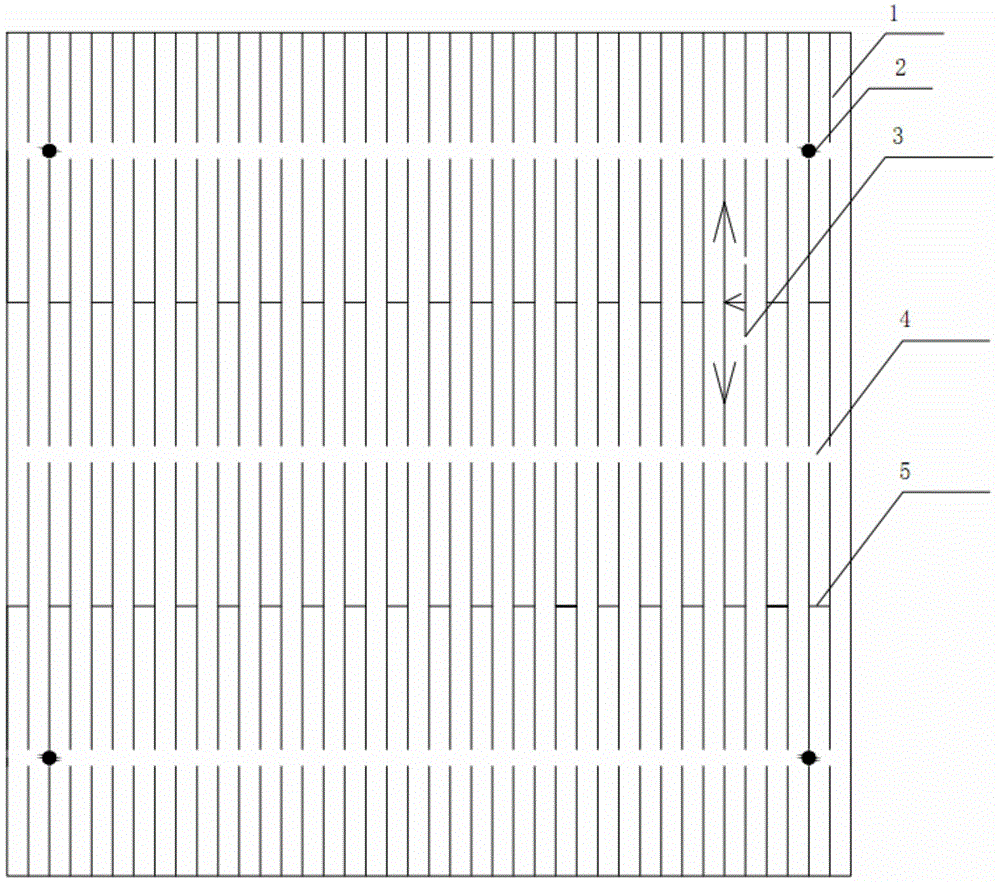

Electrode structure with grid lines on front surface

The invention discloses an electrode structure with grid lines on the front surface. The electrode structure comprises a plurality of first secondary grid lines (11) and at least two main grid lines (20) which are intersected with the first secondary grid lines (11), wherein each main grid line (20) is divided into a plurality of sections which are connected through connecting lines (22); third secondary grid lines (13) are also arranged on the front section and the tail section of each main grid lines (20); internally embedded sections (13b) of each third secondary grid line (13) are overlapped with the corresponding front sections or tail sections; and exposed sections (13a) of each third secondary grid line (13) are intersected with the first secondary grid lines (11). By adopting the electrode structure with the grid lines on the front surface, in a secondary overprinting process, counterpoint printing can be quickly and accurately performed, the using amount of silver slurry is reduced, and the battery conversion efficiency is improved.

Owner:NINGBO ULICA SOLAR SCIENCE & TECHNOLOGY CO LTD

Method for patterned polychrome printing through four separated colors

A method for printing multi-color pattern on fabric includes such steps as splitting the color of an original pattern into red, yellow, blue and black colors by computer, outputting their negative films, choosing screen, installing it on frame, exposing to preparing 4 plates, preparing the pigment slurries for said 4 colors, scrape printing four times, steaming, and water washing.

Owner:杭州喜得宝集团有限公司

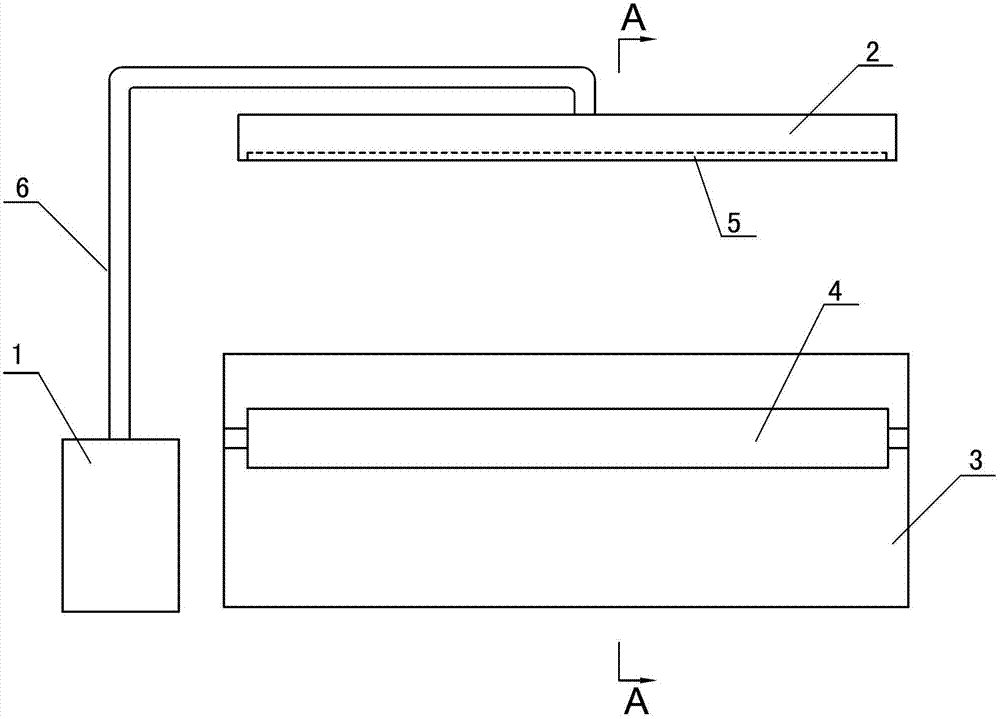

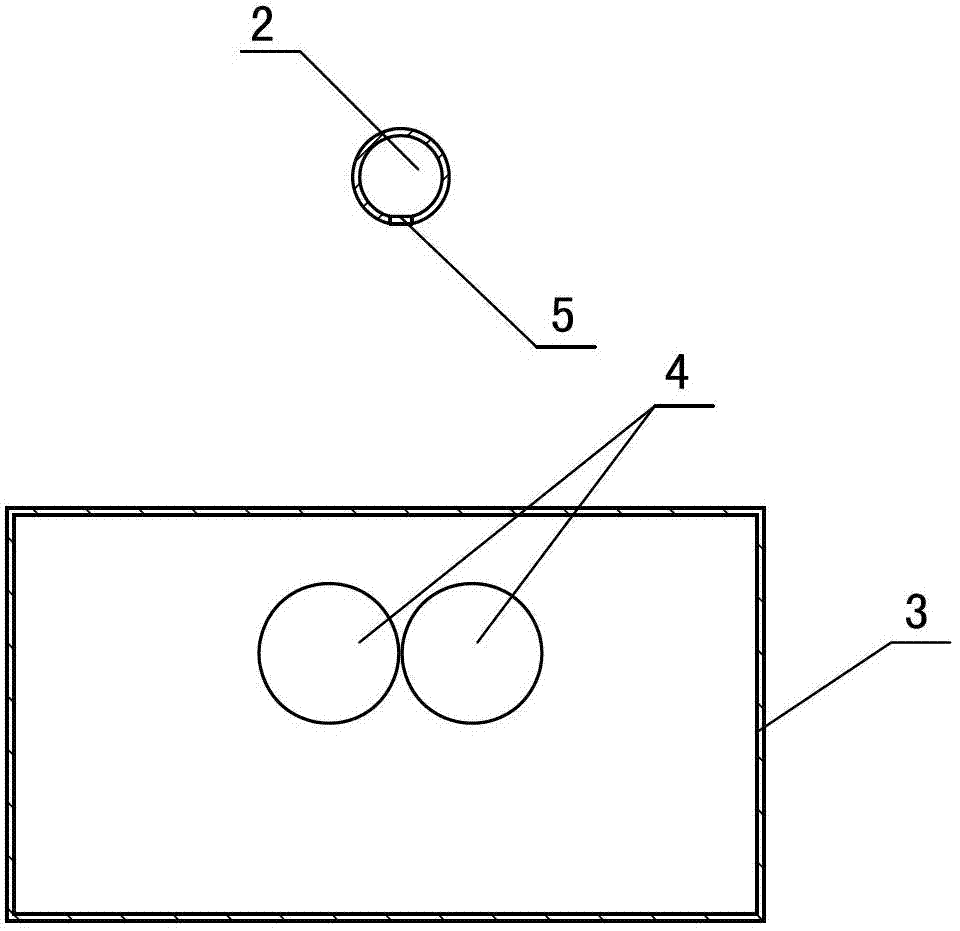

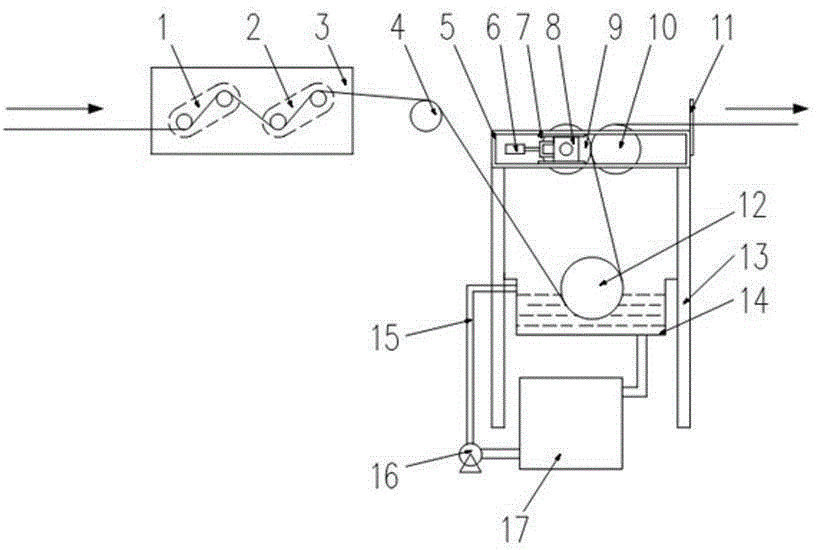

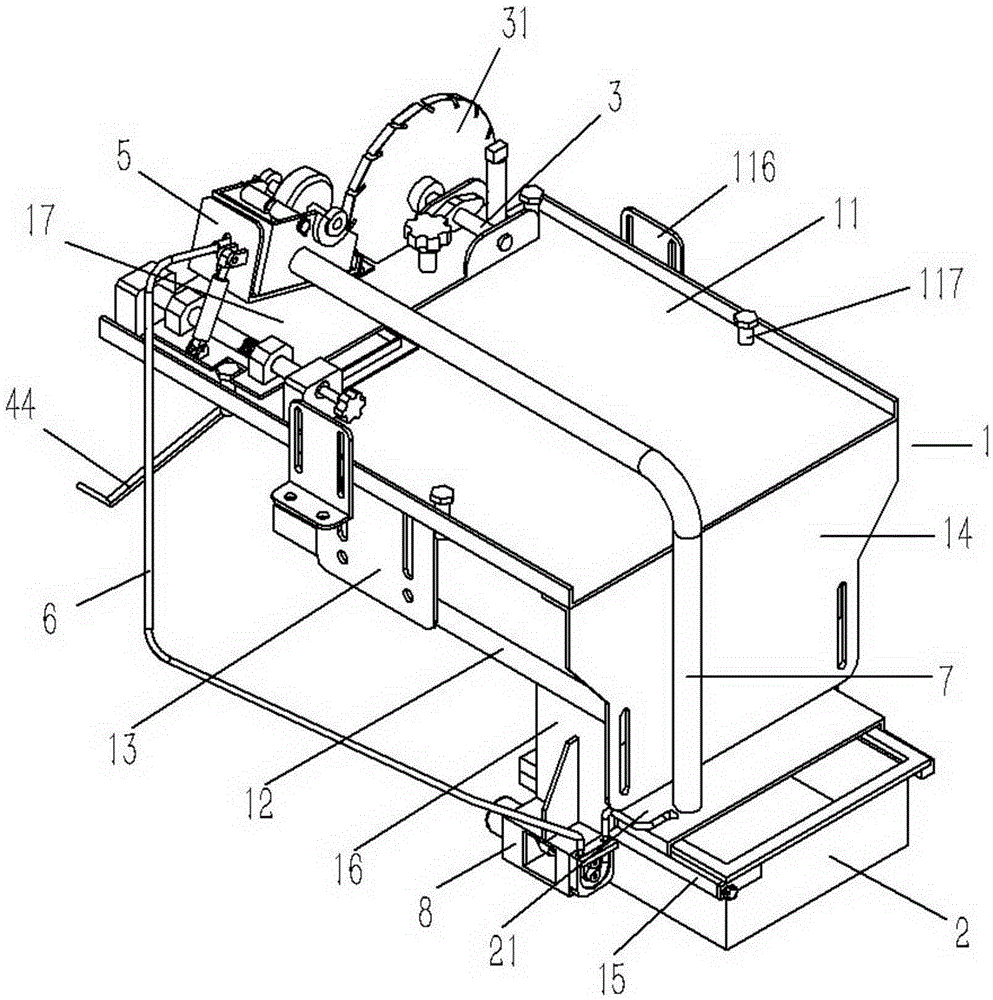

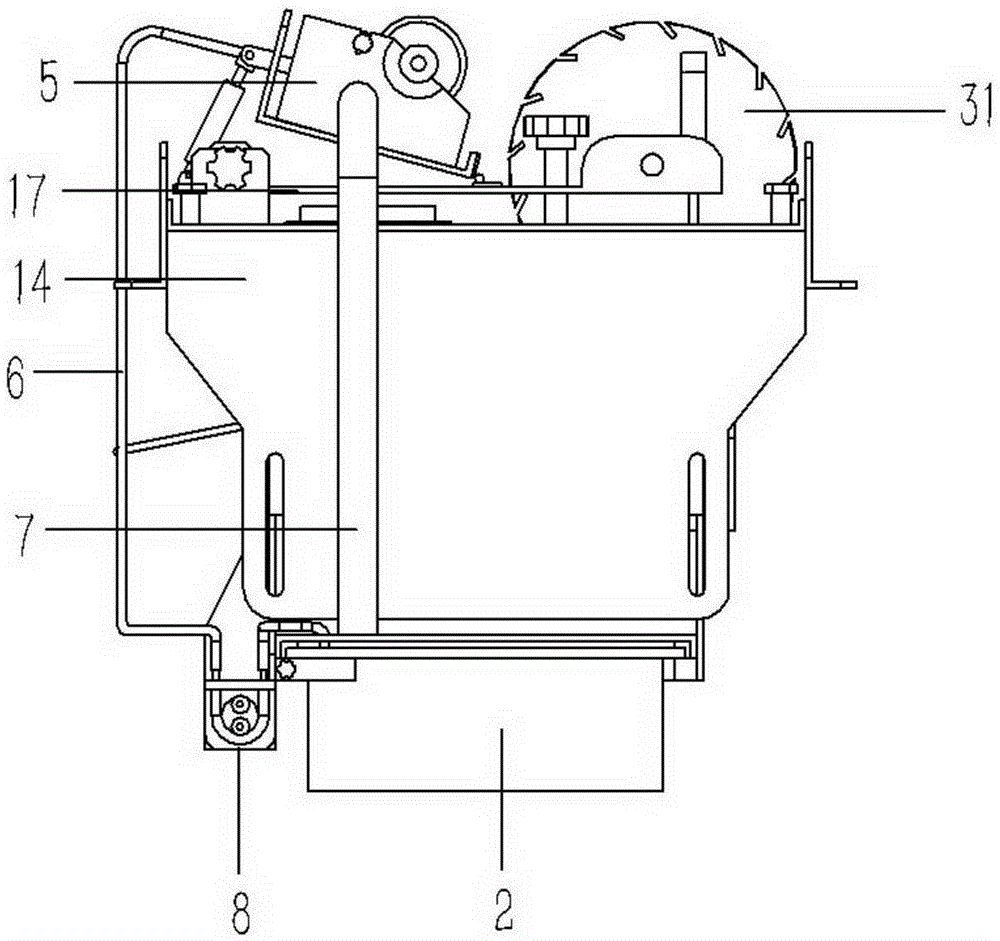

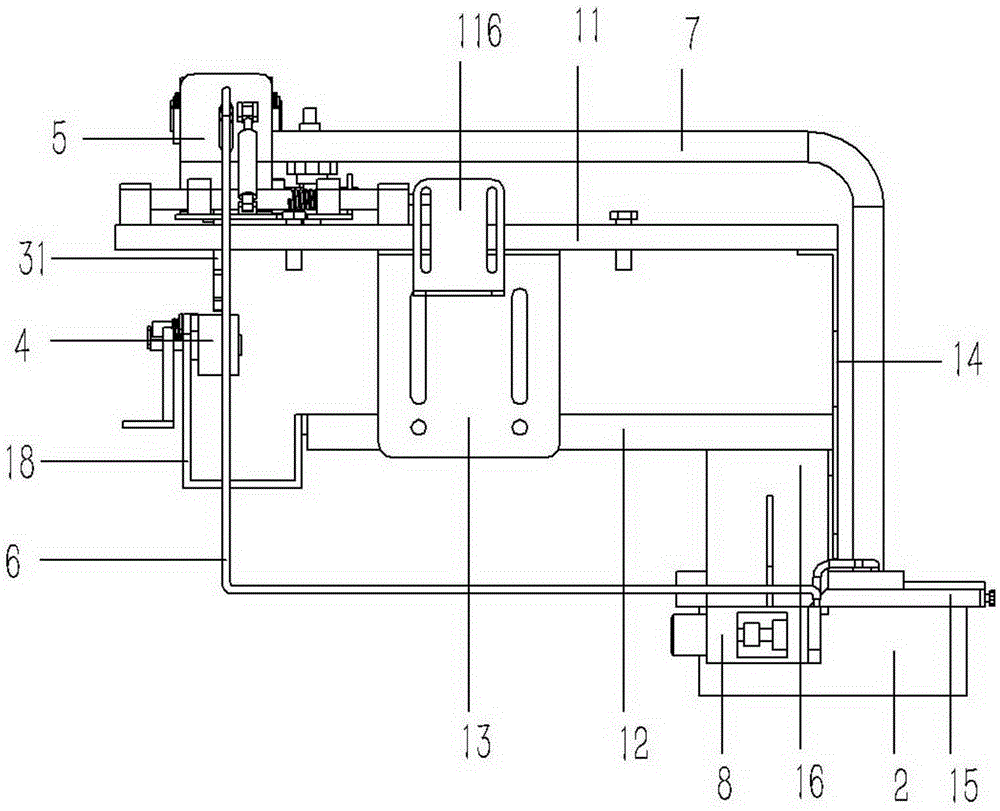

Carbon fiber short-cut production line sizing device

ActiveCN106811886ASimple structural designReasonable structural designTextile treatment machine arrangementsTextile treatment carriersFiberCarbon fibers

The invention discloses a carbon fiber short-cut production line sizing device which comprises a faceplate provided with a tension adjusting device, a godet, a rack, a rectangular frame fixed at the upper end of the rack and a sizing tank positioned below the rectangular frame and fixedly connected with the rack through bolts. A sizing roller partly soaked in size is arranged in the sizing tank, a size extruding device for extruding excessive size on carbon fiber and enabling the same to drip into the sizing tank for recycling is arranged on the rectangular frame, and after the carbon fiber is sized and extruded, extruded excessive size is enabled to drip into the sizing tank for recycling. The carbon fiber short-cut production line sizing device meets sizing application needs on a small-amount carbon fiber short-cut production line and is low in manufacturing cost, simple and reliable to operate and easy to clean and maintain.

Owner:SOUTH CHINA UNIV OF TECH

Production technology of cold-resistant breathable imitated leather coated fabric with concave-convex particles

ActiveCN105178041AImprove breathabilityGood antibacterialLaminationLamination apparatusSurface layerDiluent

The invention discloses a production technology of a cold-resistant breathable imitated leather coated fabric with concave-convex particles. The production technology comprises the following steps: (1) coating technology: preparing surface layer slurry from the following components by weight: 100 kilograms of polyurethane resin, 30 to 40 kilograms of DMF solvent, 30 to 40 kilograms of diluent, 2 to 3 kilograms of antiseptic, 0.3 to 0.5 kilogram of organic silicon aid, and 3 to 7 kilograms of pigment, preparing bottom layer slurry from the following components by weight: 100 kilograms of polyurethane resin, 4 to 6 kilograms of DMF solvent, and 4 to 6 kilograms of diluent, painting the bottom layer slurry on woven suede, drying, cooling, then painting surface layer slurry on the bottom layer, preheating, pasting cloth, drying again, cooling, peeling, and examining; (2) surface printing technology: reeling the coated cloth obtained in the step (1), performing first edition printing, drying, performing second edition printing, placing on a needle bed, drying through baking, cooling, reeling, and examining; (3) combination technology: combining the coated woven suede and leather covered basic cloth to produce sofa cloth. The technology can save slurry. The obtain product is light and thin, is similar to real leather, and has the advantages of breathability, cold resistant property, antibacterial function, hydrolysis resistant performance, and environment-friendliness.

Owner:YANGZHOU DERWINS PLASTICS TECH

Production technology of low-twist yarn

The invention discloses a production technology of low-twist yarn. The production technology comprises the steps of cotton selection, fore-spinning and post-spinning, wherein the fore-spinning processcomprises the steps of blowing, carding, drawing and roving, and the post-spinning process comprises the steps of spinning and winding. According to the production technology of the low-twist yarn, through selection control on raw materials, optimized configuration on the fore-spinning process, false twist treatment on the spinning step and vacuum low-temperature steam yarn shaping treatment on yarn fruits, the problems of more broken ends in weaving, deterioration of quality indicators, difficulty in spinning and the like caused by reduction of yarn twist in the prior art can be effectivelysolved.

Owner:ZHONGHUA GRP

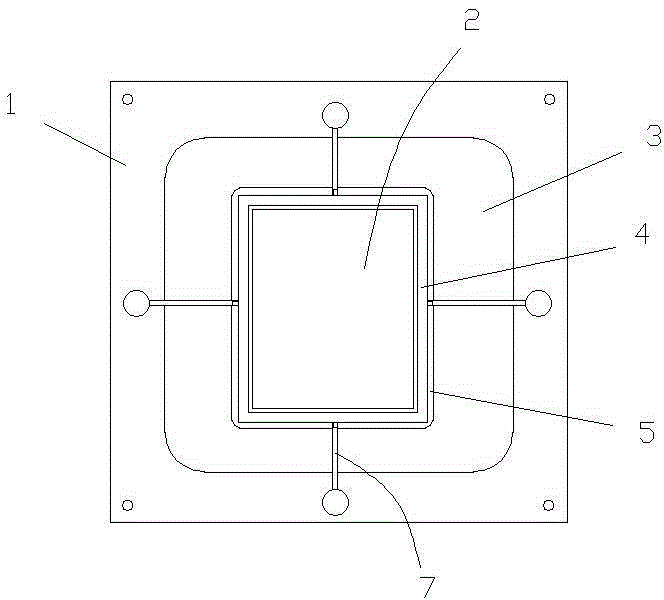

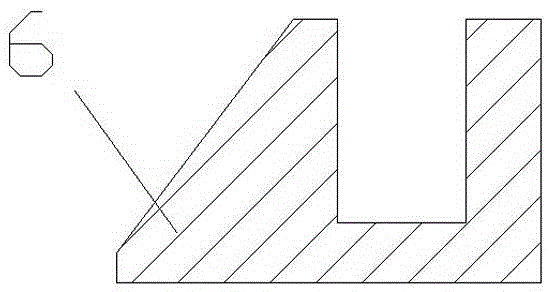

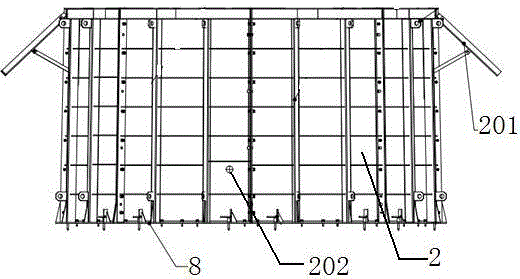

Once-formed manufacturing method and mold for glass magnesium smoke vent

InactiveCN103252838AAvoid voids or even defects that cannot be formedAvoid direct adhesionMouldsAlkali freePulp and paper industry

The invention discloses a once-formed manufacturing method for a glass magnesium smoke vent. The once-formed manufacturing method comprises the following steps: a. adjacent edges of three rectangular templates are movably connected with one another, the three rectangular templates form an outer mold, and the three rectangular templates are arranged horizontally; b. a frame is arranged on the four edges of the outer mold, namely, the outer long edges and the two end edges of the two side templates and the two end edges of the bottom template; c. a layer of medium-alkali or alkali-free gridding cloth is arranged on the inner face of the outer template, and the gridding cloth extends to the outer side of the side templates; d. glass magnesium pulp is laid on the gridding cloth on the inner frame of the outer template, the glass magnesium pulp is flattened, the thickness of the glass magnesium pulp is the same as the height of the frame, another layer of medium-alkali or alkali-free gridding cloth is laid on the glass magnesium pulp and is flattened; e. a square cylindrical core mold meeting the requirements of shape and standard is placed on the bottom template of the outer mold with the glass magnesium pulp, and the side templates of the outer mold are folded upwards to be perpendicular to the bottom template, and the side templates of the outer mold are fixed; f. glass magnesium pulp is laid on the gridding cloth of the core mold which is well arranged, and the glass magnesium pulp is flattened and solidifies.

Owner:黄新春

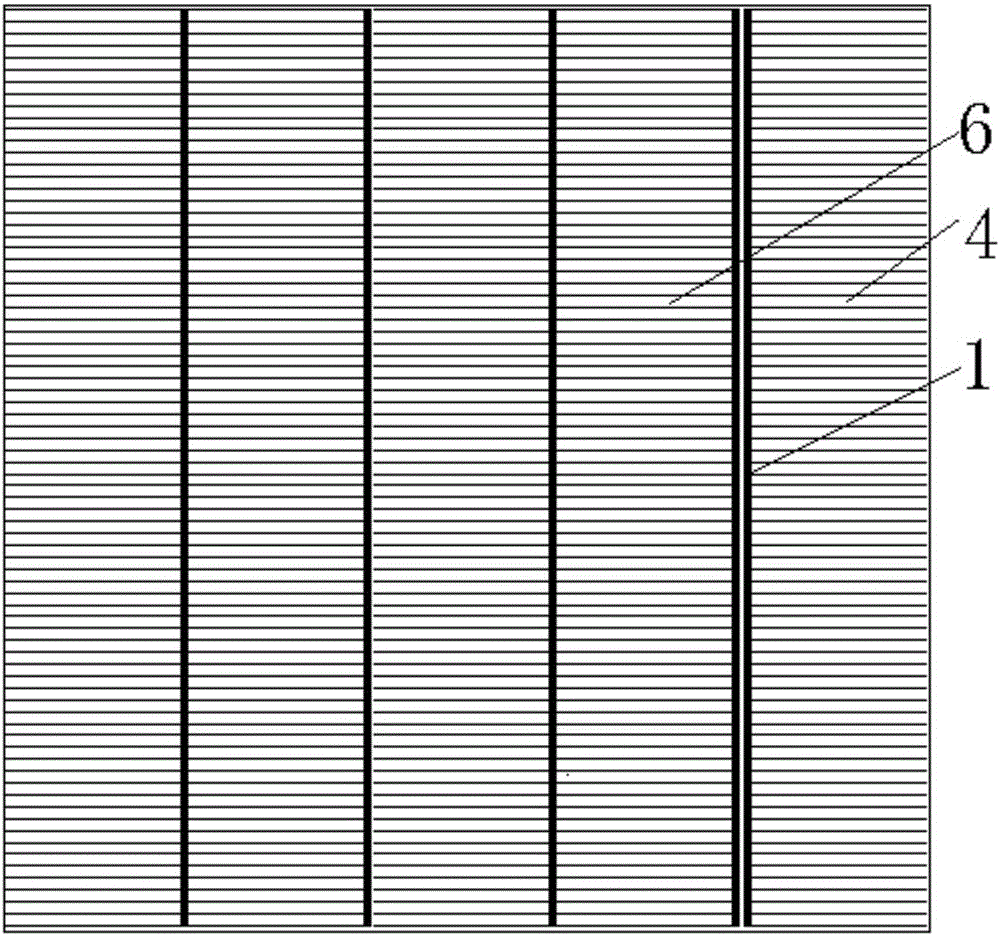

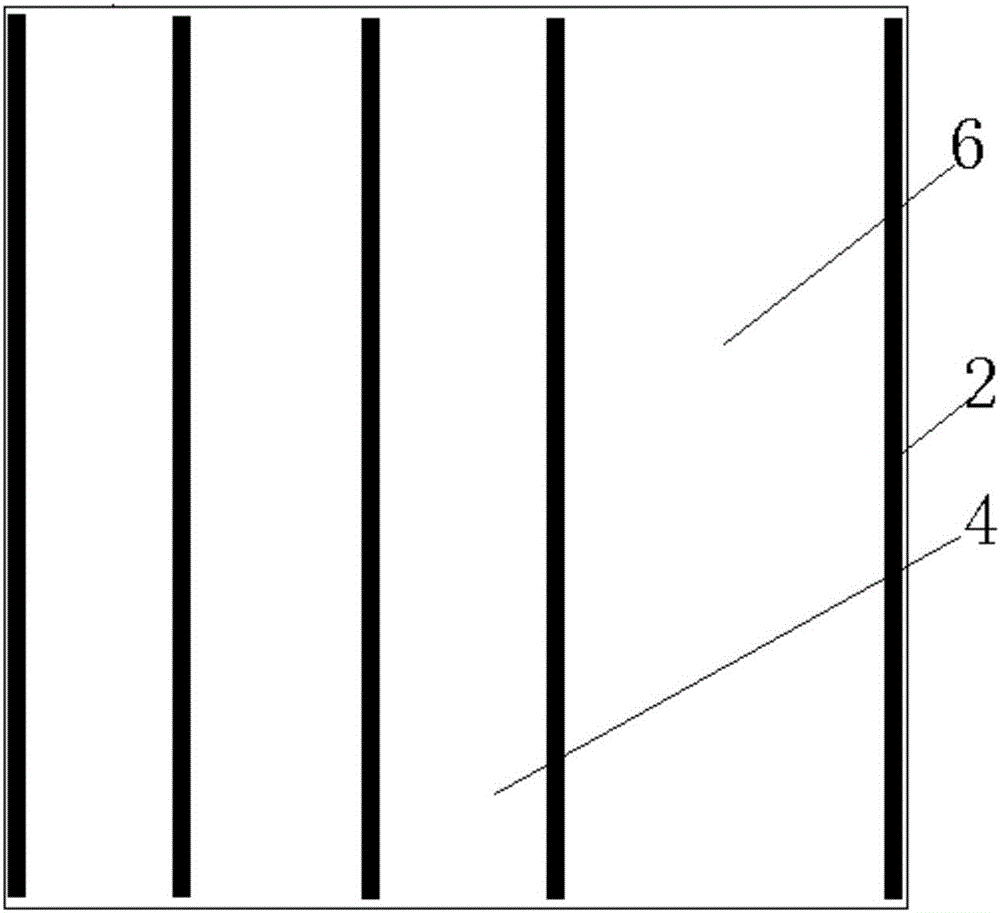

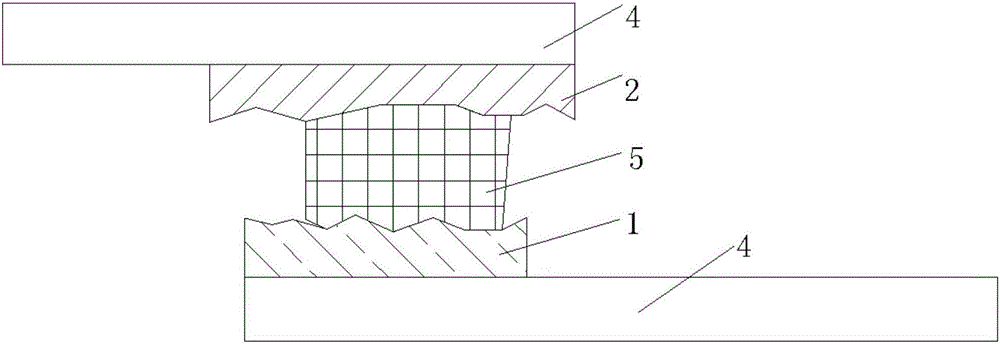

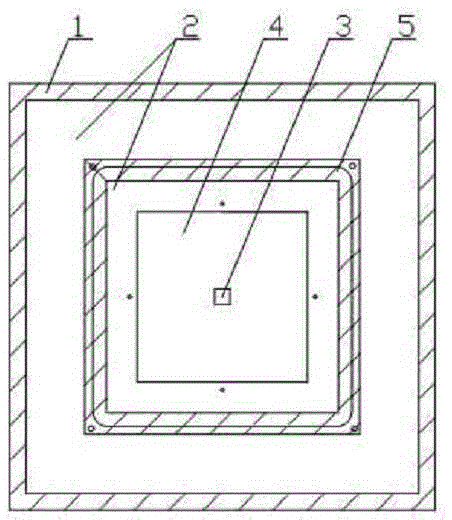

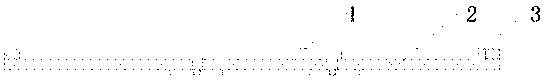

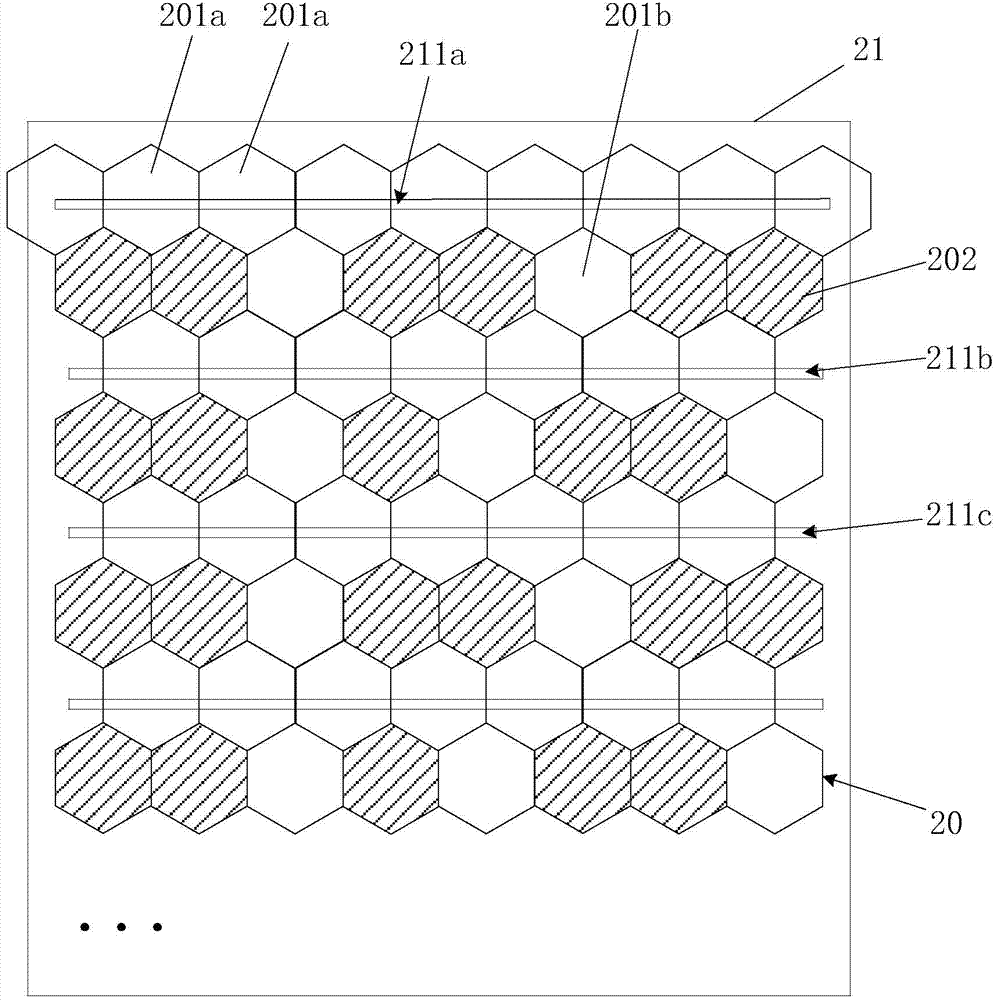

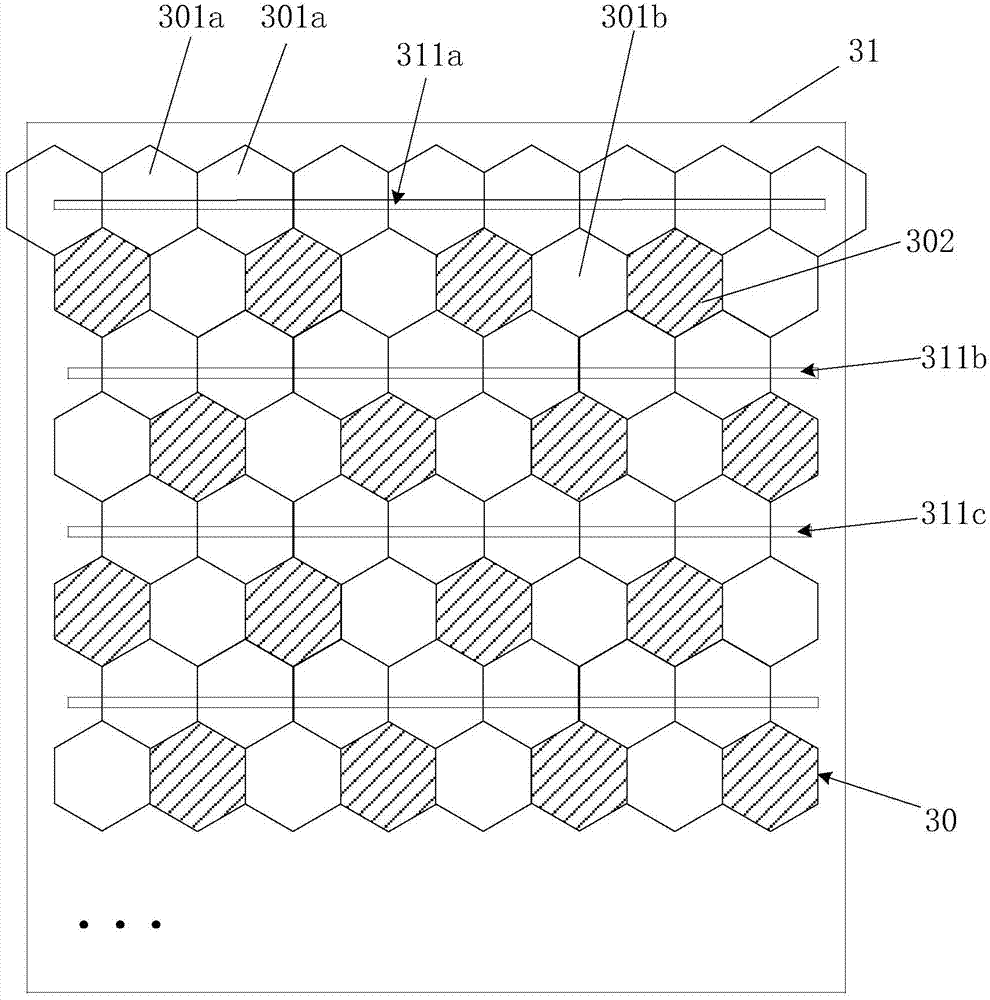

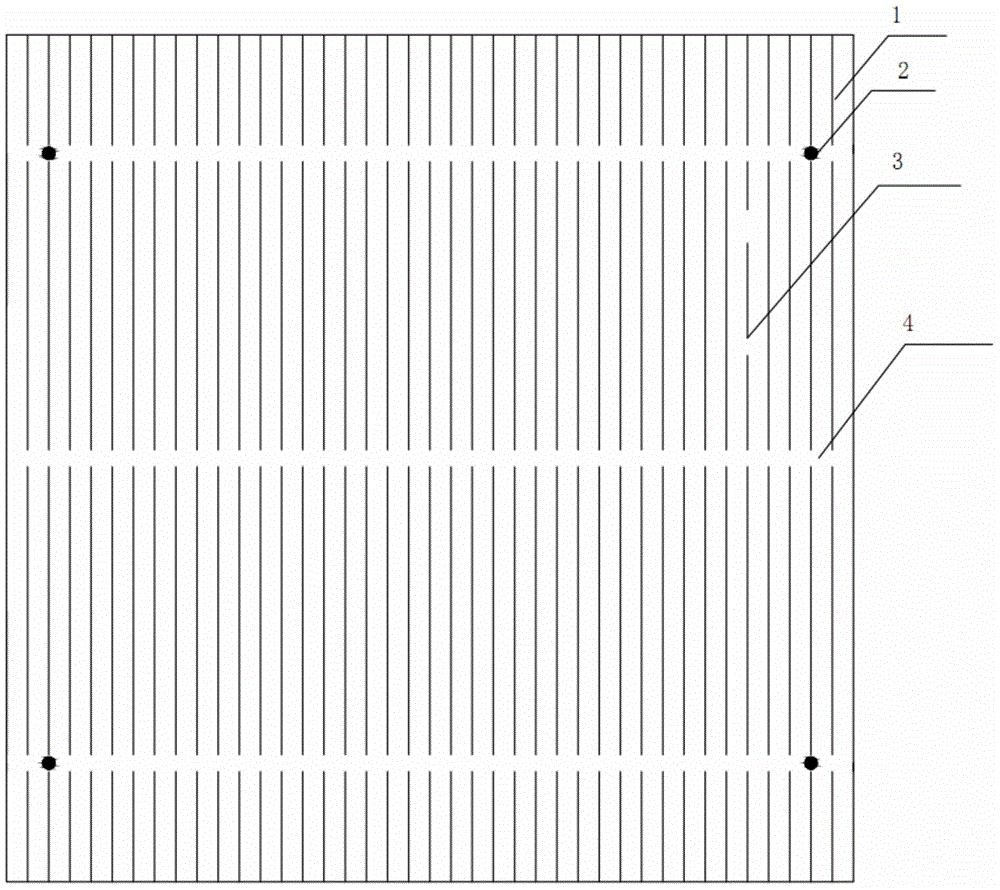

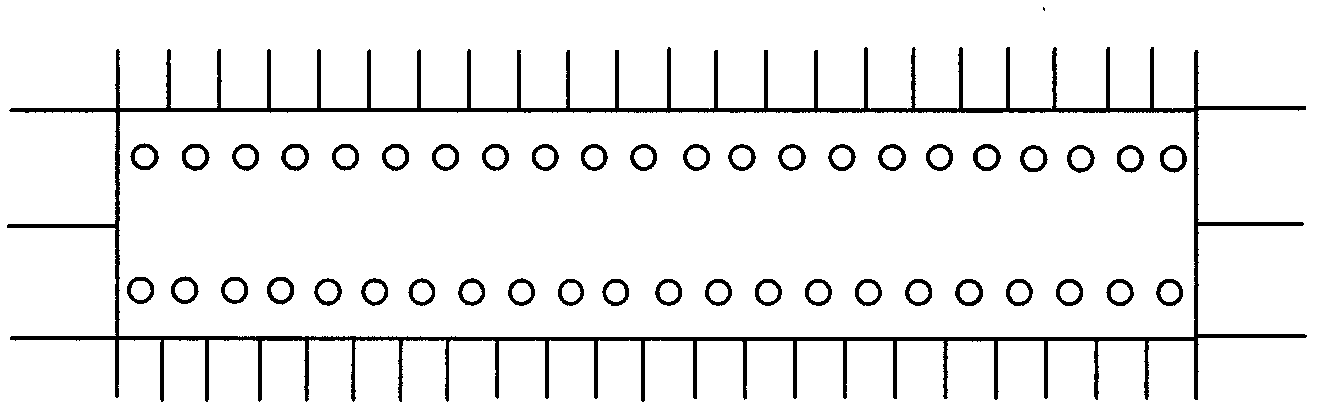

Printing mesh component and manufacturing method thereof

ActiveCN104290433AImprove transfer efficiencyAvoid full overlapScreen printersForme preparationEngineeringGrid cell

The invention discloses a printing mesh component and a manufacturing method thereof. The printing mesh component comprises a plate and a wire mesh, the wire mesh is used for bearing the plate so that subjects to be printed can pass through an opening of the plate to be attached to a printing forme, and patterns corresponding to the opening are formed on the printing forme. The wire mesh comprises multiple grid cells which are distributed in an array, the opening on the plate is a strip-shaped opening, the strip-shaped opening is only overlapped with the grid cells in the same column or row in the width direction, and the two side edges of the strip-shaped opening in the length direction and the two sides of the same grid cells overlapped with the opening intersect. By means of the printing mesh component, strip-shaped patterns on printed matter obtained through printing can be straighter and more continuous, transfer print efficiency is higher, and more sizing agents are saved.

Owner:ANHUI TATFOOK OPTOELECTRONICS TECH

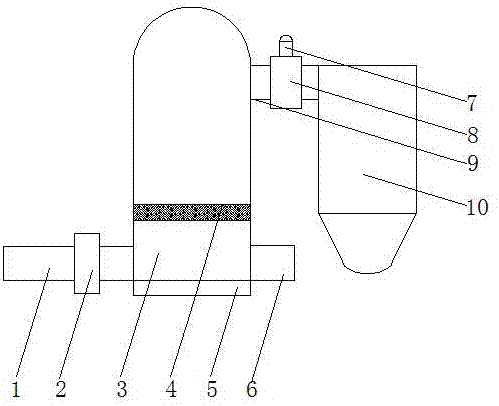

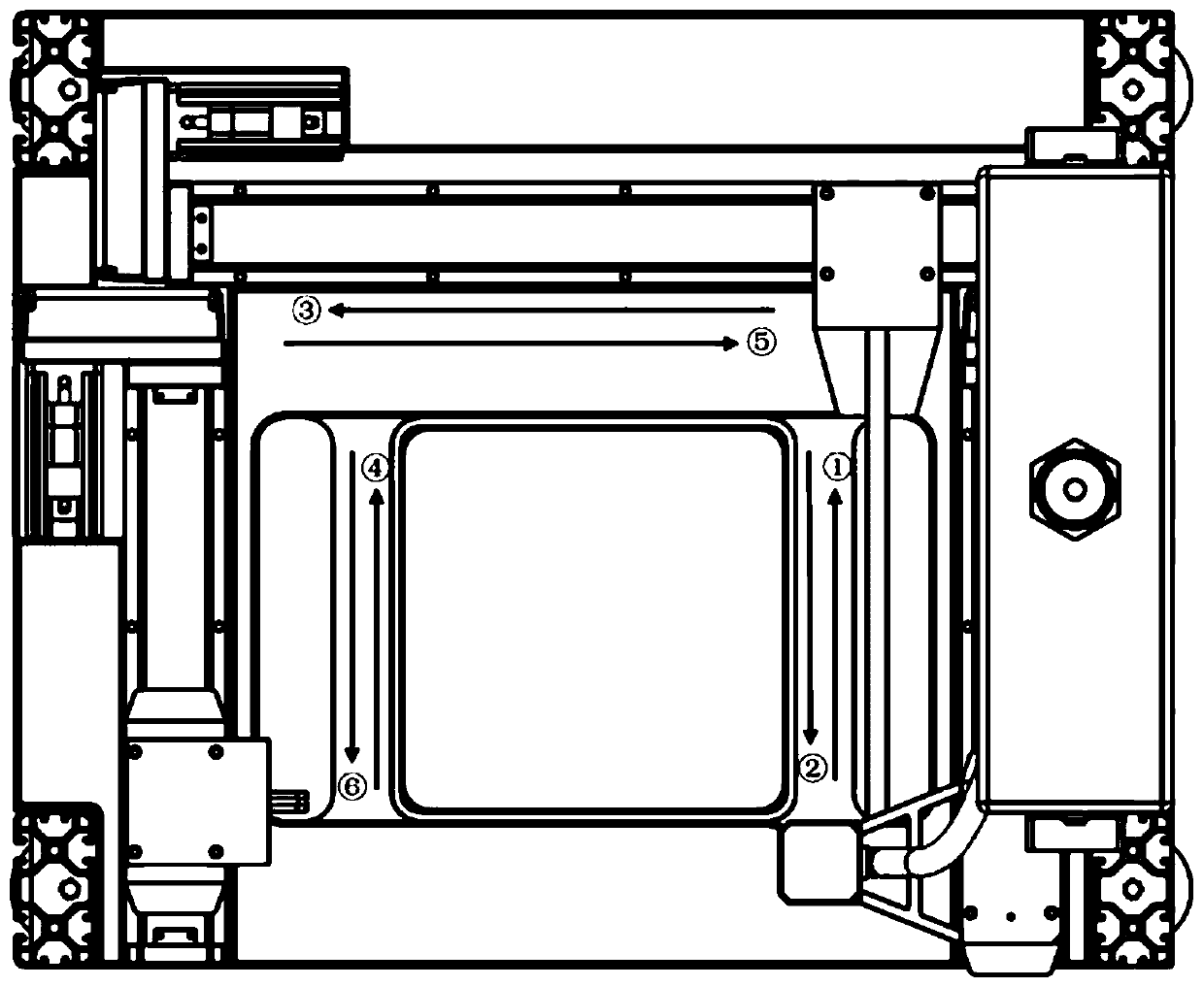

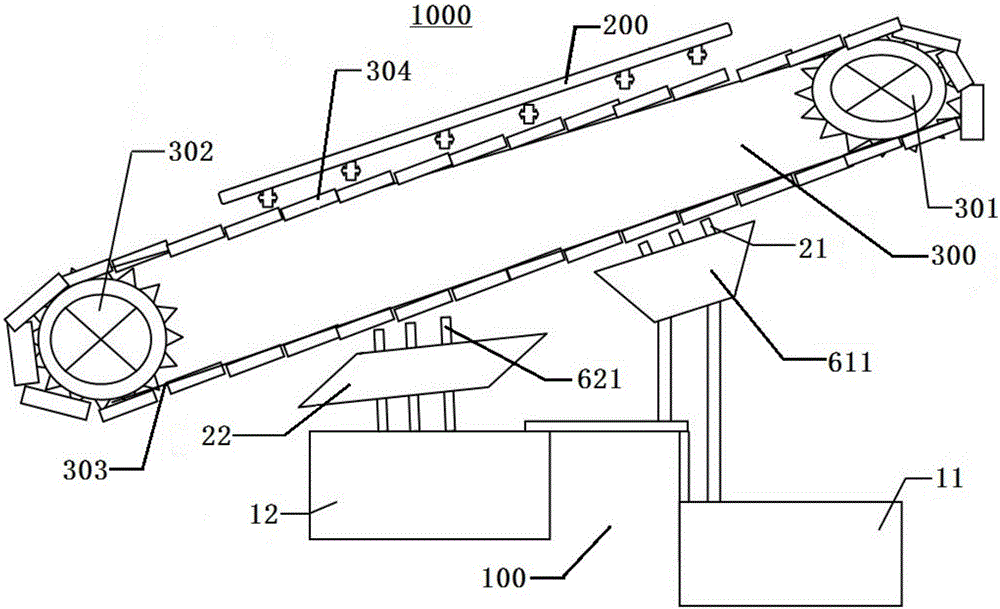

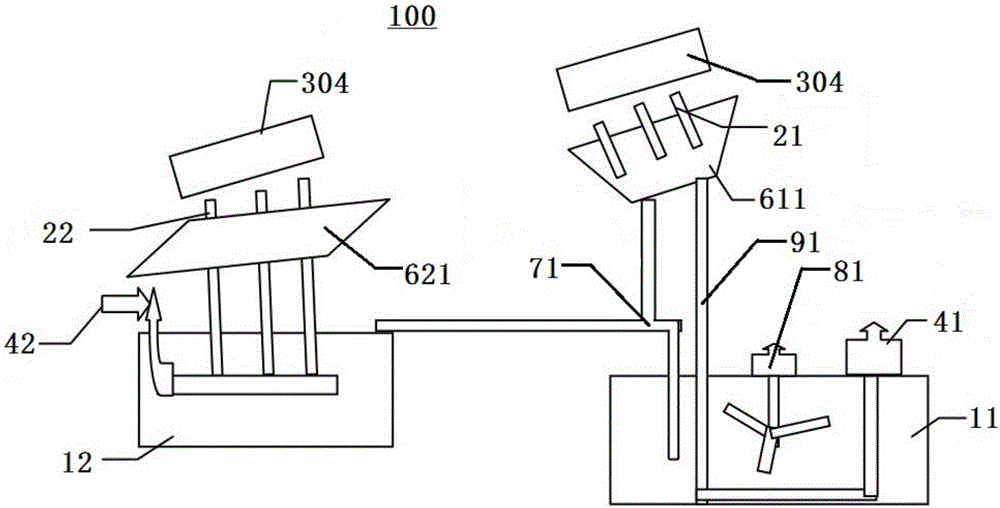

Slurry circulation and recycling device for oblique circular screen printing

InactiveCN110001198AUniform coverageQuick coverageScreen printersPrinting press partsScreen printingSlurry

The invention relates to the field of circular screen printing, in particular to a slurry circulation and recycling device for oblique circular screen printing. The slurry circulation and recycling device for oblique circular screen printing comprises a supporting frame, a circular screen roller, a dye mechanism and a rotating mechanism, wherein the supporting frame is vertically arranged; the circular screen roller is obliquely arranged at a certain angle with the supporting frame; the two ends of the circular screen roller are connected with the supporting frame; the dye mechanism is connected with the supporting frame at a certain angle; the two ends of the dye mechanism are connected with the supporting frame; the dye mechanism is connected with the two ends of the circular screen roller; the rotary mechanism is connected with the circular screen roller, and the dye mechanism comprises a dye pipe, a first feeding pipe, a second feeding pipe, a return pipe, a dye barrel and a slurryfeeding pump. An inclined design is adopted in a circular screen, the circular screen is covered with dye by the inclined circular screen, uniform covering of the dye is achieved, the printing effectis clear, the dye return speed is high, the dye cannot solidify and block the inclined circular screen, the residual dye recycling efficiency is high, the dye recycling effect is good, and the working efficiency of circular screen printing and dyeing is improved.

Owner:ZHEJIANG FURUN DYEING & PRINTING

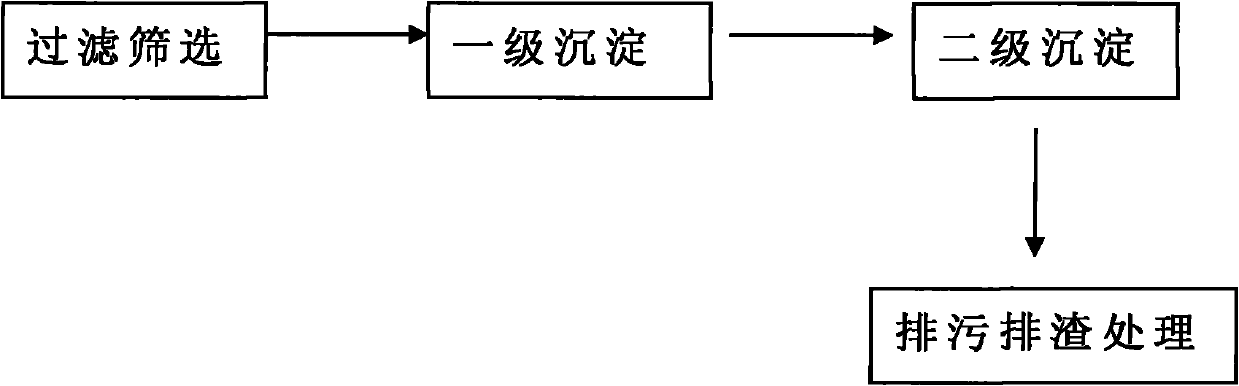

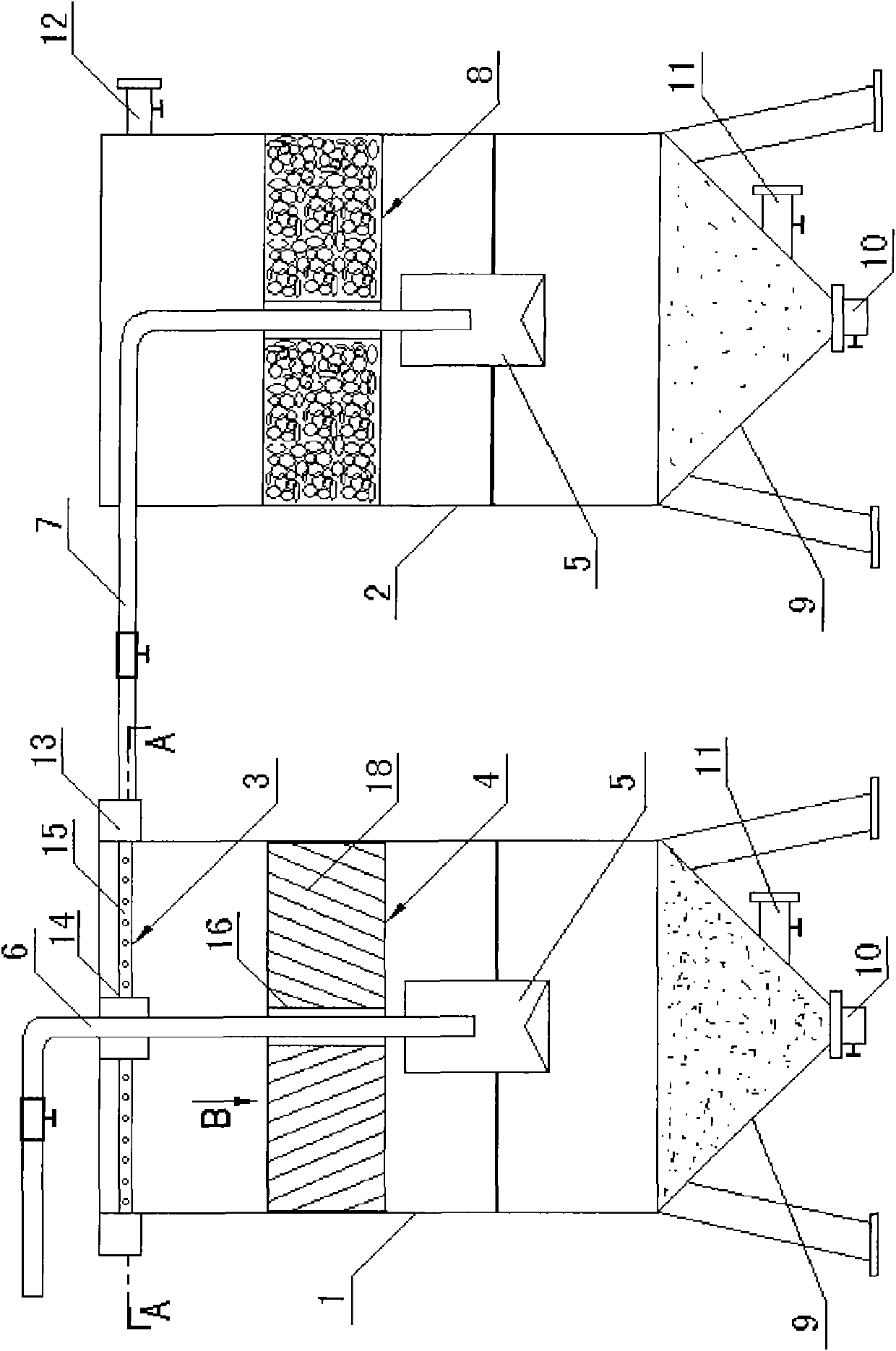

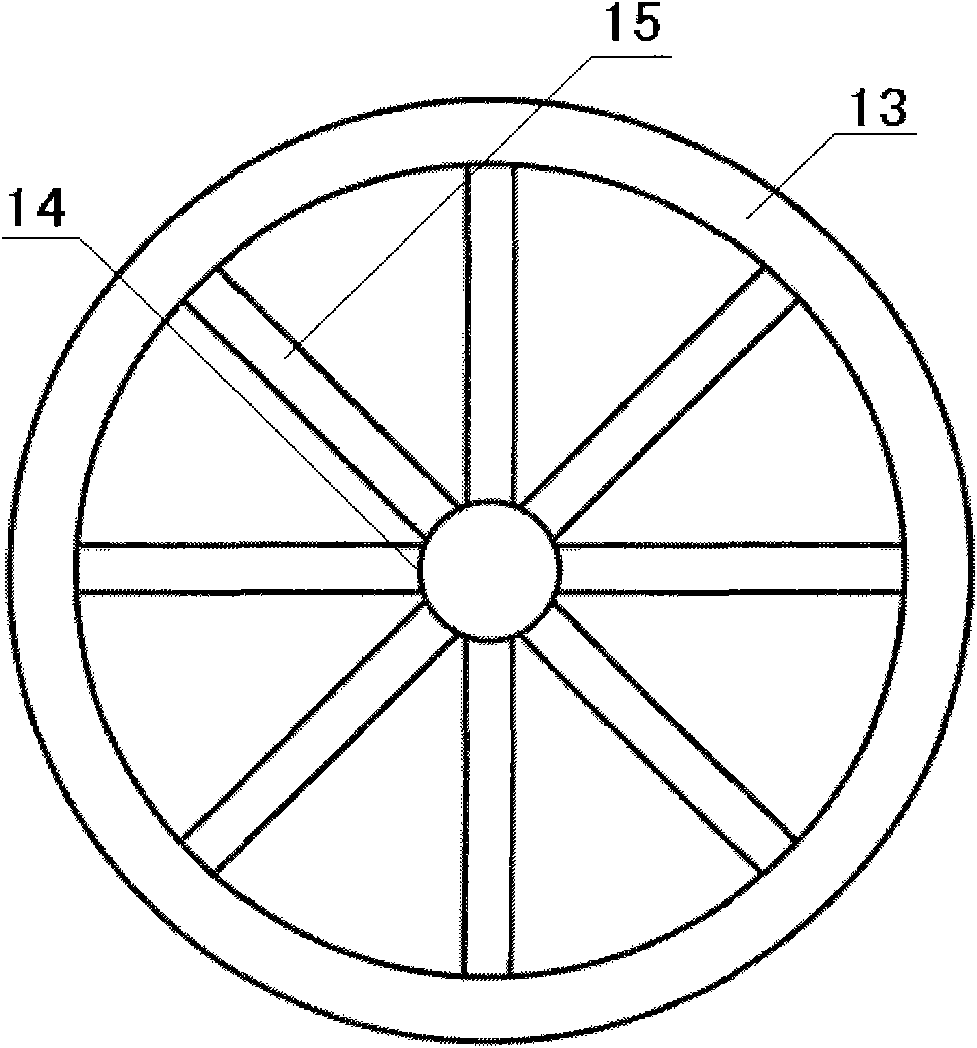

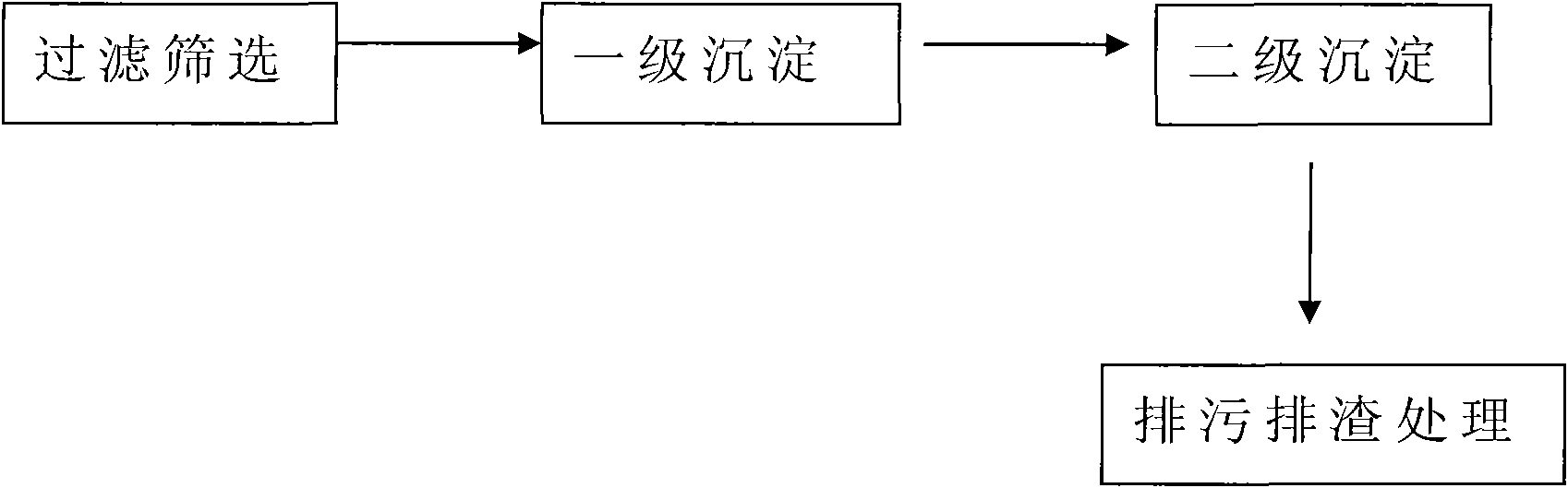

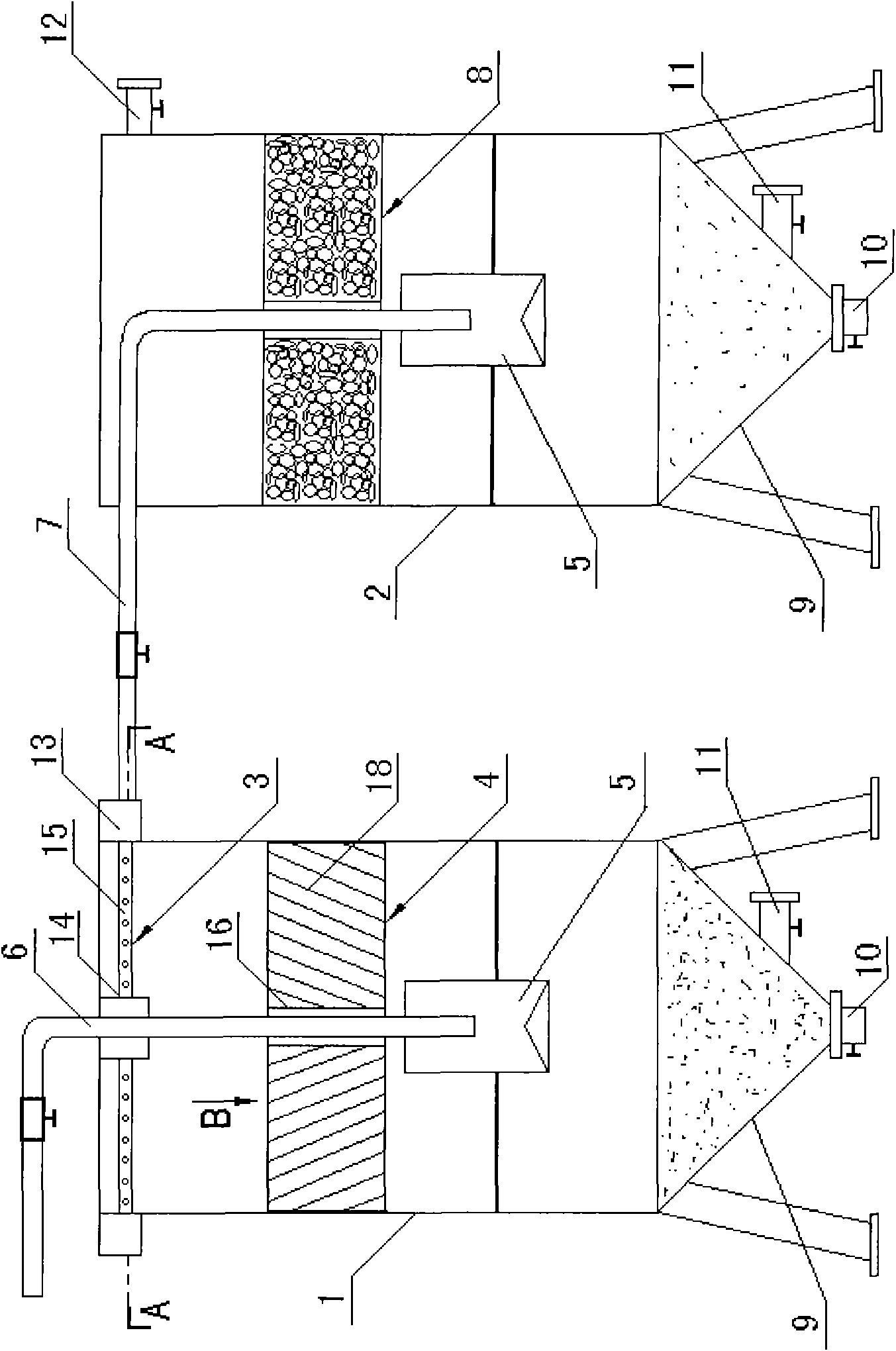

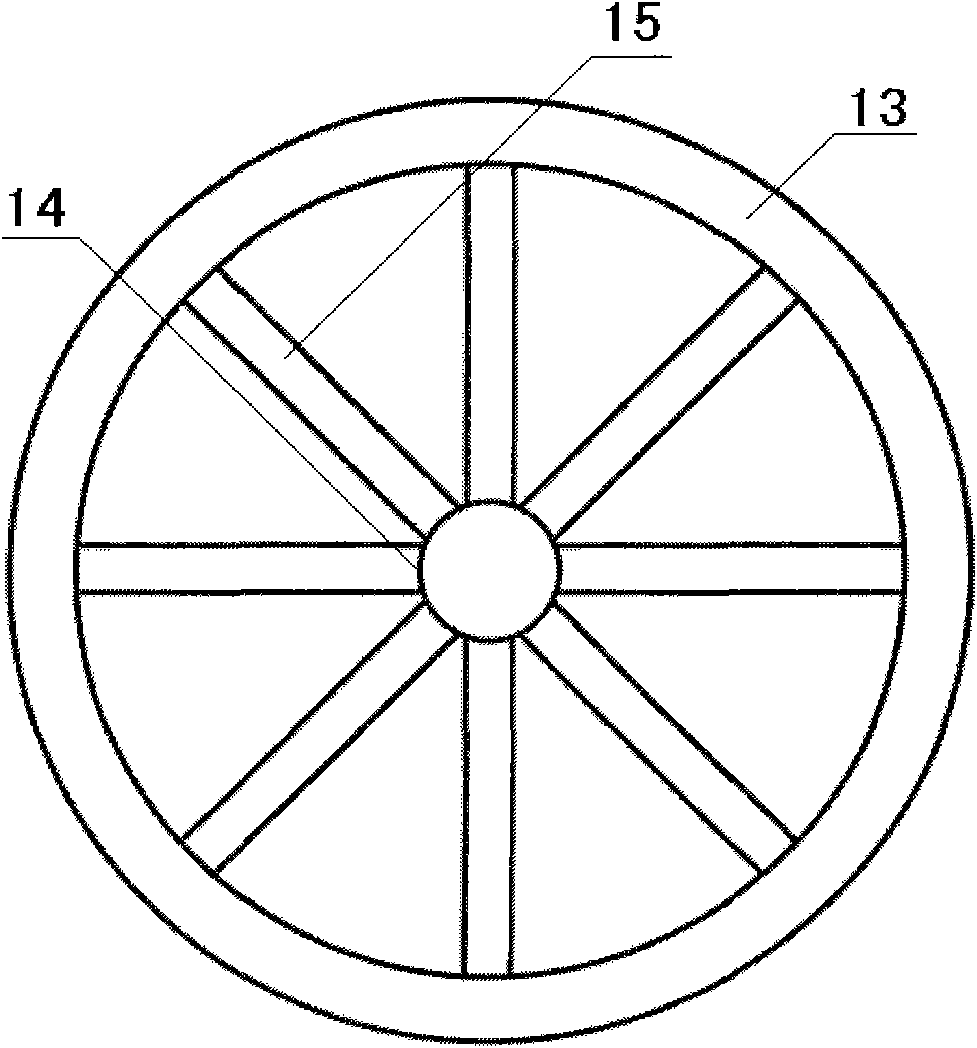

Method and tower for quickly precipitating papermaking sewage

InactiveCN102198967AGood effectTo achieve the goal of zero emissionsWaste water treatment from plant processingWater/sewage treatment by flocculation/precipitationSlagPapermaking

The invention relates to a method for treating papermaking sewage, in particular to a method and a tower for quickly precipitating the papermaking sewage. The papermaking sewage of small papermaking enterprises is treated by a two-stage quick precipitation method through synergy of a radial water outlet device, an inclined plate precipitation device, a buffer slot and a spherical filtering filler layer on the quick precipitation tower and process steps of filtering and screening, first-stage precipitation, second-stage precipitation, sewage and slag removal and the like; and the process technology is reasonable, equipment has a simple structure, and the aims of treating papermaking industrial pollution, saving energy and reducing emission can be fulfilled.

Owner:梨树县郭家店汇泉造纸机械厂

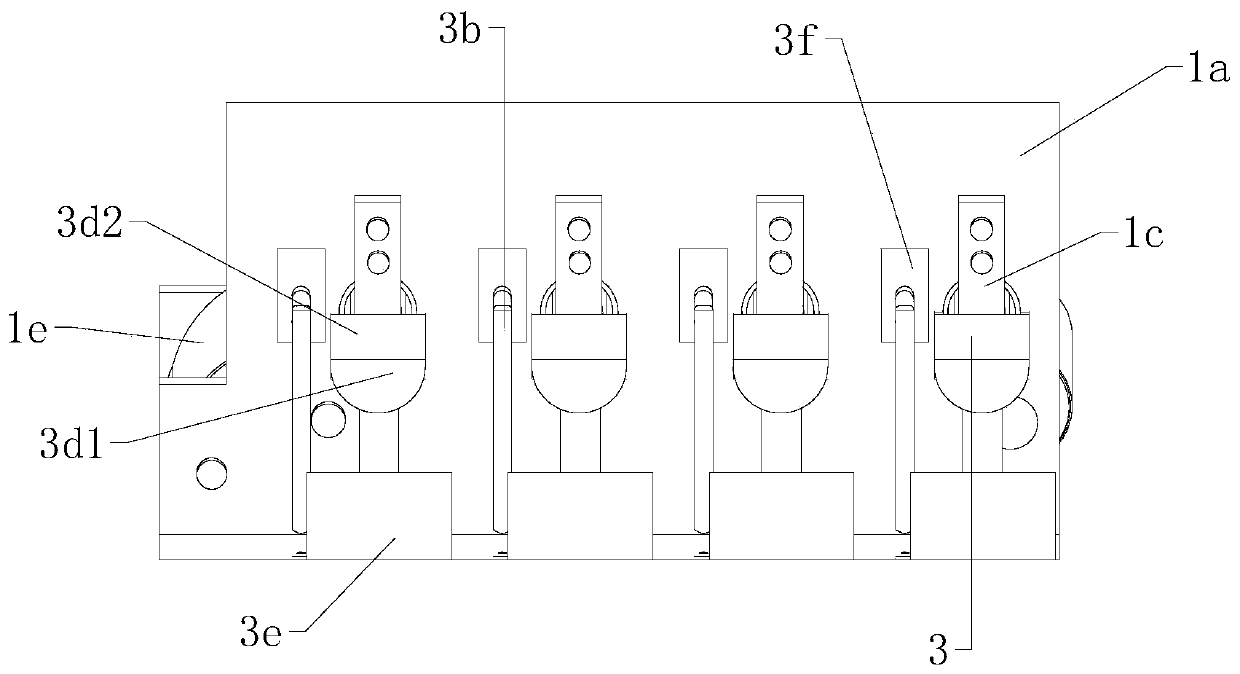

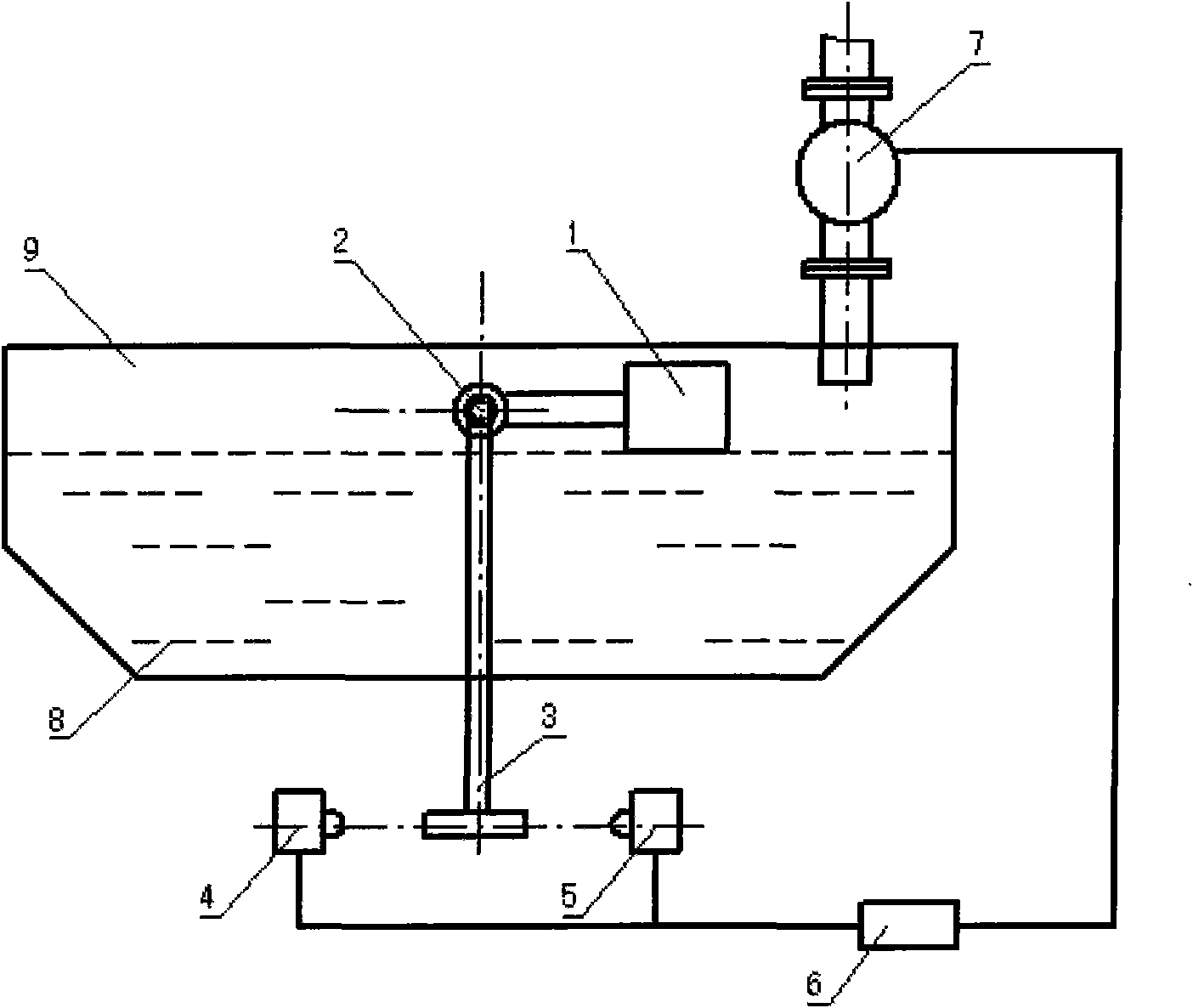

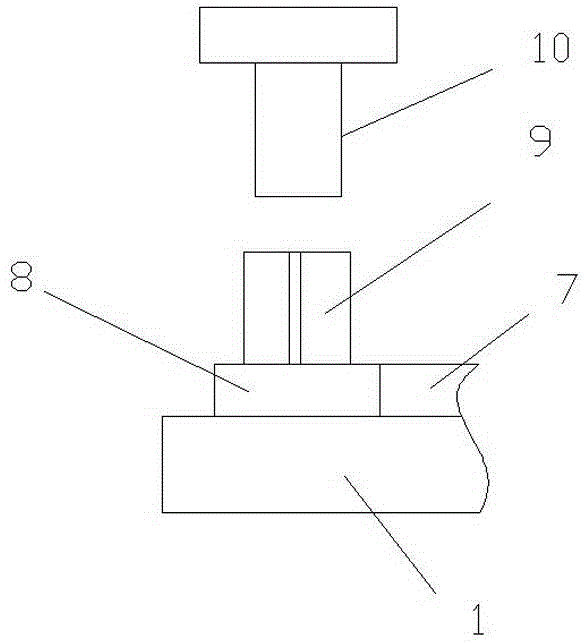

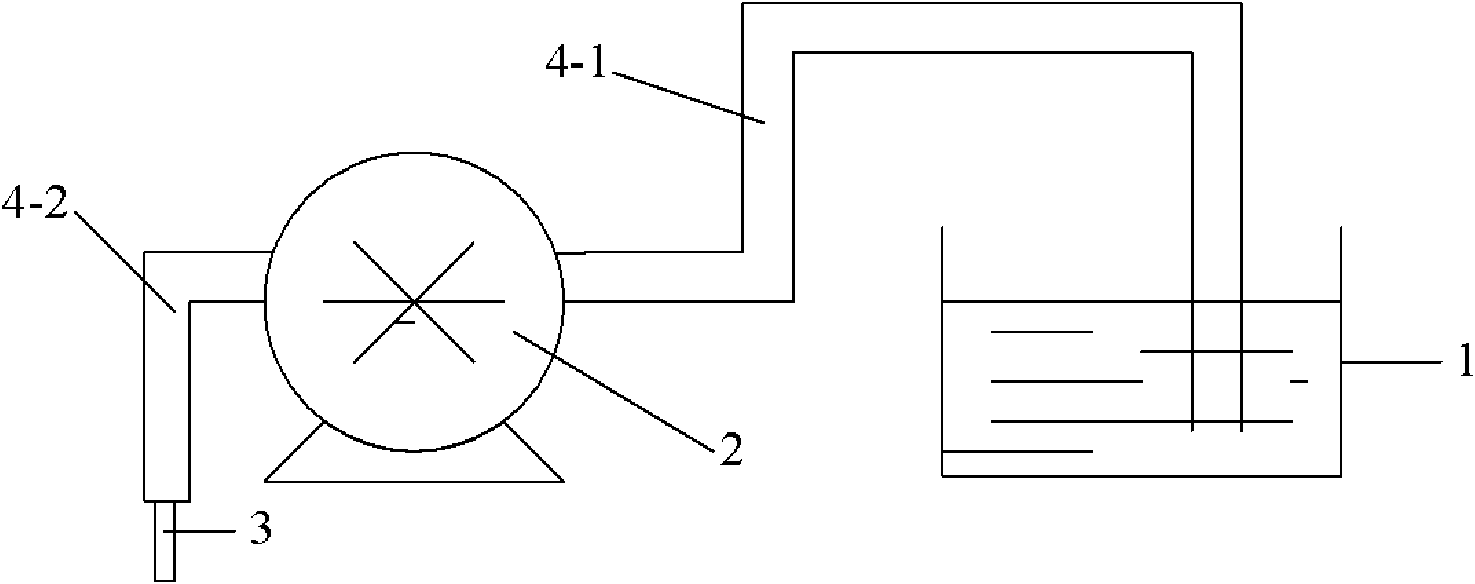

Control system for slurry supplying of modular-structure quick-reaction slurry tank

InactiveCN101603259AGuarantee the quality of sizingLiquid level stabilityLevel controlTextile treatment machine arrangementsYarnSolenoid valve

The invention relates to the technique field of textile machinery, in particular to a control system for slurry supplying of a modular-structure quick-reaction slurry tank in textile machinery, which comprises a floating ball, a rotating shaft, a rotating rod, travel switches, a solenoid valve and a cylinder ball valve. The floating ball and the rotating rod are positioned respectively on the solenoid valve; the upper and lower parts of the rotating rod are provided with two travel switches; the travel switches are connected with the solenoid valve; and the solenoid valve is connected with the cylinder ball valve. The travel switches are connected with the solenoid valve by communication cables. The control system has the following steps that: the control system is applied in small-batch multiple machine types and relates to level control under the condition of a small main slurry tank and a plurality of pre-heated auxiliary slurry tanks, thereby guaranteeing yarn sizing quality and saving slurry materials.

Owner:盐城市荣意来纺机有限公司

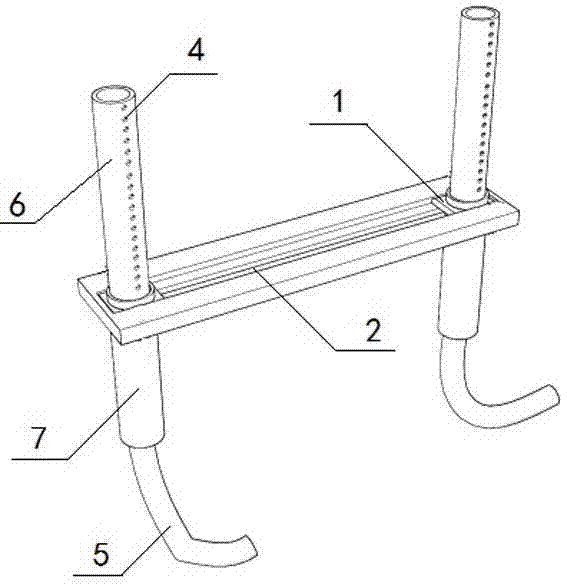

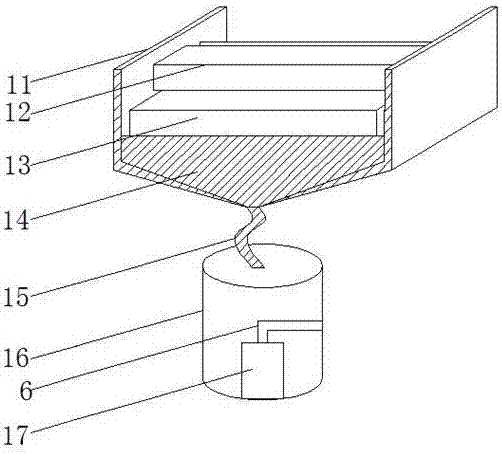

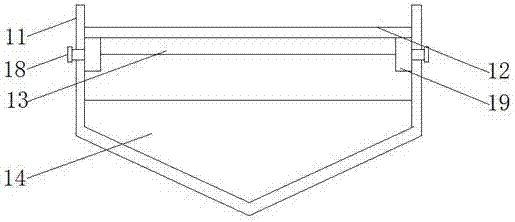

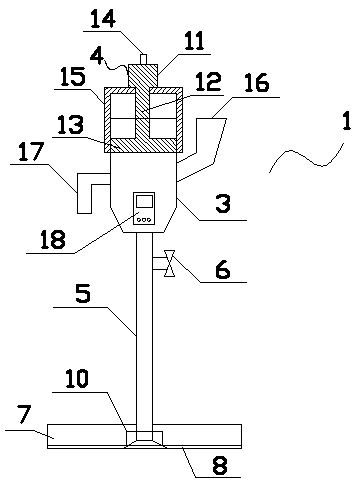

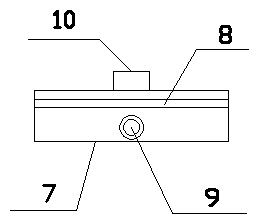

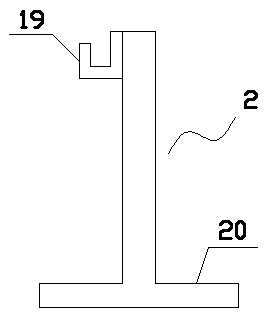

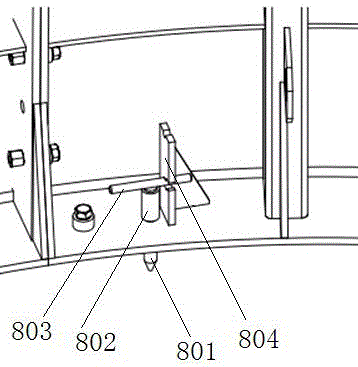

Slurry flow guide rod mechanism of solar silicon wafer fretsaw cutting machine

InactiveCN103496042AStrong process adaptabilitySave slurryWorking accessoriesFine working devicesEngineeringIngot

The invention discloses a slurry flow guide rod mechanism of a solar silicon wafer fretsaw cutting machine, and relates to the technical field of solar silicon wafer cutting machines. The slurry flow guide rod mechanism at least comprises two flow guide rods, and the flow guide rods are respectively provided with a length telescopic mechanism. The flow guide rods of the slurry flow guide rod mechanism of the solar silicon wafer fretsaw cutting machine are in sliding fit with a sliding rail through sliding blocks, and the sliding rail is perpendicular to the length direction of the flow guide rods. The slurry flow guide rod mechanism has the advantages that through the length telescopic mechanisms, the sliding blocks and the sliding rail of the slurry flow guide rod mechanism of the solar silicon wafer fretsaw cutting machine, the length and the horizontal positions of the flow guide rods can be adjusted according to the width of a fretsaw and the width of a cut silicon ingot, slurry is saved, the processing adaptability of the solar silicon wafer fretsaw cutting machine is improved, and working efficiency is improved.

Owner:HENGSHUI YINGLI NEW ENERGY

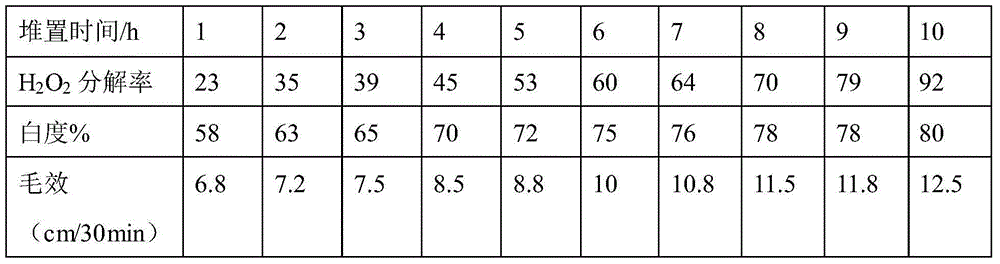

Processing method for hollowed-out jacquard corduroy

ActiveCN104963189AImprove breathabilityImprove drynessSingeingDry-cleaning apparatus for textilesPolyesterYarn

The invention discloses a processing method for a hollowed-out jacquard corduroy. The method is carried out based on grey cloth formed by weaving purified cotton yarns or polyester cotton yarns and water-soluble yarns by alternate distributing. The processing method is characterized by also comprising the following steps of A, cold batch; B, steaming and washing; C, drying; D, a dyeing procedure, a softening treatment procedure and a preshrinking procedure, finally, a finished product is obtained. According to the processing method disclosed by the invention, by adopting a pretreatment process of cold batch, short steaming and washing, the water-soluble yarns contained in the grey are dissolved, and the hollowed-out jacquard effect is formed on the cloth cover; in addition, the whiteness and the capillary effect meet the requirement of the dying procedure.

Owner:HEBEI NINGFANG GRP

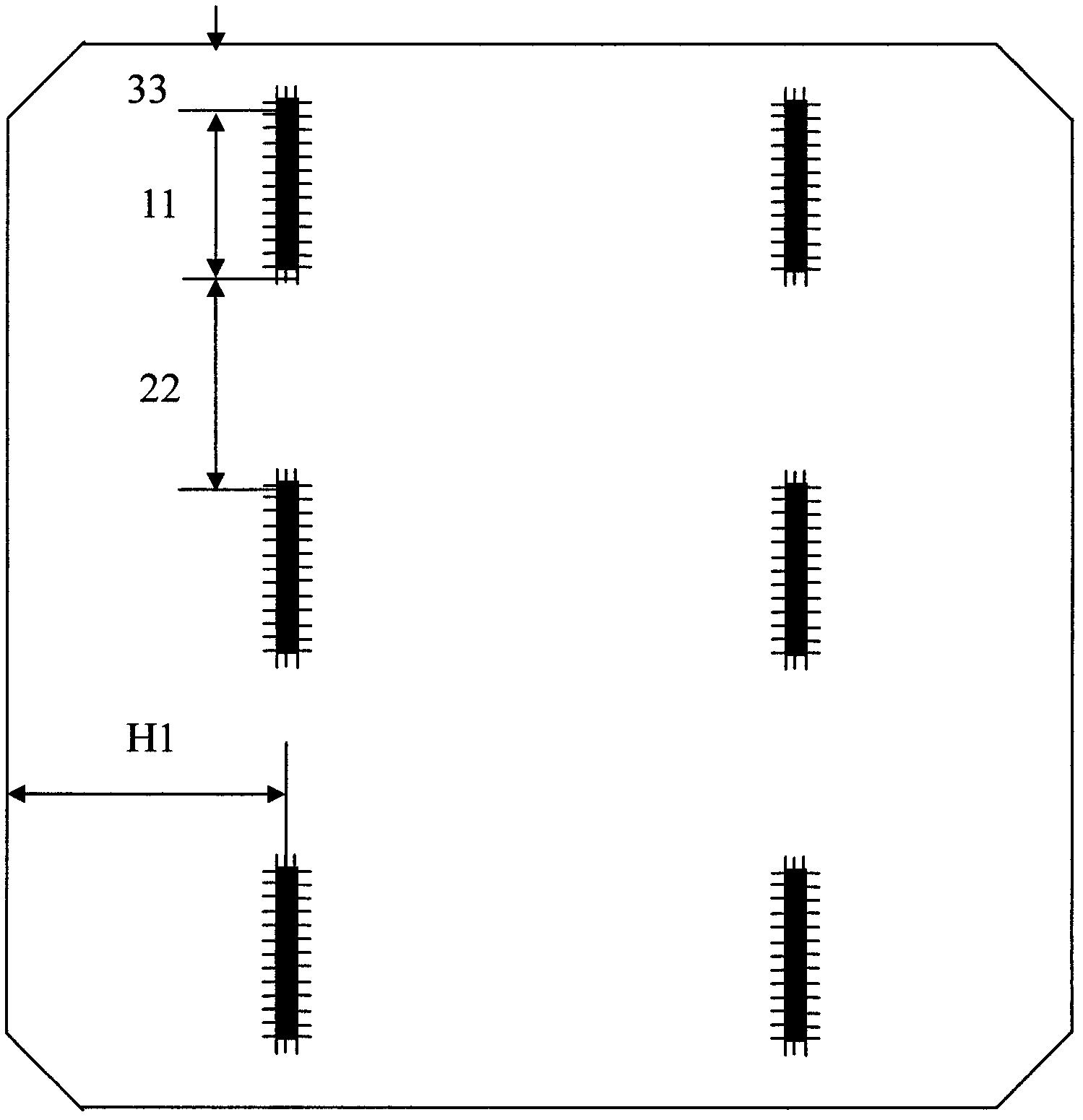

Novel electrode structure of silicon solar cell

InactiveCN104576777AIncrease investmentLow costPhotovoltaic energy generationSemiconductor devicesElectricityElectrical performance

The invention relates to a novel electrode structure of a silicon solar cell. A positive electrode for improving electrical performance and grid breakage effect of the silicon solar cell is adopted, and an auxiliary grid line comprises more than three gaps for printing of a main grid line, more than two parallel auxiliary grid lines parallel to the main grid line and multiple vertical auxiliary grid lines perpendicular to the main grid line. Compared with existing products, the parallel auxiliary grid lines parallel to the main grid line of the grid line are increased, so that the minority carrier collection probability of positive electrode grid lines is improved, conversion efficiency of a cell piece is improved, adverse influence brought by grid breakage to the cell piece reliability can be also obviously reduced, and meanwhile the novel electrode structure can be further mutually compatible with commonly-used detection devices.

Owner:JIANGSU SHUNFENG PHOTOVOLTAIC TECH CO LTD

Sizing agent circulating filtration and use device for coating machine

ActiveCN107029952ASave slurryLow costLiquid surface applicatorsCoatingsFiltrationControl engineering

The invention discloses a sizing agent circulating filtration and use device for a coating machine. The sizing agent circulating filtration and use device comprises a filter body, a collection tank, a return tank and a scraping plate. The filter body is internally provided with a filter element, the lower end of the filter body is connected with a feeding pipe, a power pump is arranged between the feeding pipe and the filter body, the other end of the filter body is connected with a return pipe, a discharging pipe is arranged at the upper end of the return pipe, a flowmeter is arranged in the discharging pipe, and an alarm lamp is arranged on the exterior of the discharging pipe. The exteriors of a scraper blade and a base material of the coating machine are fixedly provided with a fixing plate, the two sides of the fixing plate are provided with adjusting threaded rods, the adjusting threaded rods are internally connected with the scraping plate, the lower end of the fixing plate is connected with the collection tank, the lower end of the collection tank is connected with a pipeline, the other end of the pipeline is connected with the return tank, the return tank is internally provided with the return pump, and the return pump is connected with the filter body through the return pipe. The sizing agent circulating filtration and use device recycles the surplus sizing agent used during coating, and the sizing agent is saved.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

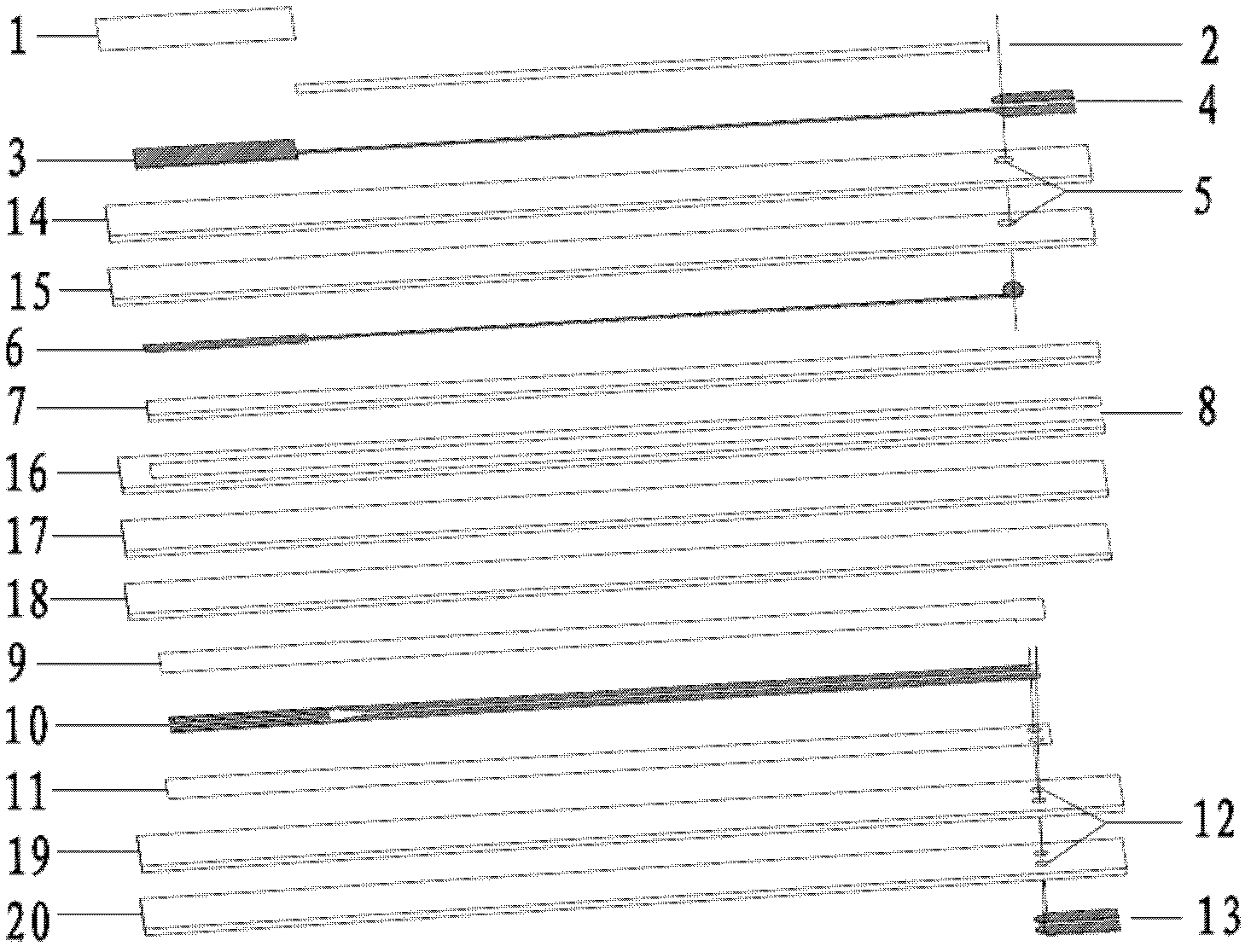

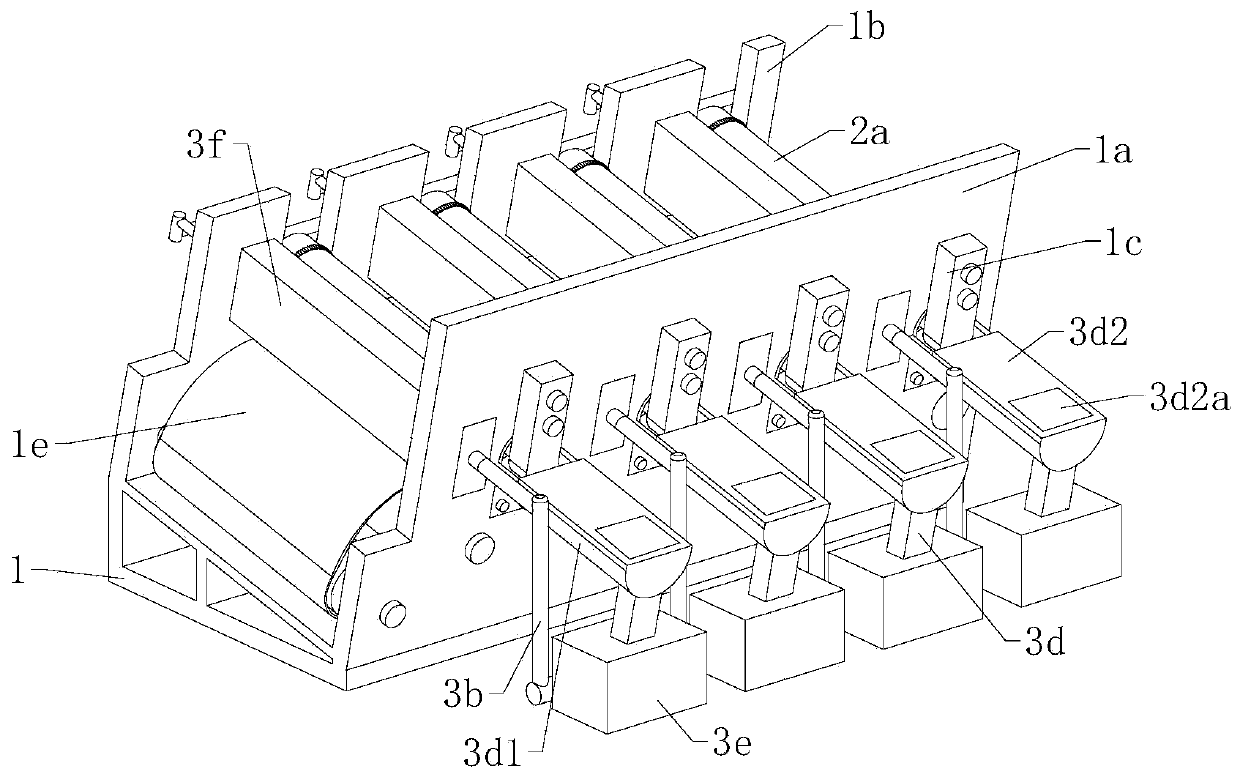

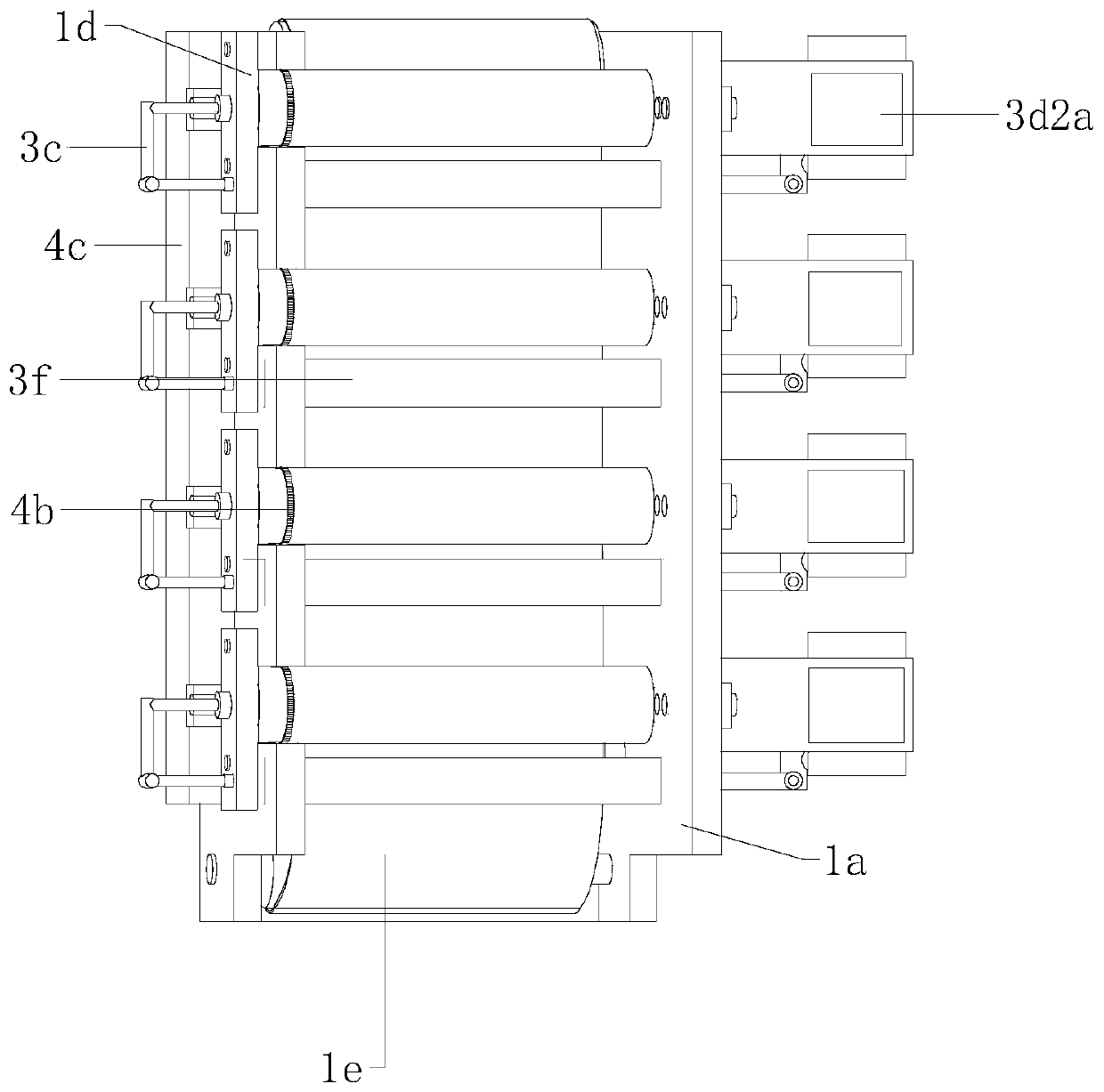

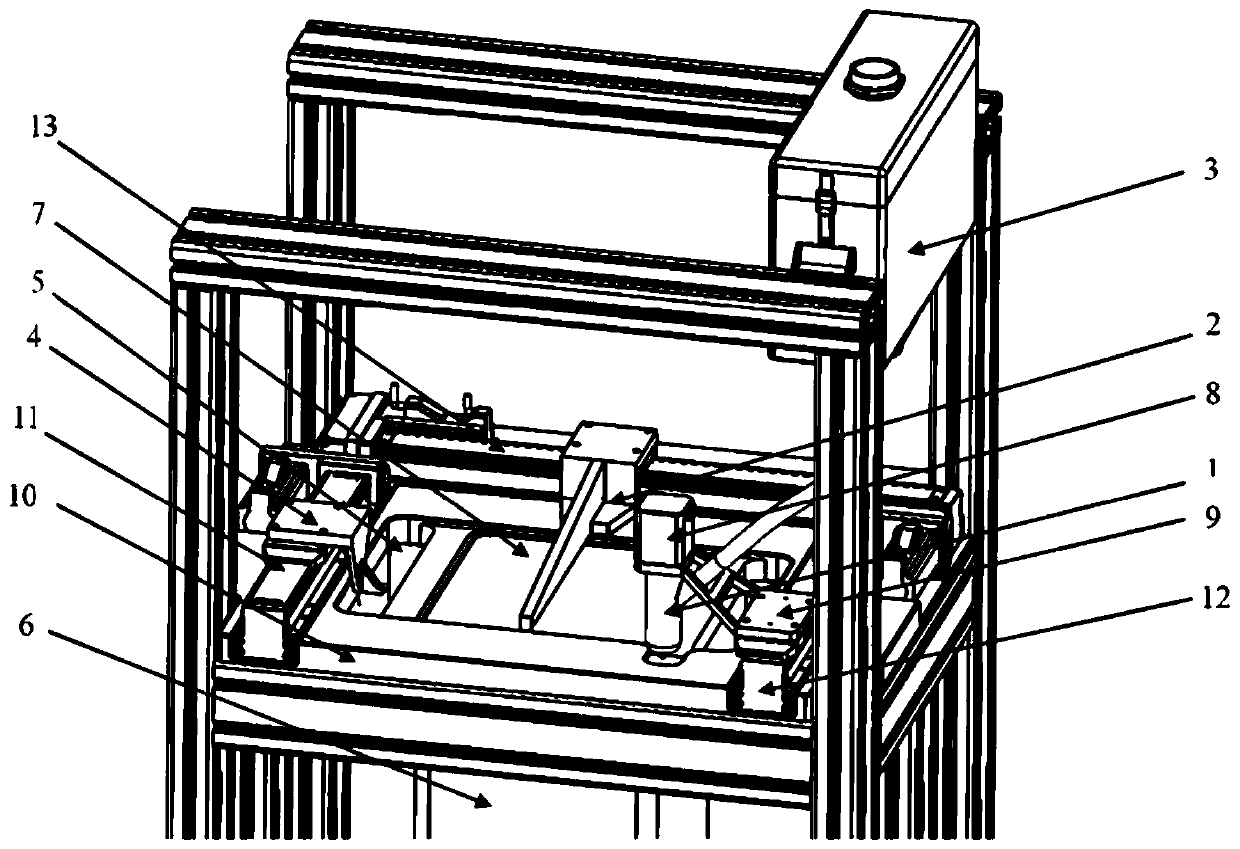

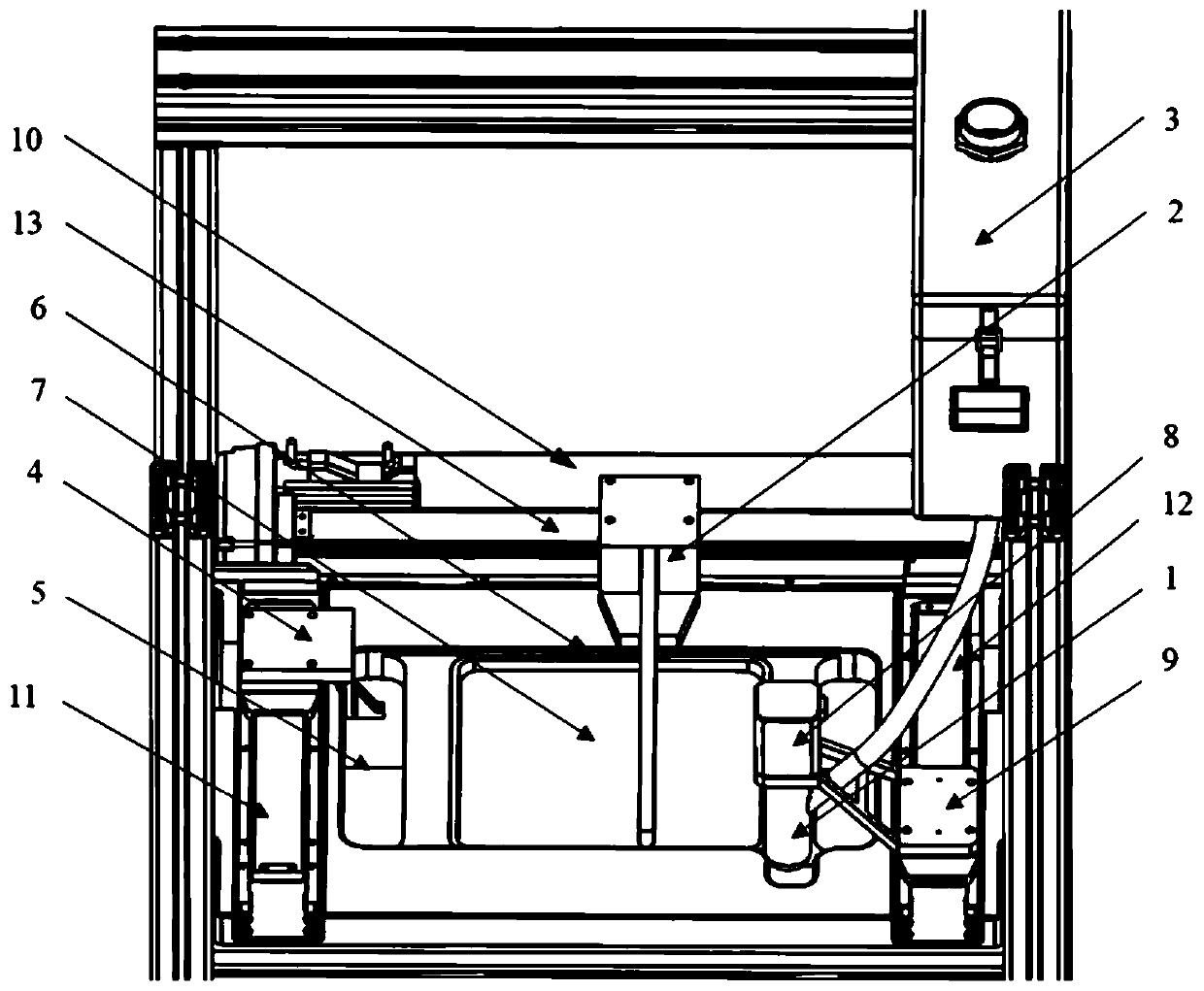

Slurry lamination automatic supply device with variable area range and control method

ActiveCN111070374ASave slurryFlatness does not decreaseAdditive manufacturing apparatusCeramic shaping apparatusAir pumpElectric machinery

The invention discloses a slurry lamination automatic supply device with variable area range and a control method. The slurry lamination automatic supply device comprises a feeding spray head, a scraper, a material storage cylinder, a pressurized air pump, a scraper cleaning device, a waste material collecting cylinder, a forming cylinder, a printing platform, a feeding spray head driving motor, afeeding spray head support frame, a spiral propeller, a mounting back plate, a first X-axis moving platform, a second X-axis moving platform and a Y-axis moving platform. According to the slurry lamination automatic supply device, a feeding mode of the scraper matching with the feeding spray head is adopted, the purposes of variable auxiliary material area and controllable range are achieved, when parts with small area are formed, the moving distance of the second X-axis moving platform can be controlled to select the slurry laying area, and thus the beneficial effect of saving slurry is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Multifunctional cement pouring device

The invention discloses a multifunctional cement pouring device, which comprises a pouring device and a supporting frame, wherein the pouring device comprises a pouring part and a flattening part, the pouring part comprises a storage tank and a pressure pump, the storage tank is an inverted frustum with a large upper opening and a small lower opening, a discharging pipeline is welded on the lower opening of the storage tank, the discharging pipeline is provided with a control valve, a sectional beam is sleeved on the lower end of the discharging pipeline, the sectional beam is vertical to the discharging pipeline, the lower bottom of the sectional beam is provided with an arc beam with the length being consistent with that of the sectional beam, the discharging pipeline runs through the sectional beam, and a discharging port on the lower end of the discharging pipeline is leveled to the bottom surface of the sectional beam; the multifunctional cement pouring device integrates the pouring and flattening, so that multifunctional integrated construction can be realized; compared with the prior art, a piston principle is adopted to control the pressure pump to pour the concrete, the pouring volume can be effectively controlled, smoothness and rapidness in pouring can be realized, the mortar is saved, and the pouring quality is guaranteed; and the flattening part is large in flattening size, good in linearity and labor-saving in operation.

Owner:周肇炎

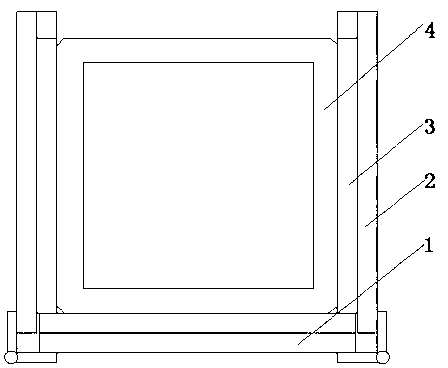

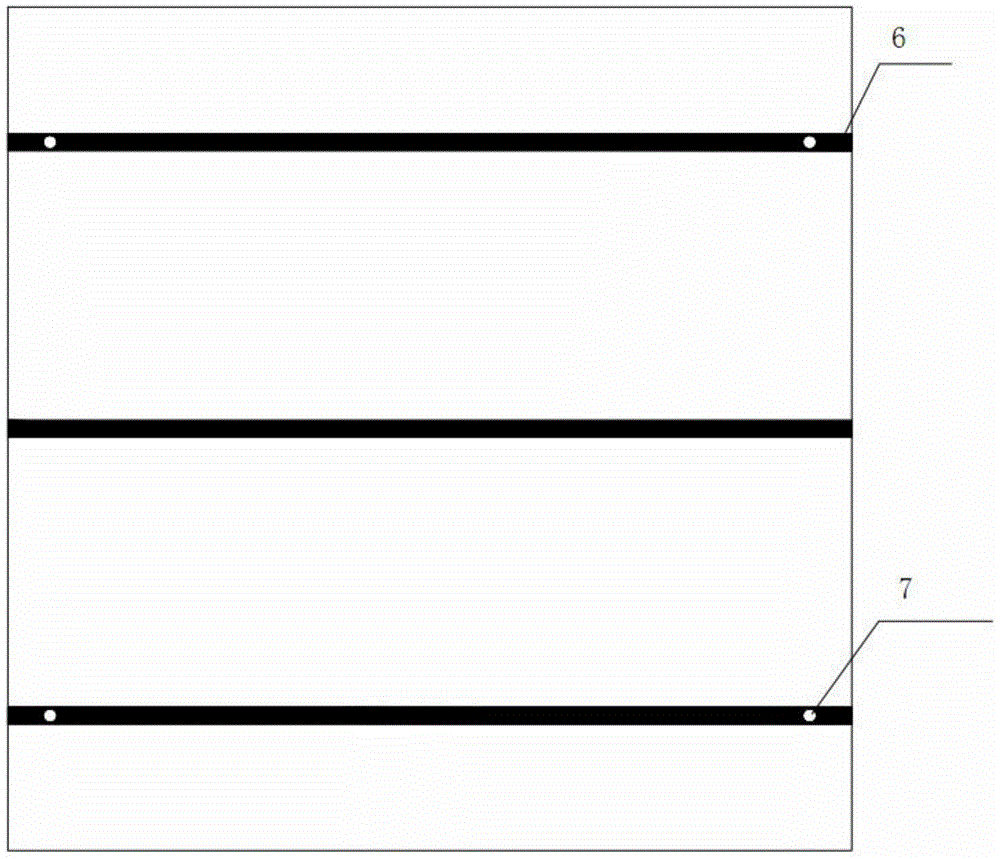

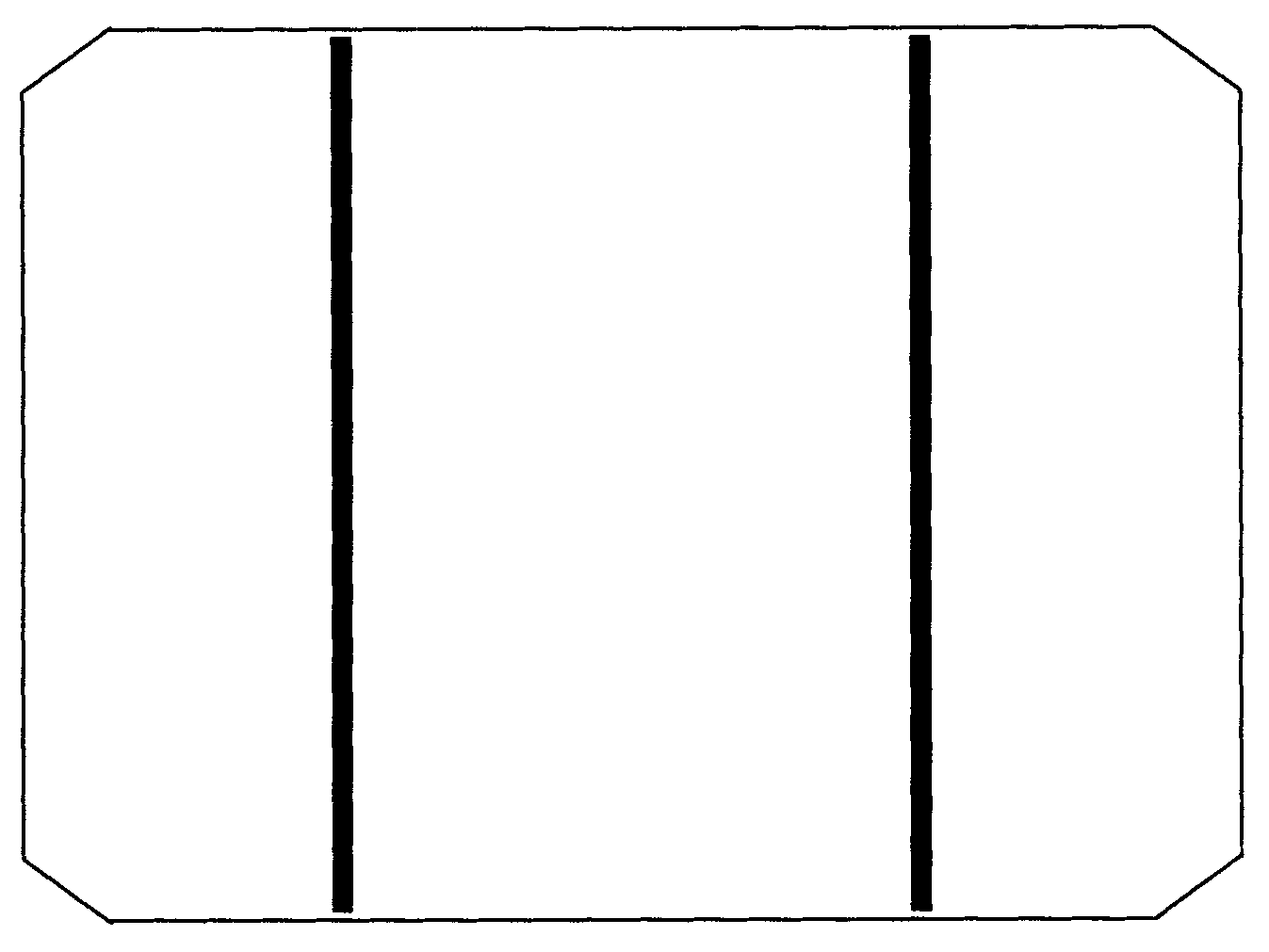

Solar cell screen printing plate having paste amount limiting function

InactiveCN104354459AReduce usagePrevent leakageFinal product manufactureScreen printersScreen printingCurrent limiting

The invention discloses a solar cell screen printing plate having a paste amount limiting function. The solar cell screen printing plate comprises an outer framework and a silk screen arranged on the outer framework, wherein the silk screen is provided with a printing surface which is in contact with a printing stock and an ink scraping surface which is in contact with a scraper; the printing surface is communicated with the ink scraping surface through silk screen holes; a pattern area is formed at the aggregating position of the silk screen holes; a non-pattern area is formed on the periphery of the pattern area; a current-limiting framework is arranged on the periphery of the pattern area of the ink-scraping surface; a sealing ring is arranged between the current-limiting framework and the silk screen ink-scraping surface; the current-limiting framework is detachably connected with the outer framework. According to the solar cell screen printing plate, the current-limiting framework is additionally arranged outside the pattern area of the screen printing plate, so that the problem of difficulty in controlling the adding amount of paste in the screen printing plate is solved, the screen printing plate is protected, and the pulp is saved.

Owner:浙江东达光伏有限公司

Back electrode design method for reducing unit consumption

InactiveCN102254993AReduce welding difficultySmall expansion coefficientFinal product manufactureSemiconductor devicesEngineeringSilicon chip

The invention discloses a back electrode design method for reducing unit consumption. The back electrode design method for reducing unit consumption comprises the following steps of: A, designing back electrodes into two parallel electrodes having the same structure, wherein the distance between an end part of each electrode and an edge of a silicon chip is 5 to 10mm; B, forming sawteeth at the periphery of each electrode, wherein the sawteeth have the width of 0.4 to 0.8mm, and a space between two adjacent sawteeth is 0.5 to 0.7mm; C, forming two columns of holes on each electrode, wherein the holes are formed at the same interval corresponding to hollow parts of the sawteeth; and D, equally segmenting each electrode into three sections, wherein each section has the length of 10 to 25mm, a space between two adjacent sections of the electrode is 20 to 30mm, and the dimension of each section of the electrode is different from the space between the two adjacent sections of the electrode. The invention has the advantages that: each electrode is segmented into three sections, an expansion coefficient can be reduced, the component welding difficulty is reduced, paste is saved, and the production cost is reduced.

Owner:ZHEJIANG FORTUNE ENERGY

Full-automatic edge gumming device of tentering and setting machine

ActiveCN105332184AReduce labor intensityImprove work efficiencyTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringFlange

A full-automatic edge gumming device of a tentering and setting machine comprises an installation support fixed to the two sides of a conveyor belt of the tentering and setting machine. The installation support is composed of an upper support plate and lower support plates, wherein a vertical baffle is fixed to the front lateral side of the upper support plate, the front lateral sides of the lower support plates are fixed to the baffle, a sizing basin is arranged at the lower end of the baffle, flange edges on the left side and the right side of the sizing basin are arranged on two supporting rods, the supporting rods are distributed on the left side and the right side of the baffle and fixed to connection plates, and the connection plates are fixed to the left lateral side and the right lateral side of the lower support plates. A positioning plate is arranged on the upper end face of the rear side of the upper support plate. A supporting shaft is hinged to the right side of the positioning plate. One end of the supporting shaft extends out of the rear lateral side of the positioning plate to be fixedly connected to a pasting wheel. An auxiliary wheel is arranged under the pasting wheel and hinged to an auxiliary support. The auxiliary support is fixed to the rear lateral sides of the lower support plates. A sizing output mechanism is arranged on the portion, on the left side the pasting wheel, on the positioning plate. By means of the full-automatic edge gumming device, labor is saved, automatic edge gumming is achieved, and the work efficiency is improved.

Owner:YOANTION IND INC LTD +1

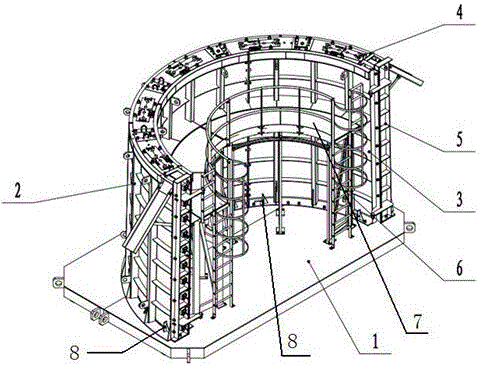

Large-scale concrete element mold and use method thereof

ActiveCN106382002ASmall footprintEasy to remove formworkForms/shuttering/falseworksTowersMold removalMaterials science

The invention discloses a large-scale concrete element mold and a use method thereof and belongs to the field of construction. The large-scale concrete element mold comprises a base plate, an arc-shaped top cover, bar-shaped end covers, an arc outer mold and an arc inner mold, wherein the radius of the arc inner mold is less than the radius of the outer mold; the inner mold and the outer mold are parallel to each other and are vertically arranged above the base plate; the top cover is covered above the inner mold and the outer mold; the end covers are vertically arranged at the two ends of the inner mold and the outer mold and are hinged with the two ends of the inner mold through a plurality of lug plates; the inner mold and the outer mold are both composed of a plurality of templates in equal arc length; one surface of each frame is arranged as a smooth plane while the other surface is arranged as a gridded frame. The large-scale concrete element mold has the advantages of convenience in mold removal, quick and convenient assembling, convenience in transportation, and the like.

Owner:QINHUANGDAO TIANYE TOLIAN HEAVY INDUSTRY CO LTD

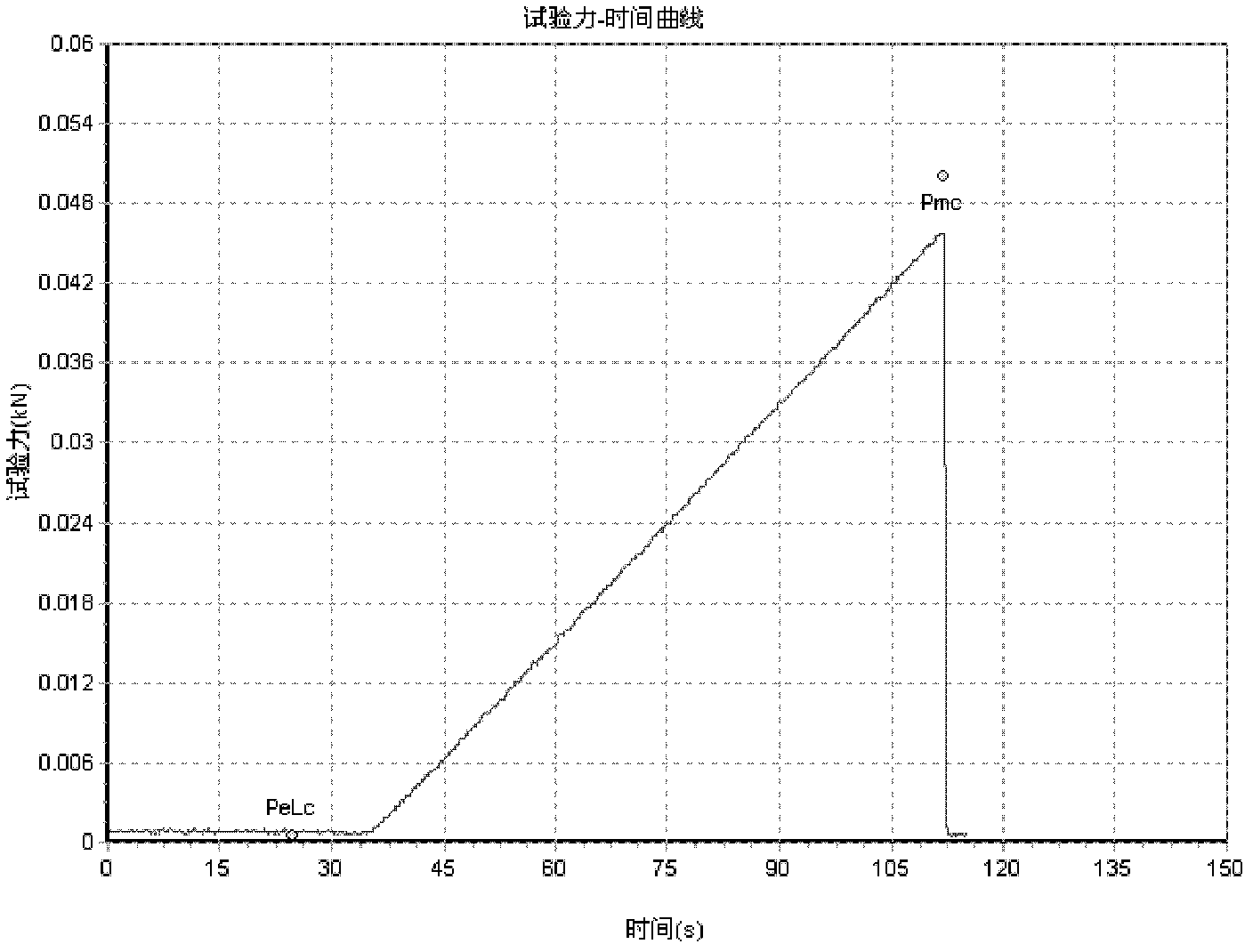

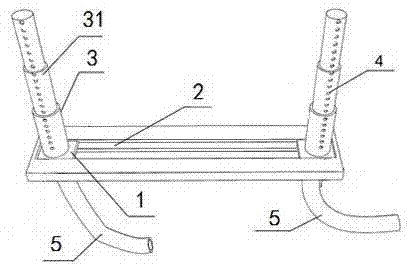

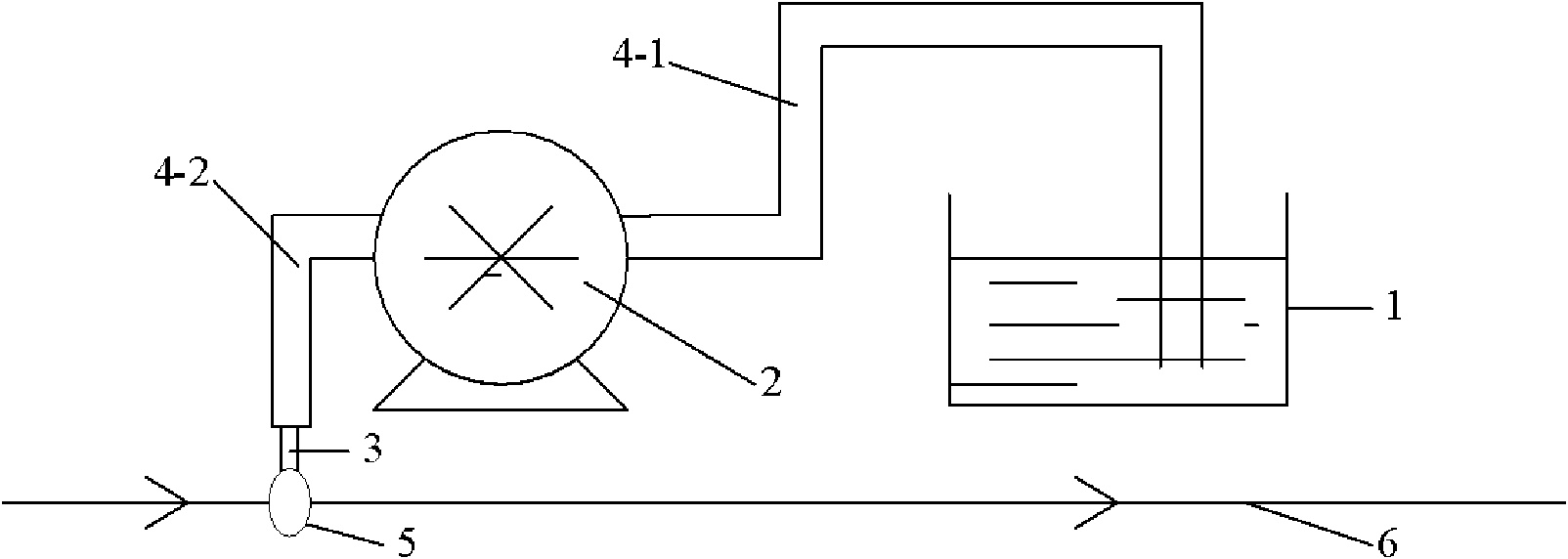

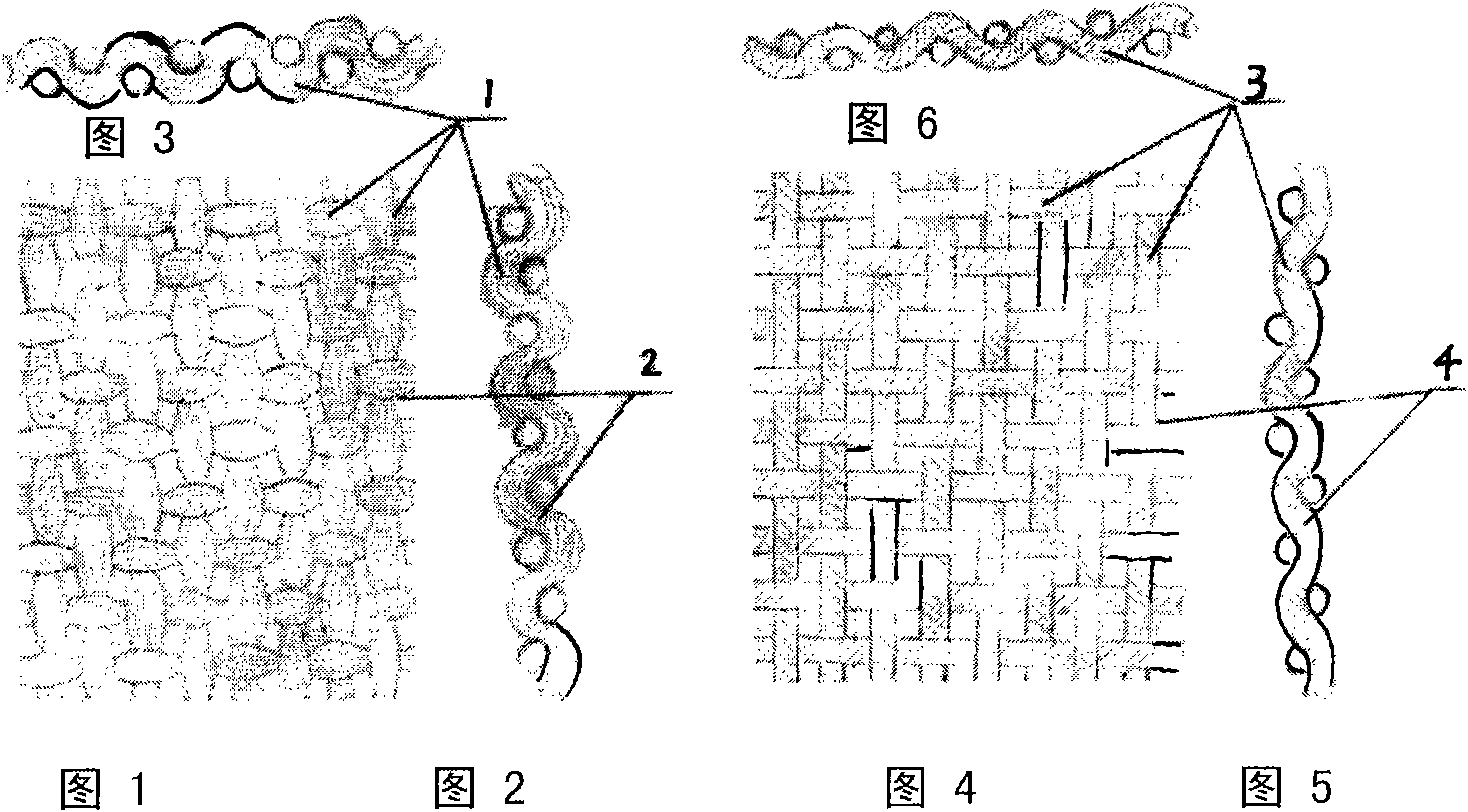

Method for sizing fiber filament by coating through hanging drop and used device thereof

InactiveCN101643983ALow amount of slurrySave slurryTextile treatment containersTextile treatment with treating outlet contectSizingPeristaltic pump

The invention discloses a method for sizing fiber filament by coating through hanging drop and used device thereof, relating to a method and device for sizing fiber filament. The invention solves theproblems that the existing fiber filament sizing method needs a large quantity of sizing material and has high cost and the existing sizing device is complex and consumes much energy. The method for sizing fiber filament by dropping includes passing the fiber filament through sizing material drop, wherein the speed for winding fiber is 0.6-1m / min. The used device by the method of the invention comprises a sizing groove, a peristaltic pump, a dropping pipe, a first conveying pipe and a second conveying pipe; one end of the first conveying pipe is extended into a sizing groove to the bottom of the sizing groove, and the other end of the first conveying pipe is communicated with the feeding opening of the peristaltic pump, and the discharging opening of the peristaltic pump is communicated with the feeding opening of the dropping pipe through the second conveying pipe. The method for sizing fiber filament by coating through hanging drop uses a little sizing material, thereby saving sizingmaterial and reducing the cost; and the using amount is 1 / 5 of the sizing material needed in the existing dipping method. The device of the invention has simple structure and low energy consumption.

Owner:HARBIN INST OF TECH

Manufacturing method of twistless fabric and product thereof

InactiveCN101929021ASimple finishing processImprove tensile capacityWoven fabricsYarnDyeingWeft yarn

The invention discloses a manufacturing method of twistless fabric and a product thereof. The method comprises the following working procedures: using a fibre rod prepared by medium staple fibre and staple fibre; taking the fibre rod as wrap and weft yarn after wrapped by Vitron; and dyeing, warping, starching, weaving and tidying according to design of pattern and flower color, wherein the weight ratio of Vitron yarn for wrapping to fibre rod body is within 10-35%, the tension at the time of beaming is not more than 8-13% of warp breaking tenacity, and weaving machine speed at the time of weaving is 15-20% lower than speed for weaving the traditional twisted fabric.

Owner:马玉成

Method and tower for quickly precipitating papermaking sewage

InactiveCN102198967BGood effectTo achieve the goal of zero emissionsWaste water treatment from plant processingWater/sewage treatment by flocculation/precipitationSlagPapermaking

Owner:梨树县郭家店汇泉造纸机械厂

Slurry spraying system for iron casting machine and iron casting machine with slurry spraying system

InactiveCN106424602AIncreasing the thicknessEasy to demouldPig casting plantsMoulding toolsSlurryCast iron

The invention discloses a slurry spraying system for an iron casting machine and an iron casting machine with the slurry spraying system. The slurry spraying system is arranged below a conveying device of the iron casting machine and is suitable for carrying out secondary slurry spraying on iron casting dies of the conveying device. The slurry spraying system comprises liquid boxes, first nozzles, second nozzles, a first drive pump, a second drive pump and a collecting device, wherein the first nozzles and the second nozzles communicate with the liquid boxes, the first nozzles and the second nozzles are arranged below the conveying device, and in the moving direction of the iron casting dies, the second nozzles are located on the downstream sides of the first nozzles. The first drive pump is suitable for driving slurry in the corresponding liquid box to be sprayed out of the first nozzles, and the second drive pump is suitable for driving slurry in the corresponding liquid box to be sprayed out of the second nozzles. The collecting device is arranged below the conveying device and is suitable for collecting slurry falling from the iron casting dies. The slurry spraying system can carry out secondary slurry spraying on the iron casting dies, iron block releasing from the dies is facilitated, the slurry can be recycled, the service life is prolonged, and the cost is saved.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com