Printing mesh component and manufacturing method thereof

A component and screen technology, used in printing, printing machines, rotary printing machines, etc., can solve the problems of low transfer efficiency, waste of printing materials, discontinuous printing patterns, etc., and achieve straight strip patterns and save paste. , The effect of high transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

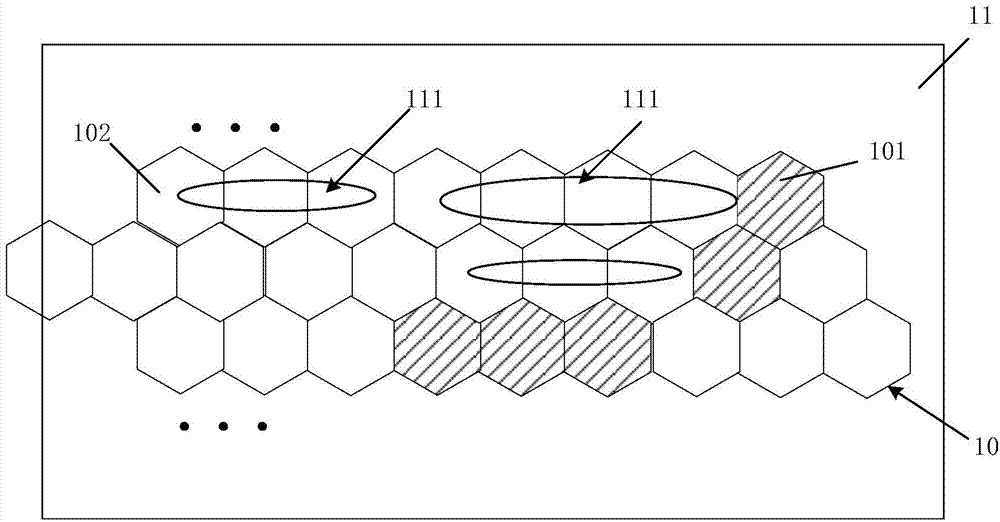

[0028] see figure 1 , figure 1 It is a structural schematic diagram of the first embodiment of the printing metal screen of the present invention. In this embodiment, the printing wire mesh 10 is used to carry the plate 11 so that the material to be printed (not shown) passes through the opening 111 on the plate 11 and adheres to the plate (not shown), and then forms a plate on the plate. A pattern corresponding to the opening 111.

[0029] The wire mesh 10 includes a plurality of grid units 101, 102, and the plurality of grid units 101, 102 are arranged in an array. Preferably, in this embodiment, the grid units 101 and 102 are regular hexagons arranged in a honeycomb shape. figure 1 Only part of the grid units are shown in the figure, and those skilled in the art can determine the complete wire mesh structure according to the illustrations and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com