Back electrode design method for reducing unit consumption

A backside electrode and design method technology, applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of high production costs, achieve the effects of reducing welding difficulty, saving paste, and reducing expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

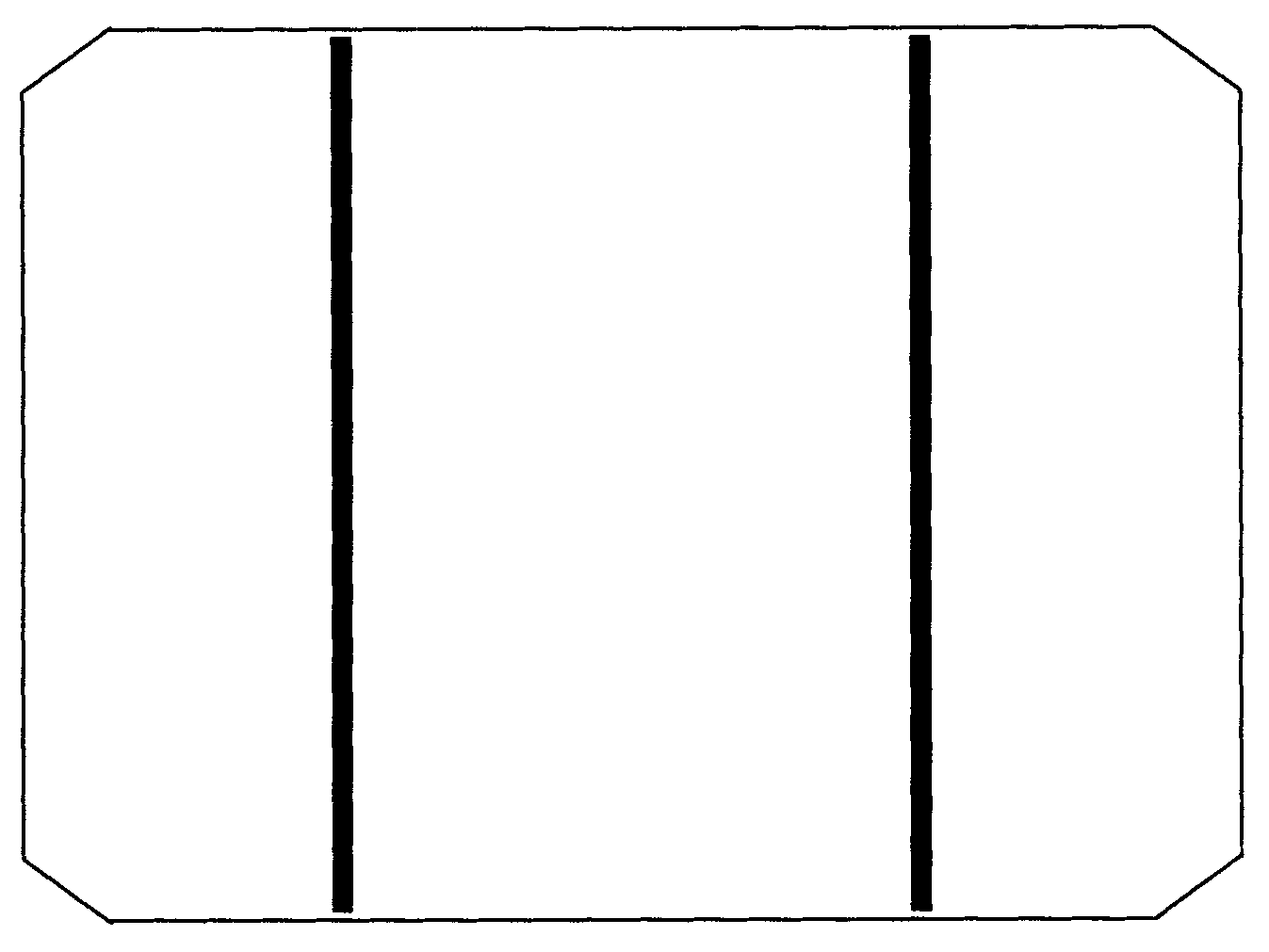

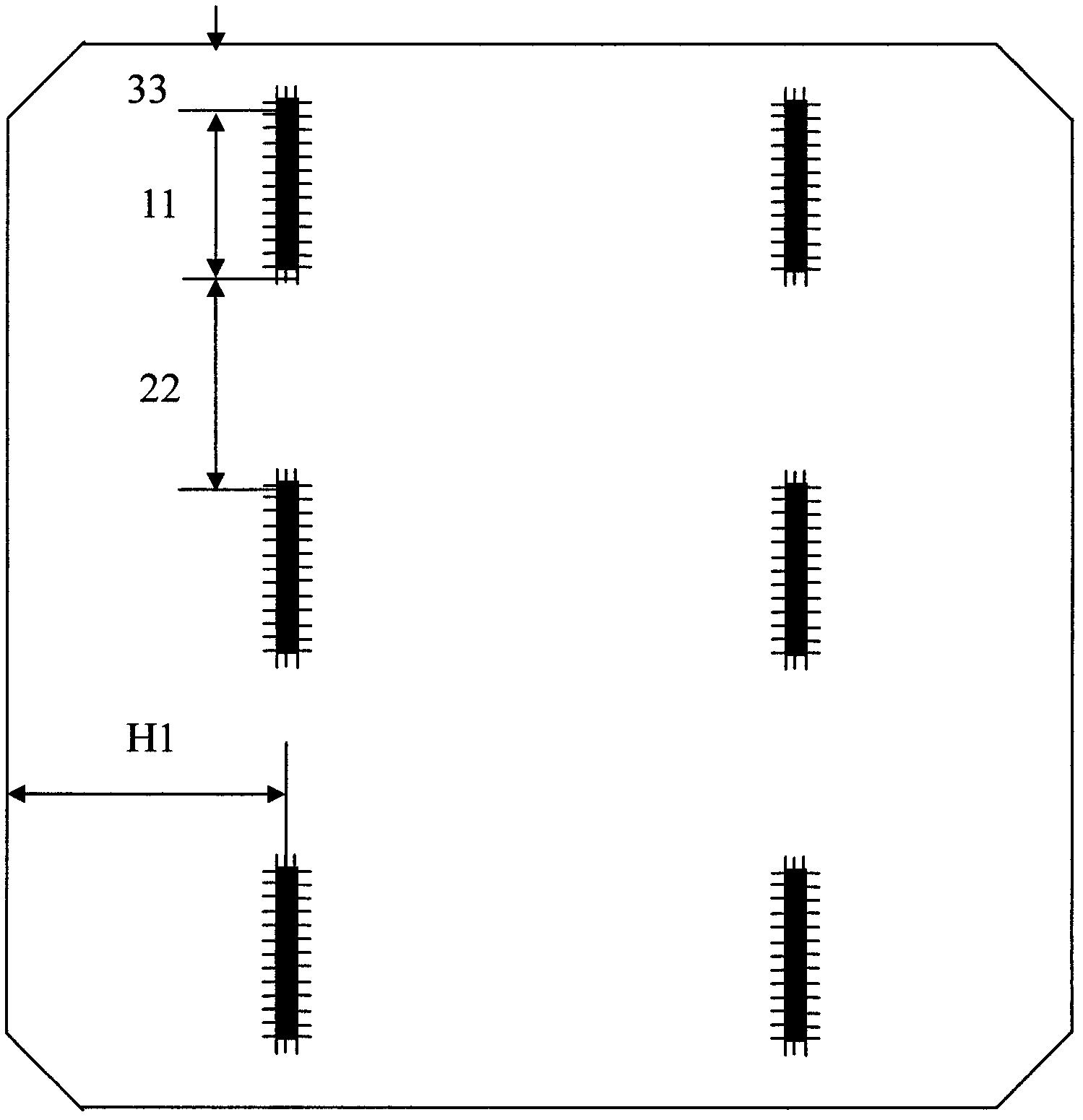

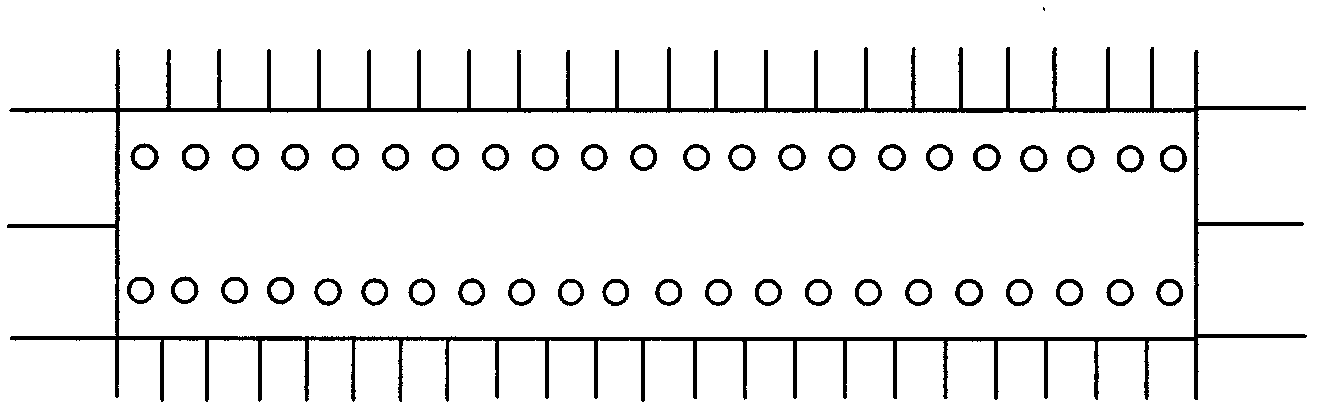

[0021] The design size of the back electrode obtained by the method of the present invention is that the size 11 of each segment electrode is 10mm, the distance 22 between the electrodes at adjacent two ends is 20mm, and the size of the distance 33 between each electrode end and the edge of the silicon chip is 5mm, the size of the horizontal distance H1 between each electrode and the edge of the silicon wafer is 31.25mm, the width of each electrode is 3mm and is not hollowed out, the length of the sawtooth is 1.2mm, and the width is 0.4mm. Root sawtooth, the distance between adjacent sawtooth is 0.5mm.

[0022] Using the same parameter screen provided by the same manufacturer and under the same experimental conditions, the comparison of the experimental data between the scheme of two complete non-segmented electrodes in the prior art and the design scheme of the present invention is shown in Table 1 and Table 2.

[0023] Table 1 is the printed wet weight of two schemes, the pr...

Embodiment 2

[0030] The design method of the back electrode used in this embodiment is the same as that in Embodiment 1, the manufacturers providing the corresponding screen plates for the back electrode are different, and the parameters are slightly changed. The size 11 of each segment electrode is 25mm, the distance 22 between the electrodes at adjacent two ends is 30mm, the size of the distance 33 between the end of each electrode and the edge of the silicon wafer is 10mm, and the horizontal distance H1 between each electrode and the edge of the silicon wafer The size of the electrode is 31.25mm, the width of each electrode is 3mm and it is not hollowed out, the length of the sawtooth is 0.8mm, the width is 0.8mm, 15 sawtooths are evenly distributed on each section, and the distance between adjacent sawtooth is 0.7mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com