Manufacturing method of twistless fabric and product thereof

A manufacturing method and fabric technology, applied in the field of textile manufacturing, can solve problems such as cloth surface wear and fluff, and achieve the effects of increased strength, improved tensile capacity, and good non-ironing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] Because the warp and weft of the fabric described in the present invention is woven with medium and long fibers and short fiber strips, and there is no twist on the fiber strips, the fabric has extremely strong fluffy, soft, hygroscopic and air-permeable properties without any finishing. , which is obvious. In particular, its fluffy and soft properties bring unexpected advantages to the fabric. A brief description is now combined with the legend as follows:

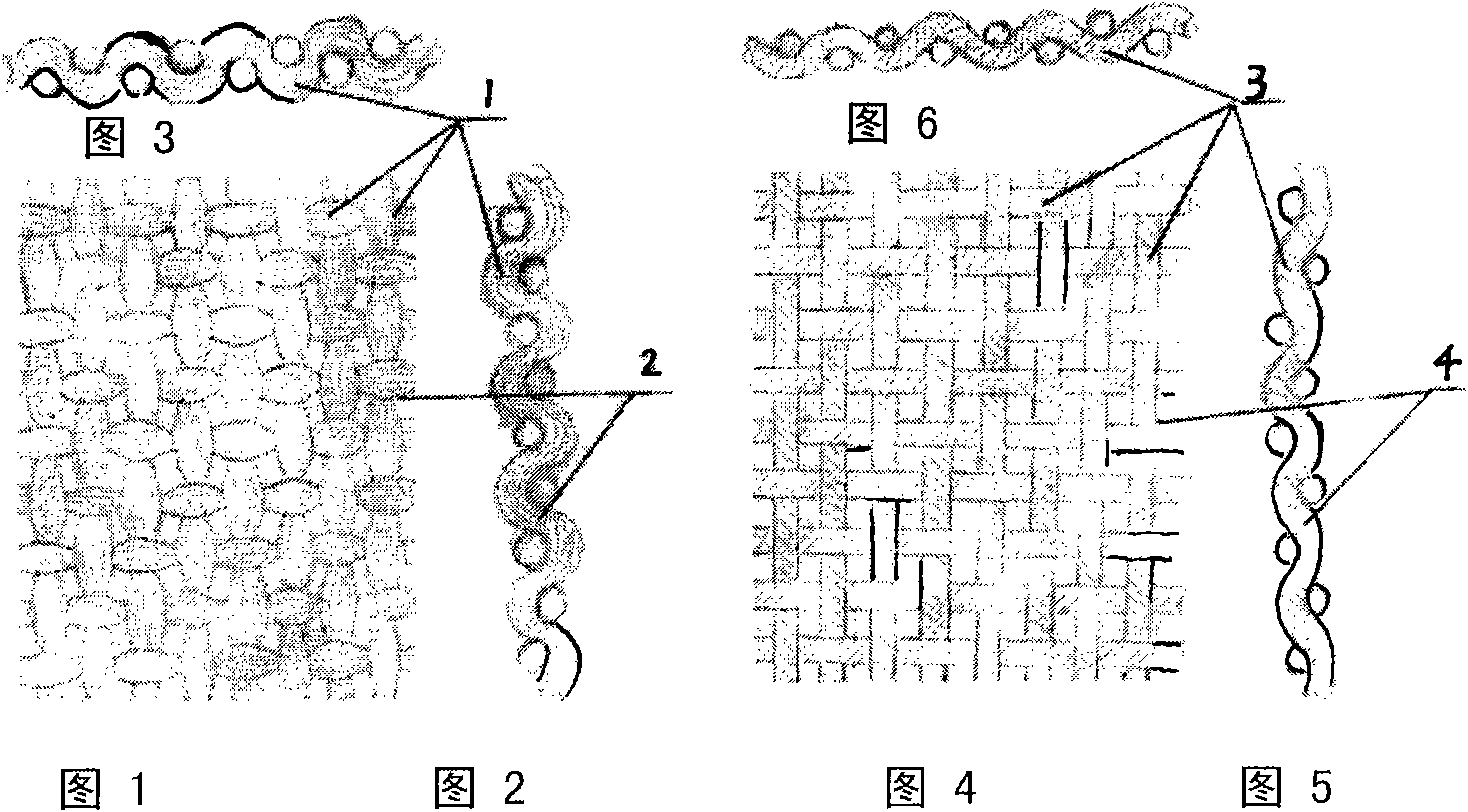

[0029] 1. Comparison figure 1 with Figure 4 It can be clearly seen that the fiber strip fabric (that is, the fabric of the present invention) is fuller, thicker and higher in total tightness than the traditional twisted fabric.

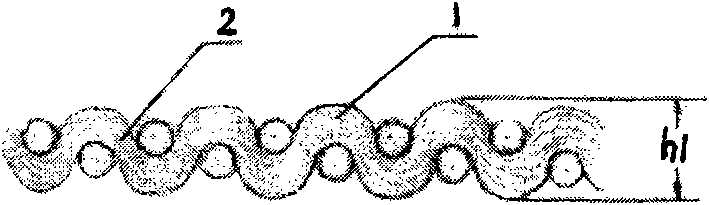

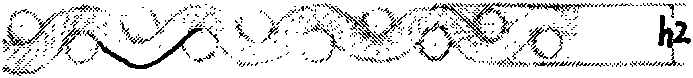

[0030] 2. From figure 2 , 3 and Figure 5 , 6 It can be seen from the comparison that the fibers in the fiber fabric of the present invention are in a fluffy state and are in the shape of candied haws in the fabric structure. The 2 places of the weaving point are thinner, the 1 pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com