A kind of preparation method and application of deodorant finishing liquid for cotton insoles

A finishing liquid and insole technology, which is applied in fiber treatment, biochemical fiber treatment, plant fiber, etc., can solve the problems of affecting the color of fabrics, difficult to obtain effects, and high temperature resistance, etc., and achieve simple production process, simple finishing process, and environmental pollution. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

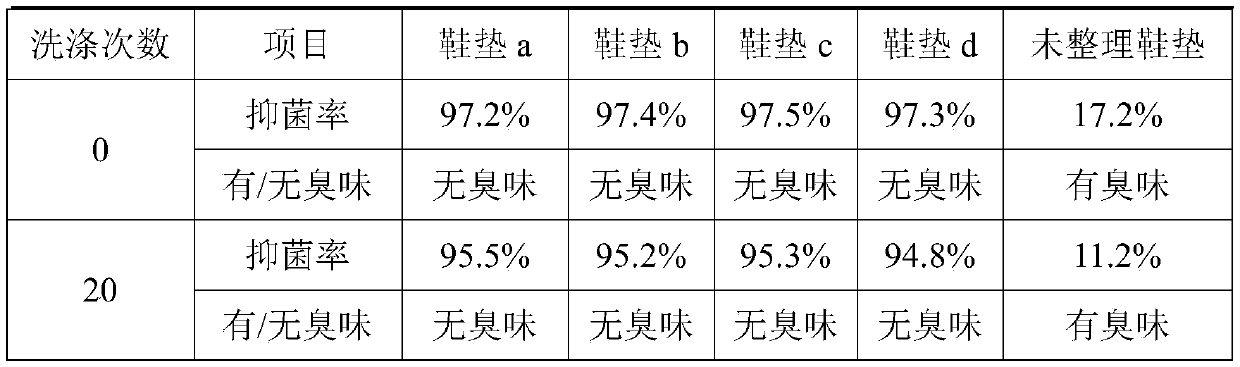

Image

Examples

Embodiment 1

[0018] In this embodiment, a cotton insole deodorant finishing liquid is prepared by the following method, including the following steps:

[0019] (1) Preparation of dispersant: Dissolve 0.1 mol of acrylic acid and 0.03 mol of allyl polyoxyethylene ether monomer with a degree of polymerization of 45 in 40 mL of deionized water at the same time to prepare a monomer solution for later use; then stir Under certain conditions, the temperature is controlled at 79-81°C, and the configured monomer and ammonium persulfate initiator are respectively added dropwise into a four-necked flask filled with 80mL of deionized water, wherein the mass of ammonium persulfate accounts for 0.1% of the total mass, the dropping time is controlled within 2 hours, after the dropping is completed, keep warm for 3 hours; finally cool to obtain the dispersant;

[0020] (2) Preparation of aqueous dispersion of nano oxide particles: weigh 5g of AgO, ZnO and TiO respectively 2 The powder is ground into a na...

Embodiment 2

[0025] In this embodiment, a cotton insole deodorant finishing liquid is prepared by the following method, including the following steps:

[0026] (1) Preparation of dispersant: Dissolve 0.1 mol of acrylic acid and 0.04 mol of allyl polyoxyethylene ether monomer with a degree of polymerization of 45 in 45 mL of deionized water at the same time to prepare a monomer solution for later use; then stir Under certain conditions, the temperature is controlled at 79-81°C, and the configured monomer and ammonium persulfate initiator are respectively added dropwise into a four-necked flask filled with 80mL of deionized water, wherein the mass of ammonium persulfate accounts for 0.15% of the total mass, the dropping time is controlled within 2 hours, after the dropping is completed, keep warm for 3 hours; finally cool to obtain the dispersant;

[0027] (2) Preparation of aqueous dispersion of nano oxide particles: weigh 5g of AgO, ZnO and TiO respectively 2 The powder is ground into a n...

Embodiment 3

[0032] In this embodiment, a cotton insole deodorant finishing liquid is prepared by the following method, including the following steps:

[0033] (1) Preparation of dispersant: Dissolve 0.1 mol of acrylic acid and 0.05 mol of allyl polyoxyethylene ether monomer with a degree of polymerization of 45 in 40 mL of deionized water at the same time to prepare a monomer solution for later use; then stir Under certain conditions, the temperature is controlled at 79-81°C, and the configured monomer and ammonium persulfate initiator are respectively added dropwise into a four-necked flask filled with 80mL of deionized water, wherein the mass of ammonium persulfate accounts for 0.25% of the total mass, the dropping time is controlled within 2 hours, after the dropping is completed, keep warm for 3 hours; finally cool to obtain the dispersant;

[0034] (2) Preparation of aqueous dispersion of nano oxide particles: weigh 5g of AgO, ZnO and TiO respectively 2 The powder is ground into a n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com