Patents

Literature

61results about How to "Simple finishing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dacron hydrophilic antistatic agent, preparing method and dacron afterfinish method

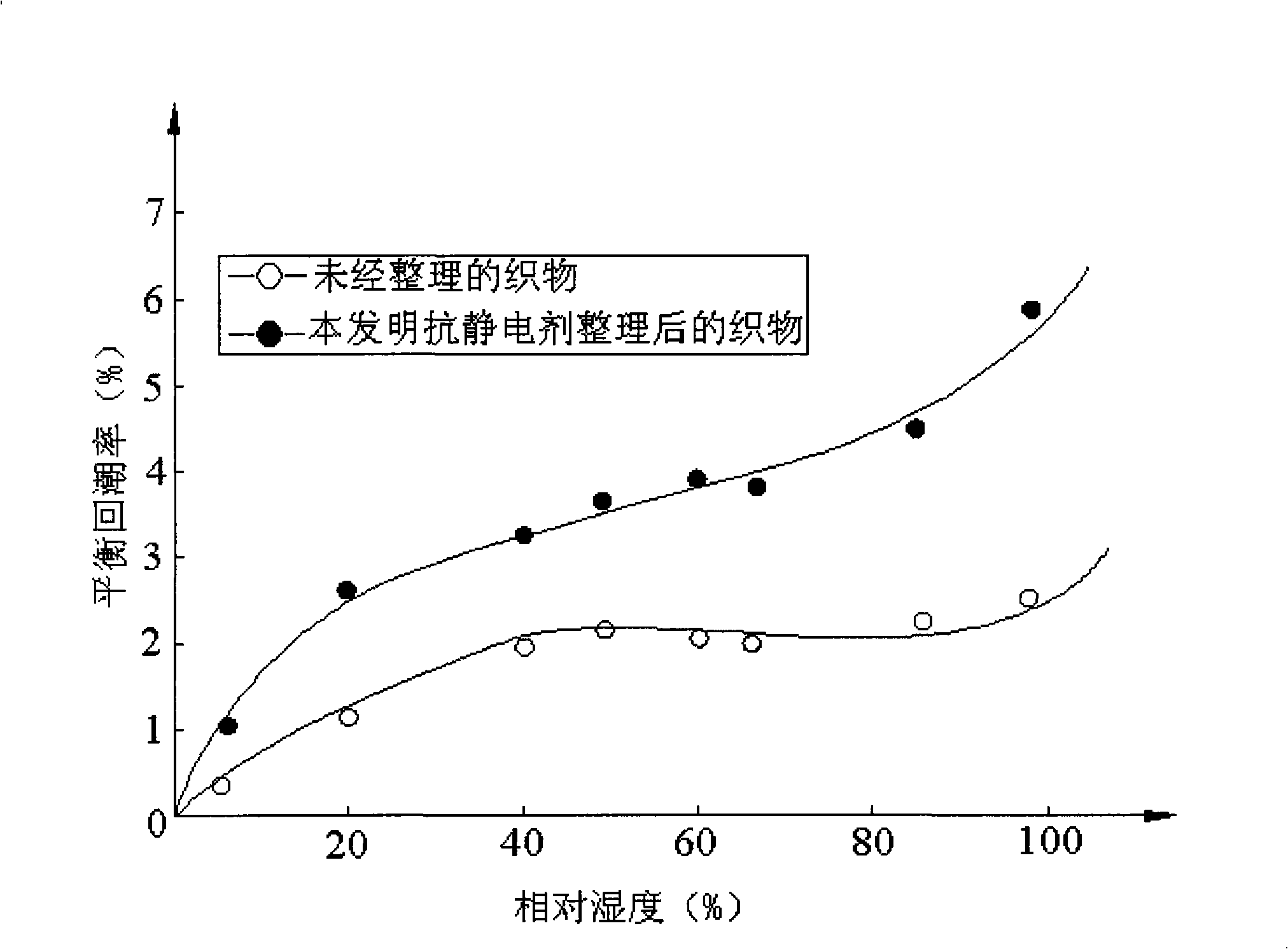

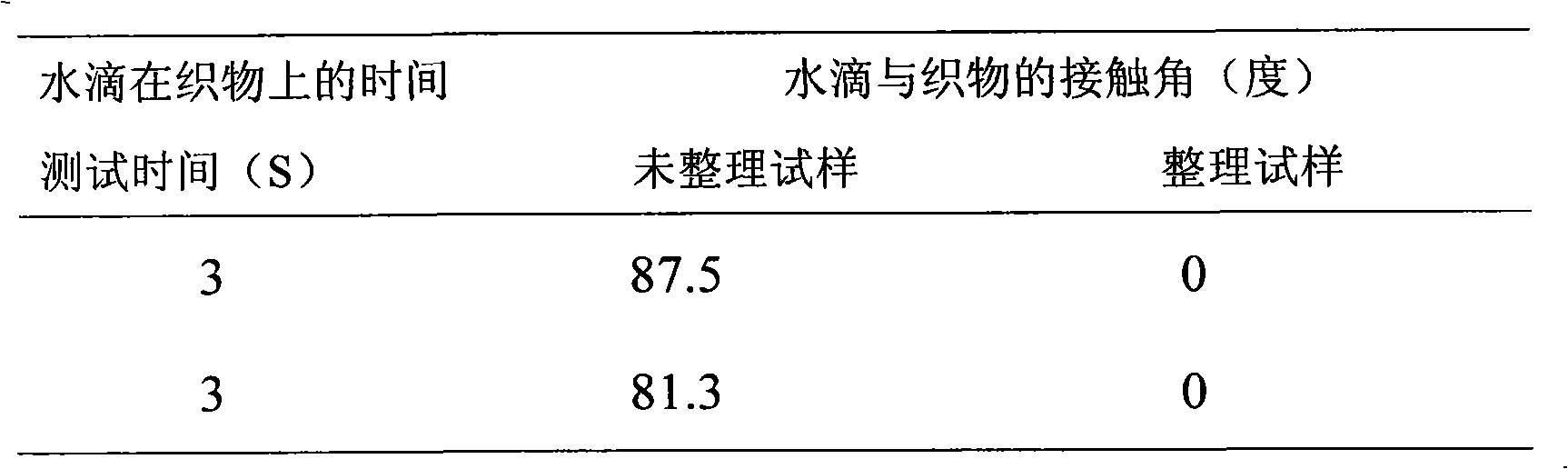

The invention discloses a polyester fabric hydrophilic antistatic agent which consists of the following components by weight percentage: 8 to 18 percent of DMT, 38 to 48 percent of glycol, 16 to 26 percent of polyoxyethylene, 6 to 16 percent of zinc acetate, 4 to 14 percent of diantimony trioxide and 3 to 8 percent of triphenyl phosphate, and the total amount of all the components is 100 percent. Interchange esterification and condensation polymerization are carried out to all the components so as to obtain the hydrophilic antistatic agent. The hydrophilic antistatic agent is adopted to prepare fabric-washing treatment liquid, and during the process the magnesium chloride hexahydrate is added and a two-dipping-two-rolling method is adopted to deal with the polyester fabric, and then the fabric is dried so as to complete the later finishing to the terylene fabric. The hydrophilic antistatic agent of the invention has stable antistatic capability, good washing resistance and low price. Adopting the antistatic agent to the later finishing of dacron can save the baking process of applied process so as to reduce energy cost and enhance the wearing property of polyester fiber and corresponding fabrics so as to meet the simulation requirement to polyester fabrics of costume fabric market.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Anti-mosquito sustained-release cloth finishing method

ActiveCN102926201ARegular structureChemically stableVegetal fibresAnimal fibresCross-linkPolyvinyl alcohol

The invention relates to the field of functional textiles, and particularly relates to an anti-mosquito sustained-release cloth finishing method suitable for textile fabrics. The anti-mosquito agent microcapsules are attached to the fabric by a fixing agent, then cross-linked by a crosslinking agent and dehydrated and dried to directly obtain anti-mosquito sustained-release cloth without roasting; the fixing agent is polyvinyl alcohol or a modified polyvinyl alcohol compound; and the crosslinking agent is boric acid. The finishing method is simple, short in flow, easy to operate and low in cost. The finished anti-mosquito sustained-release cloth has a quick and efficient killing effect on mosquitoes and realizes a good mosquito repelling effect. After anti-mosquito finishing, the fabric is safe and harmless to a human body, and the appearance and physical index are not influenced.

Owner:FUZHOU UNIV

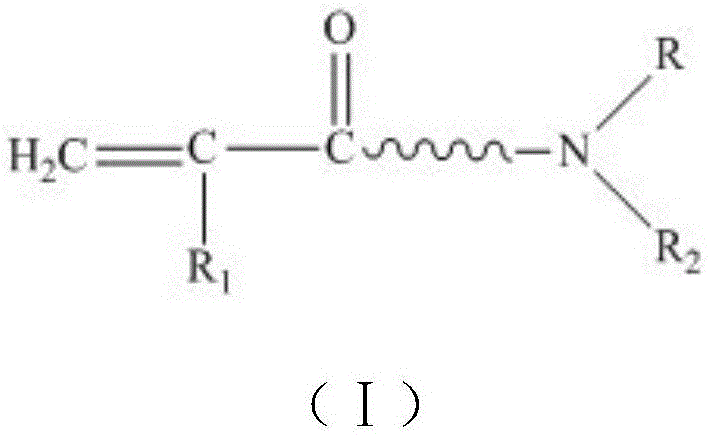

Temperature-sensitive type finishing agent as well as preparation method and applications thereof

InactiveCN101994253ANo irritating smellSimple finishing processVegetal fibresEpoxyFunctional monomer

The invention discloses a temperature-sensitive type finishing agentas well as a preparation method and the applications thereof. The finishing agent mainly contains a copolymer formed by an N-alkyl acrylamide monomer and a functional monomer, has favorable temperature sensibility and reaction activity and can further react with crosslinkers (isocyanates, melamines or epoxies) when applied to textile finishing. The method is simple and practical, and the textiles have temperature sensibility, easy decontamination function at a low temperature and favorable durability.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

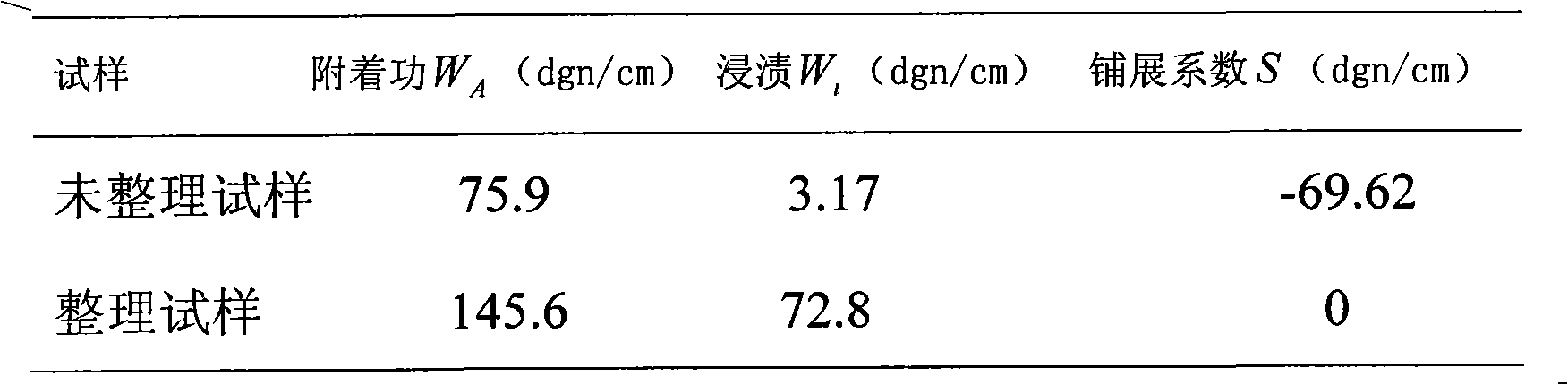

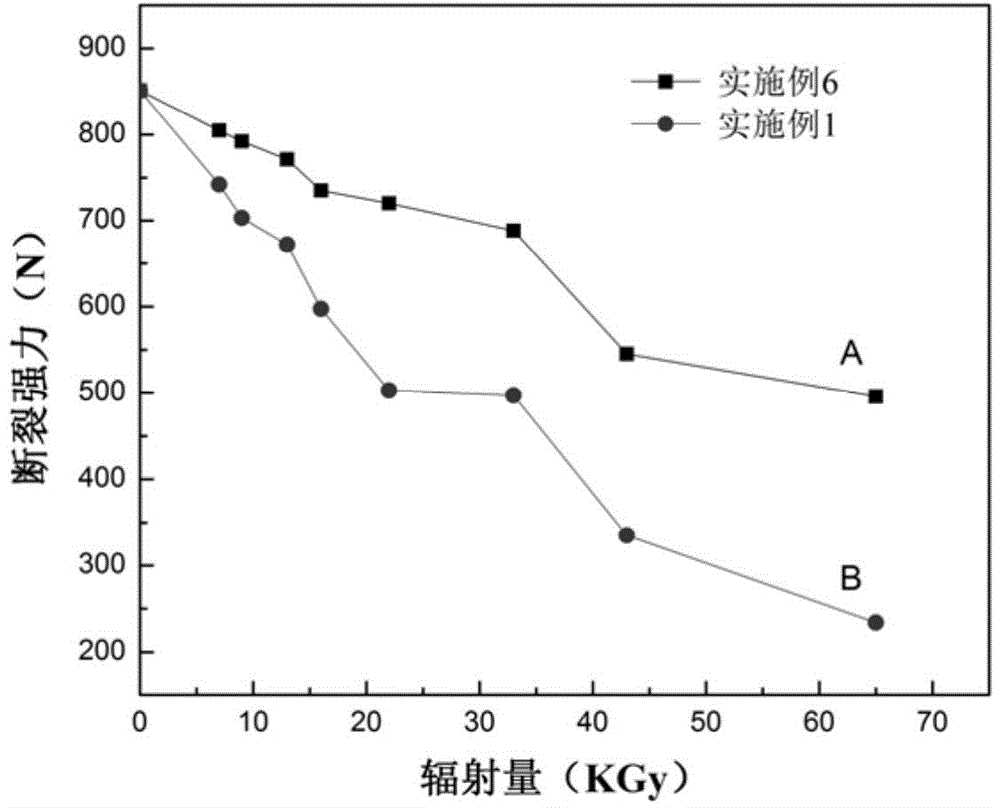

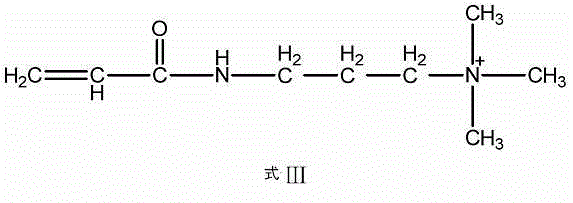

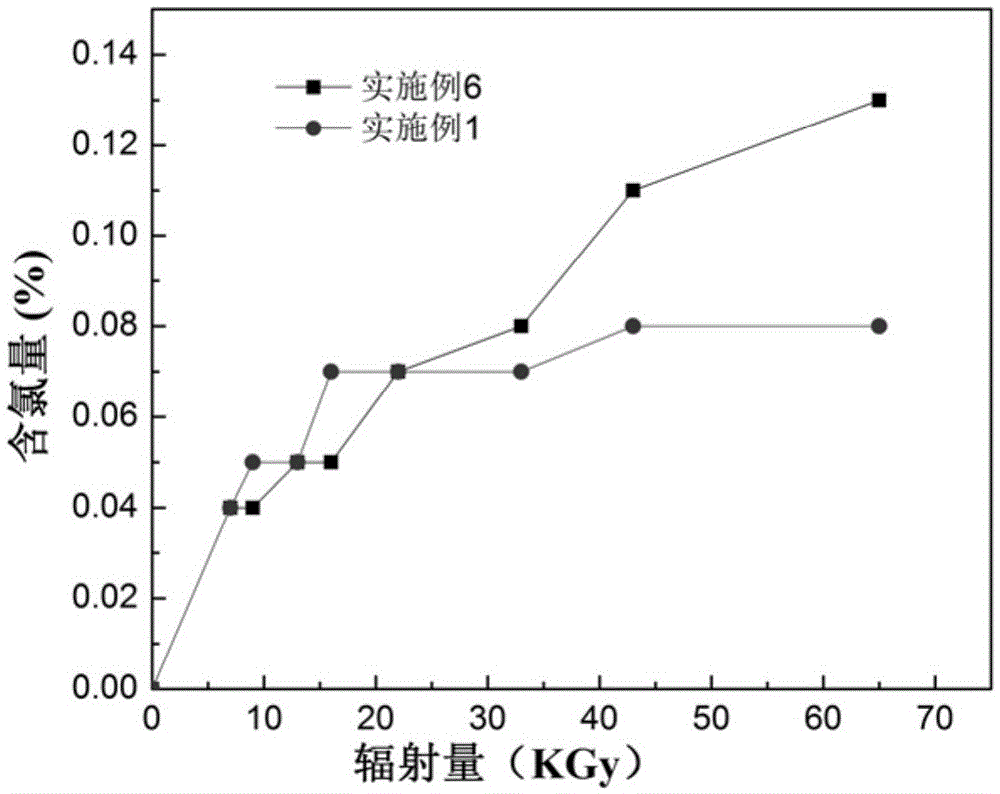

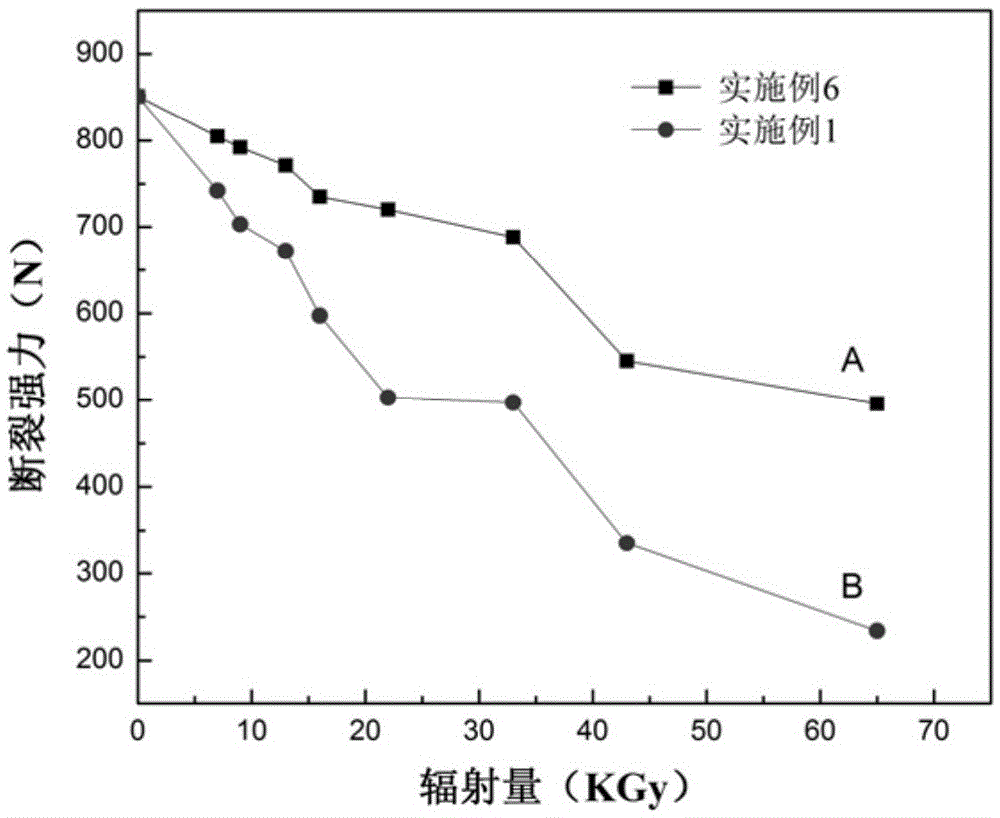

Method for preparing antimicrobial textiles by using electronic radiation technology

ActiveCN104358104AWill not polluteImprove efficiencyPhysical treatmentVegetal fibresAfter treatmentAntibacterial property

The invention discloses a method for preparing antimicrobial textiles by using an electronic radiation technology. The method comprises the following steps: dipping textiles or coating textiles by antibacterial finishing liquid and then carrying out electronic radiation; or firstly, carrying out electronic radiation on the textiles and then dipping or coating the antibacterial liquid; and baking, washing and carrying out after treatment, so as to prepare antibacterial textiles, wherein the radiation range of electronic radiation is 0-500KGy and corresponding other radiation unit conversion value; an antibacterial agent precursor in the antibacterial finishing liquid can generate free radical through electronic radiation, and can react with other substances through the free radical; and the antibacterial agent precursor can be independently used or used in a mixing manner. According to the method, the reaction can be carried out at normal temperature; the treatment process is simple, and easy to control; the antibacterial agent is high in utilization rate and low in energy consumption; and the antimicrobial textiles prepared by the method are excellent in antibacterial property, and good in wearability.

Owner:JIANGNAN UNIV

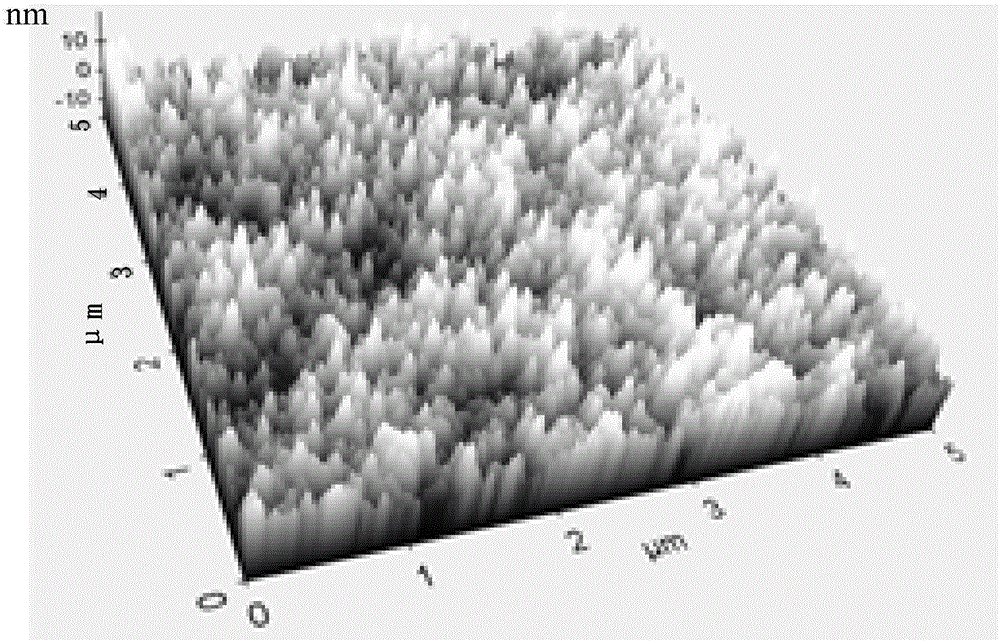

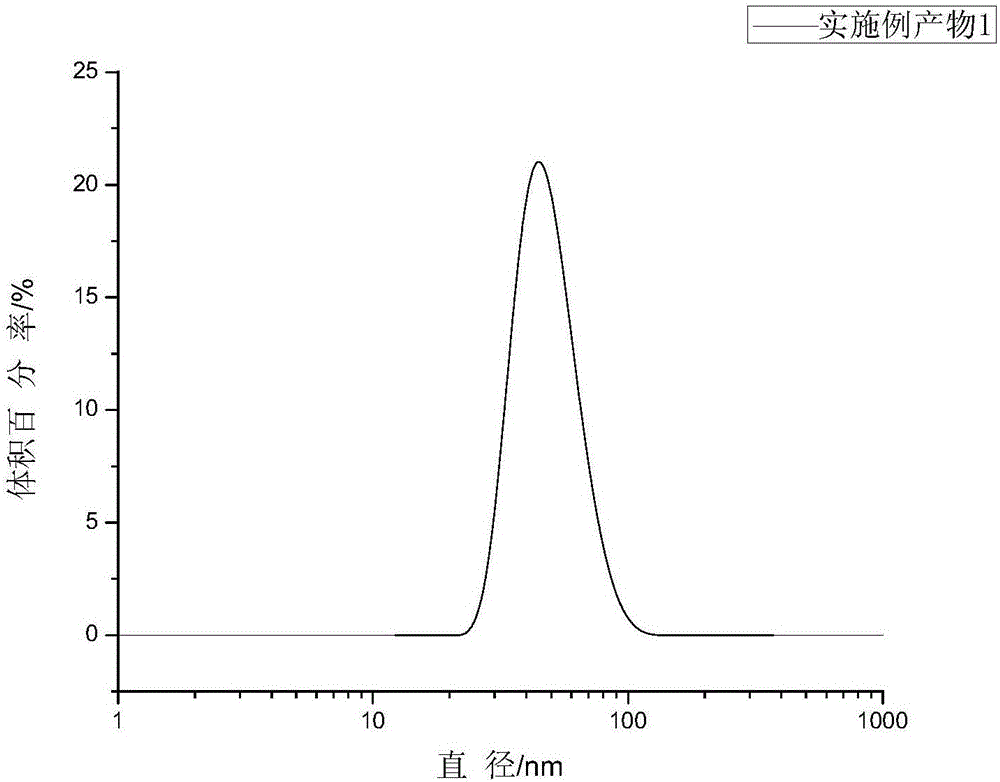

Coating liquid with latex particle reflection deducting capability as well as preparation method and application of coating liquid

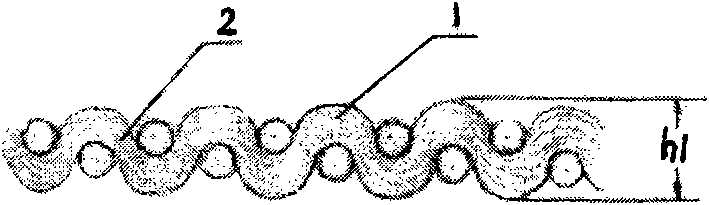

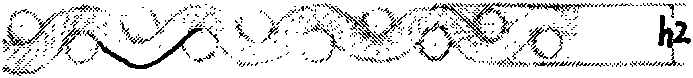

ActiveCN105113247AInhibited DiffusionLow Refractive Index PropertiesFibre typesCross-linkRough surface

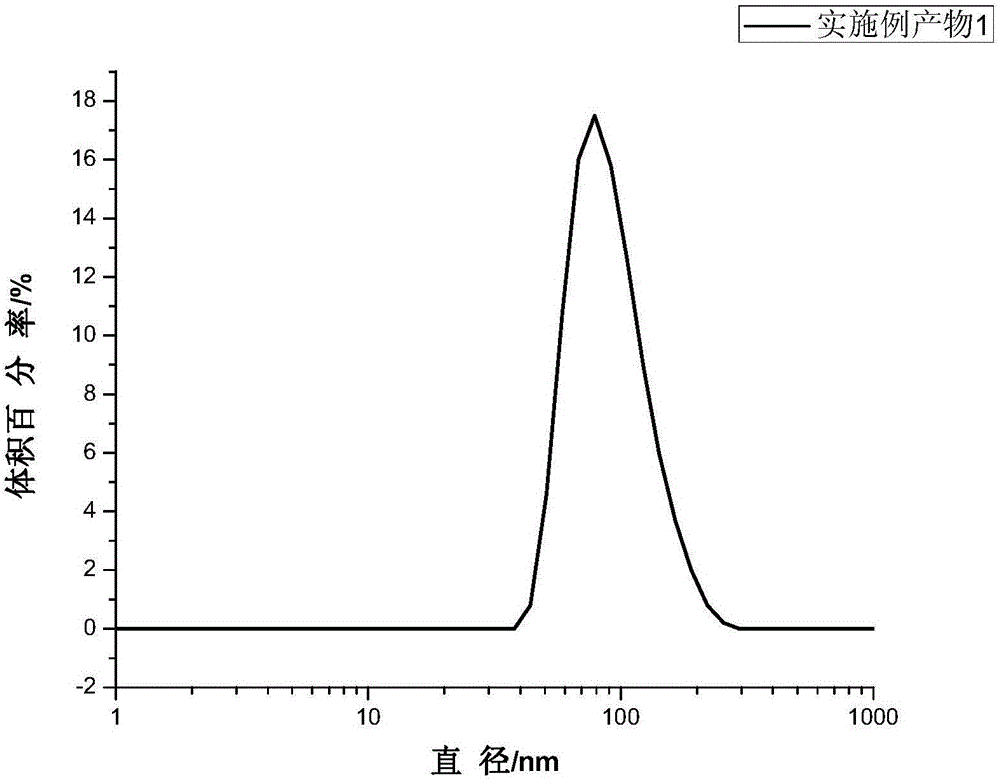

The invention discloses a coating liquid with latex particle reflection deducting capability as well as a preparation method and application of the coating liquid in a dacron fabric. The preparation method comprises the following steps: fully mixing an emulsifying agent with a part of water so as to form an emulsifying agent aqueous solution; adding a core-forming monomer and a cross-linking agent into the emulsifying agent aqueous solution, introducing protective gas so as to deoxidize for 15-20min; heating to 70-80 DEG C, adding the initiator and residual water, and reacting for 2-3 hours, so as to obtain a core-structure emulsion of latex; dropwise adding a first shell monomer and a second shell monomer into the core-structure emulsion of the latex for 1-1.5 hours; and after finishing dropwise adding, further reacting for 2-3 hours, and performing heat preservation at 85-90 DEG C for 30-45 minutes, there by obtaining the coating liquid with latex particle reflection deducting capability. The coating liquid can form a nano rough surface with low refractive index on the surface of the dacron fabric, so that reflection deduction and densification of dacron are realized, and furthermore, the structure is adhered to the fibers by virtue of shell layers and thus is endowed with a durable tidying effect.

Owner:ZHEJIANG SCI-TECH UNIV

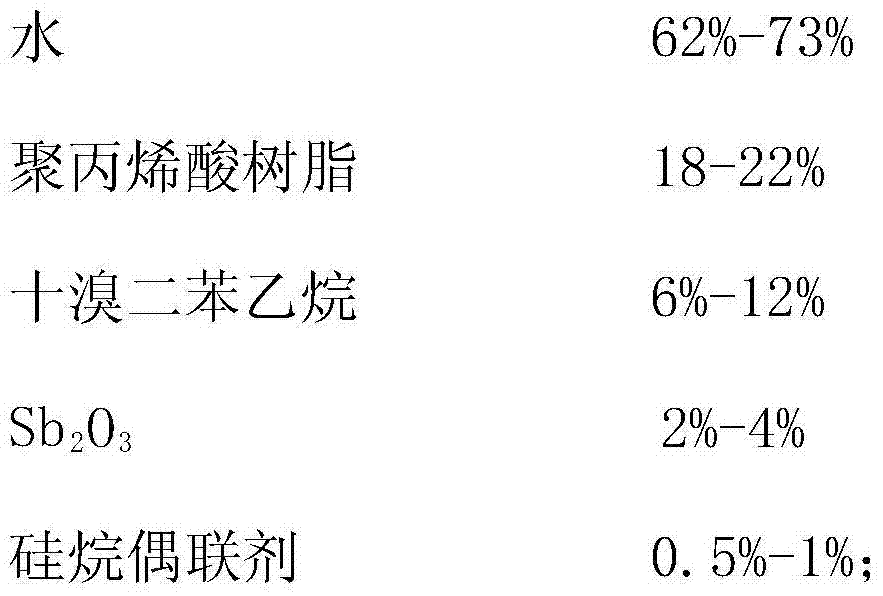

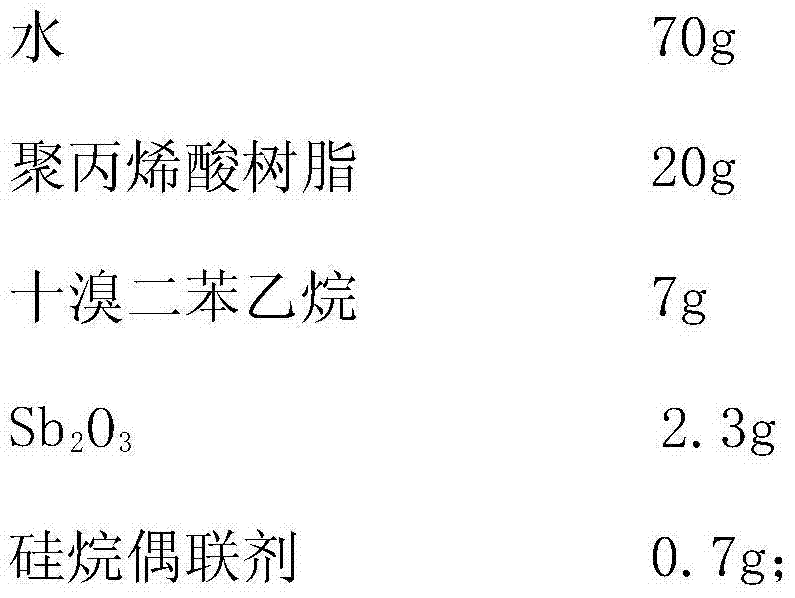

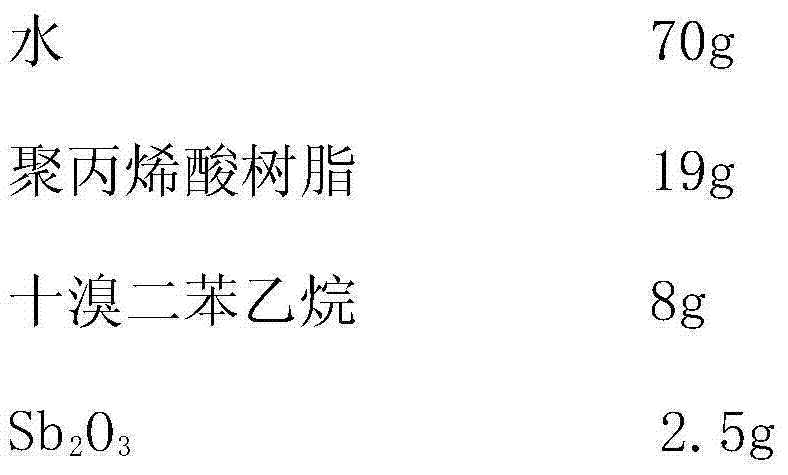

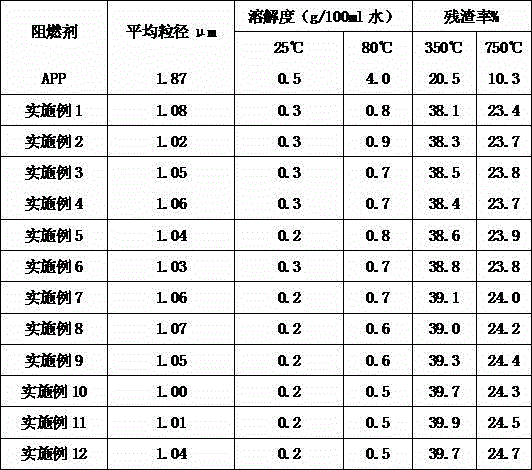

Preparation method of flame retardant PP (polypropylene) non-woven fabric

The invention relates to a preparation method of flame retardant PP (polypropylene) non-woven fabric. The non-woven base fabric obtained by a melt blowing method is subjected to flame retardant finishing. The preparation method comprises the following steps: preparing flame retardant slurry from the following components in percentage by mass: 62 to 73 percent of water, 18 to 22 percent of polyacrylic acid, 6 to 12 percent of decabromodiphenylethane, 2 to 4 percent of Sb2O3 and 0.5 to 1 percent of a silane coupling agent; pouring the flame retardant slurry into a slurry barrel with a stirring device, making the non-woven base fabric pass through a pressure roller and a slurry feeding roller, and transferring the slurry in a slurry groove to the base fabric through a screen frame by using the slurry feeding roller; placing the base fabric which is coated with the slurry between two rubber pressure rollers of a roller press for extruding to remove excessive slurry; finally, drying the base fabric to obtain the flame retardant non-woven fabric. The preparation method is simple in process, convenient to operate, and environmental friendly; the selected decabromodiphenylethane is a high-efficiency brominated flame retardant, and has the characteristics of high bromine content, high thermal stability, low toxicity and the like; meanwhile, the decabromodiphenylethane and the added Sb2O3 have a synergistic flame retardant effect, so that the prepared non-woven fabric has a good flame retardant effect.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

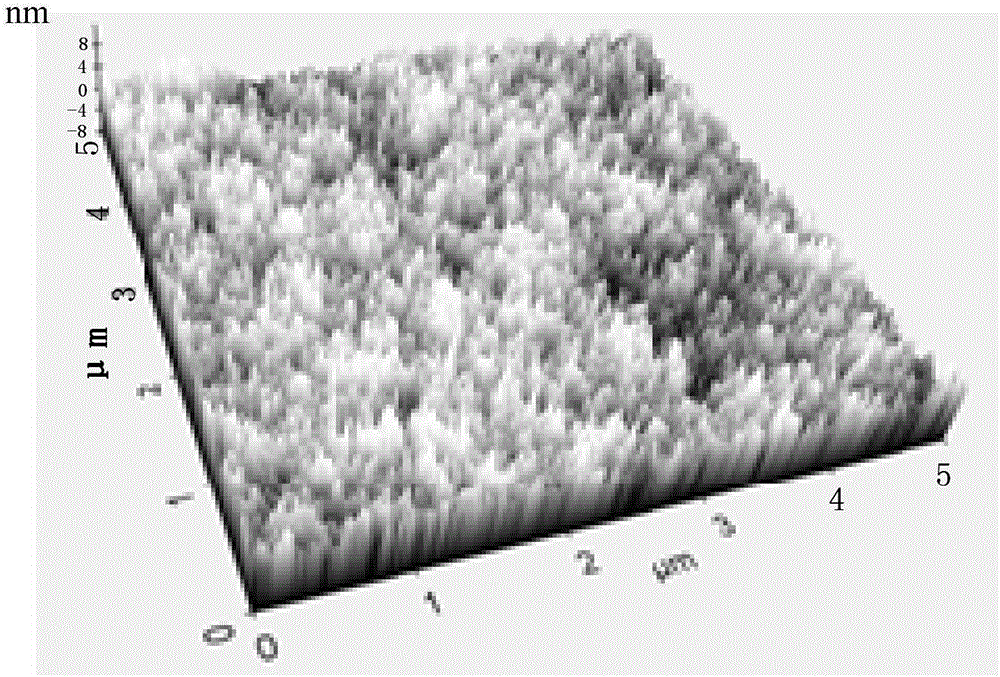

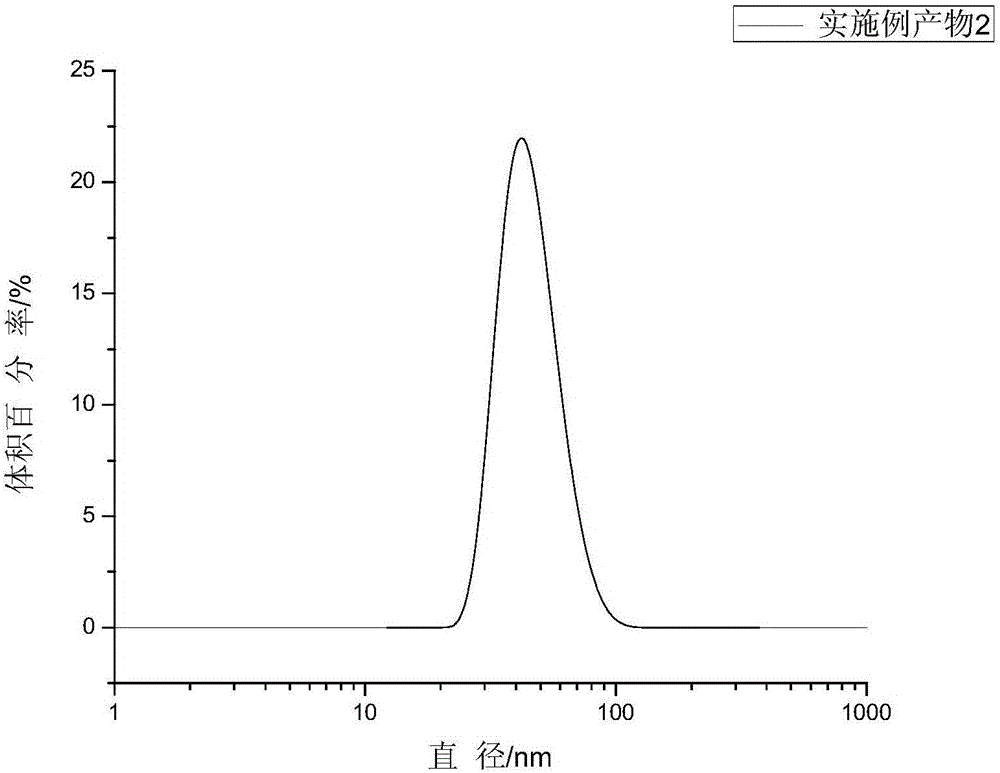

Reflection-deducting coating liquid with blended soft and hard particles as well as preparation method and application of reflection-deducing coating liquid

The invention discloses a reflection-deducting coating liquid with blended soft and hard particles as well as a preparation method and application of the reflection-deducing coating liquid. The method comprises the following steps: (1) preparing hard emulsion particles, namely fully mixing an emulsifying agent with water, adding monomers for forming the hard emulsion particles and a cross-linking agent into an emulsifying agent aqueous solution, adding an initiator and residual water, reacting and performing heat preservation, thereby obtaining a hard emulsion particle aqueous dispersion; (2) preparing soft emulsion particles, namely fully mixing an emulsifying agent with a part of water, adding monomers for forming the soft emulsion particles into an emulsifying agent aqueous solution, adding an initiator and residual water, reacting and performing heat preservation, thereby obtaining a soft emulsion particle aqueous dispersion; and (3) mixing the hard emulsion particle aqueous dispersion with the soft emulsion particle aqueous dispersion, thereby obtaining the reflection-deducting coating liquid with the blended soft and hard particles. According to the coating liquid, the soft particles and the hard particles are blended to form a nano rough surface on the surface of a dacron fabric, so that reflection deduction and densification of dacron are realized and the coating liquid has extensive application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

Method of producing flame retardant textile by electronic radiation technology

ActiveCN104818607ALower reaction energyIncrease profitPhysical treatmentEngineeringElectron beam radiation

A method of producing flame retardant textile by the electronic radiation technology is characterized in that after textile is pad-rolled or coated with flame retardant finishing liquid, and drying or baking is performed after electronic beam radiation to obtain the flame retardant textile; the flame retardant fishing liquid comprises resin cross-linking agent and organophosphorus flame retardant. The method has the advantages that the technical operation is simple and the flame retardant textile has performances such as durability, high temperature resistance and non-flammability.

Owner:JIANGNAN UNIV

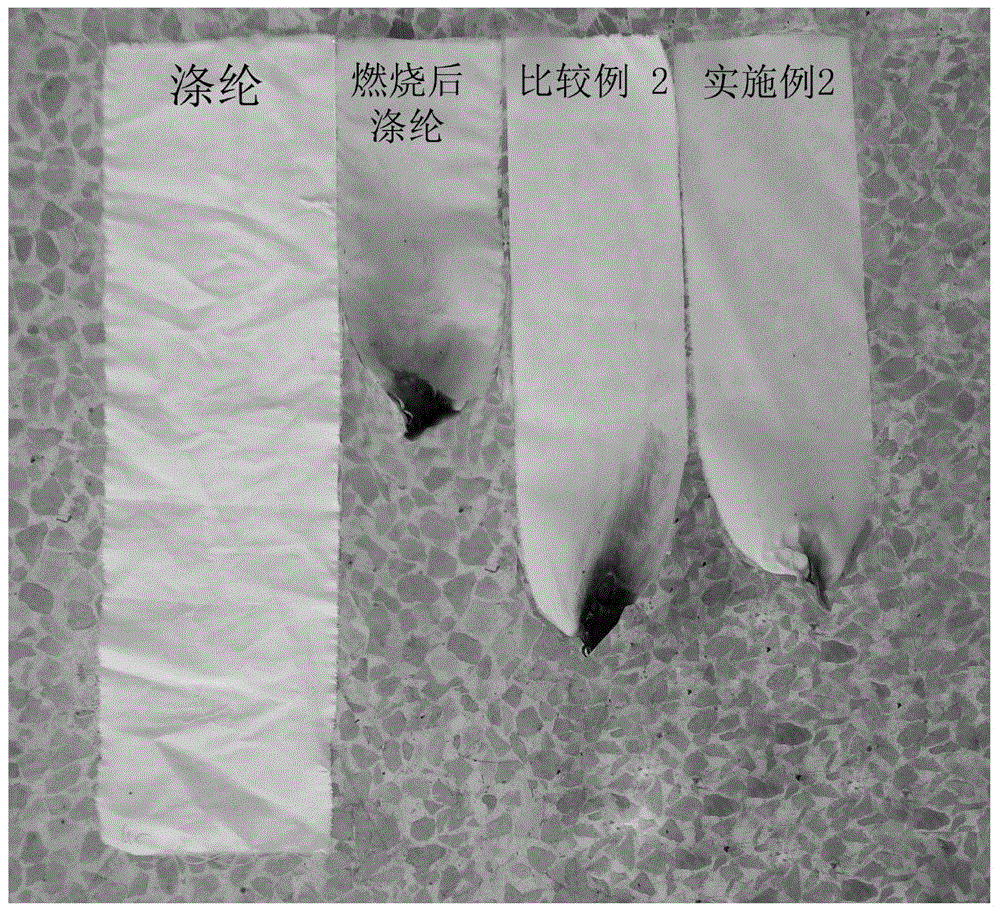

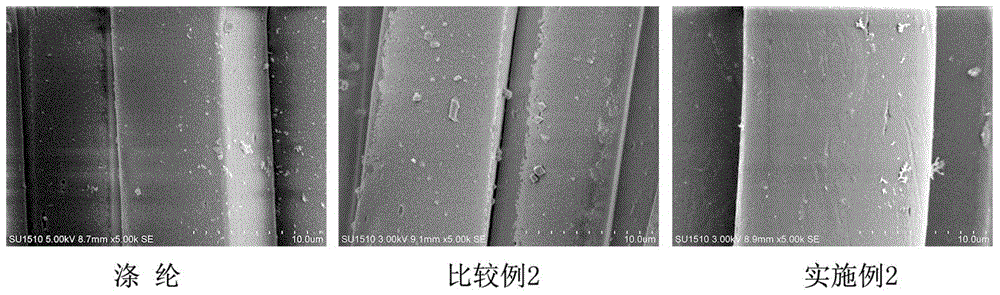

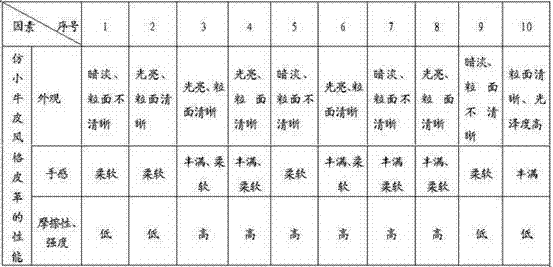

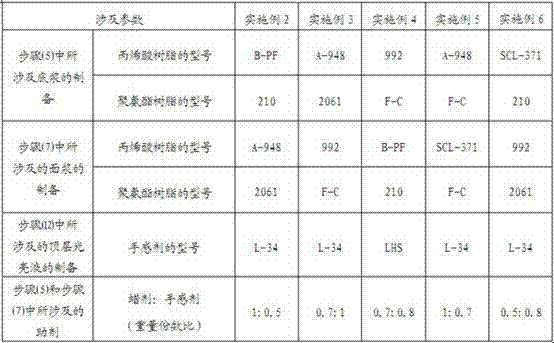

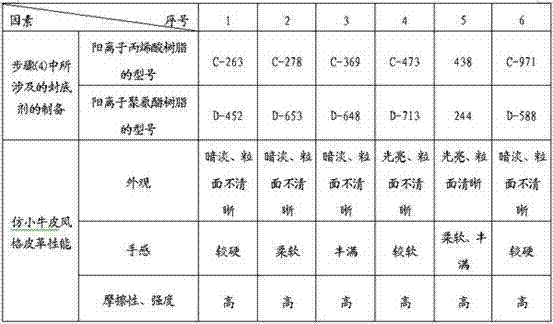

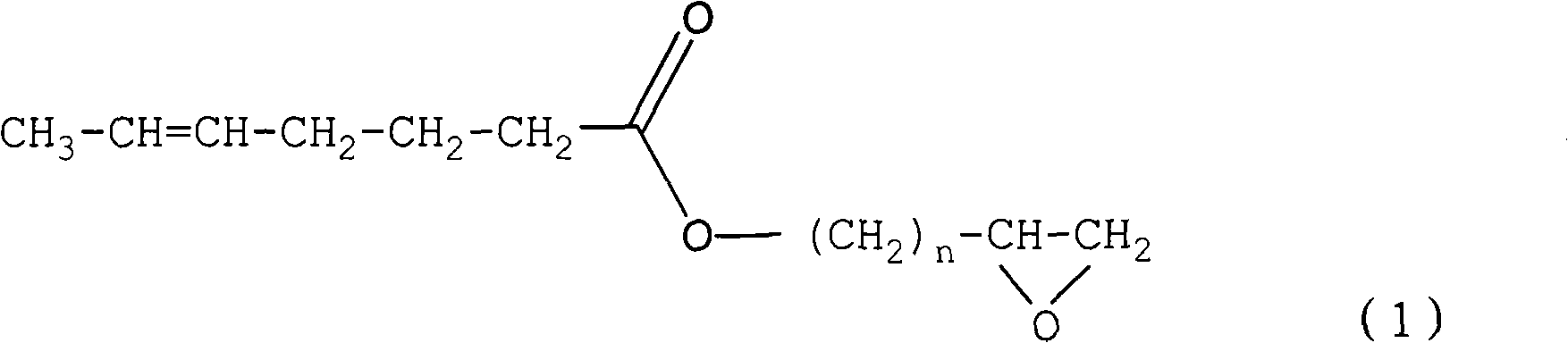

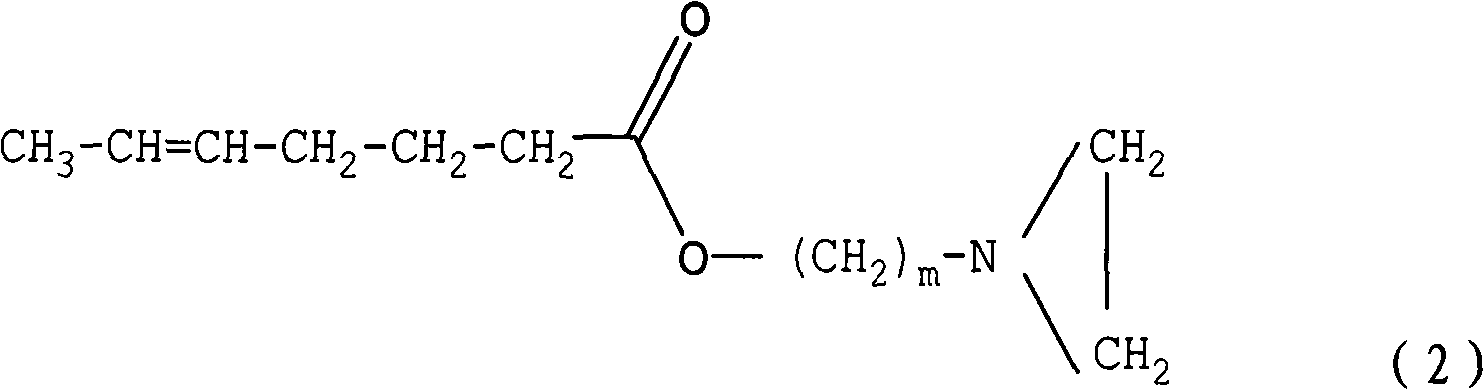

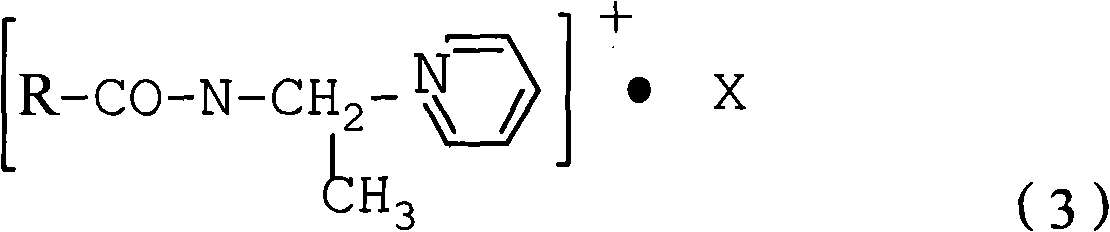

Method for finishing leather imitating calfskin style

ActiveCN103898254AMeet high demandThe appearance is bright and transparentLeather surface finishingComposite materialCeramic materials

The invention discloses a method for finishing leather imitating a calfskin style. The method comprises the steps of primary embossing, polishing, dye water spraying, bottom sealing agent spraying, bottom slurry spraying, secondary embossing, surface slurry spraying, three-time embossing, bottom-layer brightening liquid spraying, primary ironing, four-time embossing, top-layer brightening liquid spraying and secondary ironing which are implemented in sequence. The leather with the calfskin style is prepared by using a cow leather billet with a large size and a rough grain surface through a finishing process, and the prepared leather is bright and transparent in appearance, dark in color, fine in grain surface, clear in pores, soft and smooth in hand feeling, plump in body and bone, wear-resistant in coating and high in strength; the preparation method is simple in finishing process and low in cost; the difficulties of purchasing calfskin billets are solved, and a large amount of market demands for the calfskin leather are met. The method disclosed by the invention is suitable for manufacturing the leather with the calfskin style.

Owner:JIHUA 3514 LEATHER & FOOTWARE

Fabric pretreatment fluid containing vitamin, health-care fabric and preparation methods of health-care fabric

The invention discloses a fabric pretreatment fluid containing vitamin, which contains 0.3 to 8% of beta-cyclodextrin inclusion complex containing vitamin, 0.3 to 7% of binding agent and the balance of water. The invention also discloses a health-care fabric containing vitamin prepared by using the fabric pretreatment fluid, wherein the fabric can slowly release vitamin after contacting with skins. The invention also discloses two methods for preparing the health-care fabric. The prepared fabric has excellent washing-resistant property, contains 22 to 40 mg of vitamin per 100g of cloth cover, has the retaining ratio above 83% after washing once and the retaining ratio above 65% after washing for thirty times, is high in perspiration resistance, contains 20 to 35 mg of vitamin per 100g of the cloth cover after the perspiration resistance treatment, and has the cloth cover retaining ratio above 87% after washing once and perspiration resistance treatment and the cloth cover retaining ratio above 66% after washing for thirty times and perspiration resistance treatment.

Owner:三问家居股份有限公司

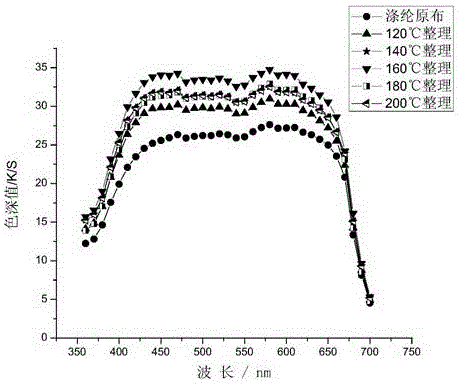

Deepening agent and preparation method thereof

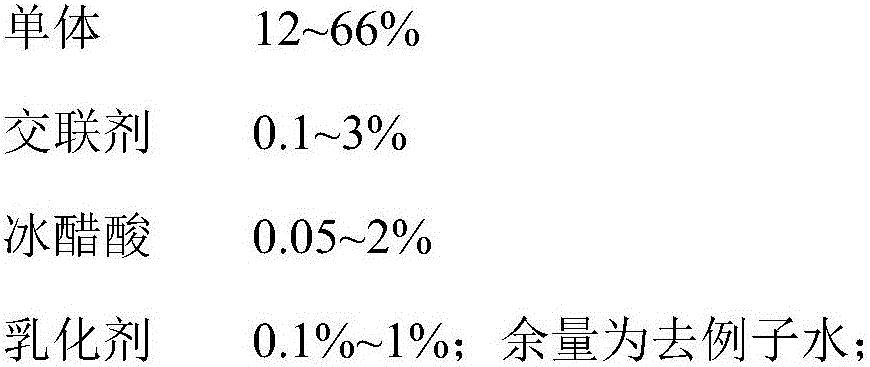

The invention provides a deepening agent for finishing a fabric. The deepening agent comprises the following components in percentage by mass: 12-66% of a monomer, 0.1-3% of a cross-linking agent, 0.05-2% of glacial acetic acid, 0.1-1% of an emulsifier and the balance of deionized water. By adopting the deepening agent, a covering membrane can be formed on the surface of fiber, a part of the deepening agent is embedded into the fiber to form diamond-like crystal, then diffuse reflection of light can be formed on the surface of fiber, and light can have multi-refraction and reflection, so that a deepening effect on a colored fabric can be achieved, and particularly a remarkable effect of deepening a fabric of a deep color can be achieved.

Owner:苏州联胜化学有限公司

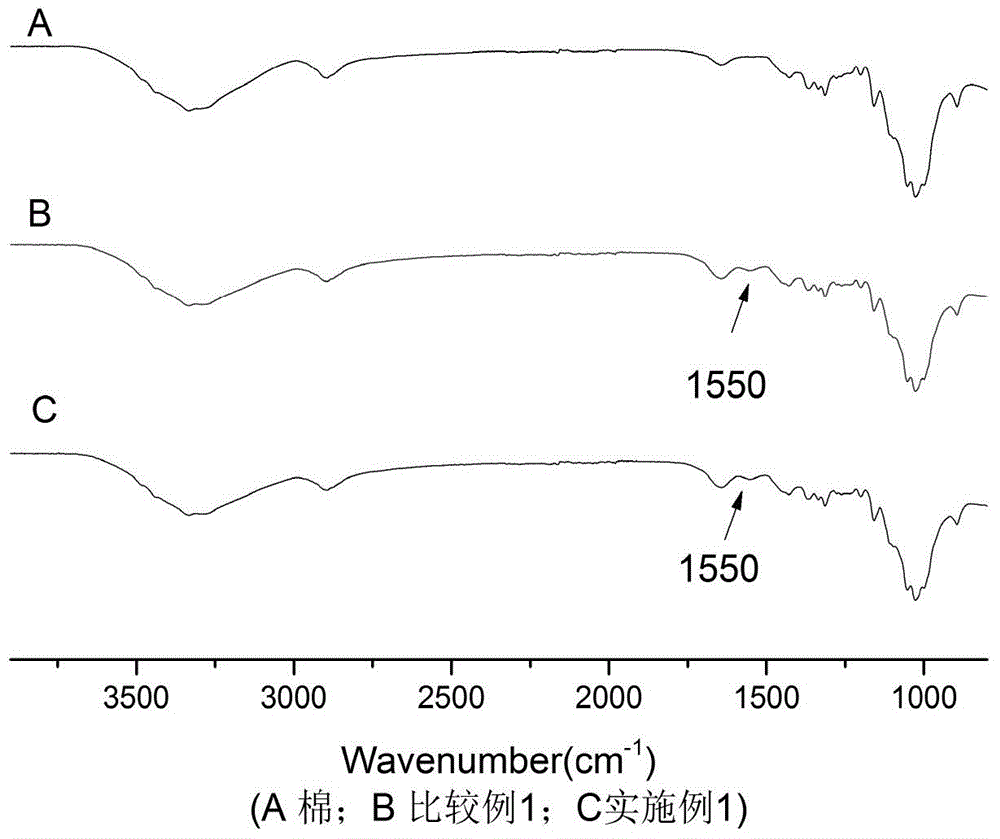

Preparation method of modified cotton fiber material

InactiveCN109023917AHas antibacterial and anti-ultraviolet functionIncreased durabilityBiochemical fibre treatmentLight resistant fibresFiberEnvironmental resistance

The invention discloses a preparation method of a modified cotton fiber material. The preparation method comprises: (1) adding an appropriate amount of nano-zinc oxide particles into a certain mass percentage of a polyethylene glycol solution, adjusting the pH value to 6.5-7.5, carrying out ultrasonic dispersion for 1-2h, and standing the dispersion liquid to obtain a modified zinc oxide dispersion liquid, (2) adding a chitosan imine solution into the modified zinc oxide dispersion liquid, controlling the temperature to 20-30 DEG C and carrying out ultrasonic dispersion for 2-5h to obtain a modified zinc oxide-chitosan imine dispersion liquid, and (3) carrying out alkali washing, slurry removal and oxidation treatment on a cotton fiber material, putting the cotton fiber material into a finishing agent containing the modified zinc oxide-chitosan imine dispersion liquid, modifying the cotton fiber material through a two-dipping and two-rolling method, drying the treated cotton fiber material at 70-90 DEG C for 5-8min, soaking the cotton fiber material in deionized water for 24h, carrying out dehydration and carrying out drying at 60-80 DEG C for 10-20min. The modified cotton fiber material has antibacterial and anti-ultraviolet functions and high durability. The finishing process is simple and environmentally friendly.

Owner:AOYANG GRP CO LTD

Preparing method of improved melamine resin essence microcapsule finishing agent

InactiveCN108004788AHigh solid contentSimple finishing processMicroballoon preparationVegetal fibresEmulsionIn situ polymerization

The invention discloses a preparing method of an improved melamine resin essence microcapsule finishing agent. The method includes the step of encapsulating essence through an in-situ polymerization method and an interface polymerization method with styrene-maleic anhydride copolymer as the emulsifying agent, essence as the capsule core and melamine resin and polyacrylate as the wall materials toprepare melamine resin essence microcapsules. The self-adhesive double-wall essence microcapsules prepared through the safe and environment-friendly preparing method have the solid content of 35-38% which is 10-15% higher than the solid content of other essence microcapsules on the market. Dual-layer wall constructing is conducted through the in-situ polymerization method and the interface polymerization method, the essence wrapping rate can reach 91-95%, and the product emulsion has high stability. The self-adhesive double-wall essence microcapsules have the unique advantages of microcapsulesand have self-adhesion performance, and the cotton fabric finishing process is simplified. The finished cotton fabric has a good fragrance depositing effect, the standing fragrance depositing time can reach 8 months, and the cotton fabric can still keep the pleasant fragrance after being washed with water 12 times.

Owner:贺州宝兴新材料股份有限公司

Technology for preparing melamine resin essence microcapsule

InactiveCN107998999ASimple finishing processGood effectMicroballoon preparationVegetal fibresEmulsionIn situ polymerization

The invention discloses a technology for preparing a melamine resin essence microcapsule. The technology comprises the steps of firstly, regarding a styrene-maleic anhydride copolymer as an emulsifier, regarding essence as a capsule core, regarding melamine resin and polyacrylate as wall materials, and covering the essence through an in-situ polymerization method and an interface polymerization method respectively to prepare the melamine resin essence microcapsule. The technology has the advantages that a safe and environment-friendly preparing method is adopted to prepare a self-adhesive double-wall essence microcapsule, and the solid content of the self-adhesive double-wall essence microcapsule is 35%-38%, 10%-15% higher than that of other self-adhesive double-wall essence microcapsuleson the market. Through the in-situ polymerization method and the interface polymerization method, dual-layer wall building is conducted, the essence encapsulation rate can reach 91%-95%, and product emulsion has high stability. The self-adhesive double-wall essence microcapsule has the self-adhesive performance while maintaining the peculiar advantages of microcapsules, and the cotton fabric finishing technology is simplified. The finished fabric has a good aroma-retaining effect, the fragrance can be retained for 8 months, and after washing is conducted 12 times, the pleasant fragrance can still be maintained.

Owner:贺州宝兴新材料股份有限公司

Nursing and felt proofing finishing method for wool fabric with ultraviolet radiation based on keratin oligopeptides, polypeptides or keratin macro-molecules

InactiveCN107541928AEasy to prepareSimple finishing processPhysical treatmentPeptide preparation methodsKeratinOligopeptide

The invention relates to a nursing and felt proofing finishing method for wool fabric with ultraviolet radiation based on keratin oligopeptides, polypeptides or keratin macro-molecules. A biochemicalmethod is used for extracting keratin oligopeptides, polypeptides or keratin macro-molecules from animal fibre, and a heterogenous protein cross-linking agent is used for carrying out a reaction in order to prepare reaction type keratin finishing liquid; the liquid is applied on wool fabric by sprinkling and dipping; after the fabric is dehydrated and spin-dried, and ultraviolet radiation and nature drying are carried out in order to realize an application of keratin oligopeptides, polypeptides or keratin macro-molecules to nursing and felt proofing finishing of wool fabric. The finishing process is simple and easy to operate with low energy consumption and little pollution, and does not have obvious influences on appearance of the wool fabric; the wool fabric treated by the nursing and felt proofing finishing method has good size stability, crease recovery performance, and improved breaking strength and elasticity.

Owner:JIAXING UNIV

Method for preparing melamine resin essence microcapsule finishing agent

InactiveCN108097185ASimple finishing processGood effectVegetal fibresMicroballoon preparationEmulsionMelamine resin

The invention discloses a method for preparing a melamine resin essence microcapsule finishing agent. The method comprises the following steps: a styrene-maleic anhydride copolymer is used as an emulsifier, essence is used as a capsule core, melamine resin and polyacrylate are used as wall materials, the essence is encapsulated with an in-situ polymerization method and an interfacial polymerization method respectively, and melamine resin essence microcapsules are prepared. Self-adhesive double-wall essence microcapsules are prepared with a safe and environment-friendly preparation method, andthe solid content of the microcapsules is 35%-38%, which is 10%-15% higher than the solid content of other essence microcapsules on the market. Double-layer wall building is performed with the in-situpolymerization method and the interfacial polymerization method, the essence encapsulation ratio can reach 91%-95%, and the product emulsion has good stability. The self-adhesive double-wall essencemicrocapsules have the self-adhesive property while maintaining the unique advantages of the microcapsules, and the finishing process of cotton fabric is simplified. The finished cotton fabric has good fragrance retention effect, fragrance can be retained for 8 months after standing, and the pleasant fragrance can still be maintained after water washing is performed 12 times.

Owner:贺州宝兴新材料股份有限公司

Preparation method for modified melamine resin essence microcapsule

InactiveCN107904929ASimple finishing processGood effectVegetal fibresMicroballoon preparationPrepolymerIn situ polymerization

The invention discloses a preparation method for a modified melamine resin essence microcapsule. The preparation method comprises the following steps: (1) preparing styrene-maleic anhydride copolymerpowder; (2) preparing styrene-maleic anhydride copolymer solution; (3) preparing melamine resin prepolymer; (4) preparing the self-splicing double-wall essence microcapsule. Firstly, the styrene-maleic anhydride copolymer is taken as emulsifier, the essence is taken as a capsule core, the melamine resin and polyacrylate are taken as wall materials, and the essence is respectively encapsulated through an in-situ polymerization method and an interfacial polymerization method, and the melamine resin essence microcapsule is prepared. The essence microcapsule prepared with the method has a good coverage rate for the essence, and the stability of a product is good.

Owner:贺州宝兴新材料股份有限公司

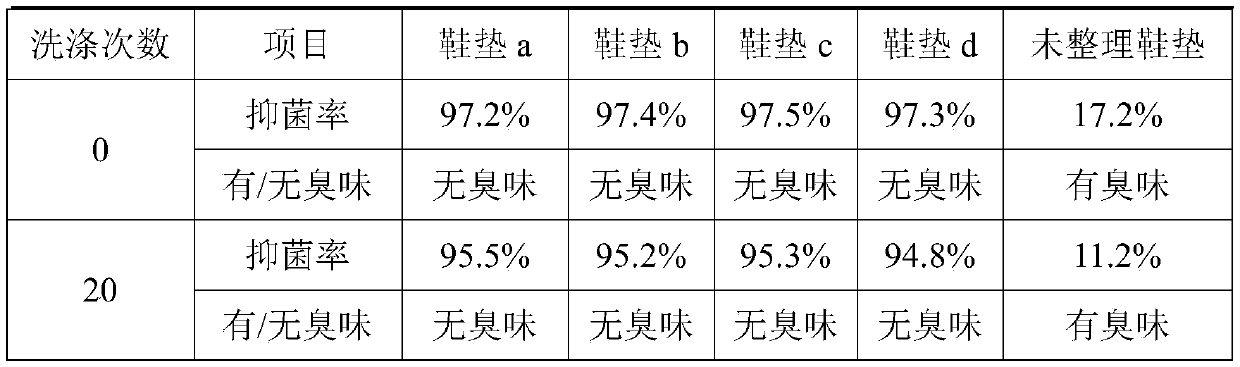

Preparation method of cotton insole deodorization finishing liquid and application

ActiveCN109403036AStrong reactivityNo precipitationBiochemical fibre treatmentVegetal fibresAllyl glycidyl etherStaphylococcus aureus bacteria

The invention relates to a preparation method of cotton insole deodorization finishing liquid and application. The preparation method is characterized by comprising the following steps: firstly preparing a dispersion agent; grinding AgO, ZnO and TiO2 powder into nanometer grade particles; then, dissolving the nanometer grade particles into the prepared dispersion agent; preparing a nanometer oxideparticle water dispersion body; performing polymerization on acrylic acid, allyl glycidyl ether and dimethyl diallyl ammonium chloride with initiators to prepare polycarboxylates; mixing nanometer oxide particle water dispersion bodies and the polycarboxylates to obtain finishing liquid. The finishing liquid is used for finishing a cotton insole, and the prepared cotton insole is obtained. The prepared finished cotton insole has strong antibacterial performance against staphylococcus aureus, colibacillus and candida albicans; the bacteriostasis rate respectively reaches 99 percent, 97 percentand 97 percent or higher; after 20 times of washing, the strong antibacterial performance is still shown against staphylococcus aureus, colibacillus and candida albicans; the bacteriostasis rate reaches 94 percent or higher; the finished cotton insole has no odor in the whole test process. The preparation process of the cotton insole deodorization finishing liquid is simple; the application is convenient; the popularization is convenient.

Owner:临沂市泰亚新型材料有限公司

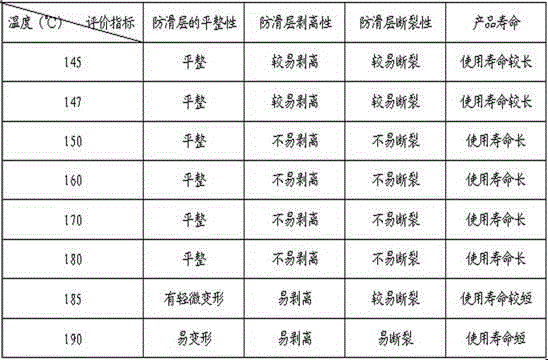

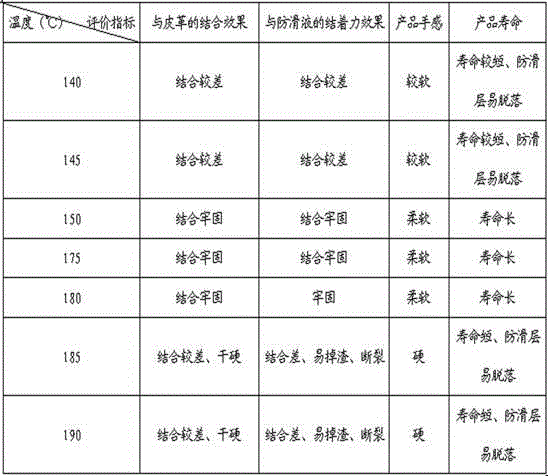

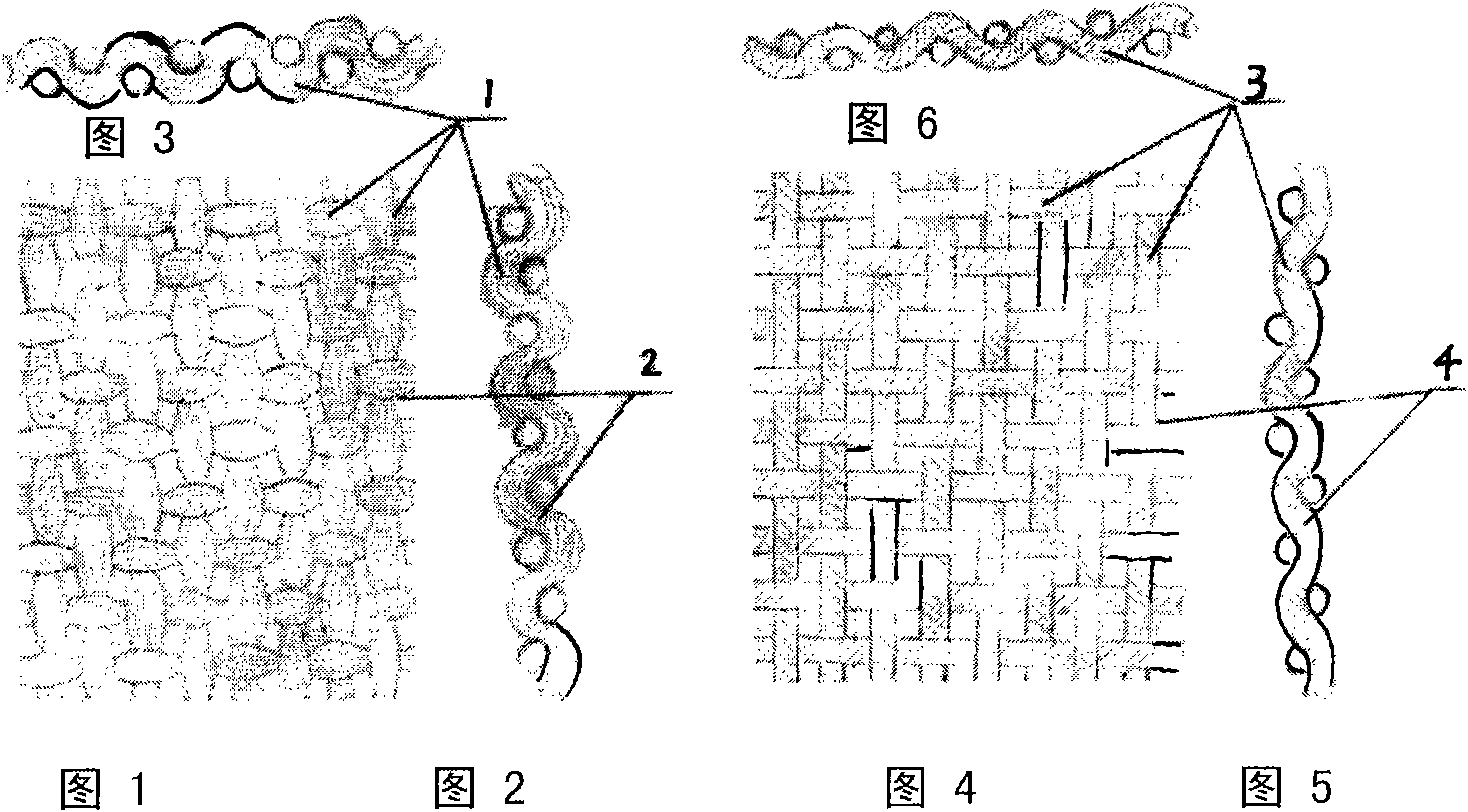

Finishing process of antiskid leather and application thereof

ActiveCN104673946ASimple finishing processEasy to controlGarment special featuresGlovesVulcanizationProcess engineering

The invention discloses a finishing process of antiskid leather. The finishing process of the antiskid leather comprises the following steps: leather selecting, priming, priming layer hot drying and reinforcing, antiskid liquid coating, drying and vulcanization sizing. The process is simple and easy to control; an adhesion force between the antiskid layer of the manufactured antiskid leather and the leather is large, the antiskid layer resists aging, is not broken and has long service life, and the manufactured antiskid leather has good antiskid performance. The invention further provides the application of the antiskid leather in manufacturing of antiskid gloves. The finishing process of the antiskid leather is suitable for manufacturing of the antiskid leather, and the antiskid leather is applied to the gloves.

Owner:JIHUA 3514 LEATHER & FOOTWARE

Preparation method of multifunctional mat

InactiveCN109877935ASimple finishing processContinuous operationFibre treatmentCane mechanical workingReagentRaw material

The invention discloses a preparation method of a multifunctional mat. The preparation method of the multifunctional mat comprises the following steps that a cooling additive, an anti-mosquito finishing agent and an antibacterial finishing agent are compounded; and a functional reagent solution is used for finishing the mat in one bath. The technological process of the multifunctional mat is achieved. According to the preparation method of the multifunctional mat, functional materials such as different coolness, mosquito prevention and antibacterial materials are added in the processing process of the mat, so that the multifunctional property of the mat is endowed. The mat finished by the preparation method of the multifunctional mat has the functions of lasting and effective cooling, mosquito prevention, antibacterial performance and the like, has better water washing resistance and friction resistance, the raw materials belong to ecological friendly auxiliary agents, and the finishing process is simple and feasible and can be applied to the finishing field of different mat materials.

Owner:南通市小象环保科技有限公司 +1

Manufacturing method of twistless fabric and product thereof

InactiveCN101929021ASimple finishing processImprove tensile capacityWoven fabricsYarnDyeingWeft yarn

The invention discloses a manufacturing method of twistless fabric and a product thereof. The method comprises the following working procedures: using a fibre rod prepared by medium staple fibre and staple fibre; taking the fibre rod as wrap and weft yarn after wrapped by Vitron; and dyeing, warping, starching, weaving and tidying according to design of pattern and flower color, wherein the weight ratio of Vitron yarn for wrapping to fibre rod body is within 10-35%, the tension at the time of beaming is not more than 8-13% of warp breaking tenacity, and weaving machine speed at the time of weaving is 15-20% lower than speed for weaving the traditional twisted fabric.

Owner:马玉成

A method for preparing antibacterial textiles using electron radiation technology

ActiveCN104358104BWill not polluteImprove efficiencyPhysical treatmentVegetal fibresAfter treatmentElectron radiation

Owner:JIANGNAN UNIV

Warp beam stamping method for multifunctional aramid fibers

InactiveCN108301239ALong-lasting and effective antibacterial propertiesDurable and effective anti-electromagnetic radiationBiochemical fibre treatmentLight resistant fibresYarnScreen printing

The invention discloses a warp beam stamping method for multifunctional aramid fibers. The method comprises the following steps: micronizing a photoinduced light storing type self-lighting material and an anion additive; mixing the functional micro-powder and warp stamping color paste; and performing functional warp stamping process. According to the method, different functional materials with fluorescence and anion are added to the warped flame-retardant aramid warp sheets in the rotary coating screen printing process, thus the aramid warps are multifunctional; the warps and the unprocessed wefts are knitted, so that the flame-retardant aramid stamping fabric has the hazy effect as well as functions such as long-lasting effective caution function, antibacterial function and electromagnetic radiation resisting function. The method can replaces traditional yarn dyeing and finishing technology; a plurality of functional materials are added; the method is applicable to the knitting of various aramid fibers; the finishing process is simple; the stamping and paste coating are combined; water stamping flower is avoided; the energy is saved; and the environment is protected.

Owner:NANTONG UNIVERSITY

Method for preparing melamine resin finishing agent

InactiveCN108085995AHigh solid contentSimple finishing processMicroballoon preparationVegetal fibresEmulsionIn situ polymerization

The invention discloses a method for preparing a melamine resin finishing agent. The method comprises respectively carrying out encapsulation on essence as a capsule core through melamine resin and polyacrylate as shell materials and a styrene-maleic anhydride copolymer as an emulsifier through an in-situ polymerization method and an interfacial polymerization method. The method can prepare self-adhesive double-walled essence microcapsules with solid content of 35% to 38%, which is 10% to 15% higher than those of other solid microcapsules on the market, through safe and eco-friendly processes.Through the in-situ polymerization method and the interfacial polymerization method, double-layer wall building is realized and the essence encapsulation rate is 91-95%. The product emulsion has goodstability. The self-adhesive double-walled essence microcapsules have self-adhesive properties while maintaining the unique advantages of microcapsules and simplify the finishing process of cotton fabrics. The finished cotton fabric has a good fragrance retention effect, can be stood for 8 months for fragrance retention and can still maintain the pleasant fragrance after being washed 12 times.

Owner:贺州宝兴新材料股份有限公司

Preparation and application of self-adhesive double-wall essence microcapsule

ActiveCN103230766BHigh solid contentSimple finishing processEssential-oils/perfumesMicroballoon preparationEnvironmental resistanceEmulsion

The invention discloses a preparation method and an application method of a self-adhesive double-wall essence microcapsule. A composite emulsifier is adopted, essences are adopted as a capsule core, melamine resin and polyacrylate are used as wall materials, and the self-adhesive double-wall essence microcapsule is prepared by respectively carrying out encapsulation on the essences by respectively adopting an in-situ polymerization method and an interfacial polymerization method. The invention also provides the application method of the self-adhesive double-wall essence microcapsule. The self-adhesive double-wall essence microcapsule which is prepared by adopting the safe and environment-friendly preparation method has the solid content of 30-35 percent, which is 10-15 percent higher than that of other essence microcapsules on the market. Double-layer wall formation is carried out by adopting the in-situ polymerization method and the interfacial polymerization method, the essence encapsulation rate can reach 92-95 percent, and the self-adhesive double-wall essence microcapsule emulsion has favorable stability. The self-adhesive double-wall essence microcapsule has a self-adhesive property while keeping the peculiar advantages of the microcapsule; and a cotton fabric finishing process is simplified. In addition, the finished cotton fabric has a favorable fragrant effect which can reach 6 months after standing; and pleasant fragrance can be kept after the cotton fabric is washed for 10 times.

Owner:TIANJIN URBAN CONSTR COLLEGE

Durable antibacterial soft leather for leather bag and preparation method thereof

ActiveCN111534650ASimple preparation processImprove wash resistanceLeather surface finishingPolymer scienceAnti bacteria

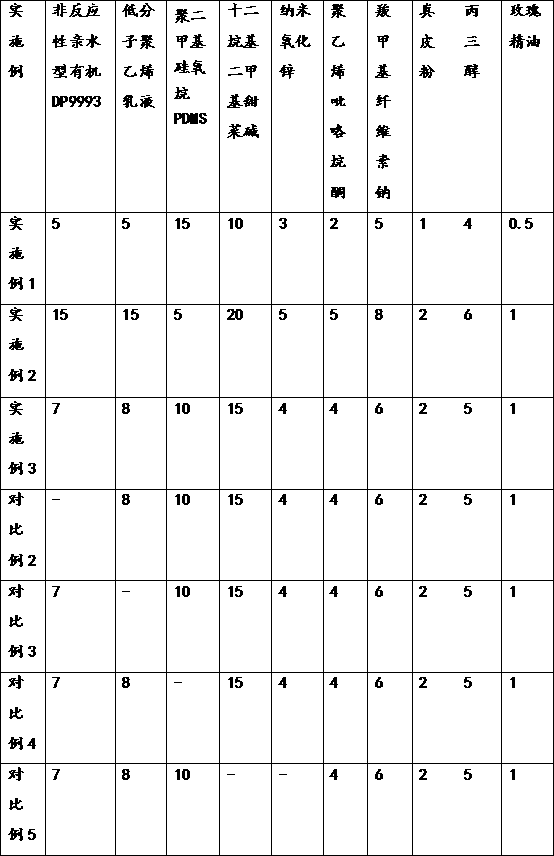

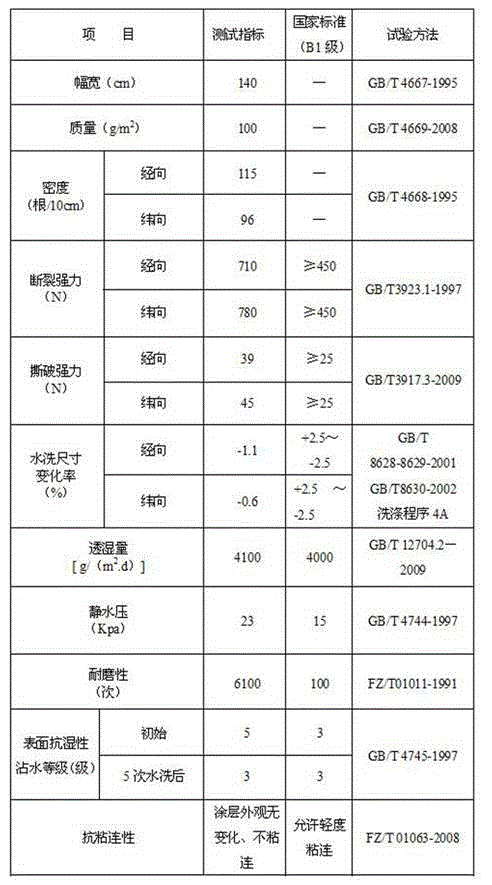

The invention relates to the field of natural leather. The invention provides durable antibacterial soft leather for a leather bag and a preparation method of the durable antibacterial soft leather. The method comprises the following steps: carrying out softening and antibacterial finishing on chrome tanned leather, dipping the leather in an aqueous solution containing non-reactive hydrophilic organosilicon, a low-molecular-weight polyethylene emulsion, a hydrophobic softener, dodecyl dimethyl betaine, nano zinc oxide, polyvinylpyrrolidone and the like, and carrying out low-temperature dryingto obtain the durable antibacterial soft leather. The durable antibacterial soft leather obtained by the method has durable, soft and antibacterial effects.

Owner:杭州天龙手袋股份有限公司

A fine drawing process of special-shaped steel pipe

The invention discloses a finish drawing process for a special-shaped steel tube body. The process comprises the following steps of (1) preparation of ram materials; (2) perforating treatment of a tube billet; (3) hot rolling treatment of a hollow billet; (4) drawing treatment of a hollow steel tube; (5) acid dipping of the special-shaped steel tube body; (6) sizing and reducing treatment of the special-shaped steel tube body; and (7) packaging of finished products. According to the finish drawing process, the structure is simple, the defective rate is reduced, and the cost is lowered; meanwhile, the finish drawing process is simple, the practical production requirements are met, and the comprehensive utilization rate is increased; moreover, the special-shaped steel tube body is machines more convenient and faster by strictly controlling the blanking size, the heating time, the pickling time and the pickling temperature in the technological process; the rate of later finished products is increased, and economic benefits of products are increased.

Owner:浙江日佳铜业科技有限公司

Temperature-sensitive type finishing agent as well as preparation method and applications thereof

InactiveCN101994253BNo irritating smellSimple finishing processVegetal fibresEpoxyFunctional monomer

The invention discloses a temperature-sensitive type finishing agentas well as a preparation method and the applications thereof. The finishing agent mainly contains a copolymer formed by an N-alkyl acrylamide monomer and a functional monomer, has favorable temperature sensibility and reaction activity and can further react with crosslinkers (isocyanates, melamines or epoxies) when applied to textile finishing. The method is simple and practical, and the textiles have temperature sensibility, easy decontamination function at a low temperature and favorable durability.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

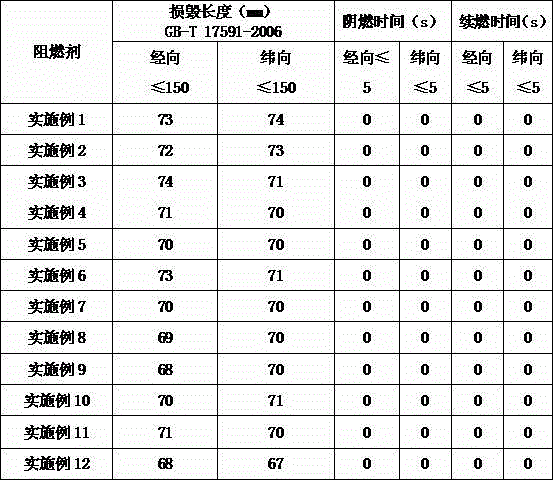

Flame-retardant coating adhesive for textile, finishing method of flame-retardant fabric with flame-retardant coating adhesive and flame-retardant fabric with flame-retardant coating adhesive

The invention provides a flame-retardant coating adhesive for textile, a finishing method of flame-retardant fabric with the flame-retardant coating adhesive and the flame-retardant fabric with the flame-retardant coating adhesive. The flame-retardant coating adhesive for the textile is prepared through steps as follows: a microcapsule flame retardant DCAPP is added to a polyurethane coating adhesive, the viscosity of the mixture is adjusted to 5,000-6,500 cps, and the mixture is uniformly stirred and compounded to form the flame-retardant coating adhesive. The finishing method of flame-retardant fabric with the flame-retardant coating adhesive comprises the steps of at least two times of coating and baking. The flame-retardant fabric has the technical advantages as follows: the flame-retardant fabric has good flame retardance and flame-retardant durability, high flame retardant efficiency, low smoke amount as well as an excellent anti-dripping effect on polyester fiber fabric, and the finishing process is simple, meets the environmental protection requirement and is low in cost.

Owner:EASTERN LIAONING UNIV

A kind of preparation method and application of deodorant finishing liquid for cotton insoles

ActiveCN109403036BHigh reactivityNo precipitationBiochemical fibre treatmentVegetal fibresBiotechnologyCarboxylic salt

The invention relates to a preparation method of cotton insole deodorization finishing liquid and application. The preparation method is characterized by comprising the following steps: firstly preparing a dispersion agent; grinding AgO, ZnO and TiO2 powder into nanometer grade particles; then, dissolving the nanometer grade particles into the prepared dispersion agent; preparing a nanometer oxideparticle water dispersion body; performing polymerization on acrylic acid, allyl glycidyl ether and dimethyl diallyl ammonium chloride with initiators to prepare polycarboxylates; mixing nanometer oxide particle water dispersion bodies and the polycarboxylates to obtain finishing liquid. The finishing liquid is used for finishing a cotton insole, and the prepared cotton insole is obtained. The prepared finished cotton insole has strong antibacterial performance against staphylococcus aureus, colibacillus and candida albicans; the bacteriostasis rate respectively reaches 99 percent, 97 percentand 97 percent or higher; after 20 times of washing, the strong antibacterial performance is still shown against staphylococcus aureus, colibacillus and candida albicans; the bacteriostasis rate reaches 94 percent or higher; the finished cotton insole has no odor in the whole test process. The preparation process of the cotton insole deodorization finishing liquid is simple; the application is convenient; the popularization is convenient.

Owner:临沂市泰亚新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com