Reflection-deducting coating liquid with blended soft and hard particles as well as preparation method and application of reflection-deducing coating liquid

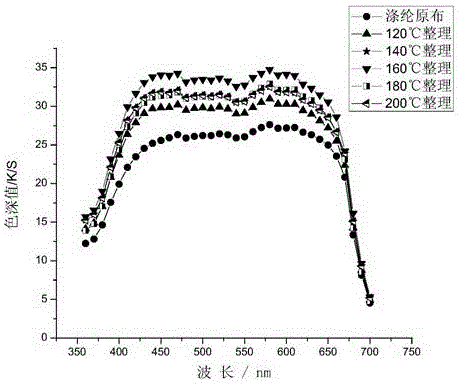

An anti-reflection coating and particle technology, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve problems such as restricting applications, achieve stable anti-reflection and deepening, avoid feeling greasy, and easily adjust the effect of rough structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

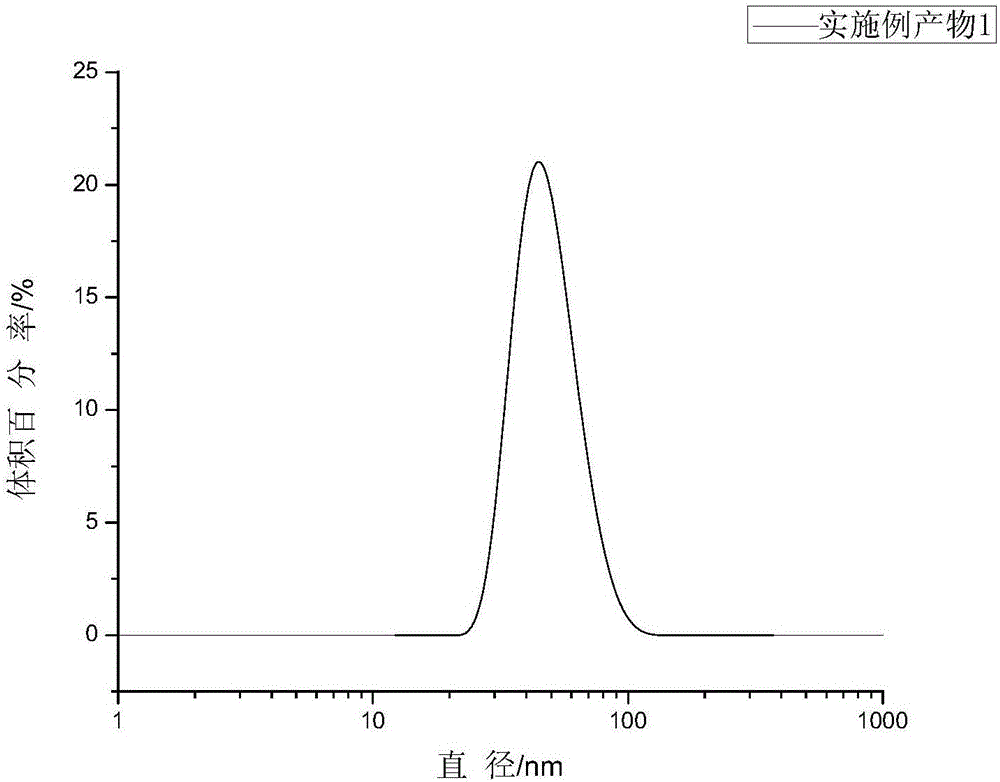

Embodiment 1

[0049] (1) Take by weighing 0.16g sodium dodecylbenzene sulfonate and join in the water of 84.76g, after mechanical stirring and mixing, add 8g methyl methacrylate and 2g divinylbenzene in the solution, after mechanical stirring, Put into the water bath and pass N 2 15min, after heating up to 70°C, dissolve 0.08g of potassium persulfate in 5g of water and add it to the above reaction mixture, after reacting for 3h, raise the temperature to 85°C and keep it warm for 30min to obtain a hard latex particle solution with a cross-linked structure Product 1, 10% solids.

[0050] (2) Weigh 1g of sodium dodecylbenzenesulfonate and add it to 83.94g of water. After mechanically stirring and mixing, add 10g of methyl acrylate to the solution. After mechanically stirring, put it into a water bath to pass N 2 15min, after heating up to 70°C, dissolve 0.06g of potassium persulfate in 5g of water and add it to the above reaction mixture, after reacting for 2.5h, raise the temperature to 85°C...

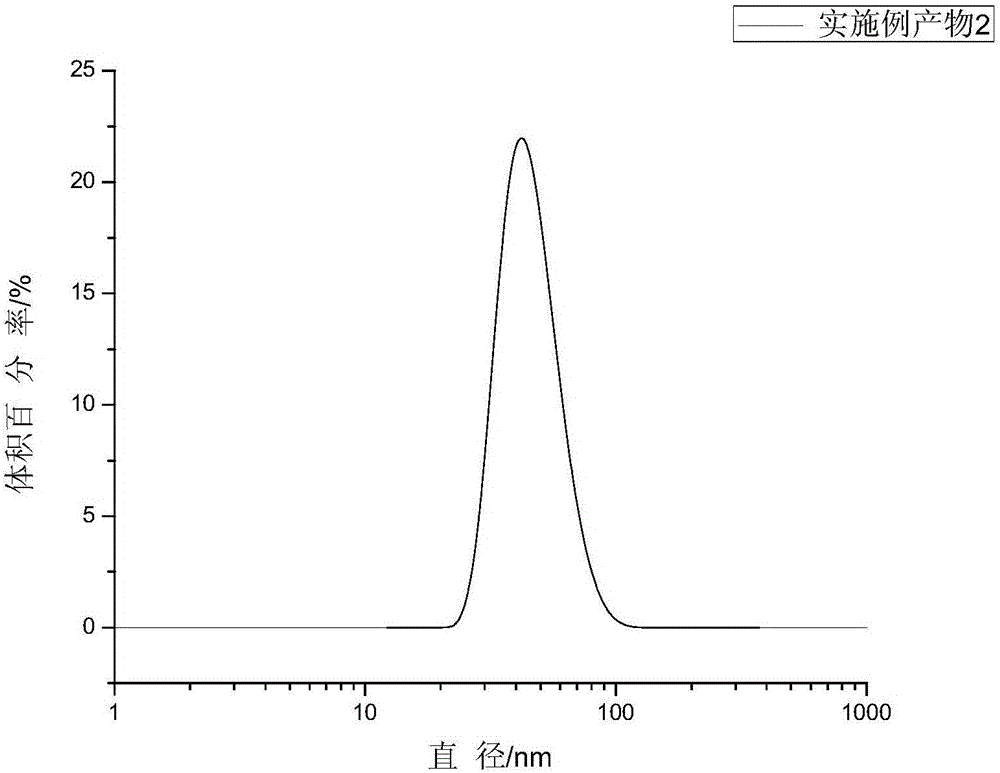

Embodiment 2

[0056] (1) Weigh 0.16g of sodium lauryl sulfate and add it to 74.78g of water. After mechanical stirring and mixing, add 16g of methyl methacrylate and 4g of divinylbenzene to the solution. After mechanical stirring, put Water bath in the pass N 2 15min, after heating up to 75°C, dissolve 0.06g of potassium persulfate in 5g of water and add it to the above reaction mixture, after reacting for 3h, raise the temperature to 85°C and keep it warm for 30min to obtain a hard latex particle solution with a cross-linked structure Product 3, 20% solids.

[0057] (2) Weigh 2g of sodium lauryl sulfate and add it to 72.94g of water. After mechanical stirring and mixing, add a mixture of 10g of acrylonitrile and 10g of ethyl acrylate to the solution. After mechanical stirring, put it into a water bath ZTO N 2 15min, after heating up to 75°C, dissolve 0.06g of potassium persulfate in 5g of water and add it to the above reaction mixture, after reacting for 2.5h, raise the temperature to 85...

Embodiment 3

[0060] (1) Weigh 0.06g of sodium lauryl sulfate and 0.14g of isooctylphenyl glycoside and add it to 69.88g of water. After mixing evenly with mechanical stirring, add 20g of ethyl methacrylate and 5g of dimethacrylic acid to the solution Ethylene glycol ester, mechanically stirred evenly, put into the water bath and pass N 2 15min, after heating up to 80°C, dissolve 0.08g of potassium persulfate in 5g of water and add it to the above reaction mixture, after reacting for 3h, raise the temperature to 90°C and keep it warm for 30min to obtain a hard latex particle solution with a cross-linked structure Product 5, 25% solids.

[0061] (2) Weigh 0.2g of sodium lauryl sulfate and add it to 69.72g of water. After mechanical stirring and mixing, add 25g of butyl acrylate to the solution. After mechanical stirring, put it into a water bath and pass N 2 15min, after heating up to 80°C, dissolve 0.08g of ammonium persulfate in 5g of water and add it to the above reaction mixture. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com