Round tool blank and method and device for making the same

A technology of blanks and cutting tools, applied in the field of manufacturing round cutting tools and blanks for round cutting tools, can solve problems such as powder material loss, and achieve the effect of increasing productivity and improving design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

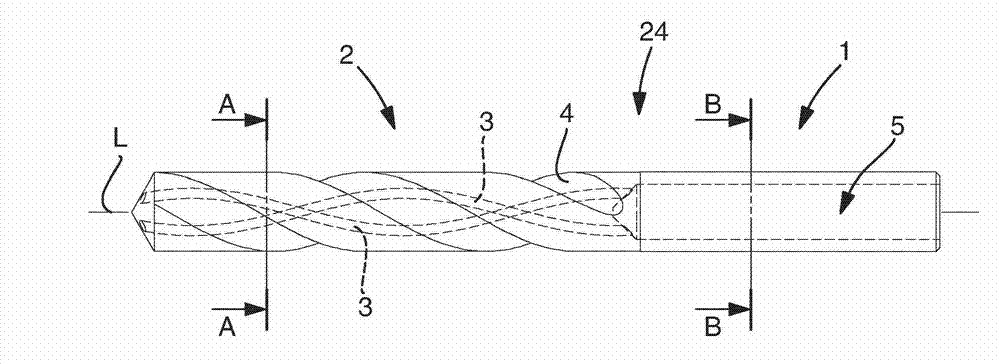

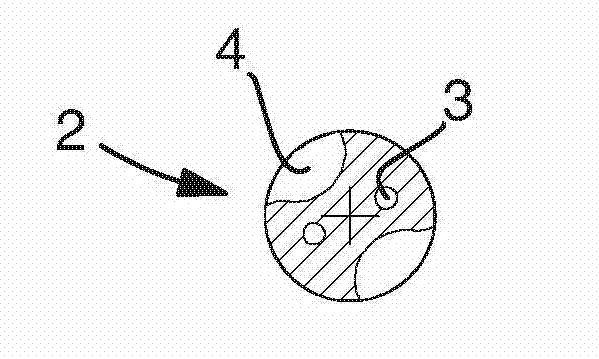

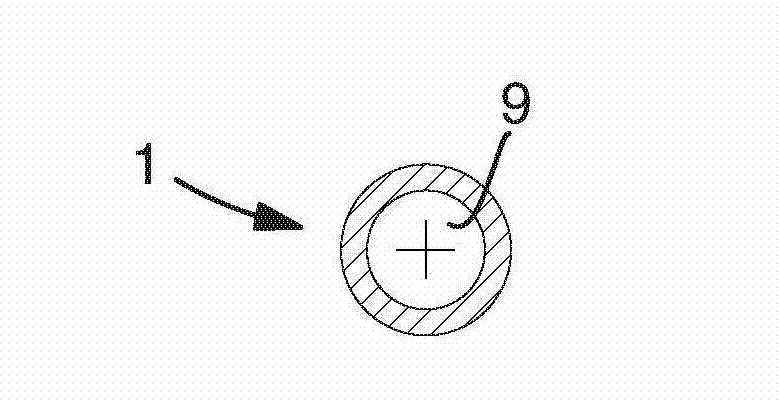

[0051] Figure 1A -D schematically discloses a drill bit 24 comprising a shank part 1 and a flute part 2 integral with the shank part 1 . The flute portion 2 refers to a portion of the drill bit 24 having chip flutes formed in its peripheral surface. This particular drill is only one example of a rounding tool according to the invention, and the invention also relates to other drill geometries as well as end mills and other rounding tools for chip forming machining by metal cutting. Hence, in the following text, the term drill bit 24 and the term rounding tool 24 can be used interchangeably. One or more internal coolant passages 3 may be provided within the drill bit 24 . For example, in Figure 1B As best shown in cross-sectional view A-A of the drill bit, the drill bit includes two internal coolant passages 3 which follow the helical chip flutes 4 of the drill bit in a torsional manner, however, the inner coolant passages 3 Arrangement, size and quantity depend on bit des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com