Powder feeding type laser 3D printing optical fiber powder feeding head

A technology of 3D printing and powder feeding head, which is applied to the improvement of process efficiency, additive manufacturing, additive processing, etc. It can solve the problem of insufficient powder feeding accuracy and powder jet stiffness, inability to withstand high power, and low powder feeding accuracy, etc. problems, to achieve the effect of improving the forming quality and powder feeding accuracy, improving the tolerance and improving the powder feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

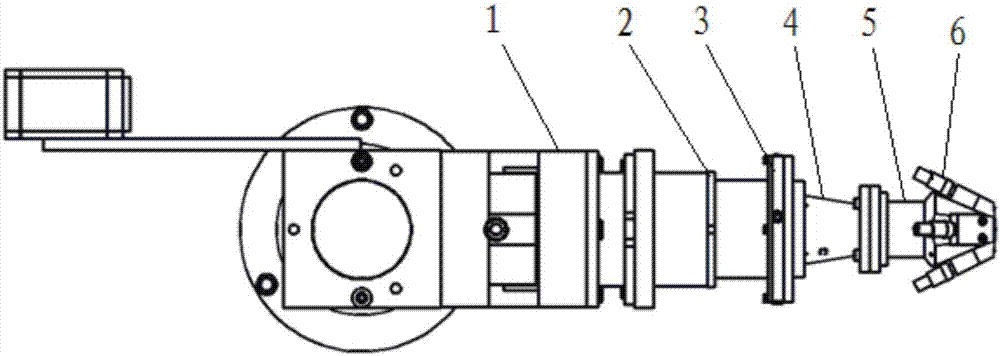

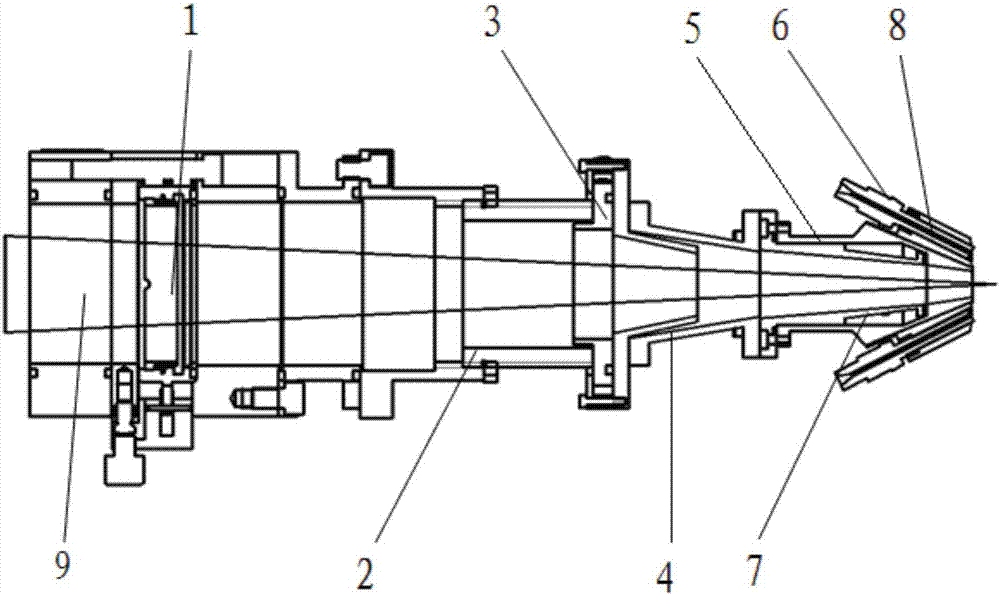

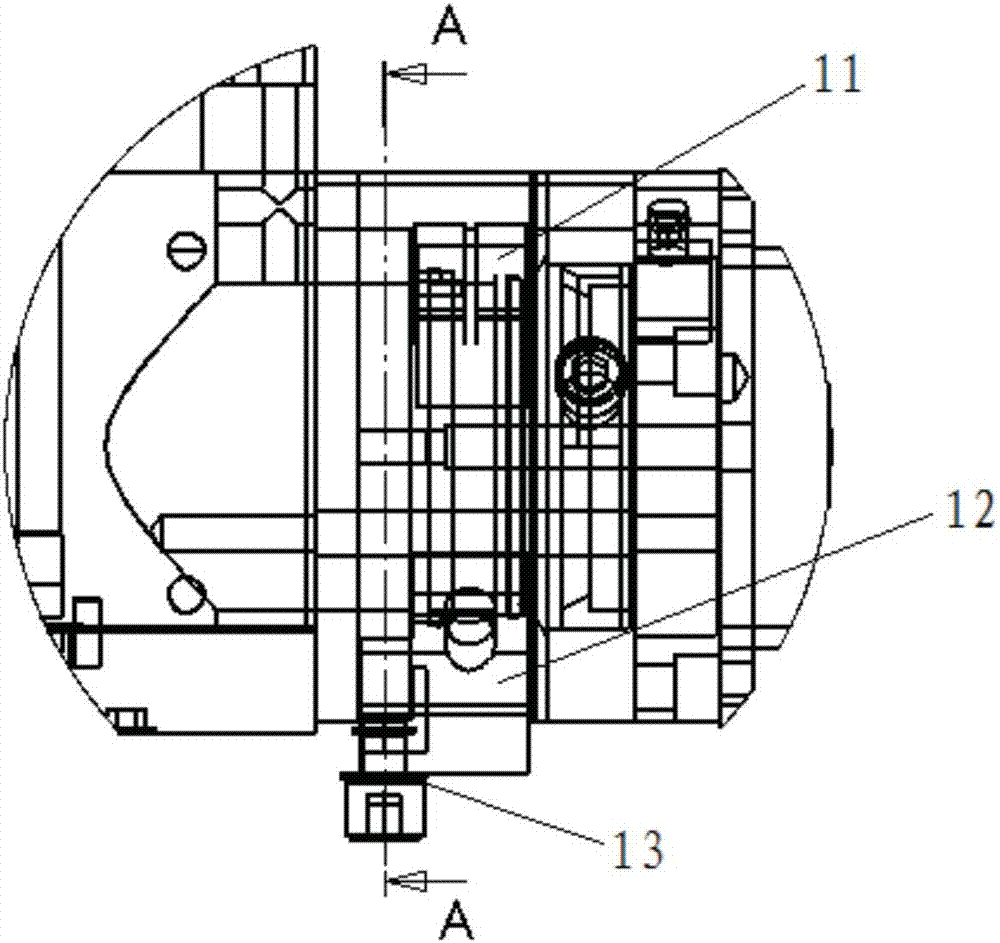

[0029] like figure 1 , figure 2 As shown in the figure, a powder feeding type laser 3D printing optical fiber powder feeding head provided by the present invention includes a window protection system 1, a telescopic sleeve 2, a centering device 3, a protective gas conveying section 4, a connecting sleeve 5 and For the powder spraying nozzle 6, the connecting sleeve 5 is provided with a double-layer cooling structure. The laser beam 9 is a focused type, and the laser beam 9 passes through the window protection system 1, the telescopic sleeve 2, the centering device 3, the protective gas conveying section 4 and the center of the inner hole of the connecting sleeve 5 in sequence, and is projected onto the processing surface. The powder spraying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com