Adjustable numerically-controlled plate-type rebar machine

An adjustable and stiffening machine technology, applied in the field of construction machinery, can solve the problems of difficulty in ensuring the flatness of double elbows, low processing efficiency, poor straightening effect of steel bars, etc., to reduce frictional mechanical damage, improve processing efficiency, The effect of preventing bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in combination with specific embodiments and accompanying drawings.

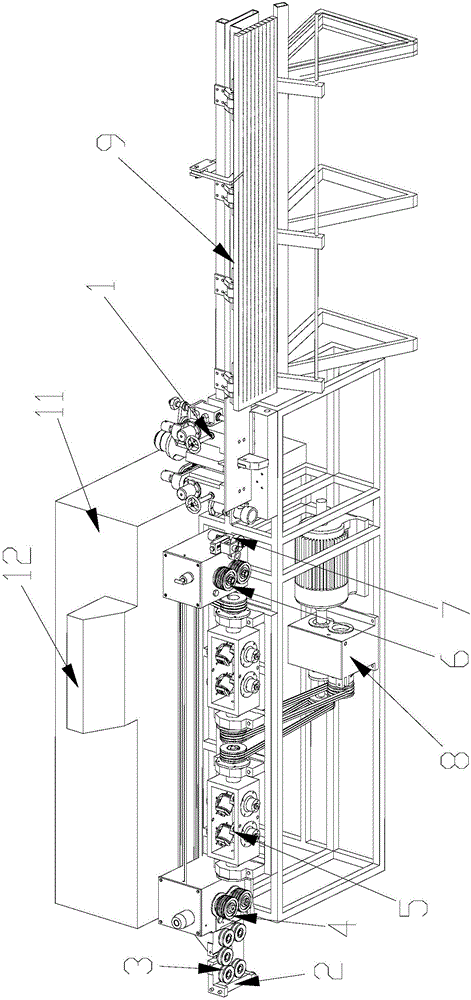

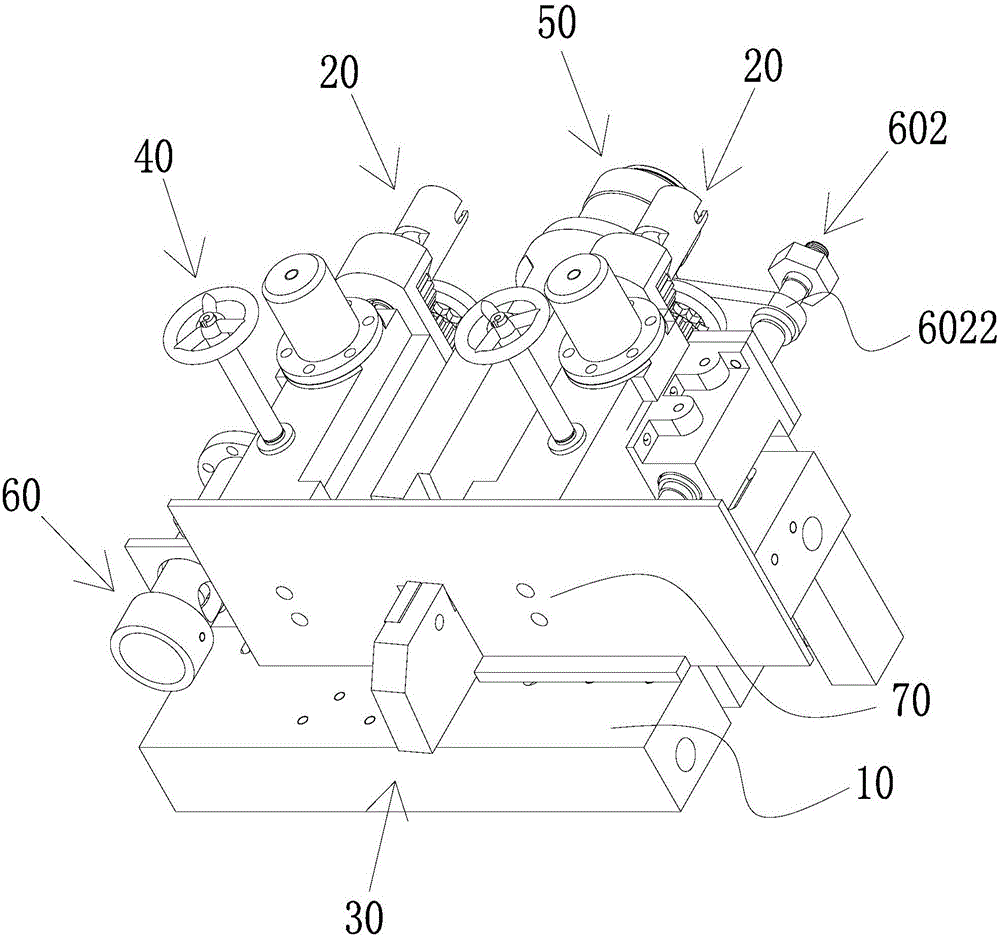

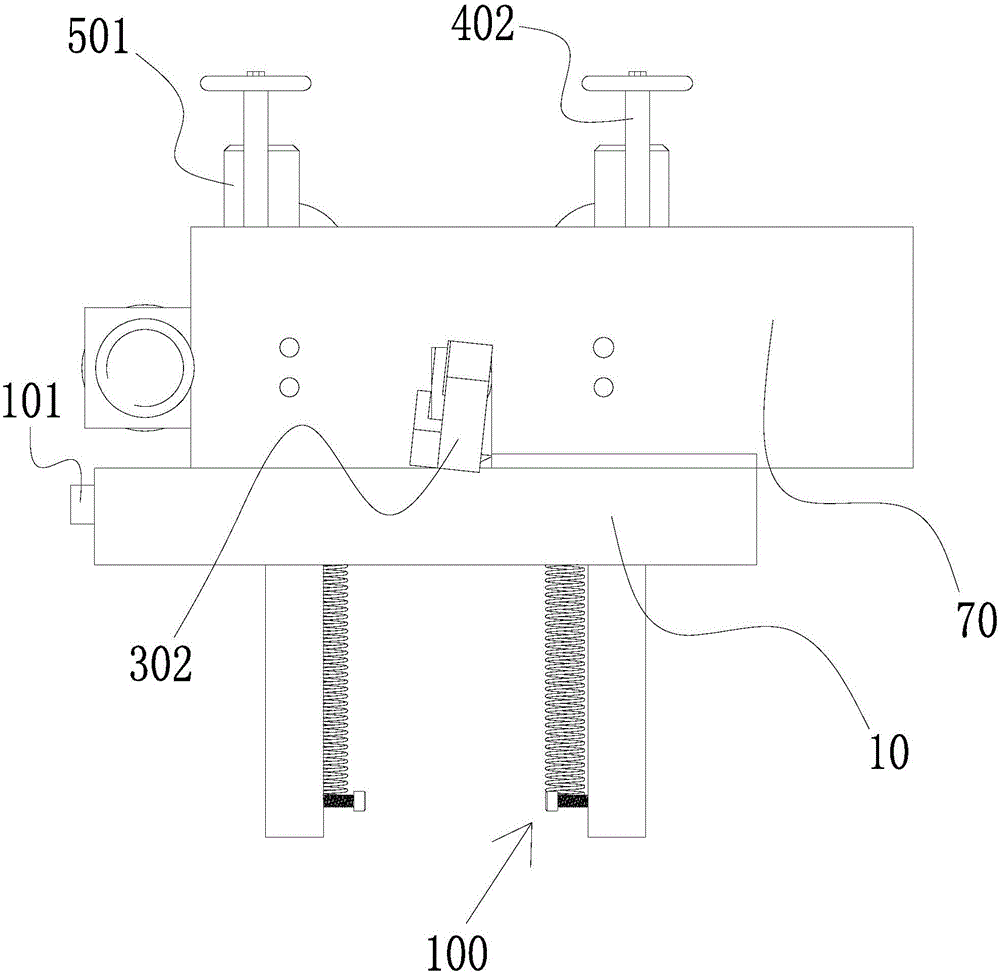

[0086] see figure 1 , an adjustable numerical control reinforcement machine in this embodiment, including a frame, and sequentially arranged on a guide mechanism 2, a pre-adjustment mechanism 3, a traction device 4, a straightening mechanism 5, a traction mechanism 6, a length measuring device 7, and Adjustable double-head shear bending machine 1, stripping mechanism 9; the guide mechanism 2 includes two rollers and a guide support, the two rollers are vertically arranged on the guide support, and there is a gap between the two rollers. Feed channel; the pre-adjustment mechanism 3 includes a pre-adjustment support and five plane wheels, wherein four plane wheels are symmetrically arranged on the pre-adjustment support in two pairs of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com