Workpiece adhesive tape pasting braider

A technology of taping machine and sticking tape, applied in the directions of external support, transportation packaging, packaging, etc., can solve the problems of low work efficiency, time-consuming and labor-intensive, etc., to avoid elongated deformation, improve bonding strength, and ensure cutting effect. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

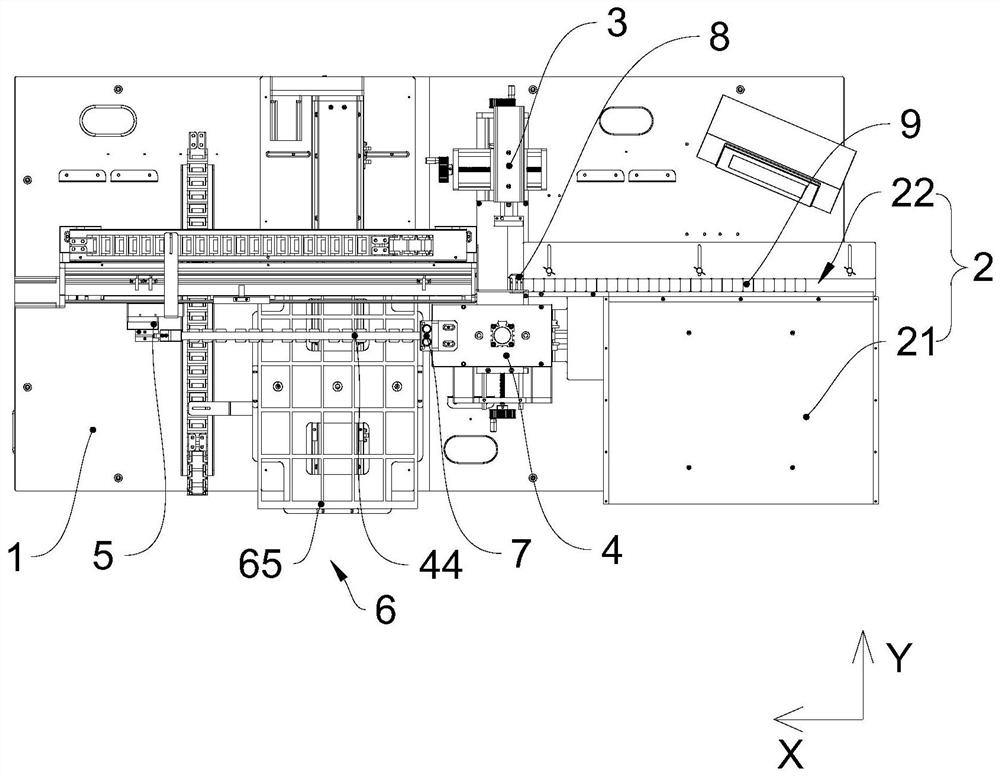

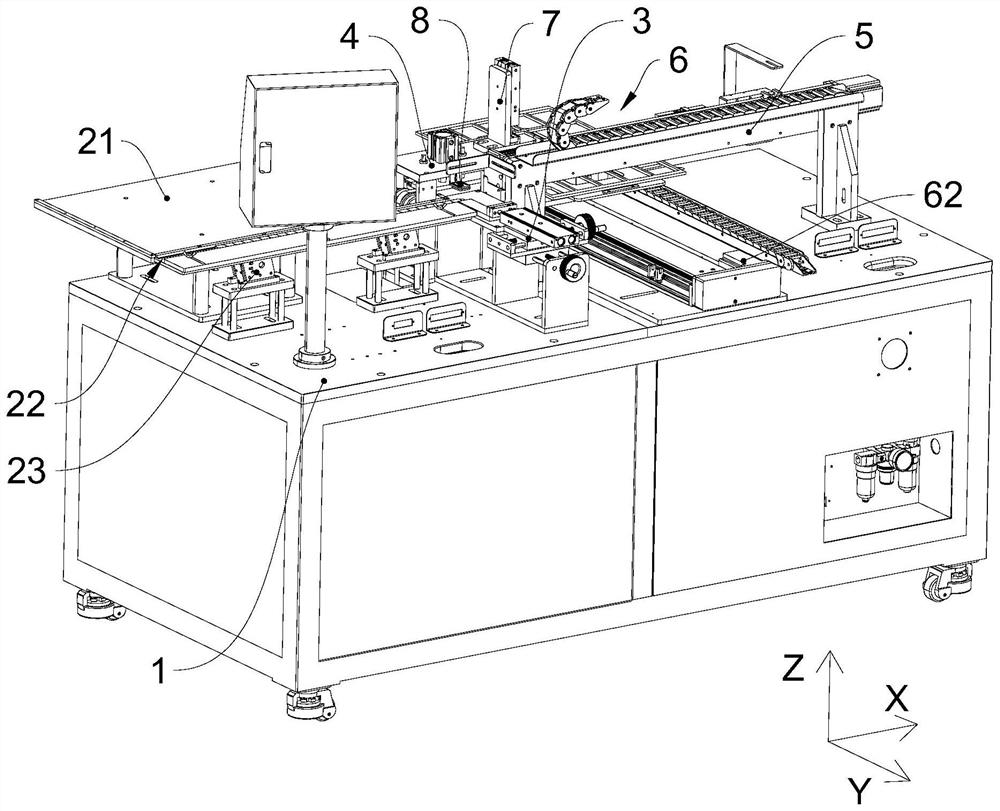

[0038] see figure 1 and figure 2 , the workpiece adhesive tape machine provided by the present invention is mainly used to produce or assist in the production of 5G products, that is, the present invention is mainly used to assist in the production of metal sheets embedded in PCBs for 5G products, so as to facilitate the browning treatment of metal sheets, and use In order to improve the production efficiency of the metal sheet, the metal sheet in this embodiment is a copper sheet.

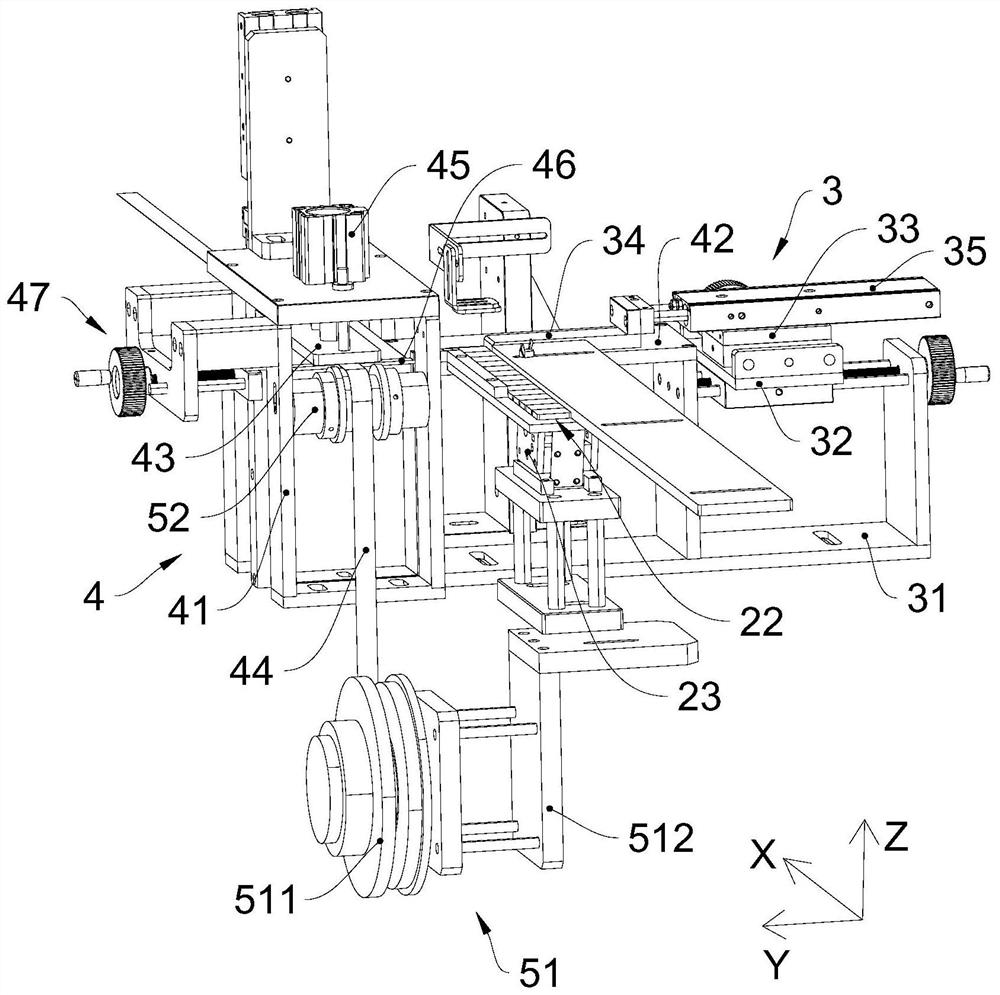

[0039] The workpiece adhesive tape braiding machine includes a working platform 1, a feeding device 2, a material shifting device 3, a pressing adhesive applying device 4, a tape pulling device 5, a lifting adhesive tape device 6 and a cutting device 7. The working platform 1 is a rectangular box structure, and the feeding device 2, the material shifting device 3, the pressing and pasting device 4, the tape pulling device 5, the jacking and pasting device 6 and the cutting device 7 are all arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com