Finishing process of antiskid leather and application thereof

A leather and process technology, applied in the application, leather surface treatment, small raw hide/large raw hide/leather/fur treatment, etc., can solve the problems of shortened life of leather gloves, cracks, small bonding force, etc., to achieve low cost, Easy to control, followed by firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1 A finishing process for anti-skid leather

[0057] The present embodiment is a kind of antiskid leather finishing process, and it carries out successively according to following step order:

[0058] (11) Leather selection

[0059] Choose leather with a thickness of 0.7mm, uniform color and nap, and get A1, and the napped surface is recorded as the front side;

[0060] (12) Primer treatment

[0061] Apply the primer on the front of A1, and dry at 140°C for 10 seconds to obtain B1;

[0062] Among them, the primer solution is a mixture of 3g of silica gel printing diluent 407 and 7g of strong primer silica gel A-3;

[0063] (13) Heat the bottom layer

[0064] Place B1 in a high-temperature baking machine at a temperature of 130°C, and heat it for 10 seconds to obtain C1;

[0065] (14) Anti-slip fluid brushing

[0066] Apply the anti-slip liquid to the front of C1, and apply it four times, and wait for the coating to dry after each application, and then app...

Embodiment 2-6

[0081] Embodiment 2-6 The finishing process of non-slip leather

[0082] This example is a finishing process of anti-slip leather, the preparation process of which is the same as that of Example 1, the only difference is that the relevant technical parameters in the process are different, see Table 1 for details.

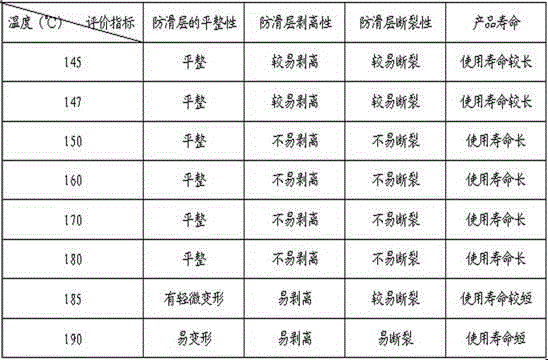

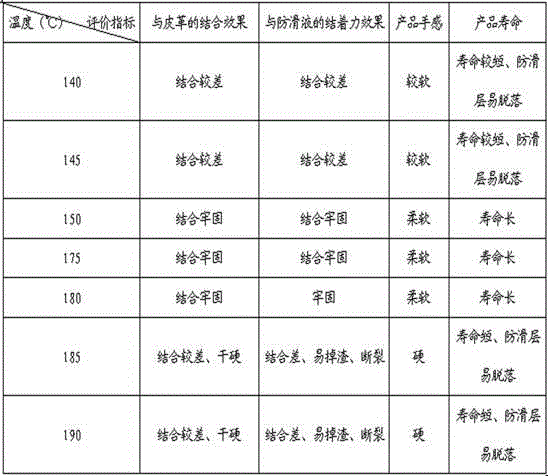

[0083] Table 1 Technical parameter table

[0084]

[0085] The anti-slip leather produced in Examples 2-6 has good anti-slip effect, and the anti-slip layer is firm, does not peel off, does not break, is anti-aging, and has a long service life; the whole process is low in cost, environmentally friendly, pollution-free, and easy for industrial production.

Embodiment 7

[0086] Example 7 Application of anti-skid leather in glove making

[0087] Each of the non-slip leathers produced in Examples 1-6 was cut as a material for gloves. The gloves produced had good anti-slip effects, and the anti-slip layer was firmly bonded, not peeled off, not broken, anti-aging, and long in life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com