Durable antibacterial soft leather for leather bag and preparation method thereof

A soft and durable technology, applied in the field of natural leather, can solve the problems of unfriendly production of high-grade leather, sticky hand feeling after soft finishing, difficult hand feeling and durability, and achieve excellent antibacterial effect, good soft effect and excellent antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1-3

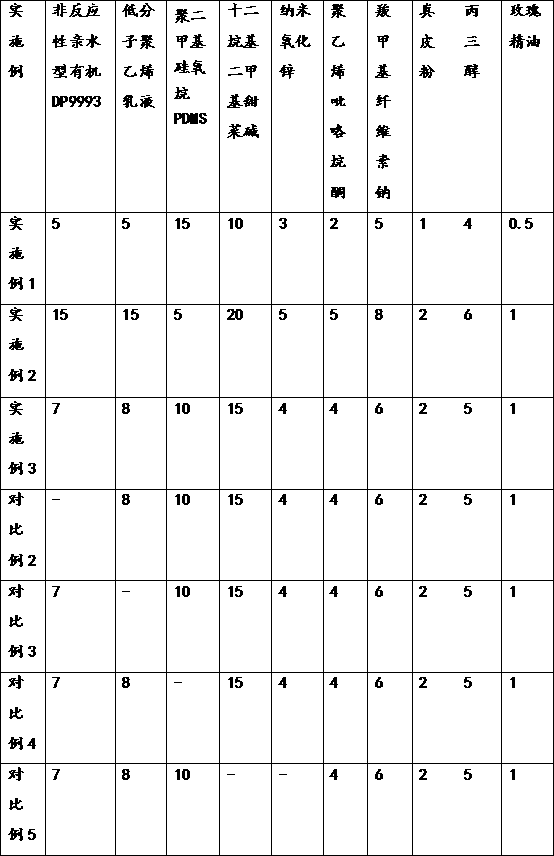

[0038] Specific embodiment 1-3: a kind of finishing method of durable type antibacterial soft leather for leather bag, soft, antibacterial finishing is carried out to the cowhide after chrome tanning finishing. The finishing method includes the following steps:

[0039] (1) Configuration of functional finishing agent:

[0040] Add a certain amount of non-reactive hydrophilic silicone DP9993, low molecular polyethylene emulsion, hydrophobic softener polydimethylsiloxane PDMS, dodecyl dimethyl betaine, nano zinc oxide, poly Vinylpyrrolidone, sodium carboxymethyl cellulose, corium powder, glycerol, rose essential oil, stir evenly at a stirring rate of 250rpm, and obtain the described functional finishing agent; the molecular weight of polyethylene in the low molecular polyethylene emulsion 1500; the size of nano-zinc oxide is 50nm; the size of dermal powder is 200nm;

[0041] (2) Finishing of functional finishing agents:

[0042] Immerse the chrome-tanned cowhide into the func...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com