Flame-retardant coating adhesive for textile, finishing method of flame-retardant fabric with flame-retardant coating adhesive and flame-retardant fabric with flame-retardant coating adhesive

A technology of flame retardant coating and flame retardant fabric, which is applied in the field of flame retardant fabric, can solve the problems of large amount of flame retardant, unsatisfactory flame retardant effect, non-ideal flame retardant durability, complicated process, etc., and achieve good flame retardant and flame retardant Combustion durability, excellent anti-dripping effect, and the effect of extending the diffusion channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

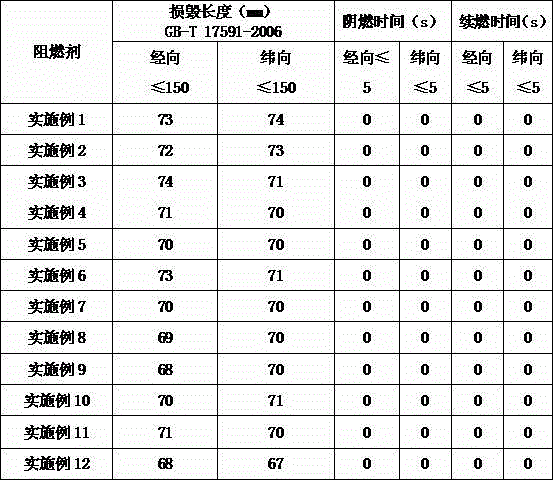

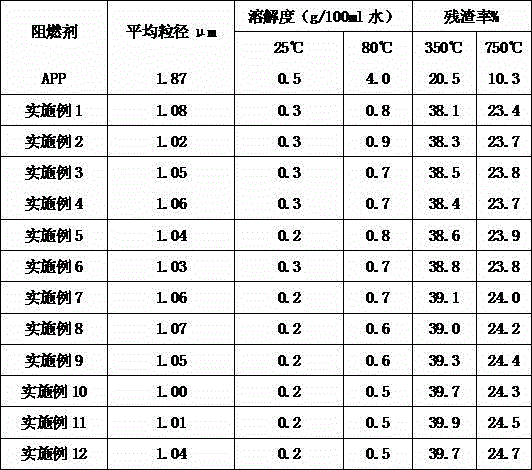

Embodiment 1

[0025] This textile is prepared by using the halogen-free environmentally friendly flame retardant through the following method, and the amount of each material mentioned in it is based on 1000g of ammonium polyphosphate APP as the standard unit:

[0026] ①. Mix 1000g of APP and absolute ethanol at a mass ratio of 1:10, and implement it until fully dispersed by a high-shear stirring device to obtain an APP dispersion;

[0027] ②. Add 0.2L methyl orthosilicate dropwise to the APP dispersion in step ①. Under magnetic stirring, add 20ml of oxalic acid with a concentration of 0.5 g / L, and stir for 2 hours in a water bath at 80°C to obtain an intermediate solution ;

[0028] ③. Add 200ml of ammonia water with a concentration of 0.05g / L to the intermediate solution in step ②. After the gel reacts in a water bath at 60°C, add absolute ethanol, exchange the water in the gel for 3 times, and then exchange the ethanol in the gel for 3 times. Surface-modified the aged wet gel at 60°C, d...

Embodiment 2

[0031] The application of halogen-free environmentally friendly flame retardants in this textile is prepared by the following method, and the amount of each material mentioned in it is based on 1000g of ammonium polyphosphate APP as the benchmark unit of measurement:

[0032] ① Put 1000g of APP into anhydrous propanol, the mass ratio of the two is 1:20, and fully disperse it by a high-shear stirring device to obtain an APP dispersion;

[0033] ②. Add 0.2L tetraethyl orthosilicate dropwise to the APP dispersion in step ①, add 20ml of citric acid with a concentration of 0.8 g / L to the magnetic stirring, and stir in a water bath at 80°C for 2 hours;

[0034] ③. Add 200ml of sodium hydroxide with a concentration of 0.05g / L to the intermediate solution in step ②, and react with gel in a water bath at 60°C. After the reaction, add absolute ethanol, exchange the water in the gel for 3 times, and then exchange the gel Ethanol was used for 3 times, and the aged wet gel was subjected to s...

Embodiment 3

[0037] The application of halogen-free environmentally friendly flame retardants in this textile is prepared by the following method, and the amount of each material mentioned in it is based on 1000g of ammonium polyphosphate APP as the benchmark unit of measurement:

[0038] ① Put 1000g of APP into absolute ethanol, the mass ratio of the two is 1:50, and fully disperse it by a high-shear stirring device to obtain an APP dispersion;

[0039] ②. Add dropwise 0.2L butyl orthosilicate to the APP dispersion in step ①, then add 20ml of propionic acid with a concentration of 0.5 g / L under magnetic stirring, and stir in a water bath at 80°C for 2 hours;

[0040] ③. Add 200ml of potassium hydroxide with a concentration of 0.05g / L to the intermediate solution in step ②. After the gelation reaction in a water bath at 60°C, add absolute ethanol, exchange the water in the gel for 3 times, and then exchange the ethanol in the gel 3 times, surface-modified the aged wet gel at 60°C, dried an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com