Deepening agent and preparation method thereof

A technology of deepening agent and emulsifier, applied in the field of deepening agent and its preparation, can solve the problems of easily changing the physical index of the fabric, inconspicuous deepening effect, and difficult to control the deepening rate, etc., and achieves low scrub fastness, Small influence, small effect on washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

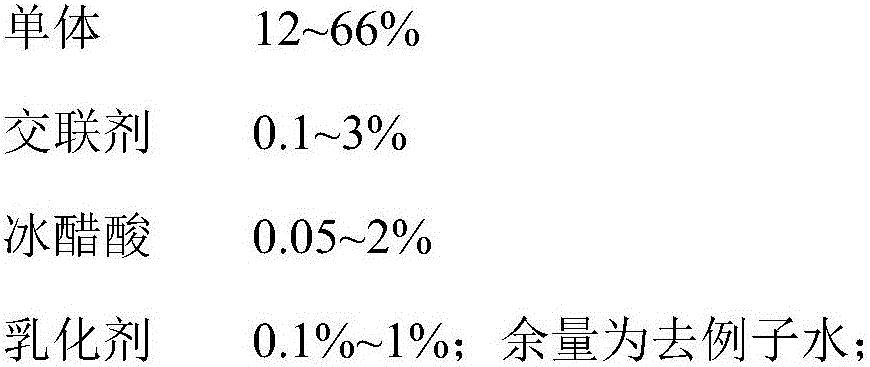

[0026] In this embodiment, a darkening agent is provided. The specific preparation is as follows:

[0027] Step S10. Pre-emulsification: Weigh 109g butyl acrylate, 30g methyl methacrylate, 3.5g hydroxyethyl methacrylate, 2.2g methacryloyloxyethyltrimethylammonium chloride, 0.6g cationic emulsifier 1831, 1.2g of non-ionic emulsifier EFS-630, 0.23g of ammonium persulfate, 1g of glacial acetic acid and 135g of deionized water were added to the reaction flask, and the stirring speed of the mixer was controlled at about 2000rpm at room temperature, and stirred for 30 minutes to prepare a milky white pre-emulsion.

[0028] Step S20. Preparation of seed emulsion: first weigh 40 g of the pre-emulsion obtained in step S10, then weigh 0.6 g of cationic emulsifier 1831, 1.2 g of nonionic emulsifier EFS-630, 0.23 g of ammonium persulfate and 210 g of deionized water Add them together into a reaction four-neck flask, then connect a thermometer, a condenser tube, and a nitrogen tube, and ...

Embodiment 2

[0031] In this embodiment, a darkening agent is provided. The specific preparation is as follows:

[0032] Step S10. Pre-emulsification: Weigh 80.5g butyl acrylate, 23.2g isooctyl acrylate, 35.8g methyl methacrylate, 3.5g hydroxyethyl methacrylate, 2.2g methacryloyloxyethyl trimethyl Add ammonium chloride, 0.6g cationic emulsifier 1831, 1.2g nonionic emulsifier EFS-630, 0.23g ammonium persulfate, 1g glacial acetic acid and 135g deionized water into the reaction flask, and control the stirring speed of the mixer at about 2000rpm at room temperature , and stirred for 30 minutes to prepare a milky white pre-emulsion.

[0033]Step S20. Preparation of seed emulsion: first weigh 40 g of the pre-emulsion obtained in step S10, then weigh 0.6 g of cationic emulsifier 1831, 1.2 g of nonionic emulsifier EFS-630, 0.23 g of ammonium persulfate and 210 g of deionized water Add them together into a reaction four-neck flask, then connect a thermometer, a condenser tube, and a nitrogen tube,...

Embodiment 3

[0036] In this embodiment, a darkening agent is provided. The specific preparation is as follows:

[0037] Step S10. Pre-emulsification: Weigh 80.5g butyl acrylate, 23.2g isooctyl acrylate, 35.8g methyl methacrylate, 3.7g 1,6-hexanediol diacrylate, 2.2g methacryloyloxyethyl Trimethylammonium chloride, 0.5g cationic emulsifier tallow trimethylammonium chloride, 1.0g nonionic emulsifier EFS-630, 0.23g ammonium persulfate, 1g glacial acetic acid and 138g deionized water were added to the reaction flask In the process, control the stirring speed of the stirrer at about 2000rpm at normal temperature, and stir for 30 minutes to prepare a milky white pre-emulsion.

[0038] Step S20. Preparation of seed emulsion: first weigh 40 g of the pre-emulsion obtained in step S10, then weigh 0.5 g of cationic emulsifier tallow trimethylammonium chloride, 1.0 g of nonionic emulsifier EFS-630, 0.23 g of Ammonium sulfate and 210 g of deionized water were added into the reaction four-necked flask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com